Device and method for plasma enhanced porous media combustion treatment of organic waste gas

A technology of porous media and plasma, applied in the field of environmental pollution control, can solve the problems that the regenerative combustion chamber is difficult to maintain the combustion temperature, cannot meet the requirements of organic waste gas treatment, and the degradation of organic pollutants is insufficient, so as to reduce secondary pollution The formation of substances, expanding the application range of concentration, and achieving the effect of efficient utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

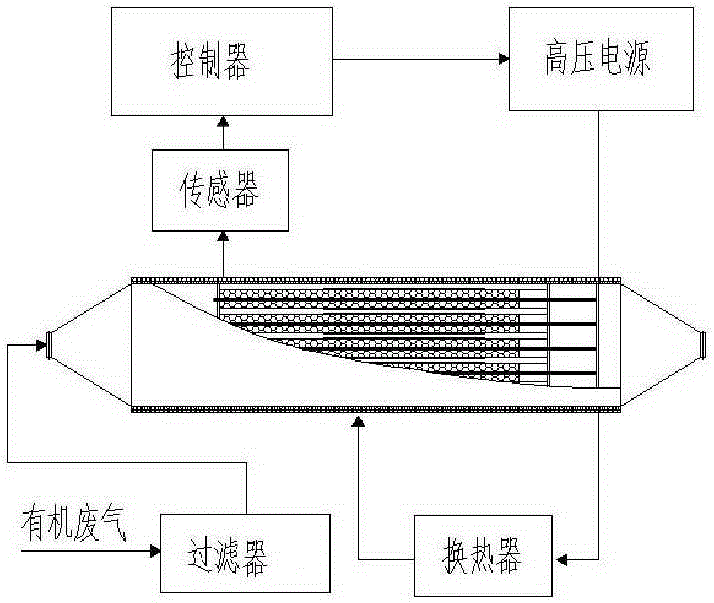

[0034] Reference figure 1 , A plasma-enhanced porous medium combustion treatment device for organic waste gas, said device comprising a filter for removing particulate matter in organic waste gas, a reactor for thermal oxidation and plasma oxidation to achieve organic waste gas degradation, and The high-voltage power supply of the plasma and the controller for controlling the flow and temperature of the reactor, the filter is connected with the reactor, and the reactor is respectively connected with the controller and the high-voltage power supply. The reactor is provided with a sensor, and the sensor is connected with the controller; the reactor is also connected with a heat exchanger.

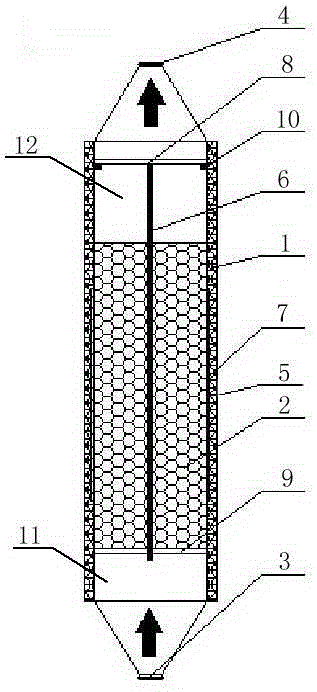

[0035] Reference figure 2 The reactor includes a reactor shell 1, a porous medium filling zone and a plasma generator, the porous medium filling zone and the plasma generator are both located in the reactor shell, and the plasma generator is connected to the controller; The reactor shell 1 is p...

Embodiment 2

[0041] Reference figure 1 , A plasma-enhanced porous medium combustion treatment device for organic waste gas, said device comprising a filter for removing particulate matter in organic waste gas, a reactor for thermal oxidation and plasma oxidation to achieve organic waste gas degradation, and The high-voltage power supply of the plasma and the controller for controlling the flow and temperature of the reactor, the filter is connected with the reactor, and the reactor is respectively connected with the controller and the high-voltage power supply. The reactor is provided with a sensor, and the sensor is connected with the controller; the reactor is also connected with a heat exchanger.

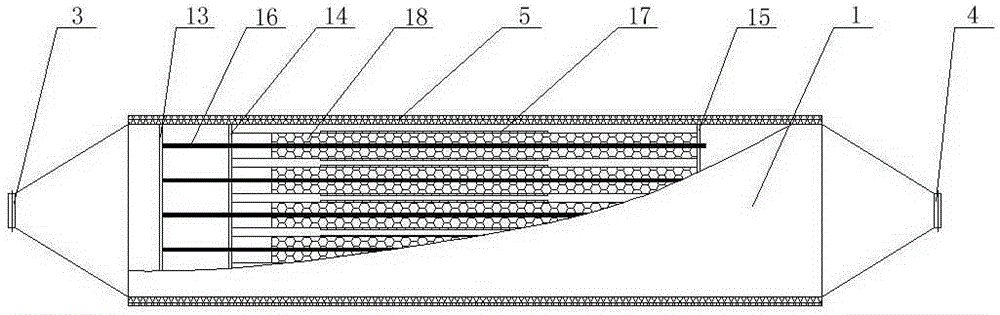

[0042] Reference image 3 The reactor includes a reactor shell 1, a porous medium filling zone and a plasma generator, the porous medium filling zone and the plasma generator are both located in the reactor shell, and the plasma generator is connected to the controller; The reactor shell 1 is pr...

Embodiment 3

[0048] Reference Figure 4 , A plasma-enhanced porous medium combustion treatment device for organic waste gas, said device comprising a filter for removing particulate matter in organic waste gas, a reactor for thermal oxidation and plasma oxidation to achieve organic waste gas degradation, and The high-voltage power supply of the plasma and the controller for controlling the flow and temperature of the reactor, the filter is connected with the reactor, and the reactor is respectively connected with the controller and the high-voltage power supply. A sensor is arranged in the reactor, and the sensor is connected with the controller.

[0049] Reference figure 2 The reactor includes a reactor shell 1, a porous medium filling zone and a plasma generator, the porous medium filling zone and the plasma generator are both located in the reactor shell, and the plasma generator is connected to the controller; The reactor shell 1 is provided with an air inlet 3 at one end, and the other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com