Method for synthesizing downstream products of formaldehyde directly by gas-phase formaldehyde mixture and use

A mixture and formaldehyde technology, applied in the preparation of organic compounds, chemical instruments and methods, organic chemistry, etc., can solve the problems of large investment and high power consumption, and achieve the effect of less equipment modification, short process and investment saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

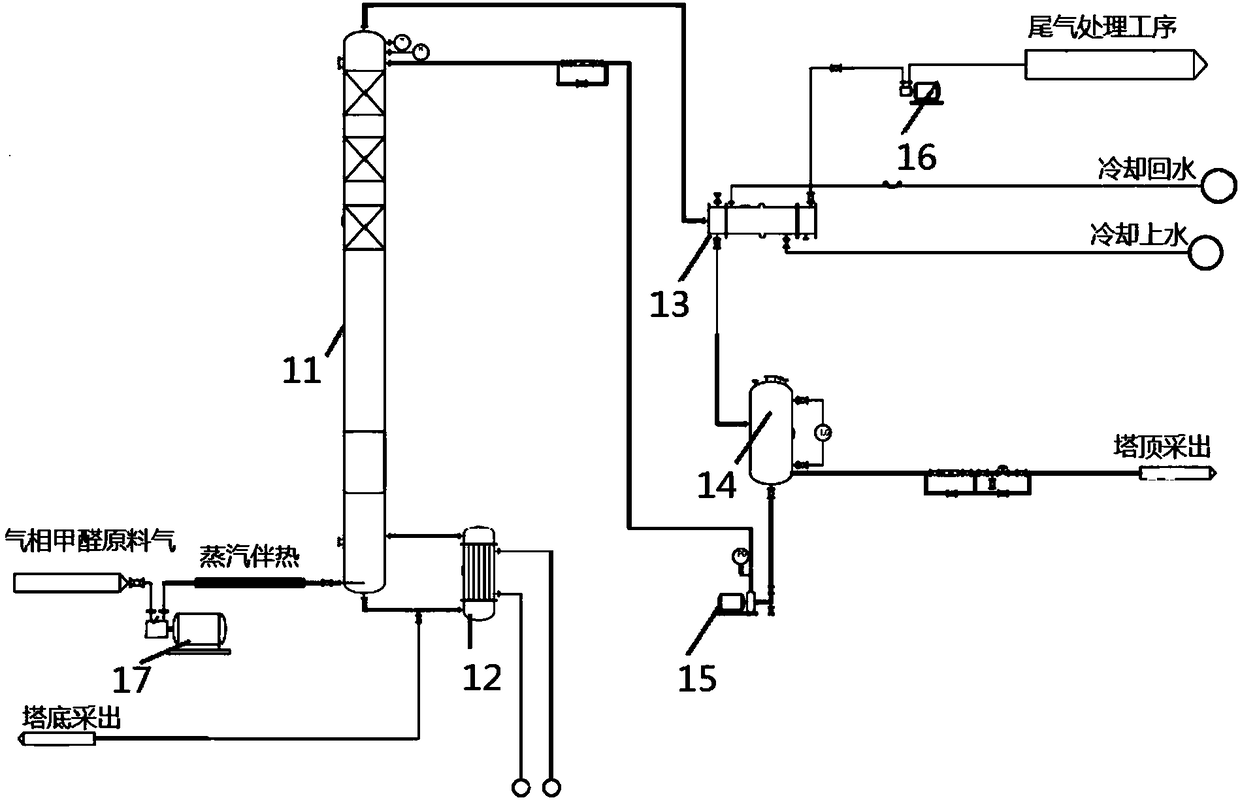

[0044] Embodiment 1 gas-phase formaldehyde mixture directly synthesizes trioxymethylene

[0045] The main components in the gas-phase formaldehyde mixture: formaldehyde 19.5wt%; water vapor 20wt%; hydrogen 21wt%; nitrogen 39wt%; carbon dioxide 0.4wt%; other impurities 0.1wt%.

[0046] The gas-phase formaldehyde mixture is transported to the trioxymethylene synthesis reaction rectifying tower 11 at the flow rate of 500kg / h through the raw material gas conveyor (Roots blower) 17, and the air inlet pipe is 20cm below the liquid level of the tower kettle, and the equipment and pipeline are carried out with steam. Insulation, the temperature of the gas-phase formaldehyde mixture is maintained at 110 ° C, and the jacket steam is controlled by chain.

[0047] The tower kettle solution is a 60% formaldehyde aqueous solution containing 3wt% of catalyst sulfuric acid, and the formaldehyde and water vapor components in the gas-phase formaldehyde mixture participate in the reaction of syn...

Embodiment 2

[0049] Embodiment 2 gas-phase formaldehyde mixture directly synthesizes trioxymethylene

[0050]Trioxymethylene was synthesized in a similar manner to Example 1, wherein the main components in the gas-phase formaldehyde mixture: based on the total weight of the gas-phase formaldehyde mixture, formaldehyde 19.5wt%; water vapor 20wt%; hydrogen 21wt%; nitrogen 39wt%; carbon dioxide 0.4 wt%; other impurities 0.1wt%. The gas-phase formaldehyde mixture is fed at a flow rate of 550kg / h, and the air inlet pipe is 25cm below the liquid level of the tower kettle. The equipment and pipelines are kept warm by steam, so that the temperature of the gas-phase formaldehyde mixture is maintained at 108°C, and the jacket steam is chain-controlled.

