Lightweight high-strength ceramsite concrete as well as preparation method and application thereof

A high-strength ceramsite and concrete technology, applied in the field of building materials, can solve problems such as the difficulty of lightweight and high-strength ceramsite concrete materials, and achieve the effects of increasing self-weight, increasing compactness, and improving homogeneity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

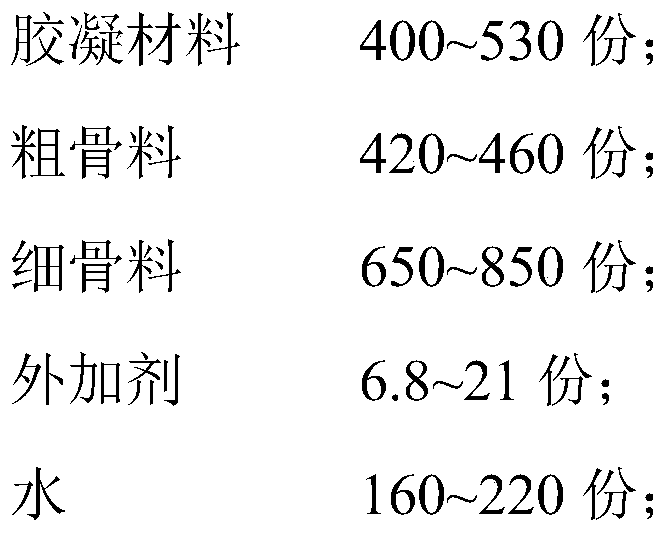

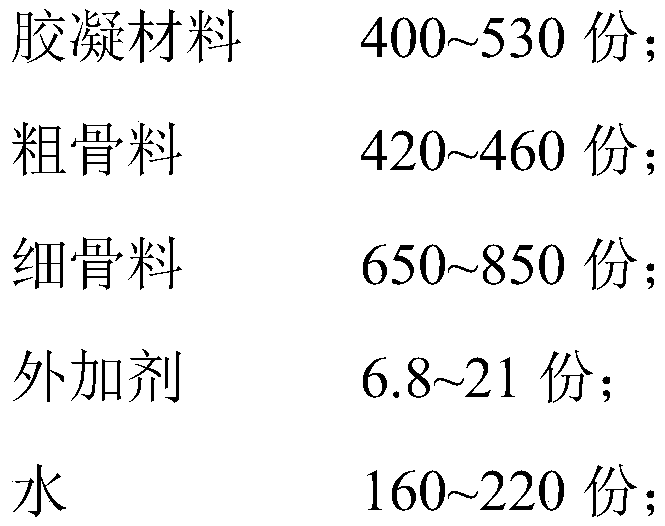

Method used

Image

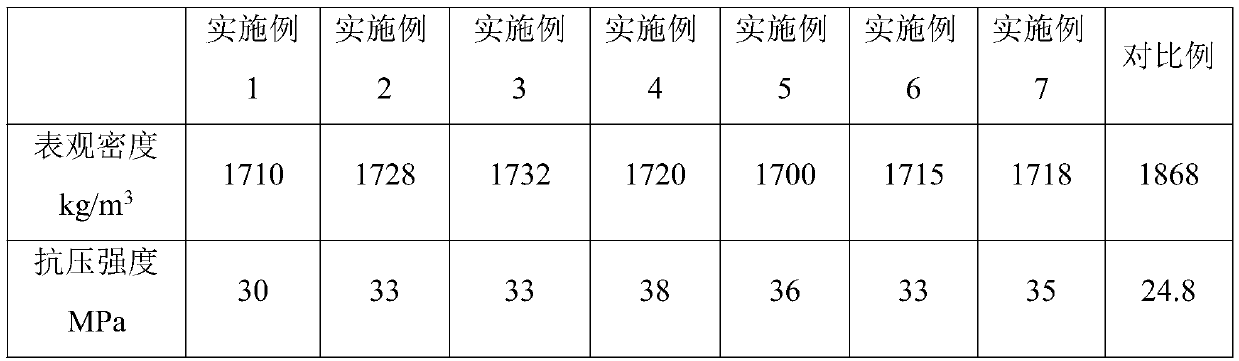

Examples

preparation example Construction

[0038] Preparation of fly ash ceramsite: Mix 200 parts of fly ash, 6 parts of activator, 6 parts of co-solvent, and 3 parts of foaming agent evenly, then add them to the granulator to form granules, and maintain them in a standard curing room for 28 days . The river sand is Class II river sand that meets GB / T 14684-2011; the river sand refers to Class II river sand that meets GB / T 14684-2011; machine-made sand refers to Class II river sand that meets GB / T14684-2011 Machine-made sand. The fineness modulus of river sand is 1.4, and the apparent density is 2700kg / m 3 , bulk density 1360kg / m 3 , porosity 41.5%; machine-made sand modulus 3.3, apparent density 2690kg / m 3 , bulk density 1620kg / m 3 , porosity 38.7%; Jiangsha has a fineness modulus of 1.2 and an apparent density of 2410kg / m 3 , Bulk density 1490kg / m 3 , porosity 42.3%;

[0039] The cement is P.O 425 cement or P.II525 Portland cement that meets the requirements of GB175-2007; the ultra-fine modified fly ash is gr...

Embodiment 1

[0048] The preparation method of lightweight high-strength ceramsite concrete comprises the following steps:

[0049] S1. After pre-wetting 445kg of coarse aggregate, dry it until the surface is dry and the interior is saturated with water absorption;

[0050] S2, mixing the coarse aggregate treated in S1 with 607kg fine aggregate for 90s;

[0051] S3. Add 445kg of gelling material to the mixed material after S2 treatment, and stir for 30s;

[0052] S4. Slowly add the aqueous solution prepared by adding 10 kg of polycarboxylate water reducer to the mixed material mixed in S3, and stir for 60 seconds to prepare lightweight high-strength ceramsite concrete;

[0053] The cementitious materials include 400kg cement and 45kg superfine modified fly ash;

[0054] Coarse aggregate includes 445kg fly ash ceramsite;

[0055] Fine aggregate includes 217kg slag and 390kg river sand; the volume of slag accounts for 50% of the total volume of fine aggregate;

[0056] The dosage of the a...

Embodiment 2

[0058] The preparation method of lightweight high-strength ceramsite concrete comprises the following steps:

[0059] S1. After pre-wetting 445kg of coarse aggregate, dry it until the surface is dry and the interior is saturated with water absorption;

[0060] S2, mixing the coarse aggregate treated in S1 with 676kg fine aggregate for 30s;

[0061] S3. Add 445kg of gelling material to the mixed material after S2 treatment, and stir for 90s;

[0062] S4. Slowly add an aqueous solution prepared by adding 8.5kg of polycarboxylate water reducer to the mixed material mixed in S3, and stir for 60 seconds to prepare lightweight high-strength ceramsite concrete;

[0063] The cementitious materials include 400kg cement and 45kg superfine modified fly ash;

[0064] Coarse aggregate includes 445kg fly ash ceramsite;

[0065] Fine aggregate includes 130kg slag and 546kg river sand; the volume of slag accounts for 30% of the total volume of fine aggregate;

[0066] The dosage of the ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com