Preparation technology of hydroxypropyl methylcellulose ether (HPMC)

A technology for preparing hydroxypropyl methyl cellulose, which is applied in the production process of hydroxypropyl methyl cellulose ether (HPMC), can solve problems such as low efficiency, poor product controllability, and uneven substitution degree. Achieve stable operation, increase production efficiency, and shorten reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Carry out following steps successively to prepare HPMC (traditional process):

[0024] (1) Prepare 8000Kg of solvent (toluene and isopropanol) of about 17:3, of which 100Kg is reserved for spraying; (2) Add 900Kg of caustic soda and 8000Kg of prepared solvent (toluene: isopropanol) into the reactor ≈17:3, save 1000Kg for spraying); (3) Heat up and stir, heat up to 75°C, keep the temperature for 40 minutes, then cool down to 22°C; (4) Add refined cotton (800Kg) into the reactor, spray, keep the temperature constant (<26°C) Stir for 140 minutes; (5) Add 350Kg of propylene oxide and 1000kg of methyl chloride respectively, and keep the temperature at 55°C and 85°C for 150 minutes and 180 minutes respectively; (6) Add 250Kg of acetic acid into the reactor, Neutralize. Neutralize for 30 minutes, measure the pH value to 6.5-7.5, and then discharge.

Embodiment 2

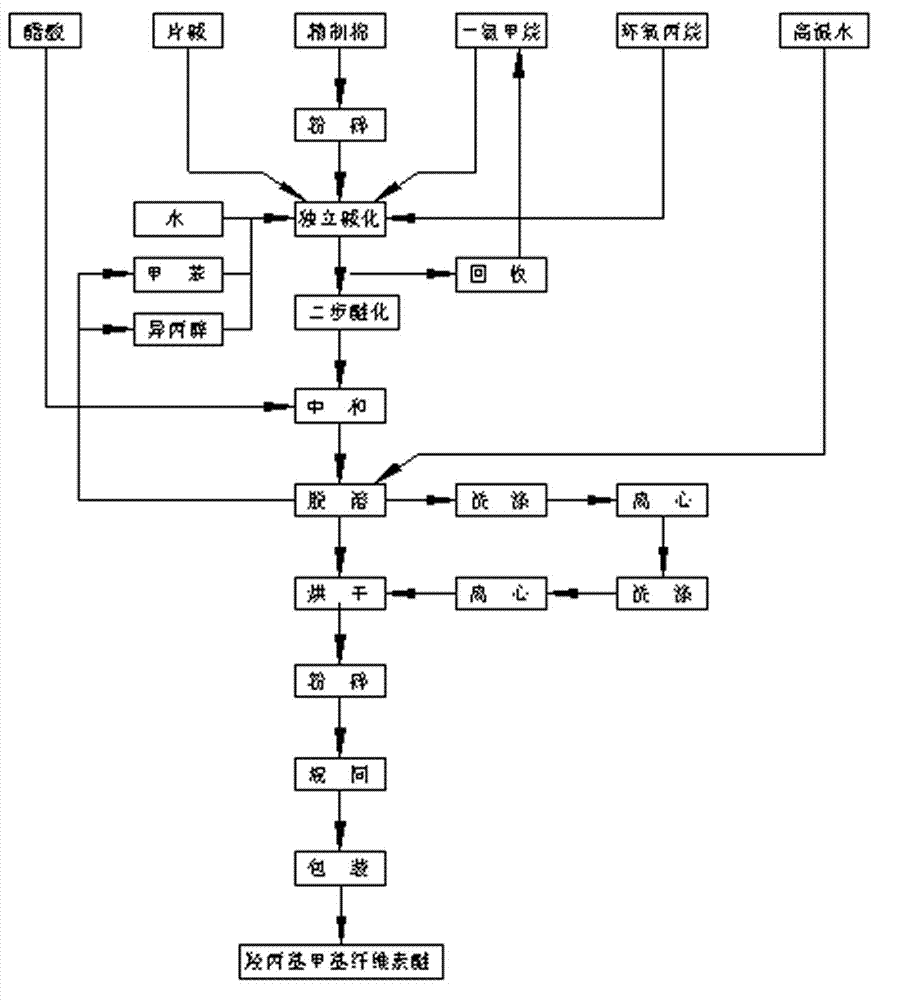

[0026] Carry out the following steps in order to prepare HPMC (new process), figure 1 Shown:

[0027] (1) Prepare 750Kg of solvent (mass ratio of toluene to isopropanol 3:1), 50Kg of which is reserved for spraying; (2) Open the feeding valve of the alkalization kettle, inject 700Kg of solvent, and close the valve; (3) Open the feeding Valve, add 75Kg of caustic soda, close the valve; (4) heat up to about 75°C, keep the temperature for 30 minutes and then cool down to about 25°C; (5) open the feeding valve, add 80Kg of refined cotton, and spray; (6) Under 0.5 kg pressure and 25°C temperature, alkalinize for 2 hours; (7) Press the material to the etherification kettle, add 95Kg of methyl chloride and 32Kg of propylene oxide; (8) Raise the temperature to 55°C and 85°C constant temperature for 120 minutes and 150 minutes; (9) Press the material to the recovery kettle and add 20kg of acetic acid for neutralization. Neutralize for 30 minutes, measure the pH value to 7±0.5, and the...

Embodiment 3

[0029] Carry out the following steps in order to prepare HPMC (new process), figure 1 Shown:

[0030] (1) Prepare 700Kg of solvent (mass ratio of toluene to isopropanol 4:1), 50Kg of which is reserved for spraying; (2) Open the feeding valve of the alkalization kettle, inject 650Kg of solvent, and close the valve; (3) Open the feeding Valve, add 70Kg of caustic soda, close the valve; (4) heat up to about 85°C, keep the temperature for 30 minutes and then cool down to about 10°C; (5) open the feeding valve, add 90Kg of refined cotton, and spray; (6) Under 0.5 kg pressure and 10°C temperature, alkalinize for 3 hours; (7) Press the material to etherification kettle, add 85Kg of methyl chloride and 38Kg of propylene oxide; (8) Raise the temperature to 55°C and 85°C constant temperature for 130 minutes and 140 minutes; (9) Press the material to the recovery kettle and add 18kg of acetic acid for neutralization. Neutralize for 40 minutes, measure the pH value to 6+0.5, and then di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com