[0051] The phenomenon of polymerization blockage did not occur during the experiment. The pressure at the top of the tower is controlled to 88kPa absolute pressure, and the reflux ratio is 9:1. The crude trioxymethylene content of 33% in the tower ...

Embodiment 3

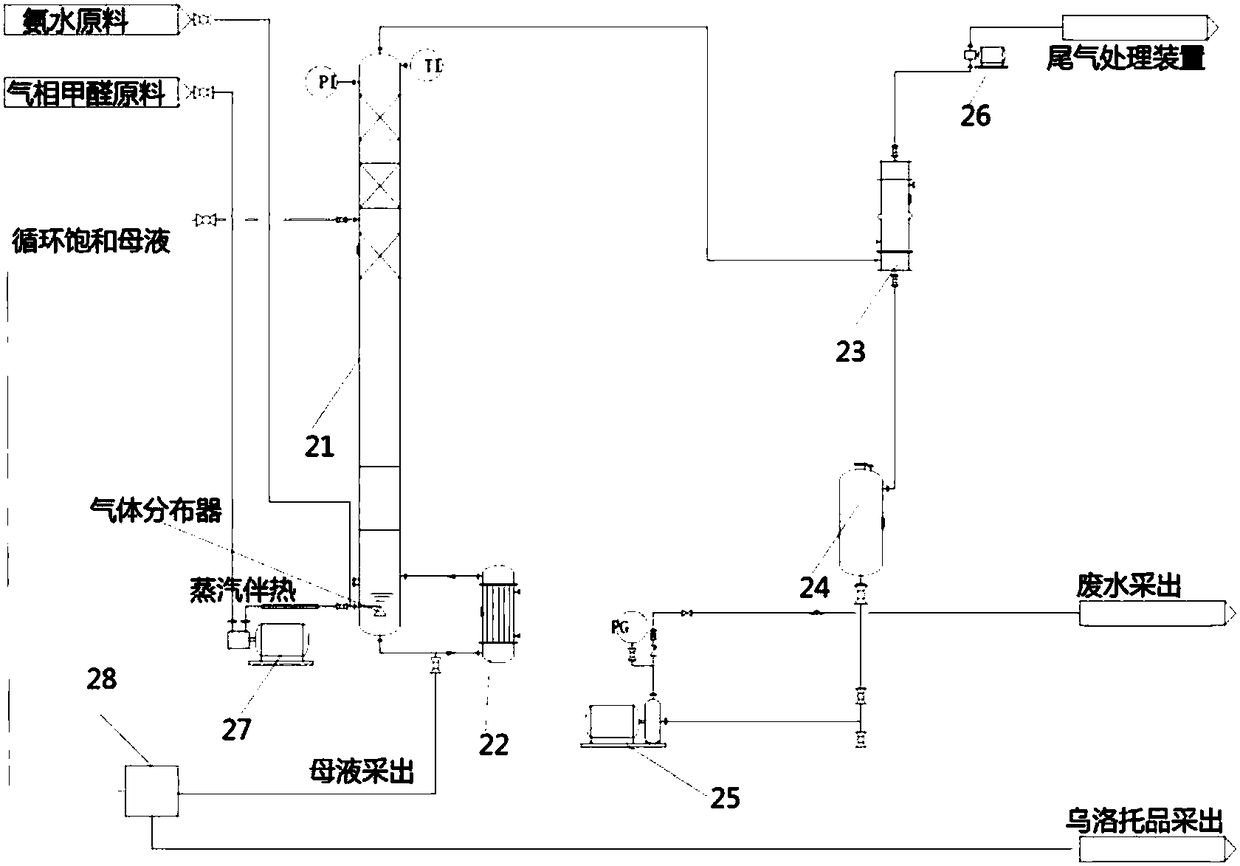

[0052] Embodiment 3 gas-phase formaldehyde mixture directly synthesizes urotropine

[0053] The main components in the gas-phase formaldehyde mixture: formaldehyde 19.5wt%; water vapor 19.5wt%; hydrogen 21wt%; nitrogen 39wt%; carbon dioxide 0.4wt%; other impurities 0.1wt%.

[0054] The gas-phase formaldehyde mixture is transported by the raw material gas conveyor (Roots blower) 27 at the flow rate of 500kg / h, mixed with the ammonia water raw material 500kg / h (concentration 20%) and sent to the synthesis reaction rectification tower 21 through the gas distributor, and the The gas pipe is 20cm below the liquid level of the tower kettle, and the equipment and pipelines are kept warm by steam, so that the temperature of the gas-phase formaldehyde mixture material is maintained at 108 ℃, and the jacket steam is interlocked.

[0055] The tower kettle solution is a saturated aqueous ammonia solution of urotropine, and the formaldehyde and water vapor components in the gas-phase forma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com