Patents

Literature

38results about How to "Constant weight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

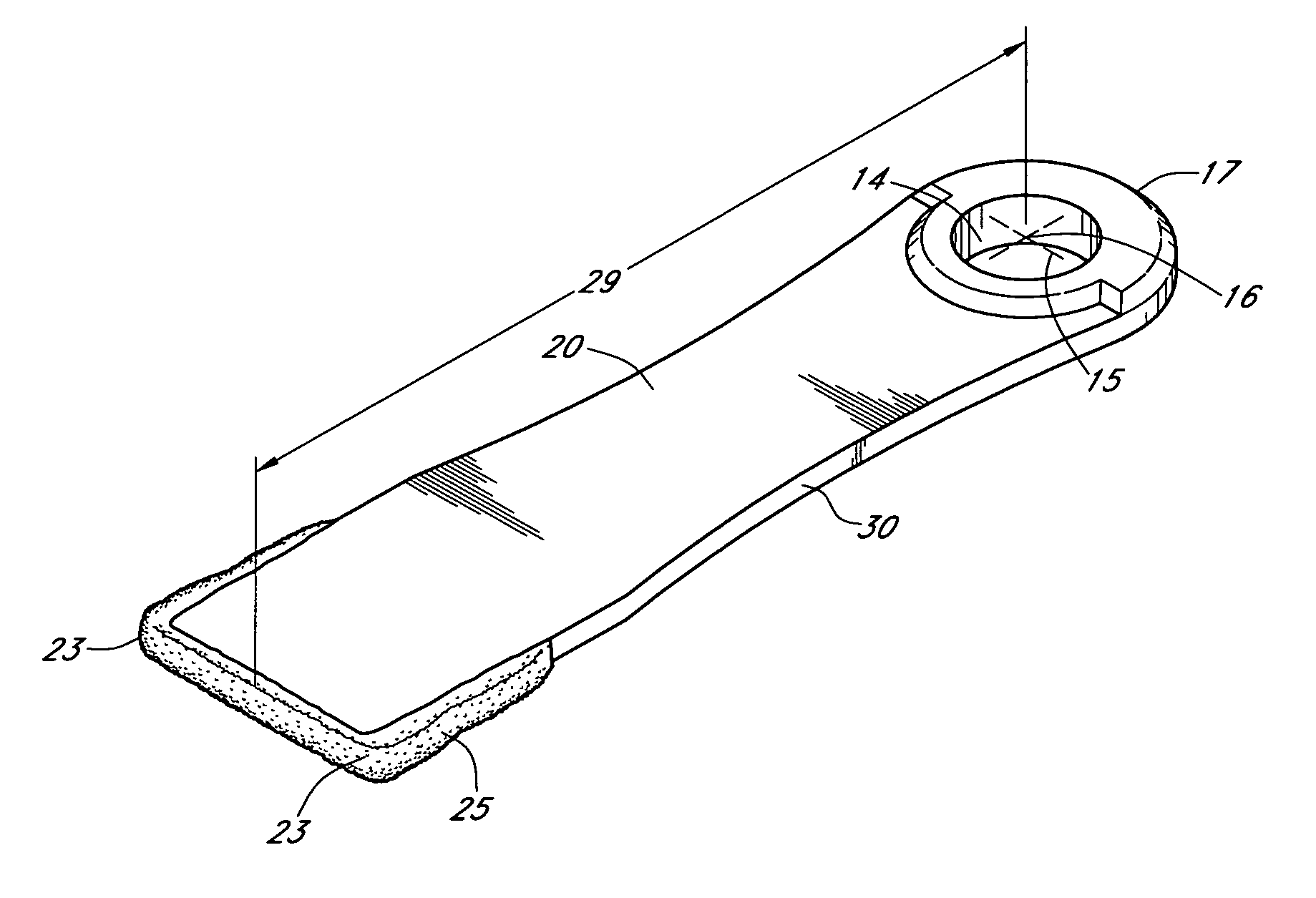

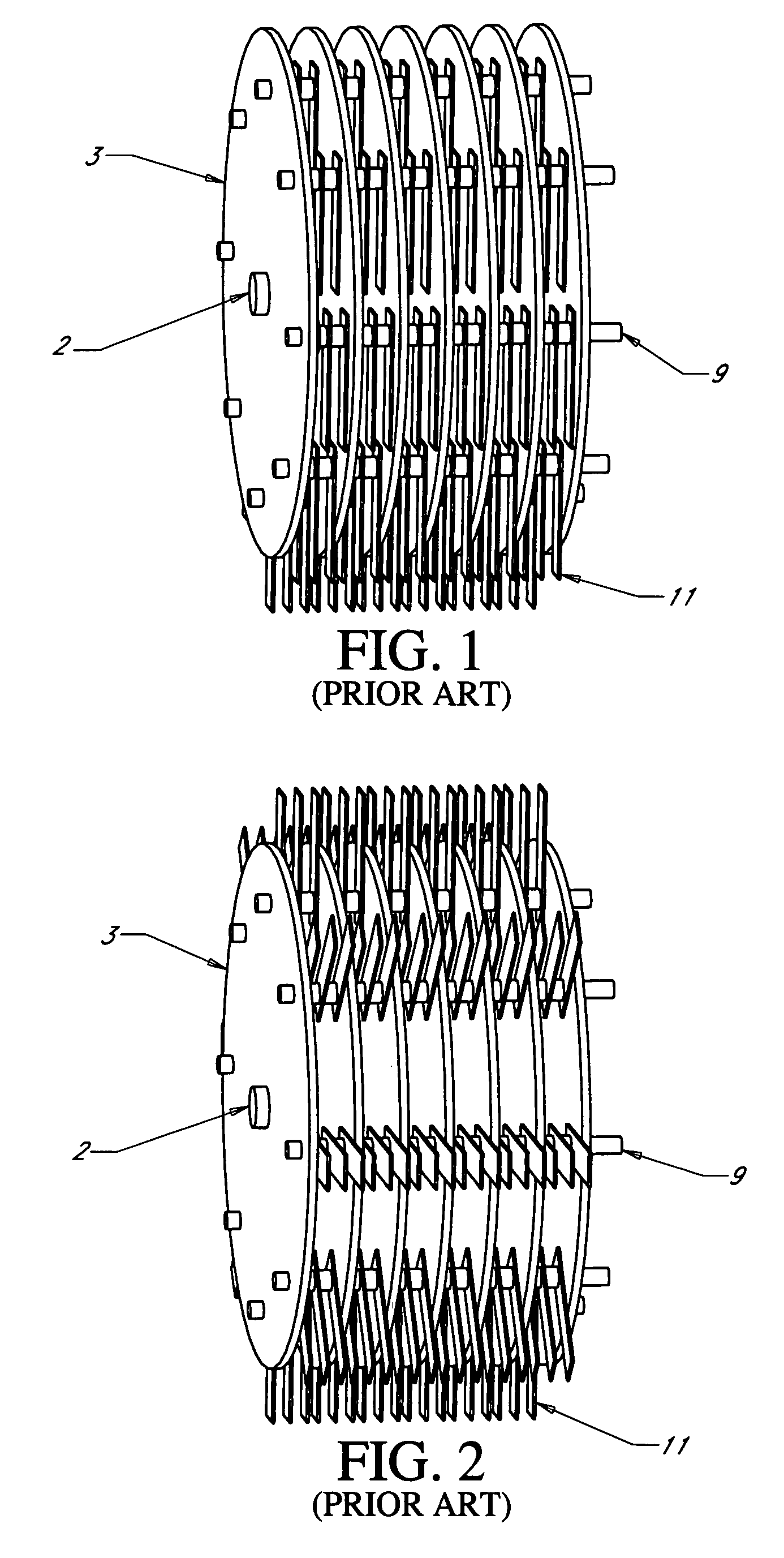

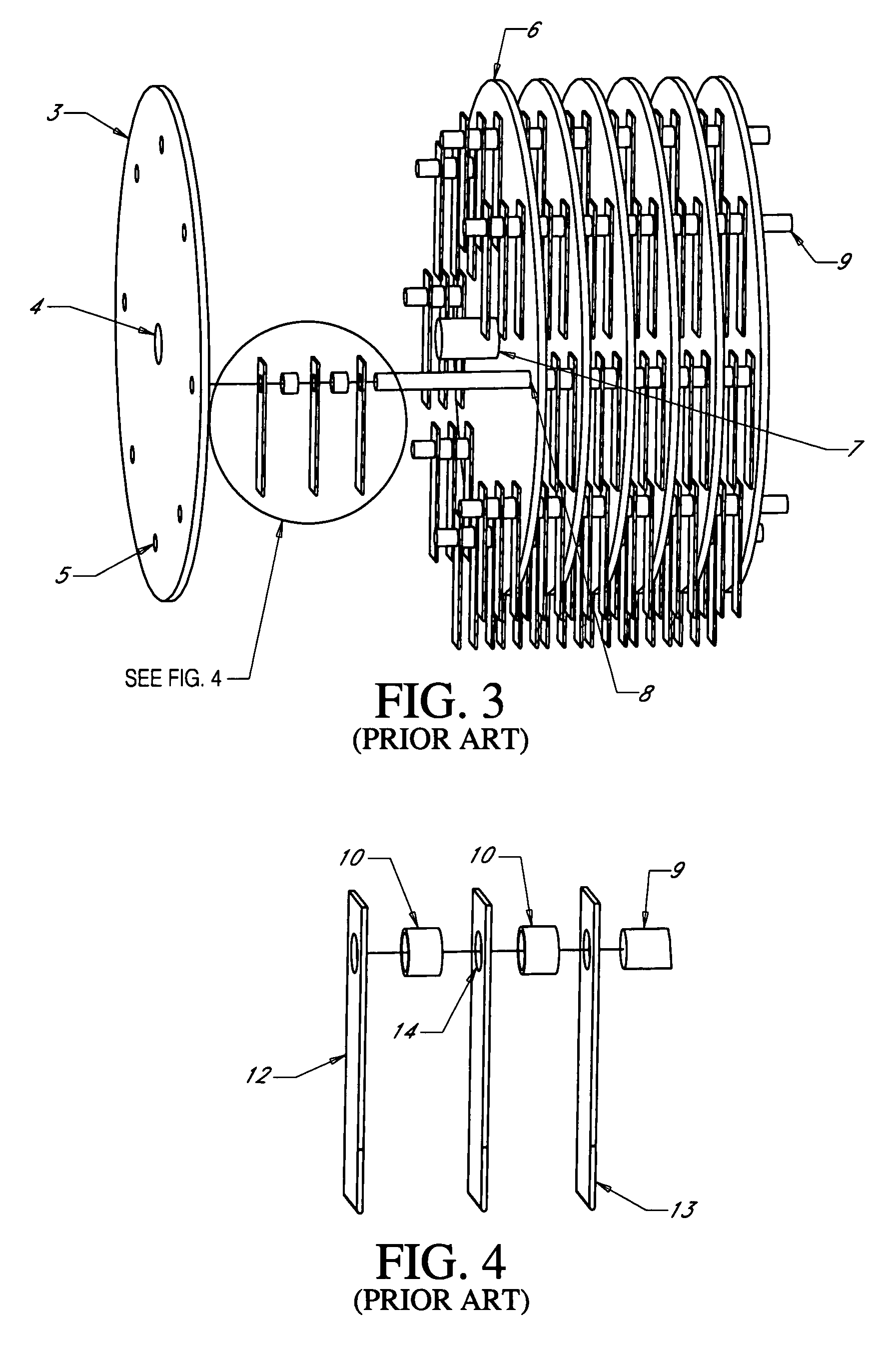

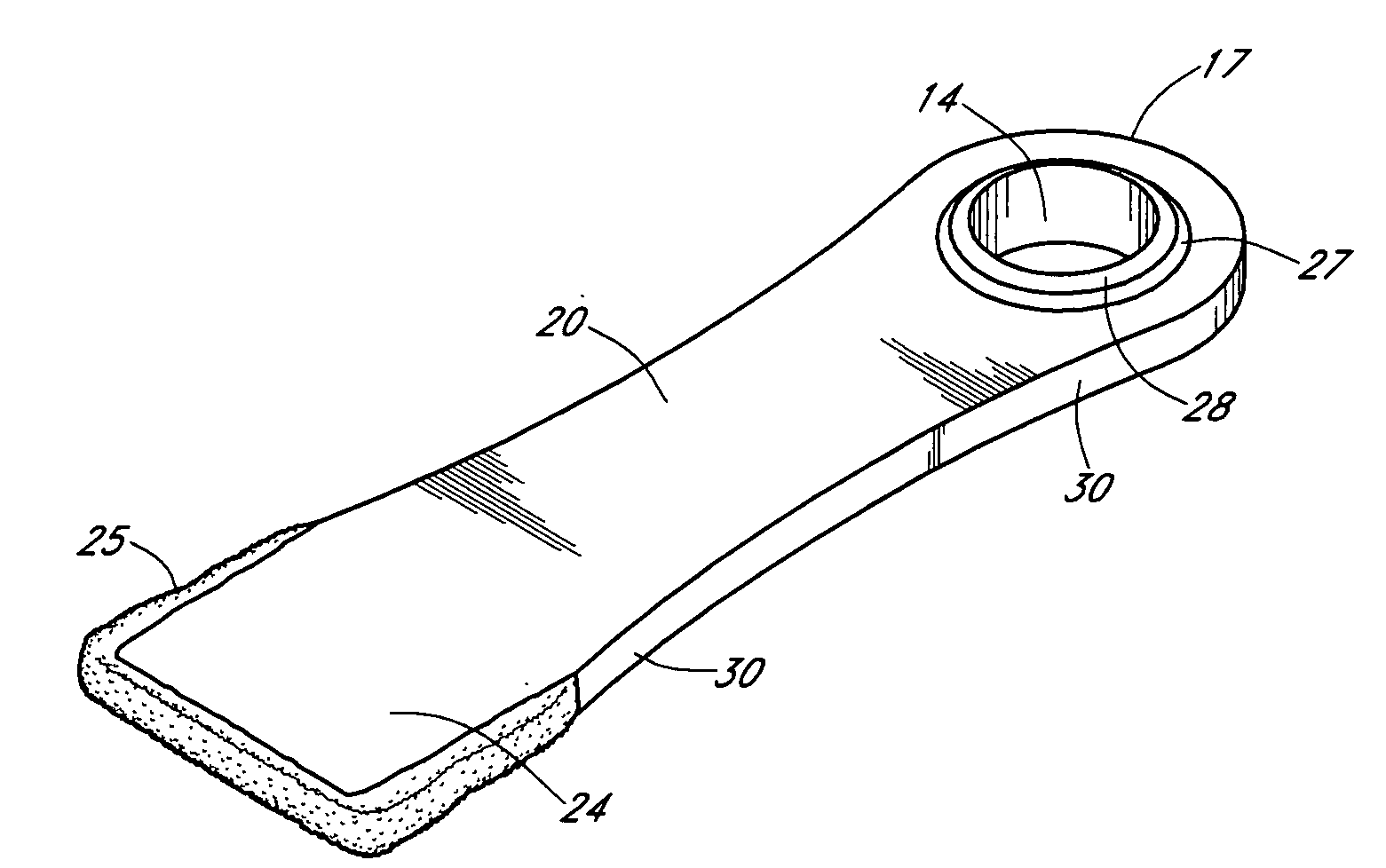

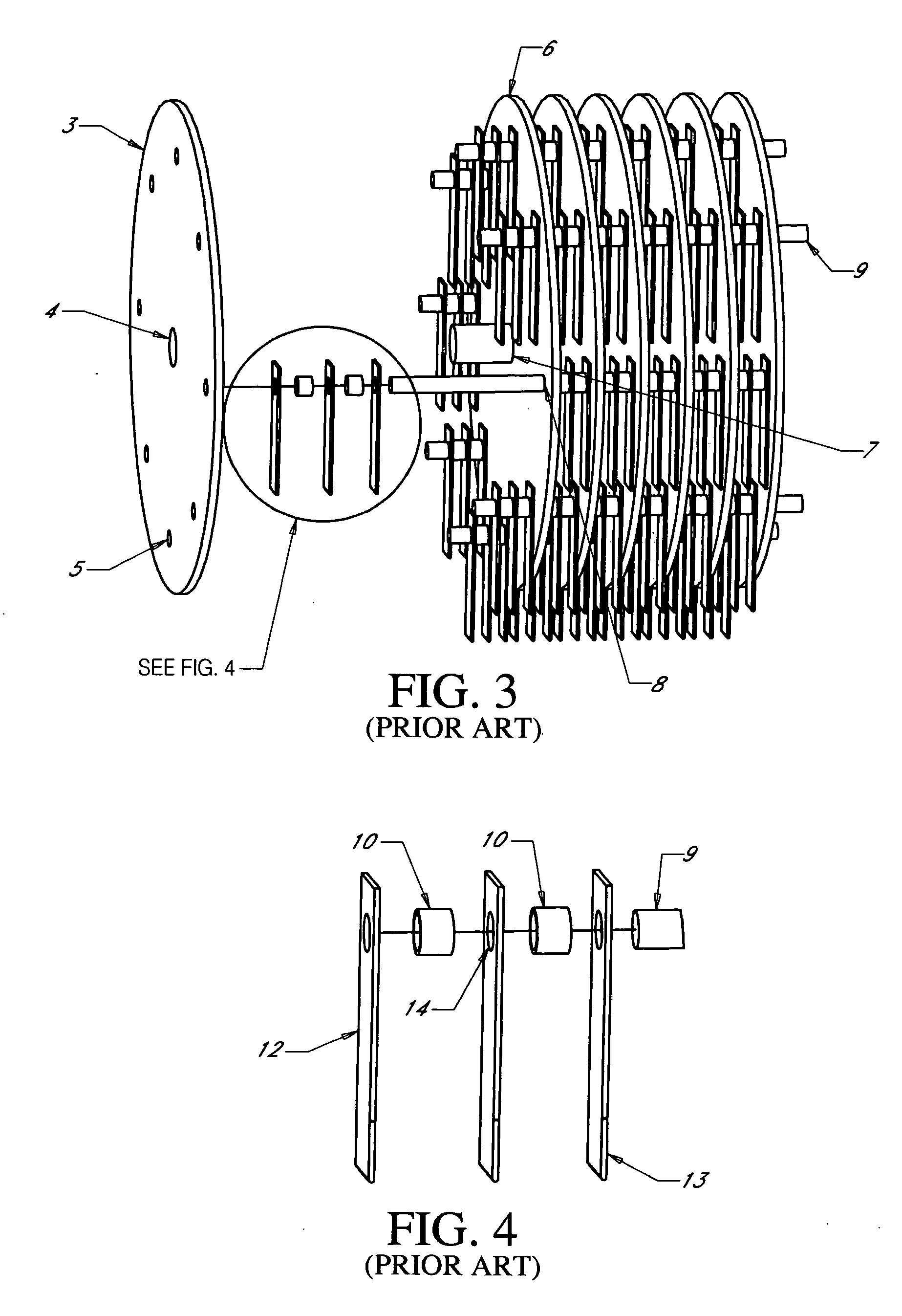

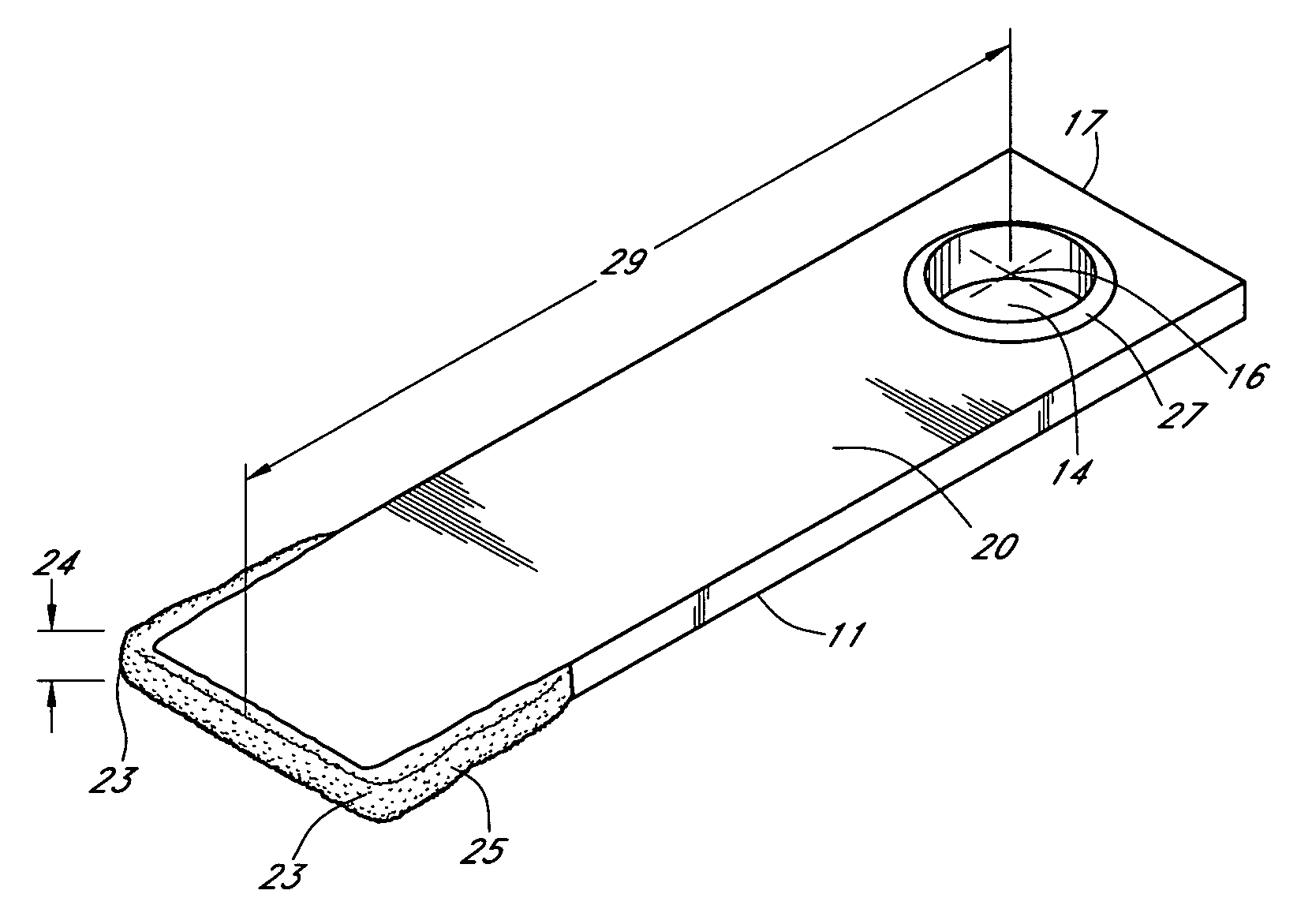

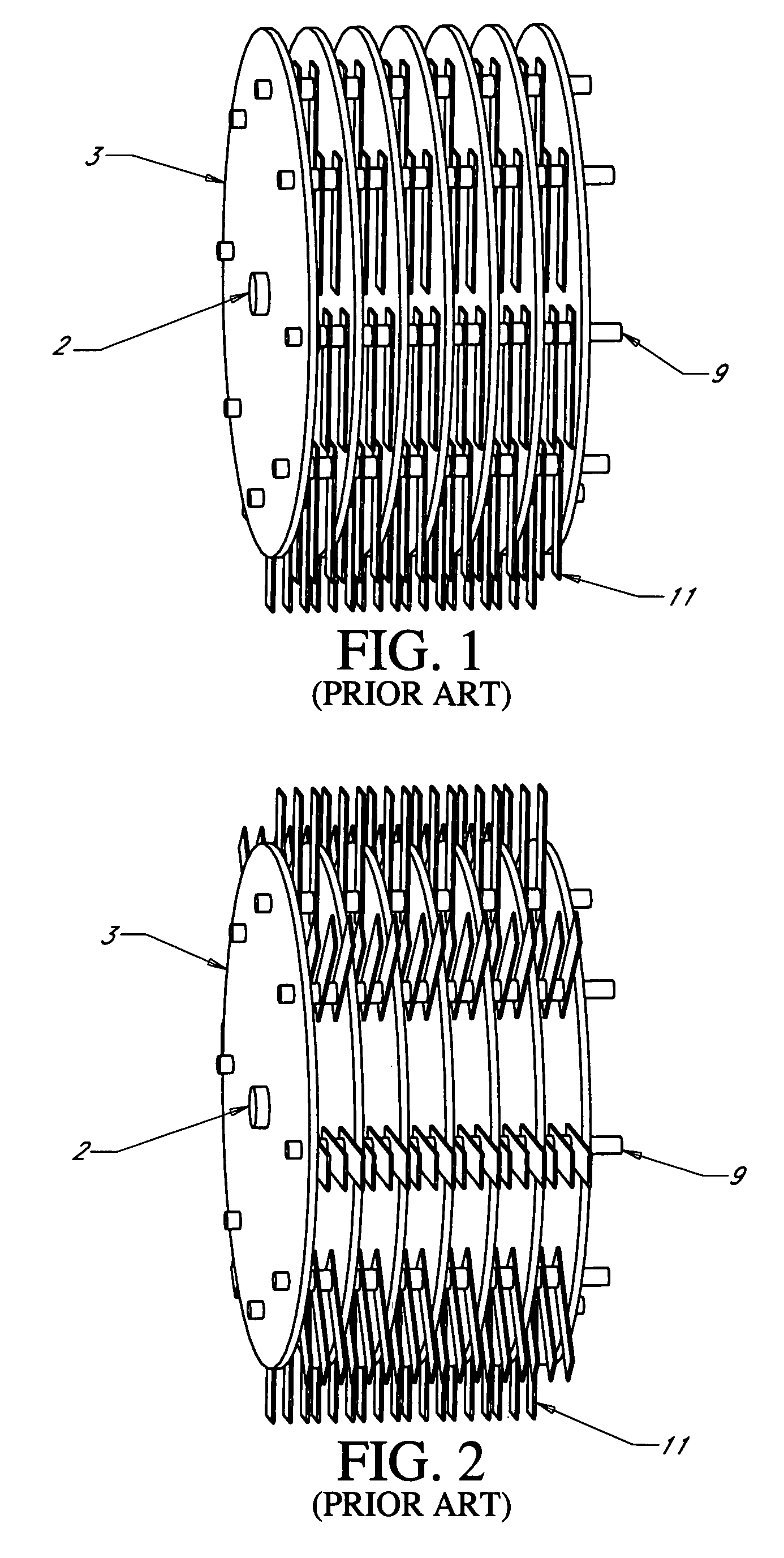

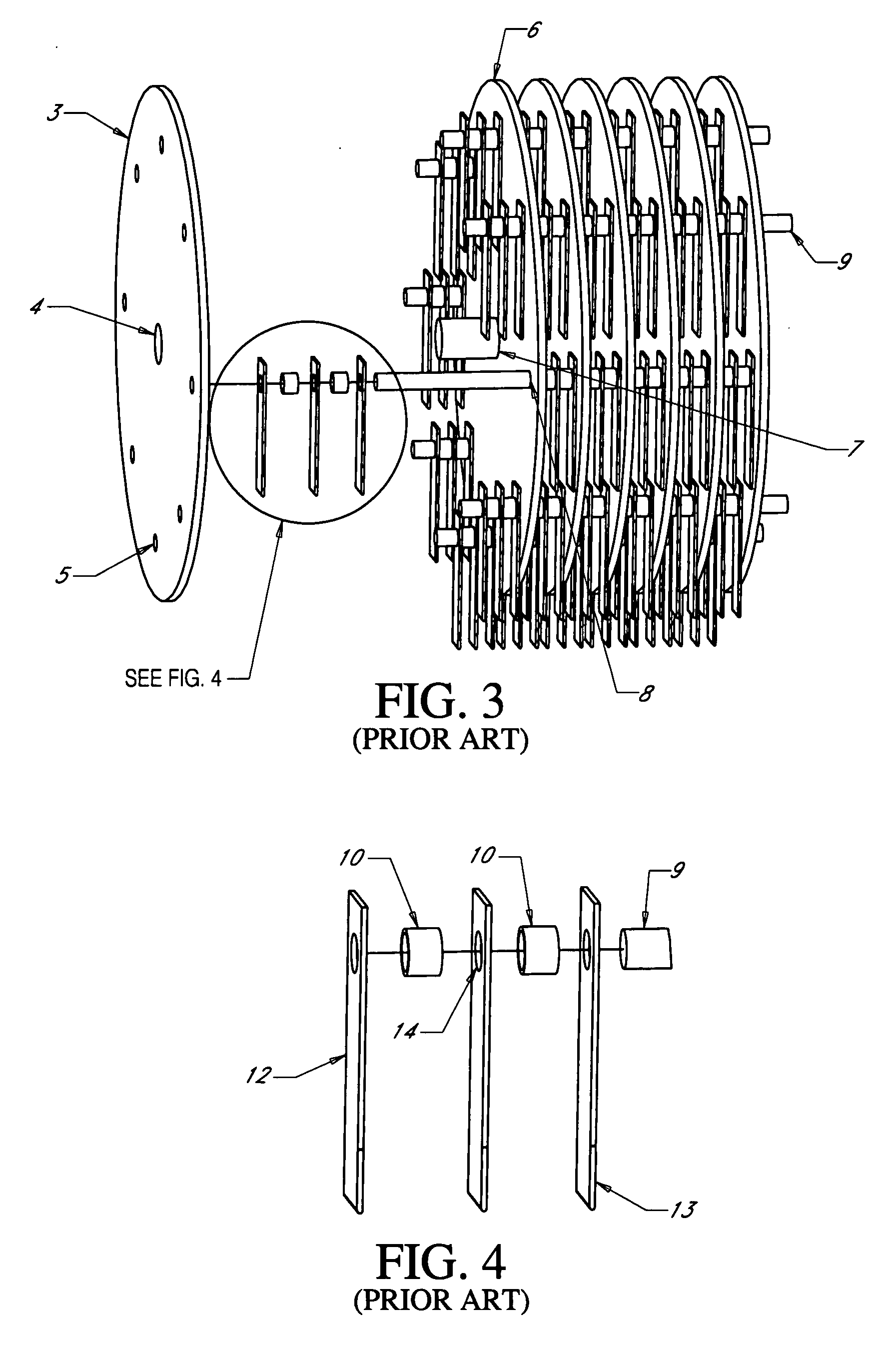

