Double-sided digital printing paste with bacteriostasis function

A digital printing, double-sided technology, applied in dyeing, textile and papermaking, etc., can solve the problems that the fabric does not have antibacterial function, cannot be printed on both sides of the fabric, and is unfavorable to human health, so as to reduce the permeability and prevent bacteria. function, the effect of improving the water retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

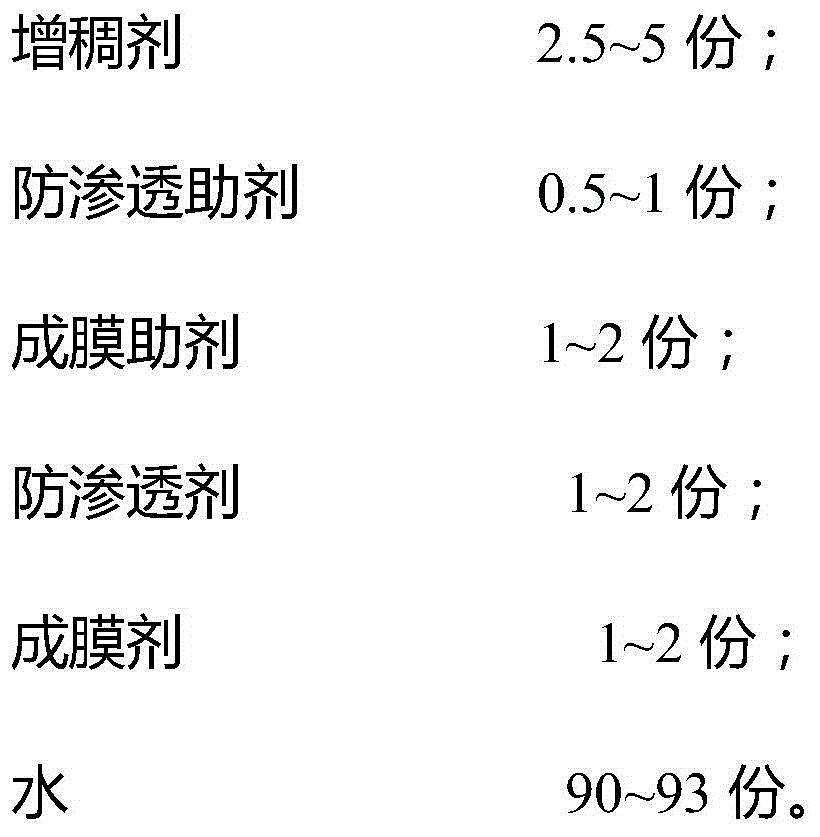

[0028] A double-sided digital printing slurry with antibacterial function, comprising the following components mixed in parts by weight:

[0029]

Embodiment 2

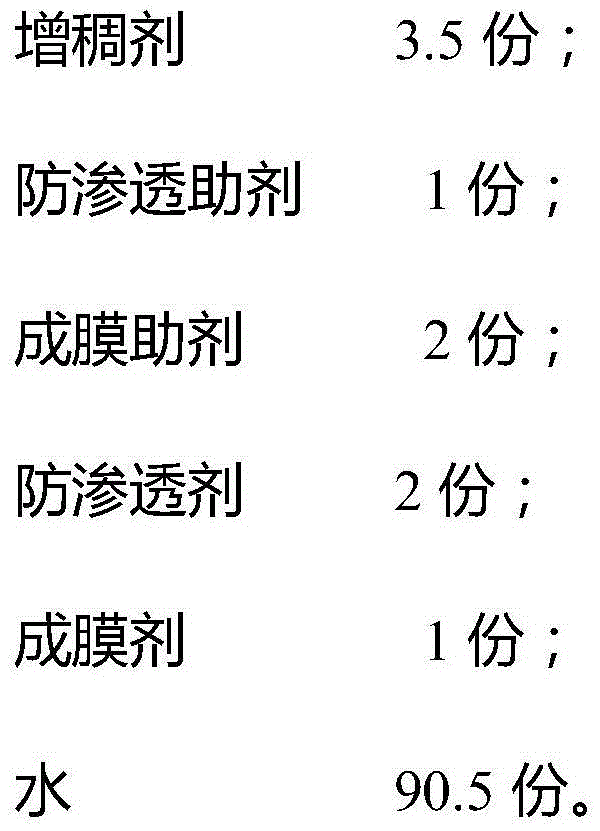

[0030] Embodiment 2: a kind of double-sided digital printing slurry with bacteriostasis function, comprises the following components mixed by parts by weight:

[0031]

Embodiment 3

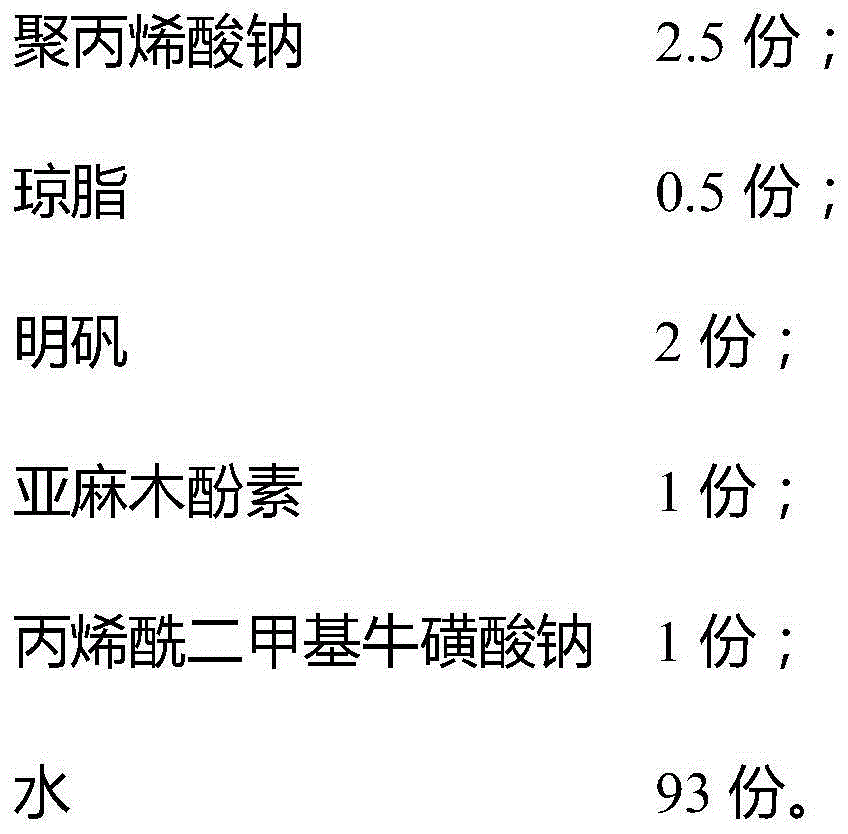

[0032] Embodiment 3: a kind of double-sided digital printing slurry with bacteriostasis function, comprises the following components mixed by parts by weight:

[0033]

PUM

| Property | Measurement | Unit |

|---|---|---|

| antibacterial rate | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com