City sponge water permeable structure brick and production technology thereof

A sponge, urban technology, applied in other household appliances, applications, pavement details, etc., can solve the problems of poor water permeability and water retention performance, low strength, etc., and achieve the effect of easy operation, high water permeability, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

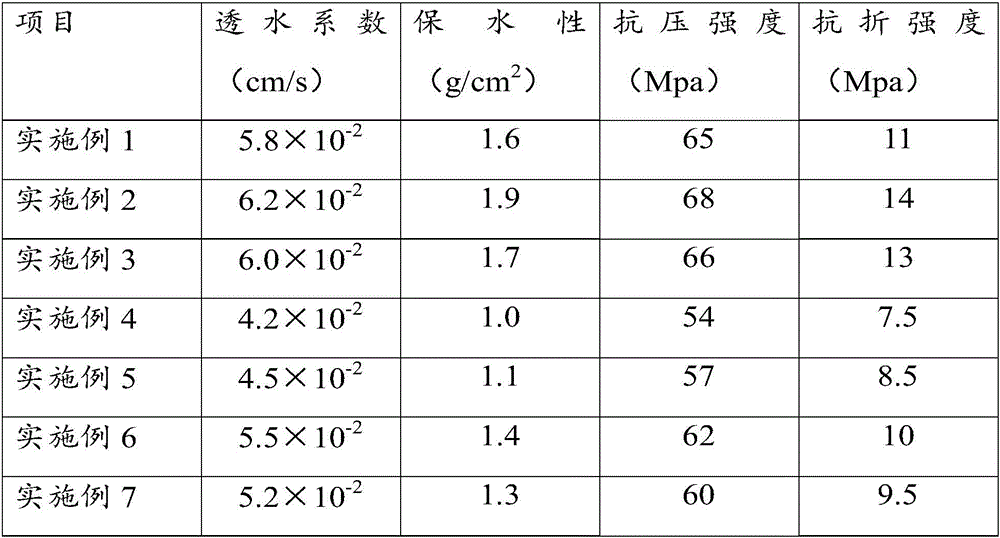

Examples

Embodiment 1

[0106] In terms of parts by weight, the raw material components of the bottom layer were weighed as follows: 80 parts of cement, 350 parts of fine sand, 400 parts of gravel, 50 parts of solid waste powder and 100 parts of water;

[0107] The raw material components of the surface layer are as follows: 10 parts of cement, 25 parts of fine sand, 35 parts of crushed stone, 2 parts of white cement, 0.5 part of pigment and 1 part of water.

[0108] Then prepare the urban sponge permeable structural brick according to the following steps:

[0109] (1) Add cement, fine sand, gravel, solid waste powder and water into the mixer according to the formula ratio of the bottom layer and stir for 1.5 minutes to obtain permeable concrete mortar;

[0110] (2) Add cement, fine sand, crushed stone, white cement, pigment and water into the mixer according to the formula ratio of the surface layer and stir for 1.5 minutes to obtain the permeable brick fabric mortar;

[0111] (3) First pour the pe...

Embodiment 2

[0114] In terms of parts by weight, the raw material components of the bottom layer were weighed as follows: 120 parts of cement, 450 parts of fine sand, 550 parts of gravel, 100 parts of solid waste powder and 150 parts of water;

[0115] The raw material components of the surface layer are as follows: 18 parts of cement, 45 parts of fine sand, 55 parts of crushed stone, 10 parts of white cement, 2 parts of pigment and 6 parts of water.

[0116] The preparation steps are the same as in Example 1.

Embodiment 3

[0118] In terms of parts by weight, the raw material components of the bottom layer were weighed as follows: 100 parts of cement, 400 parts of fine sand, 500 parts of gravel, 80 parts of solid waste powder and 120 parts of water;

[0119] The raw material components of the surface layer were weighed as follows: 15 parts of cement, 30 parts of fine sand, 40 parts of gravel, 5 parts of white cement, 1 part of pigment and 3 parts of water.

[0120] The preparation steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com