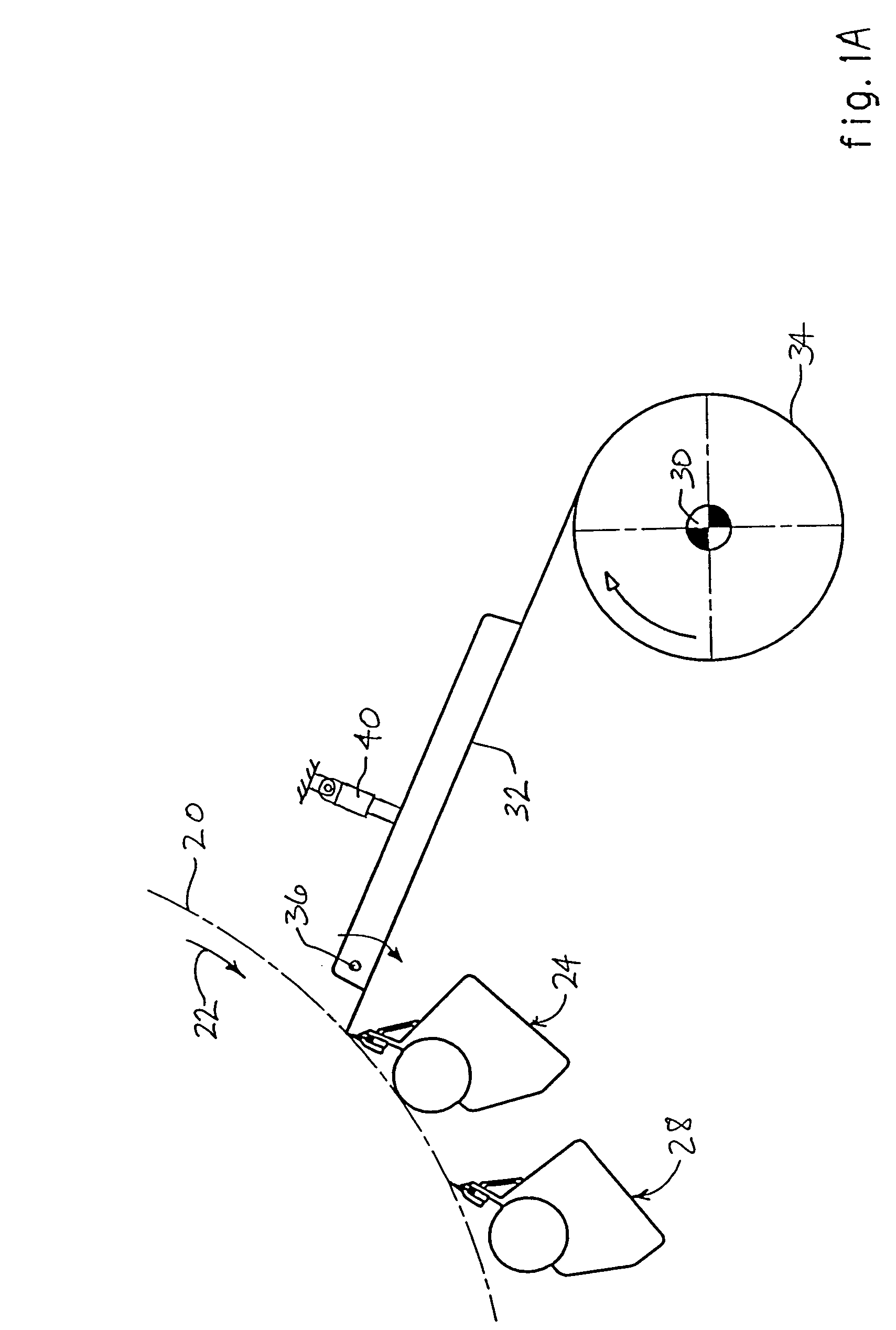

Hammermill hammer

An improved free swinging hammer mill hammer design is disclosed and described for comminution of materials such as grain and refuse. The hammer design of the present art is adaptable to most hammer mill or grinders having free swinging systems. The improved hammermill hammer may incorporate multiple comminution edges for increased comminution efficiencies. The design as disclosed and claimed may be forged to increase the strength of the hammer. A rod hole shoulder surrounding a portion of the rod hole adjacent the neck may be reduced in the radial dimension. The shape of the hammer body may be varied, as disclosed and claimed, to further improve hammer strength, or reduce or maintain the weight of the hammer while increasing the amount of force delivered to the material to be comminuted.

