Chromium removal enhancer and preparation method thereof

A technology of reinforcing agent and reducing agent, applied in the field of removing harmful substances in cement, can solve the problems that the reducing agent is easily oxidized, loses the reducing effect, and the liquid chromium removing agent is not very effective in removing chromium, and achieves the promotion of hydration process, Improve physical properties and ensure the effect of restoring effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The embodiment of the present invention discloses a preparation method of a chromium removal enhancer, comprising the following steps:

[0028] a) Calcining kaolin, mixing the calcined kaolin with an acidic solution, then performing suction filtration, washing and drying the obtained solid;

[0029] b) mixing the kaolin obtained in step a) with the mixed solution to obtain a chromium removal enhancer; the mixed solution is a mixed solution of reducing agent, antioxidant, enhancer and water.

[0030] The application provides a chromium removal enhancer and a preparation method thereof. The chromium removal enhancer uses modified kaolin as a carrier and is used to remove hexavalent chromium in cement or concrete. Under the double action of adsorption and reduction, the enhancer provided by the invention can effectively remove hexavalent chromium in cement to reduce the harm to human body and environment, and meanwhile, the enhancer can also effectively improve the physica...

Embodiment 1

[0051] (1) Calcining kaolin at 850°C for 3 hours;

[0052] (2) Add calcined kaolin to 0.1mol / L sulfuric acid solution under stirring condition, stir at 80°C for 4 hours, filter with suction, wash, and dry for later use;

[0053] (3) Add 15wt% ferrous sulfate, 3wt% citric acid, and 25wt% sodium chloride into deionized water to prepare a 500mL mixture;

[0054] (4) Add 57wt% of the kaolin obtained in step 2) to the mixed liquid prepared in step 3), continuously stir for 2 hours, filter with suction, air dry naturally, and pulverize to obtain a chromium removal enhancer.

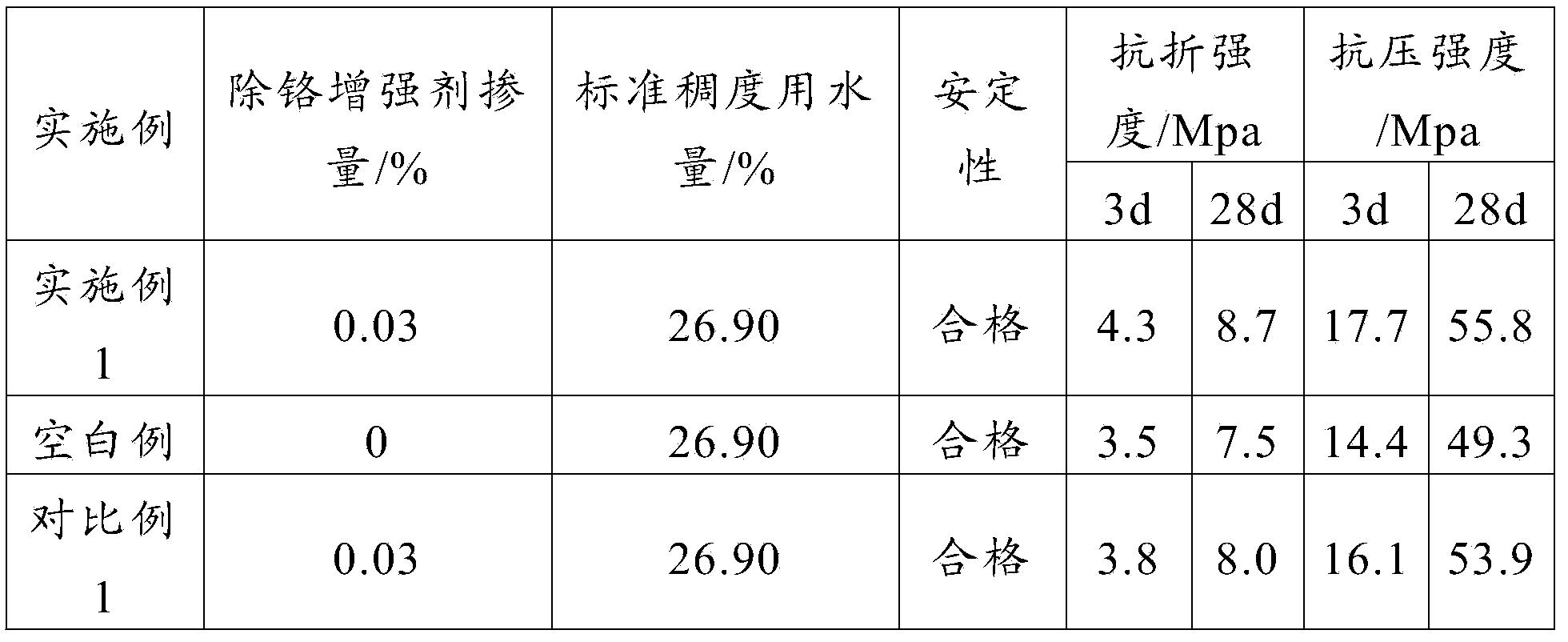

[0055] The determination of chromium content in cement was determined by diphenylcarbazide spectrophotometry. Detect the chromium removal efficiency of the chromium removal enhancer prepared in this embodiment, the chromium removal enhancer without adding the chromium removal enhancer and the chromium removal enhancer prepared in Comparative Example 1, as shown in Table 1, and table 1 is the chromium removal e...

Embodiment 2

[0057] (1) Calcining kaolin at 900°C for 4 hours;

[0058] (2) Add calcined kaolin to 0.15mol / L hydrochloric acid solution under stirring, stir at 80°C for 4 hours, filter with suction, wash, and dry for later use;

[0059] (3) Add 10wt% ferrous chloride, 1wt% ascorbic acid, and 20wt% calcium chloride into deionized water to prepare a 500mL mixture;

[0060] (4) Take 69wt% of the kaolin obtained in step 2) and add it to the mixed solution prepared in step 3), stir continuously for 2 hours, filter with suction, air dry naturally, and pulverize to obtain the chromium removal enhancer.

[0061] The determination of chromium content in cement was determined by diphenylcarbazide spectrophotometry. Detect the chromium removal efficiency of the chromium removal enhancer prepared in this embodiment, the chromium removal enhancer without adding the chromium removal enhancer and the chromium removal enhancer prepared in Comparative Example 1, as shown in Table 1, and table 1 is the chr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com