Addition agent having synergistic effect on cement and preparing method

A synergistic effect and additive technology, applied in the field of building materials, can solve problems such as unsatisfactory strength improvement, imperfect additives, complex composition, etc., and achieve the effect of improving physical and mechanical properties, significant strengthening effect, and reasonable formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

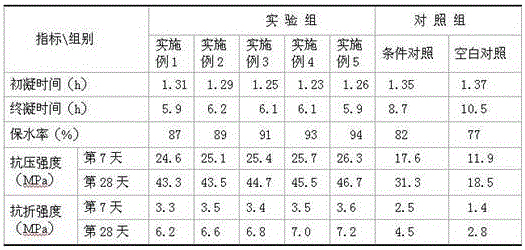

Examples

Embodiment 1

[0046] Example 1 The additive that has a synergistic effect on cement is prepared from the following main raw materials (20 kg per part): 5.4 parts of aminotriacetic acid, 1.8 parts of sodium ethylenediamine tetramethylene phosphate, 2.4 parts of triisopropanolamine 3.7 parts of acrylamide, 3.2 parts of sodium α-olefin sulfonate, 3.3 parts of waste lubricating oil, 3.9 parts of sodium lauryl sulfate, 4.9 parts of urea, 2.2 parts of calcium lignosulfonate, 0.6 parts of molasses, thiosulfuric acid 2.6 parts of sodium, 2.1 parts of silicone lubricant, 1.5 parts of fluorine-containing lubricant, 2.1 parts of polysorbate-80, 2.3 parts of sorbitol.

[0047] The preparation steps of additives with synergistic effect on cement are as follows:

[0048] (1) Add triisopropanolamine, sodium α-olefin sulfonate and silicone lubricant (purchased from Hangzhou Tuoli New Material Co., Ltd.) into a reaction kettle with a thermometer and a stirrer, and when heated to 50°C Add sodium ethylenedia...

Embodiment 2

[0054] Example 2 The additive that has a synergistic effect on cement is prepared from the following main raw materials (10 kg per part): 5.8 parts of aminotriacetic acid, 2.4 parts of sodium ethylenediamine tetramethylene phosphate, 2.7 parts of triisopropanolamine 4.3 parts of acrylamide, 3.5 parts of sodium α-olefin sulfonate, 3.6 parts of waste lubricating oil, 4.4 parts of sodium lauryl sulfate, 5.7 parts of urea, 2.5 parts of calcium lignosulfonate, 0.8 parts of molasses, thiosulfuric acid 3.0 parts of sodium, 2.5 parts of silicone lubricant, 1.9 parts of fluorine-containing lubricant, 2.5 parts of polysorbate-80, 2.7 parts of sorbitol.

[0055] The preparation steps of additives with synergistic effect on cement are as follows:

[0056] (1) Add triisopropanolamine, sodium α-olefin sulfonate and silicone lubricant (purchased from Hangzhou Tuoli New Material Co., Ltd.) into a reaction kettle with a thermometer and a stirrer, and when heated to 60°C Add sodium ethylenedia...

Embodiment 3

[0062] Example 3 The additive that has a synergistic effect on cement is prepared from the following main raw materials (15 kg per part): 5.5 parts of aminotriacetic acid, 2.0 parts of sodium ethylenediamine tetramethylene phosphate, 2.5 parts of triisopropanolamine 3.9 parts of acrylamide, 3.3 parts of sodium α-olefin sulfonate, 3.4 parts of waste lubricating oil, 4.1 parts of sodium lauryl sulfate, 5.2 parts of urea, 2.3 parts of calcium lignosulfonate, 0.65 parts of molasses, thiosulfuric acid 2.7 parts of sodium, 2.2 parts of silicone lubricant, 1.6 parts of fluorine-containing lubricant, 2.2 parts of polysorbate-80, 2.4 parts of sorbitol.

[0063] The preparation steps of additives with synergistic effect on cement are as follows:

[0064] (1) Add triisopropanolamine, sodium α-olefin sulfonate and silicone lubricant (purchased from Hangzhou Tuoli New Material Co., Ltd.) into a reaction kettle with a thermometer and agitator, and when heated to 53°C Add sodium ethylenedia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com