Owner:GENESIS III

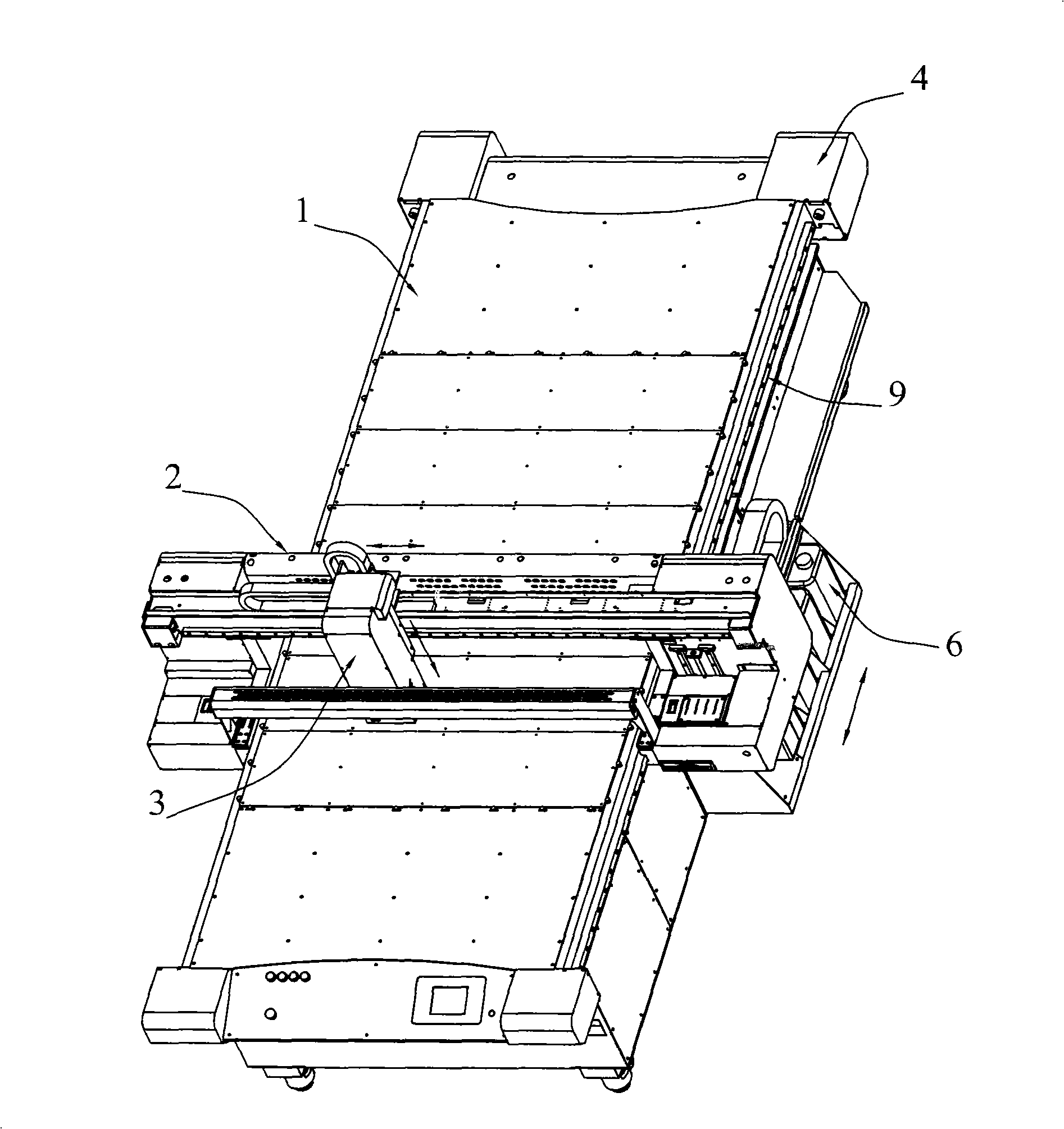

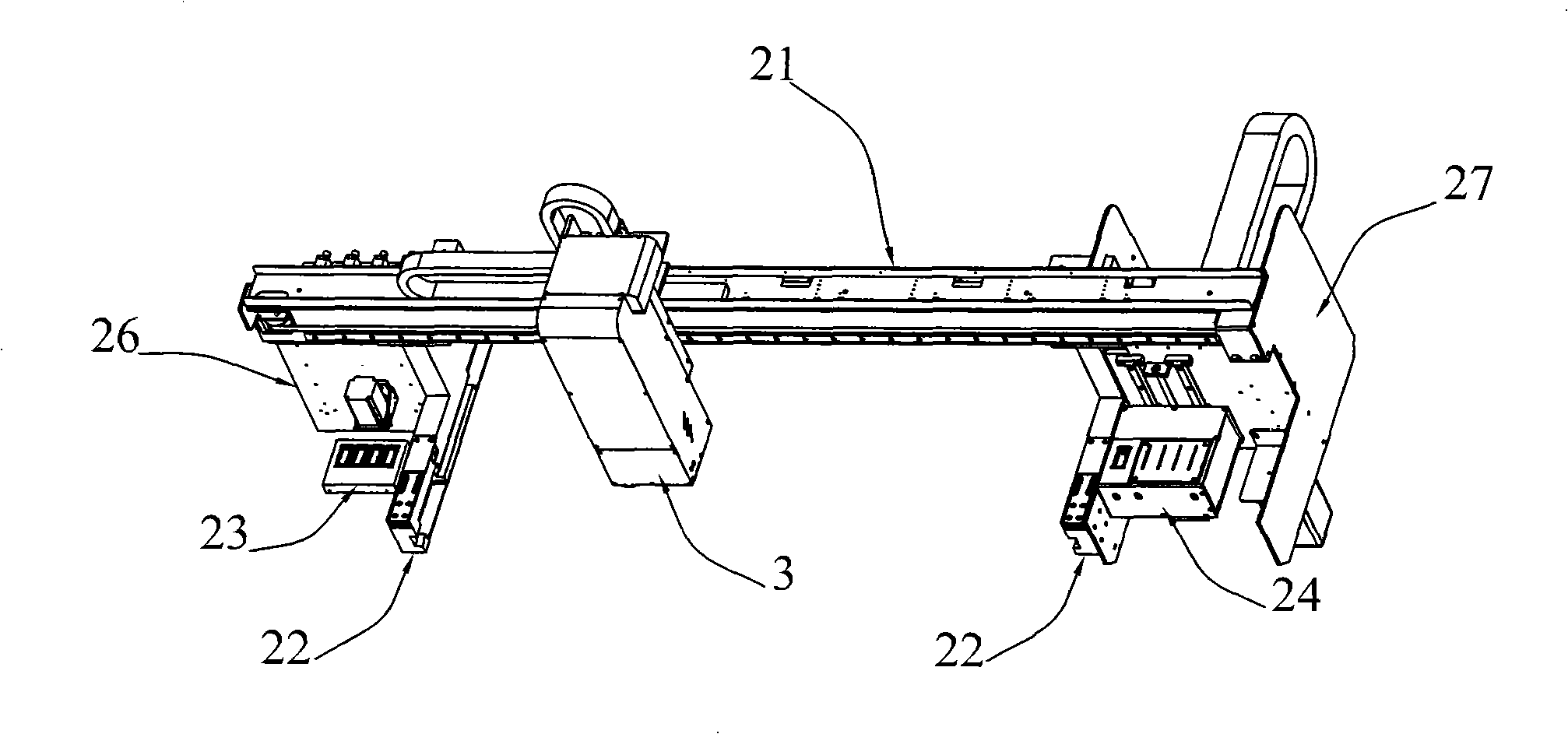

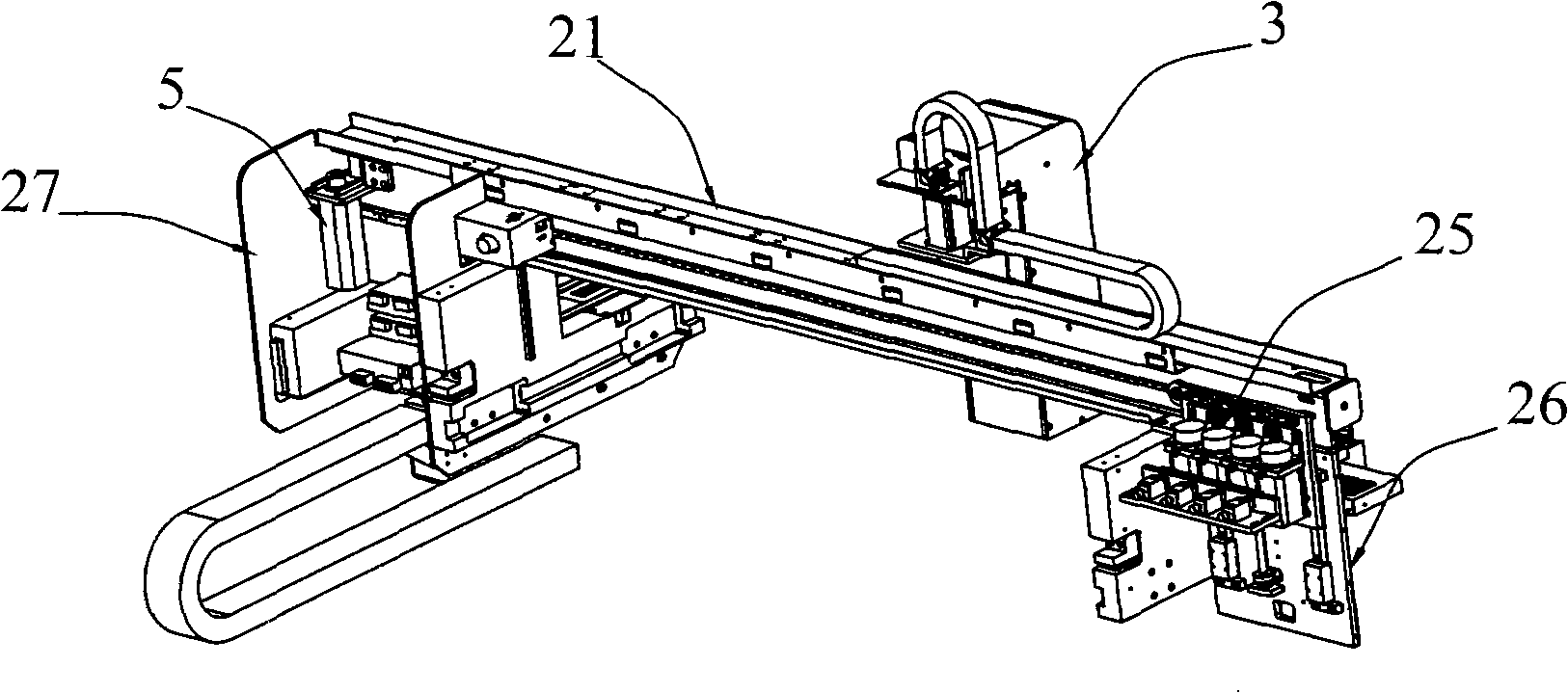

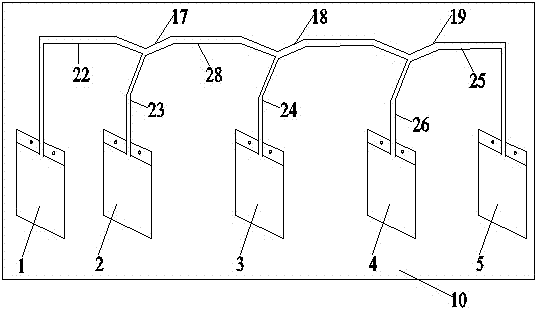

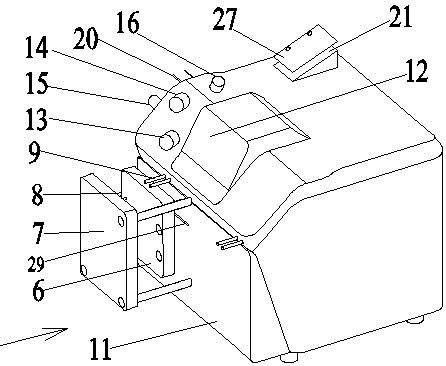

Print mechanism of flat-panel printer

The invention relates to the field of printers, which aims at overcomes the shortages in the prior art and provides a completely novel plate printer printing mechanism with high efficiency and easy control. The plate printer printing mechanism mainly comprises two parts: a jet car and a printing sprinkler, wherein, the jet car is composed of two sliding seats and a crossbeam used for connecting the two sliding seats; the printing sprinkler is arranged on the crossbeam and has two DOFs: left movement and right movement along the crossbeam and lifting vertically to the crossbeam; the sliding seat of the jet car is provided with a transmission box used for driving the printing sprinkler to move to the left side and the right side; the printing sprinkler is internally provided with a lifting mechanism which drives the printing sprinkler to be lifted. The plate printer printing mechanism is arranged on a fixed printing platform, the jet car can longitudinally move along the platform, the printing sprinkler can transversely move along the jet car, thus realizing the planar printing. The height of the printing sprinkler can be freely adjusted; the printing sprinkler is suitable for the products with different thickness, and realizes the printing of solid articles.

Owner:汤振华

Hammermill hammer

ActiveUS20070023554A1Excellent hardness propertiesIncrease torqueGrain treatmentsEngineeringHardness

An improved free swinging hammer mill hammer design is disclosed and described for comminution of materials such as grain and refuse. The hammer design of the present art is adaptable to most hammer mill or grinders having free swinging systems. The improved hammermill hammer may incorporate multiple comminution edges for increased comminution efficiencies. The improved hammermill hammer may incorporate multiple comminution edges for having increased hardness for longer operational run times. The design as disclosed and claimed may be forged to increase the strength of the hammer. The shape of the hammer body may be varied, as disclosed and claimed, to improve the hammer strength reduce or maintain the weight of the hammer while increasing the amount of force delivered to the material to be comminuted. The improved design may also incorporate comminution edges having increased hardness for longer operational run times.

Owner:GENESIS III

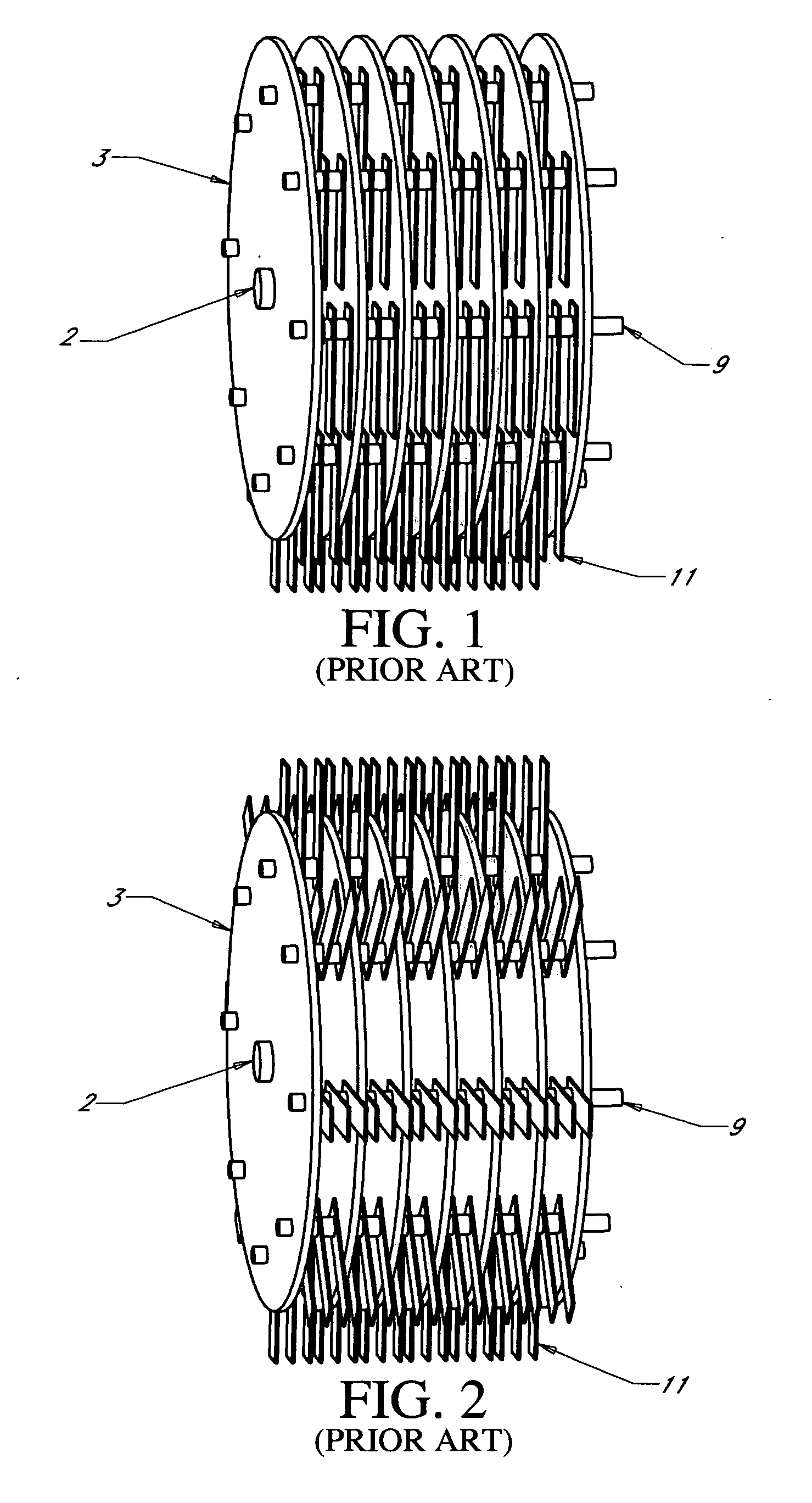

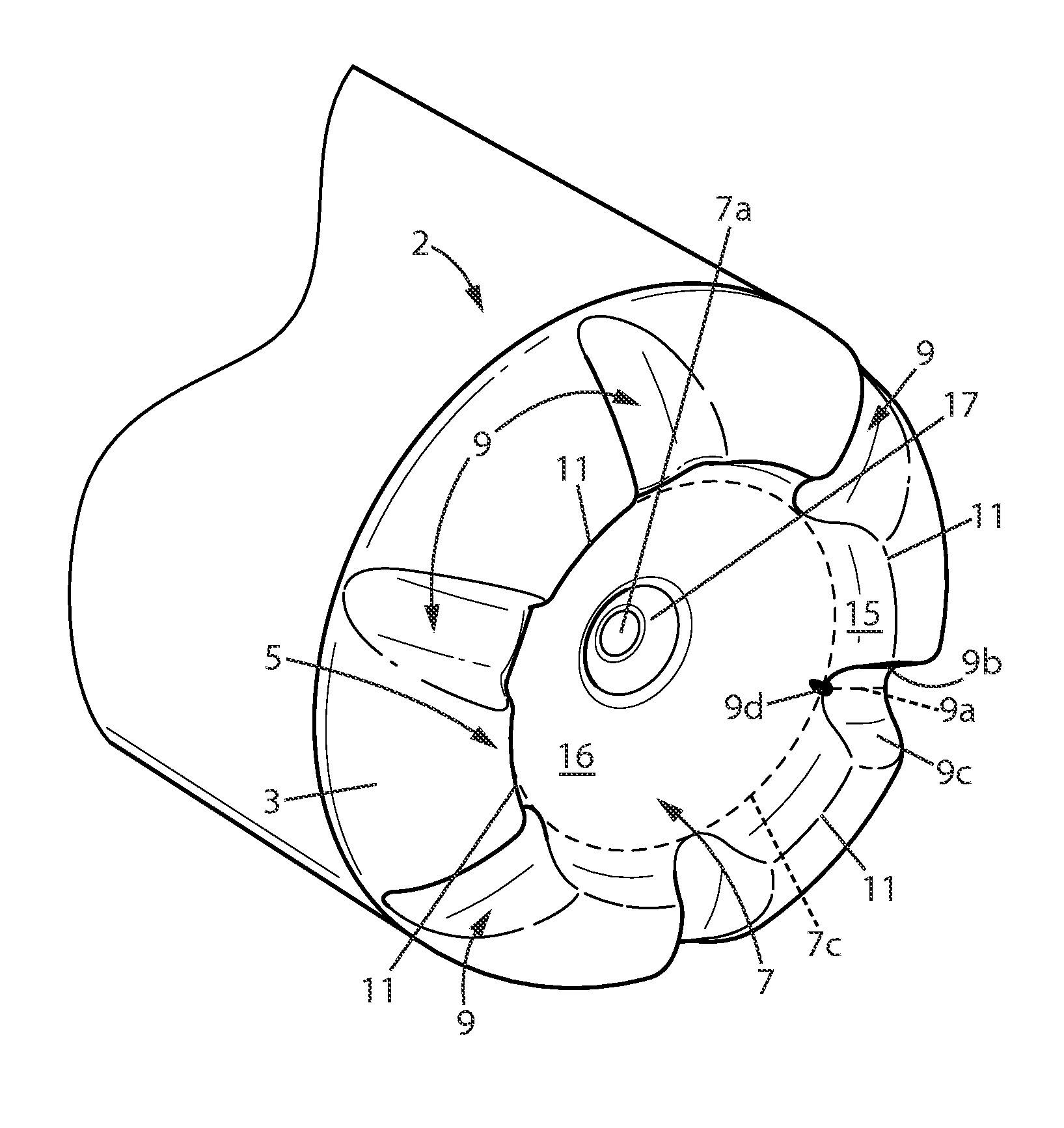

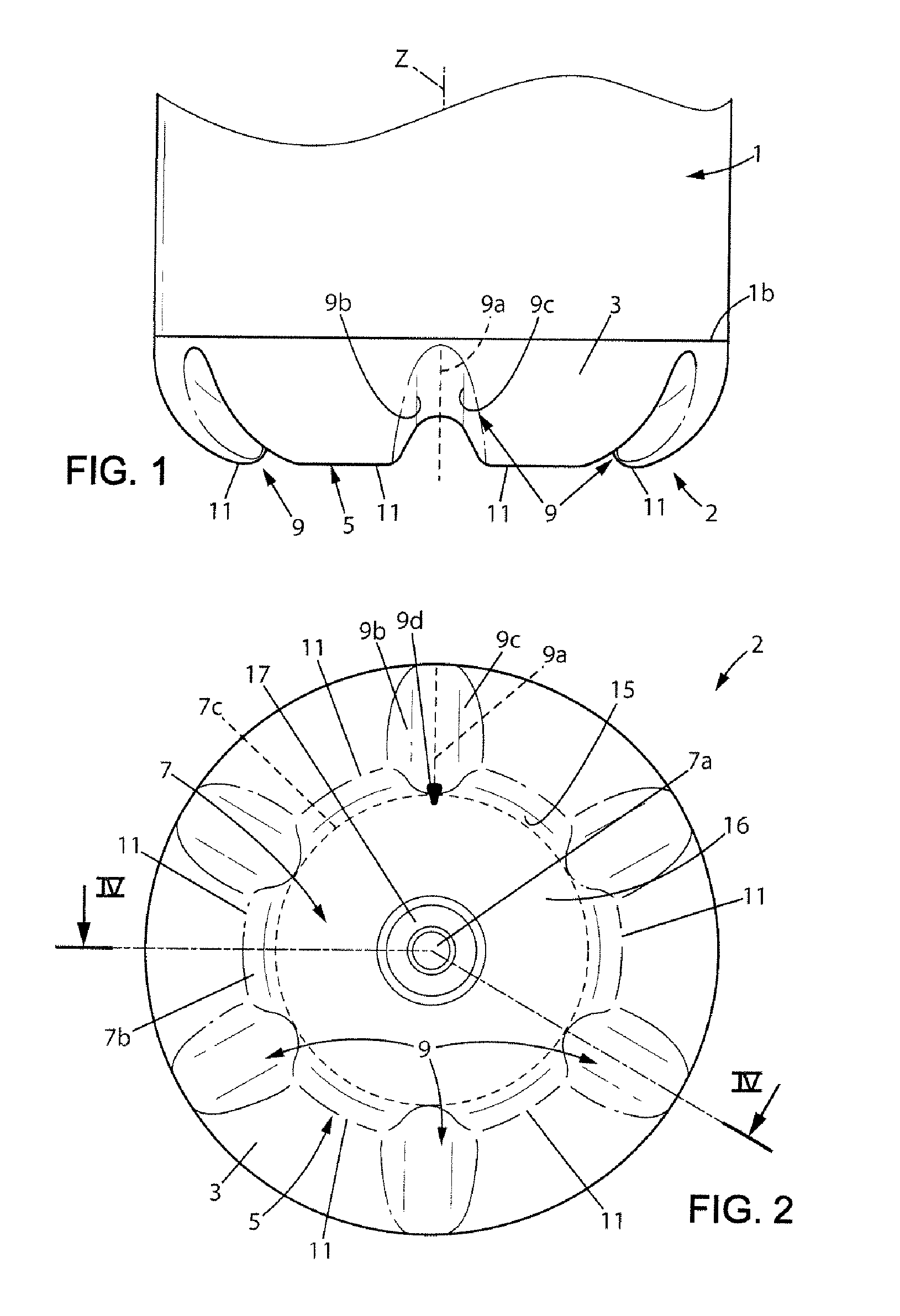

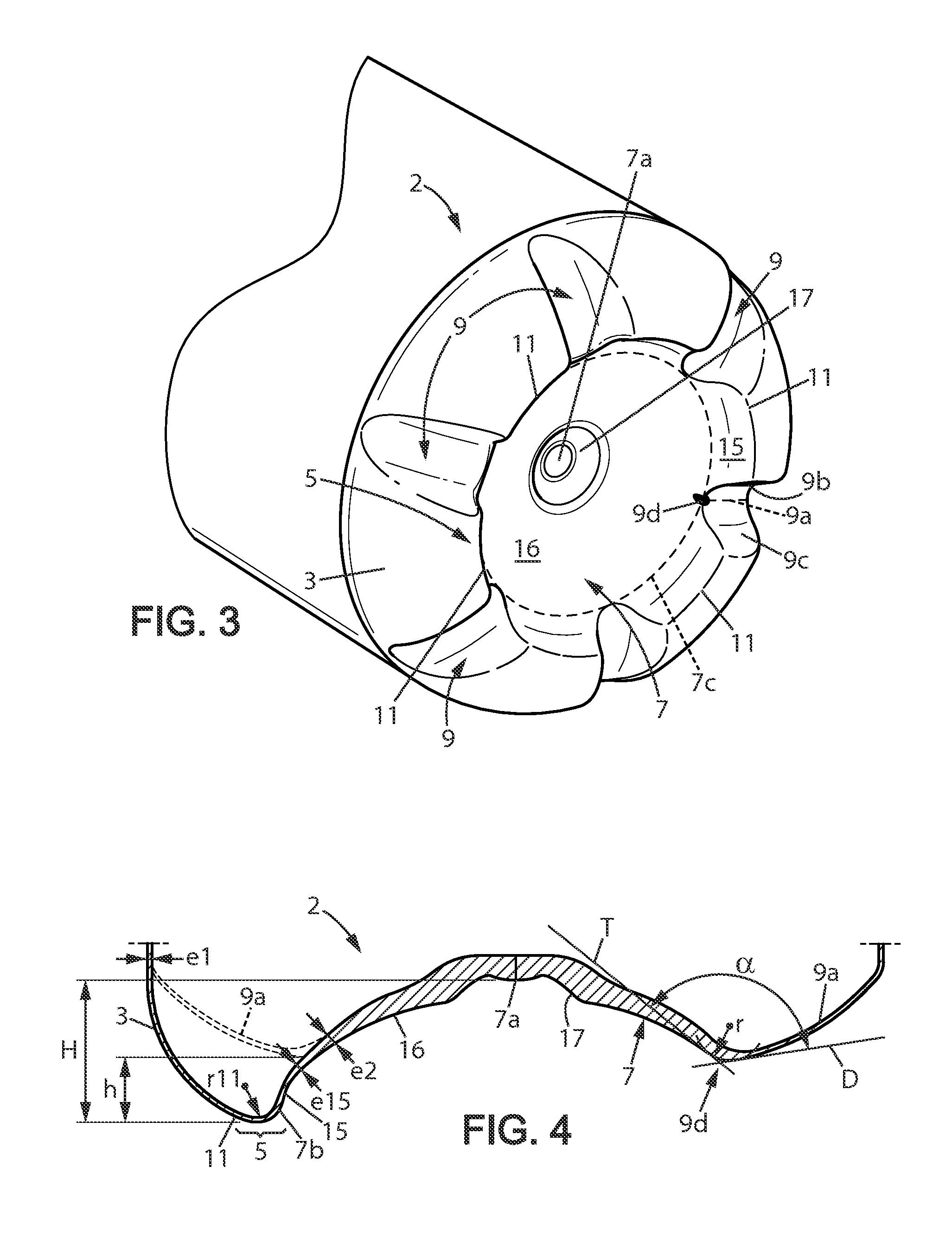

Plastic bottle with a champagne base and production method thereof

A plastic bottle includes: a body which extends longitudinally along a central axis from the neck to the lower end thereof and which has a pre-determined thickness, and a base (2) including an apron (3) which is connected to the lower end of the body and which extends to a peripheral bearing area. In addition, a dome (7) extends from the peripheral bearing area to the apex (7a) located essentially on the central axis and grooves (9) extend radially between the apron and the dome, the grooves having a base line (9a). The direction of the base lines (9a) of the grooves forms a sharp angle with the direction tangential to the dome (7) at the point (9d) at which the base of the grooves (9) opens into the dome (7).

Owner:DES EAUX MINERALES DEVIAN

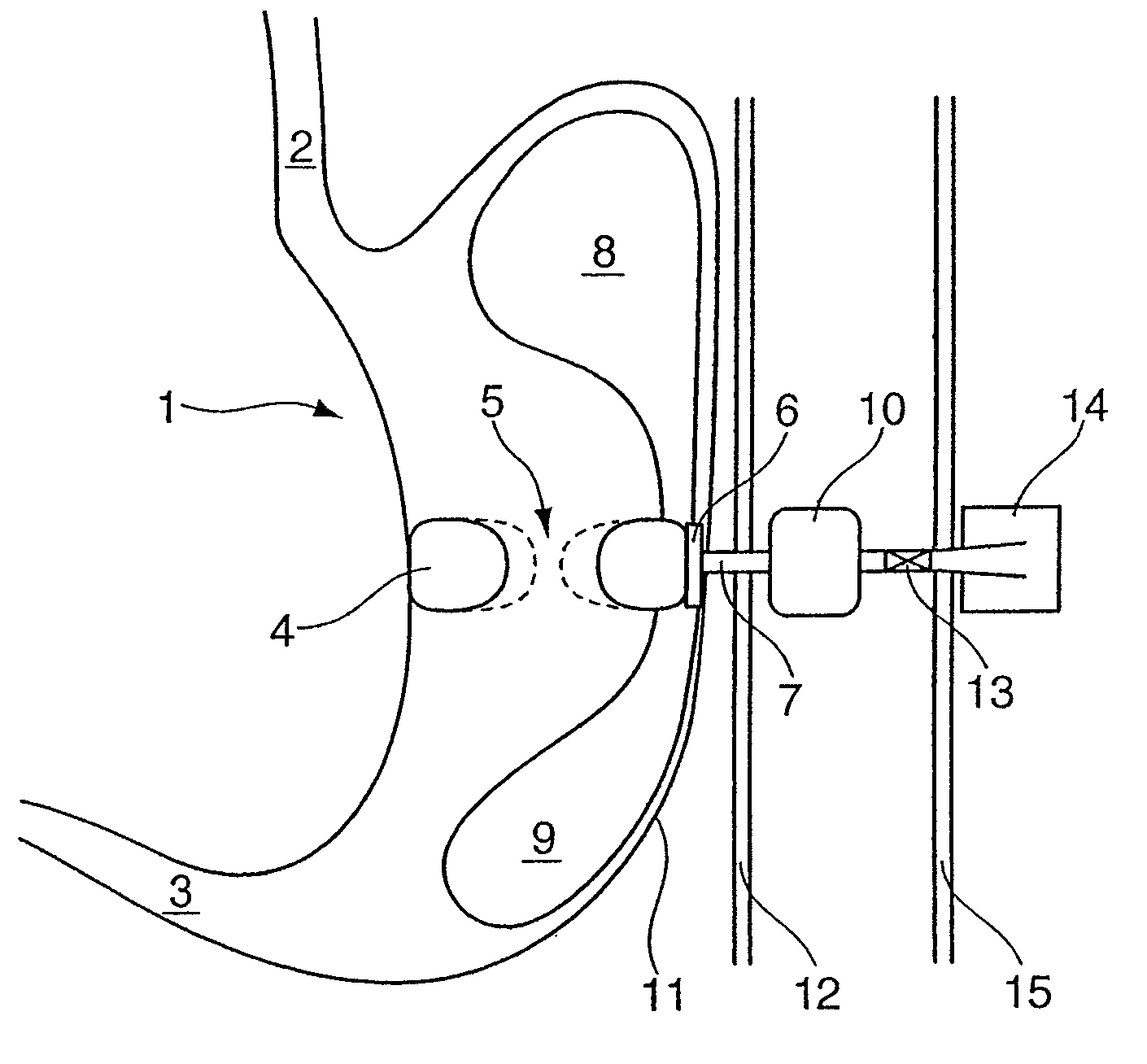

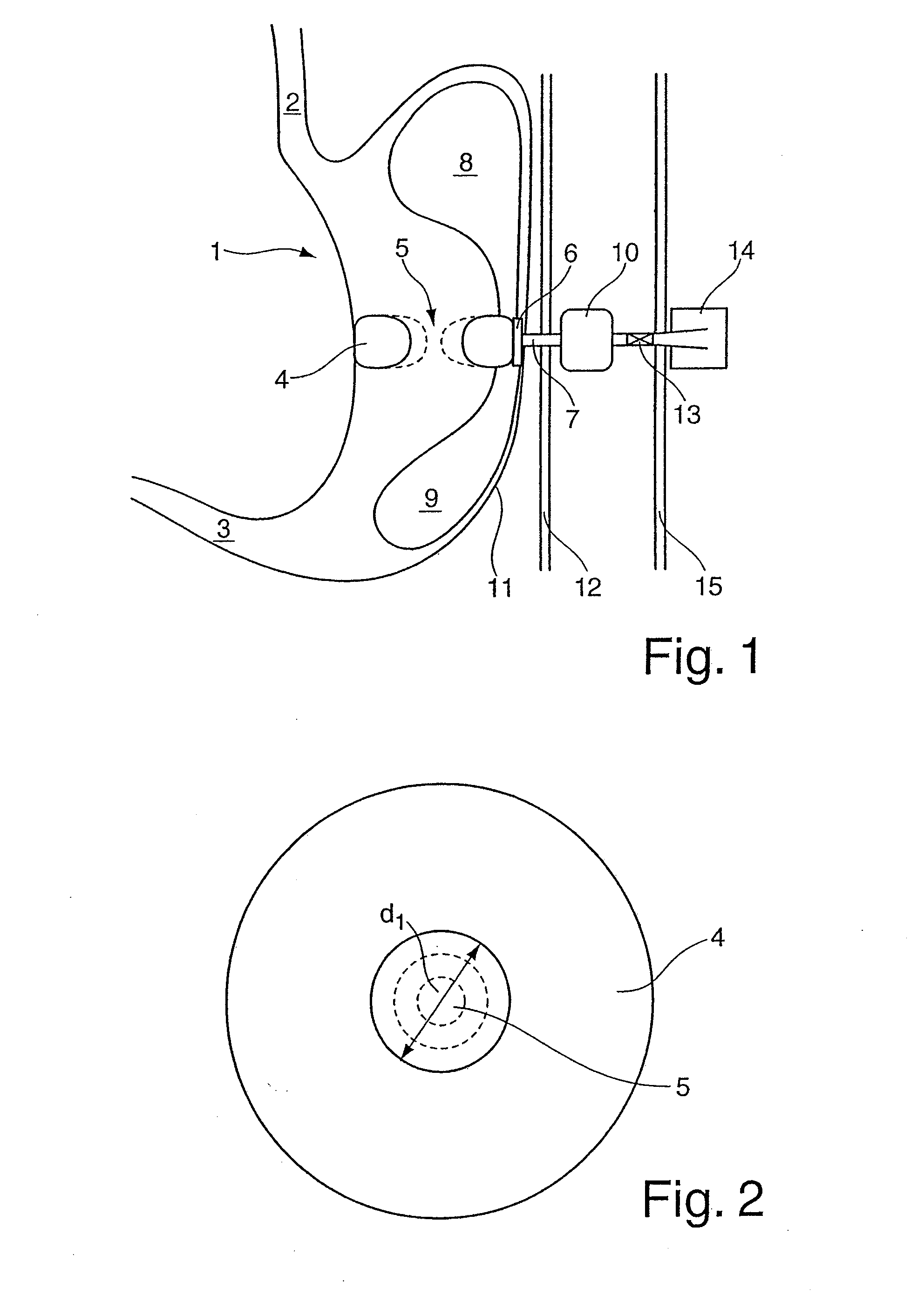

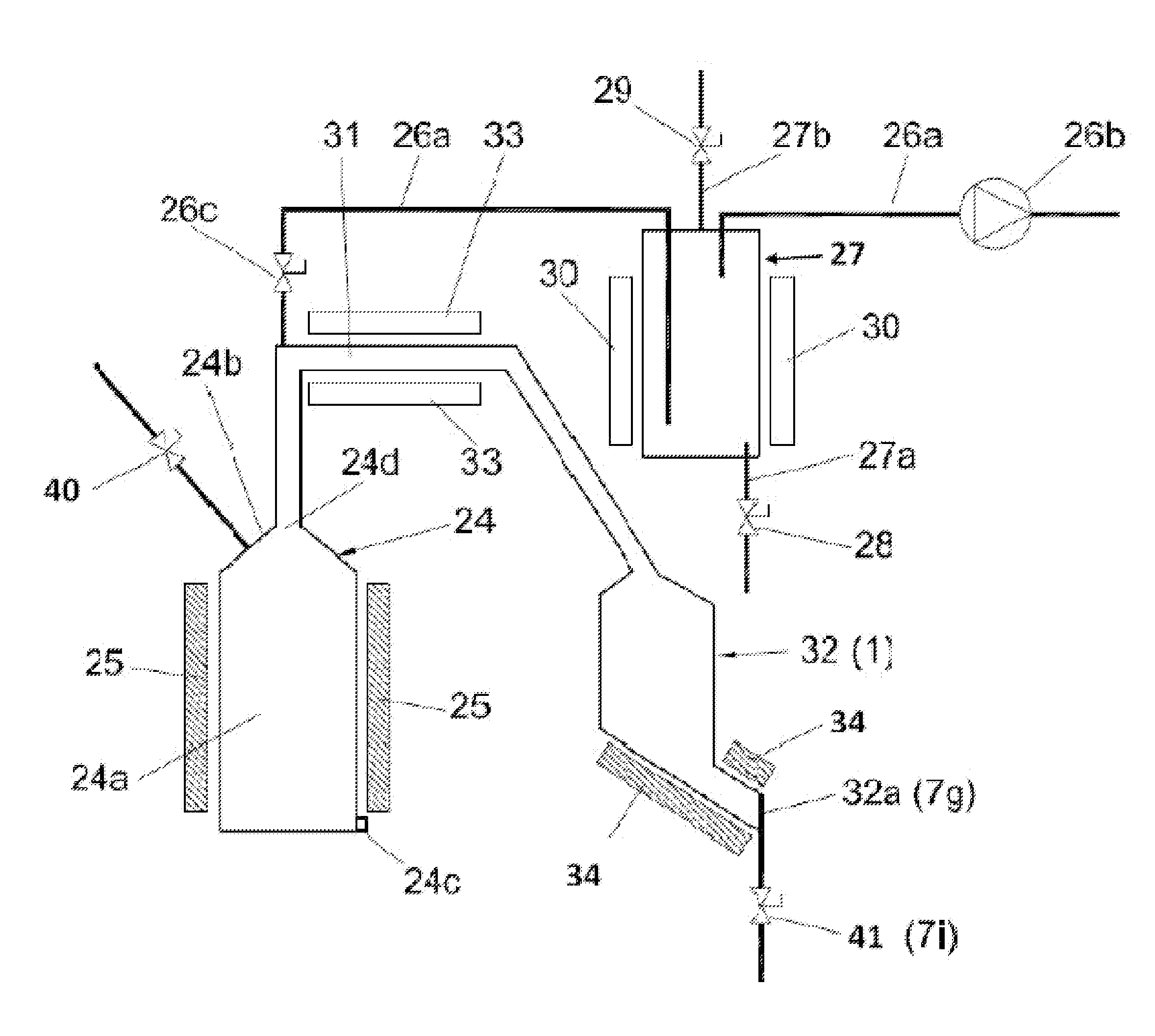

Device for treating obesity

InactiveUS20100152764A1Level of filling be reduceReduction of excess weightStentsSurgeryLoop shapingBiomedical engineering

A device for treating obesity in humans is described, with a balloon arrangement that can be introduced into the human stomach and that can be filled with a fluid and emptied inside the stomach for controlled reduction of the stomach volume; with at least one fluid line, which is connected in a fluid tight manner to the balloon arrangement and via which the balloon arrangement can be filled and emptied transcutaneously; with at least one securing means provided along the fluid line in order to fix the fluid line to skin and tissue layers enclosing the stomach; and with at least one valve unit provided along the fluid line. The balloon arrangement has a first means that can be filled with the fluid and assumes a balloon-like configuration in a filled state, a second fillable means which, in a filled state, assumes a ring-shaped or loop-shaped configuration and radially encloses a clear internal diameter, and the first and second means are connected to each other in so that the first means extends into a first half space via a plane enclosed by the ring-shaped or loop-shaped configuration of the filled second means.

Owner:MERKLE DOMINIQUE

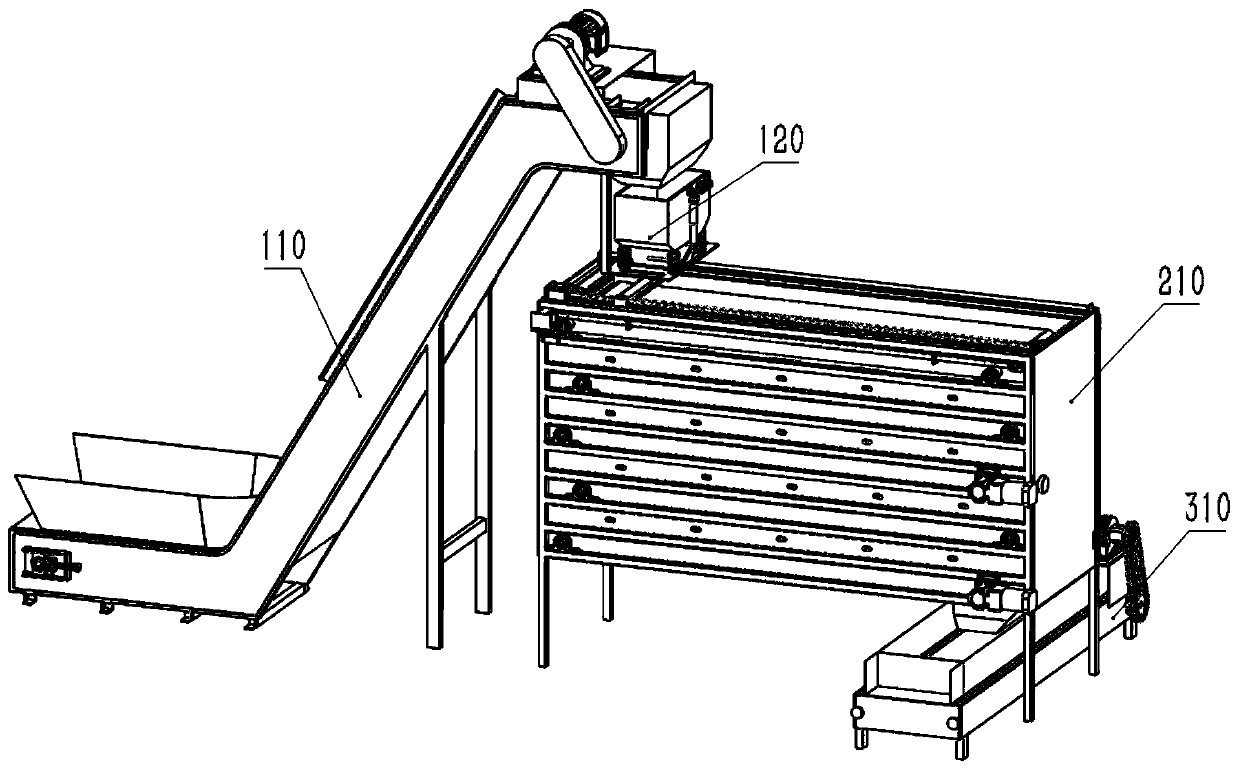

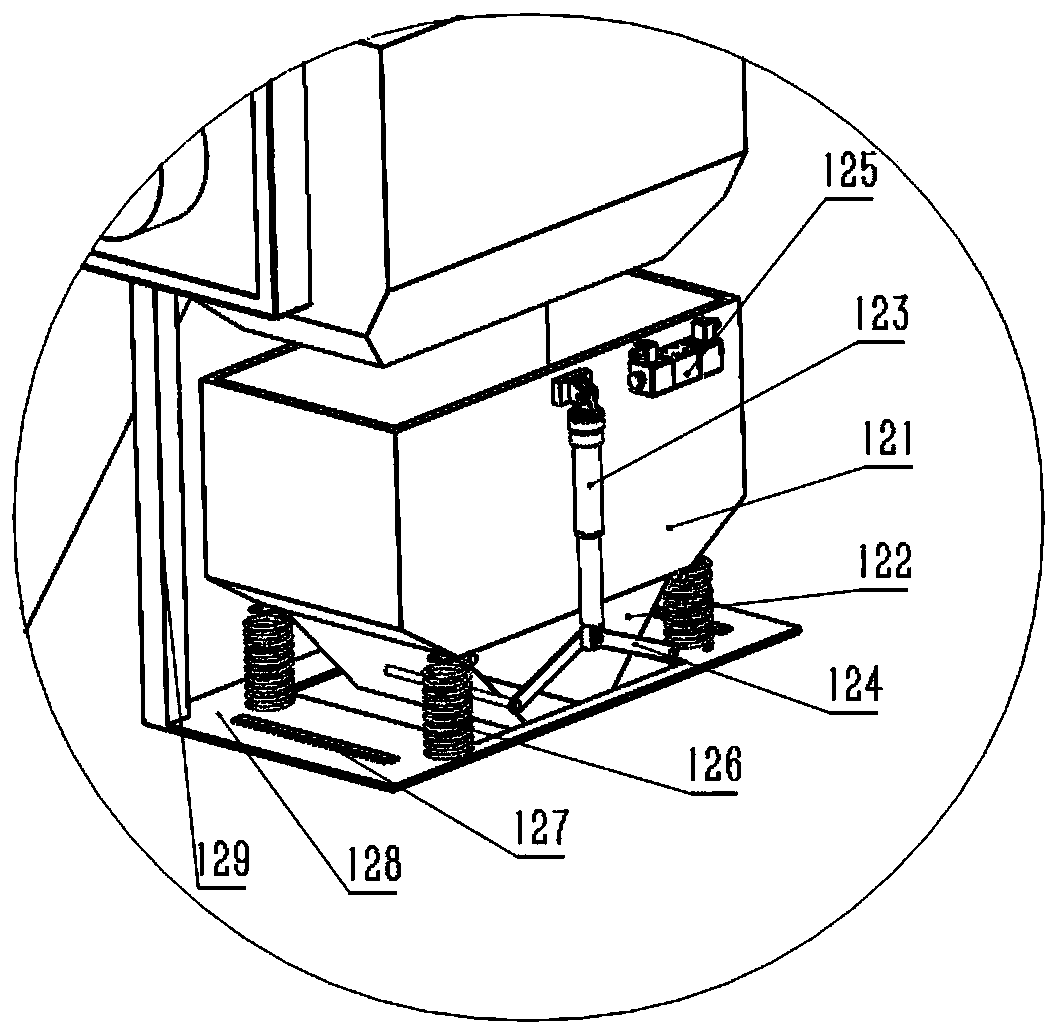

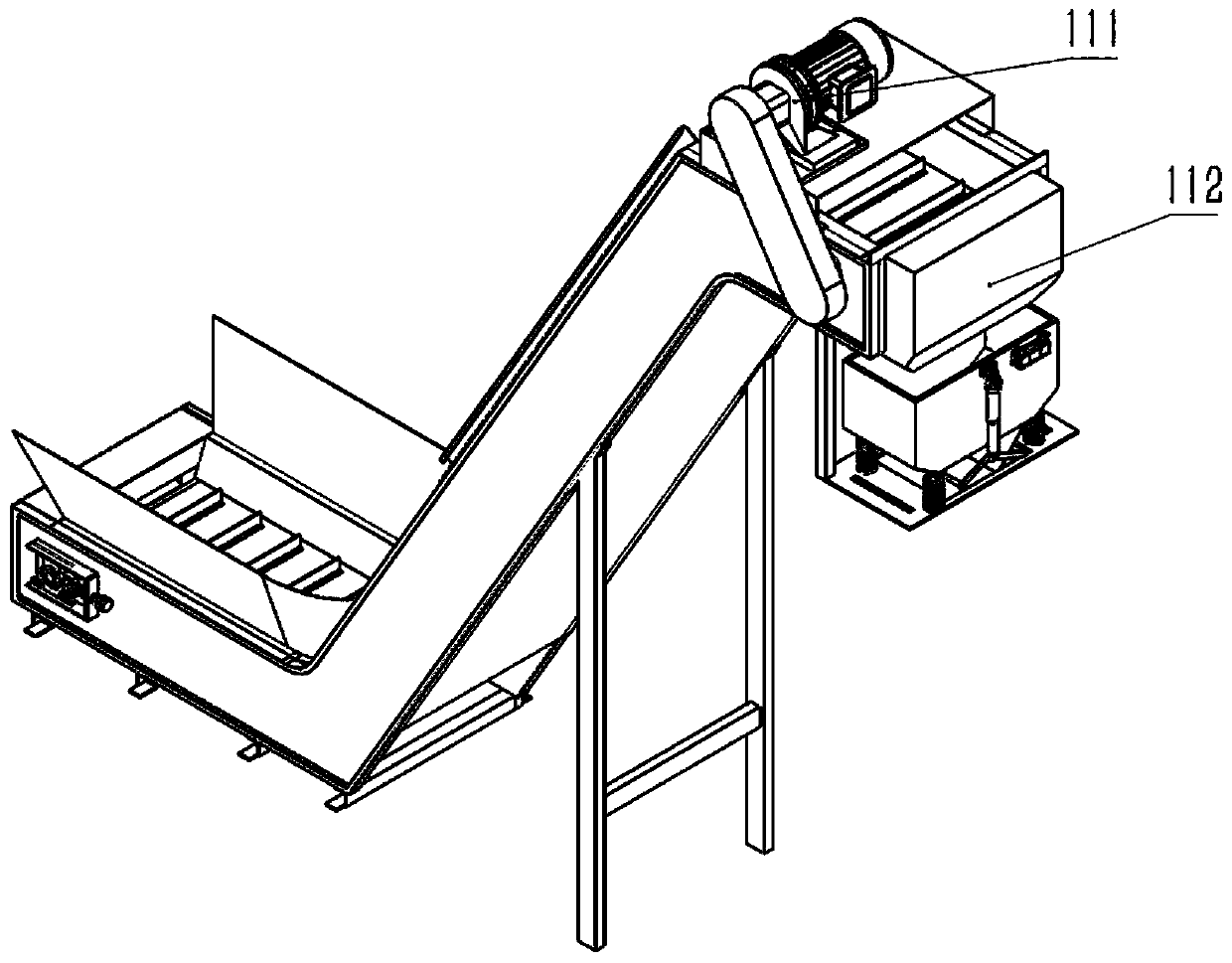

Multi-layer conveying belt tea leaf fragrance extraction machine and control method

PendingCN111217080AGuaranteed uniformityAchieve uniformitySievingConveyorsAgricultural engineeringTea leaf

The invention relates to a multi-layer conveying belt tea leaf fragrance extraction machine and a control method. The fragrance extraction machine comprises a PLC control unit, an automatic tea leaf feeding unit, a fragrance extraction and baking unit and an automatic tea leaf discharging unit, wherein the automatic tea leaf feeding unit comprises a vertical elevator and an automatic tea leaf weighing device, and the fragrance extraction and baking unit comprises a transferring conveying belt, a transverse leaf evening device, a longitudinal leaf evening device and a multi-layer conveying beltbaking unit; and the transferring conveying belt is arranged below a discharge port of the automatic tea leaf weighing device and conveys tea leaves to the multi-layer conveying belt baking unit, thetransverse leaf evening device moves in the length direction of the transferring conveying belt to evenly scrape the tea leaves on the transferring conveying belt, the longitudinal leaf evening device moves in the width direction of the transferring conveying belt to evenly scrape the tea leaves on the transferring conveying belt, and the multi-layer conveying belt baking unit comprises a plurality of layers of conveying belts for conveying the tea leaves from top to bottom and heating baking units arranged on the two sides of the conveying belts. The multi-layer conveying belt tea leaf fragrance extraction machine and the control method solve the problem that the tea leaves are stacked on the conveying belts, and guarantees the tea leaf baking uniformity.

Owner:ANHUI AGRICULTURAL UNIVERSITY

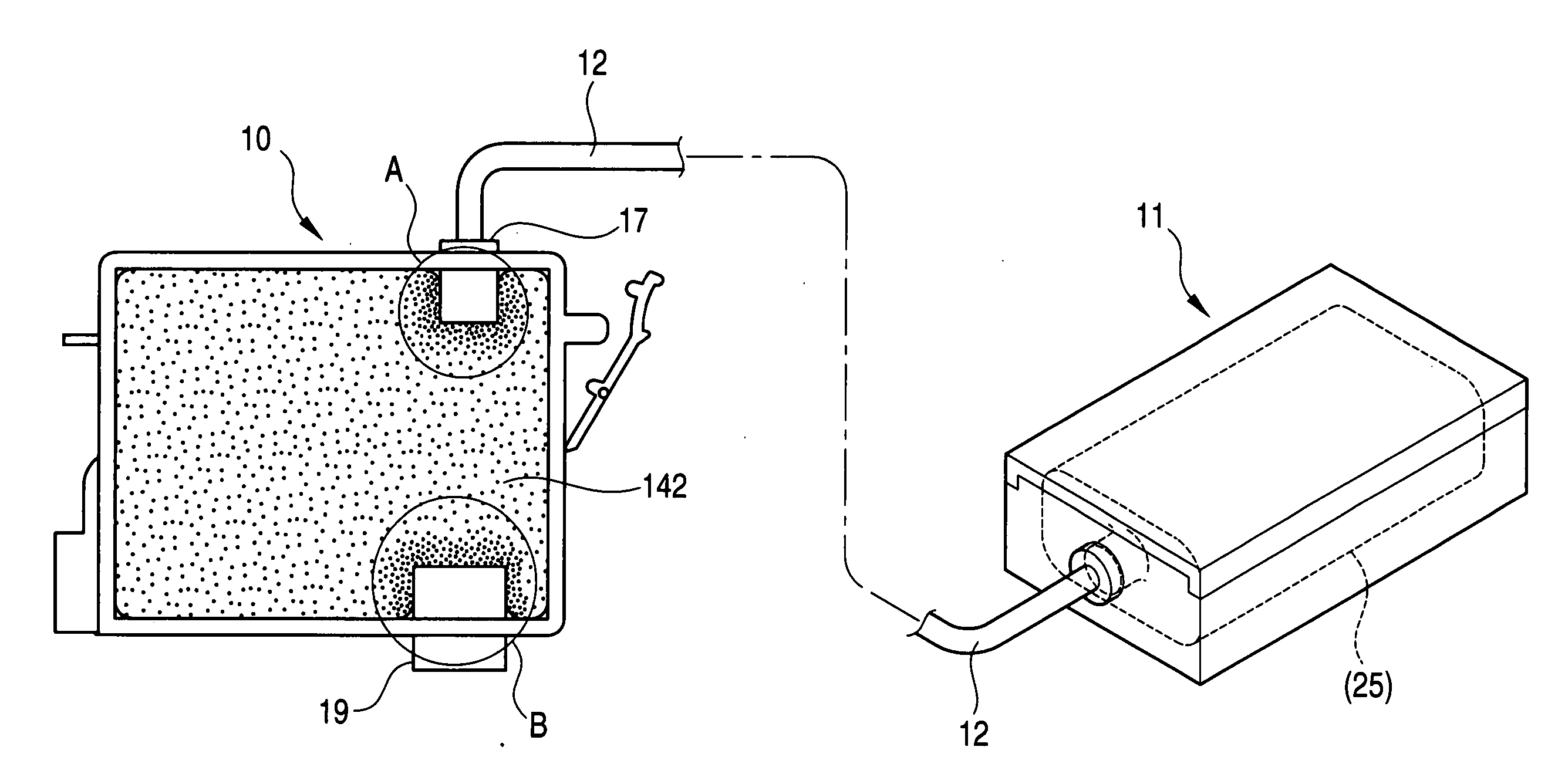

Attachment and liquid supplying

InactiveUS20050219281A1Uniform liquid jet qualityIncrease liquid pressureOther printing apparatusLiquid jetEngineering

An attachment is mountable on a carriage in place of a liquid container that contains liquid and that is mounted on the carriage having a liquid jet head for jetting liquid, so that the attachment can supply liquid introduced from outside to the liquid jet head. The attachment has a pressure control means provided in a flow passage which is formed in an attachment body and through which the liquid introduced from the outside is supplied to the liquid jet head.

Owner:SEIKO EPSON CORP

Hammermill hammer

ActiveUS20080011890A1Improve efficiencyExcellent hardness propertiesGrain treatmentsEngineeringComminution

An improved free swinging hammer mill hammer design is disclosed and described for comminution of materials such as grain and refuse. The hammer design of the present art is adaptable to most hammer mill or grinders having free swinging systems. The improved hammermill hammer may incorporate multiple comminution edges for increased comminution efficiencies. The design as disclosed and claimed may be forged to increase the strength of the hammer. A rod hole shoulder surrounding a portion of the rod hole adjacent the neck may be reduced in the radial dimension. The shape of the hammer body may be varied, as disclosed and claimed, to further improve hammer strength, or reduce or maintain the weight of the hammer while increasing the amount of force delivered to the material to be comminuted.

Owner:GENESIS III

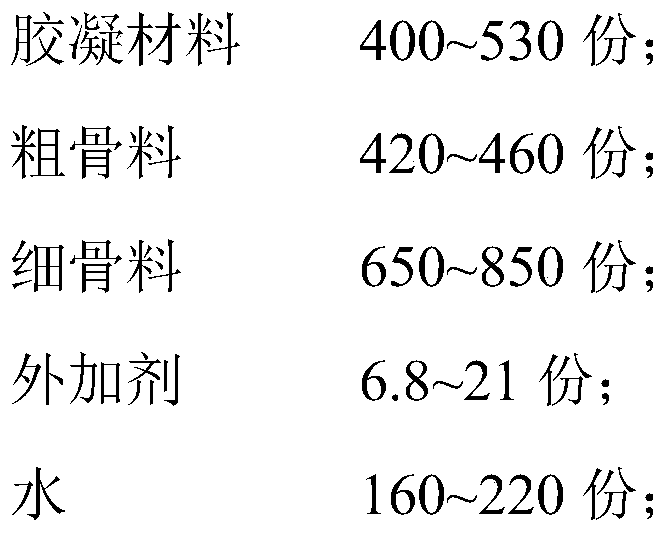

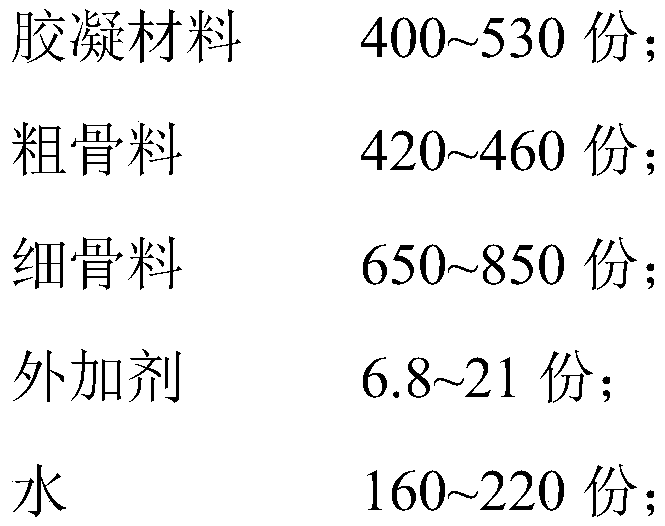

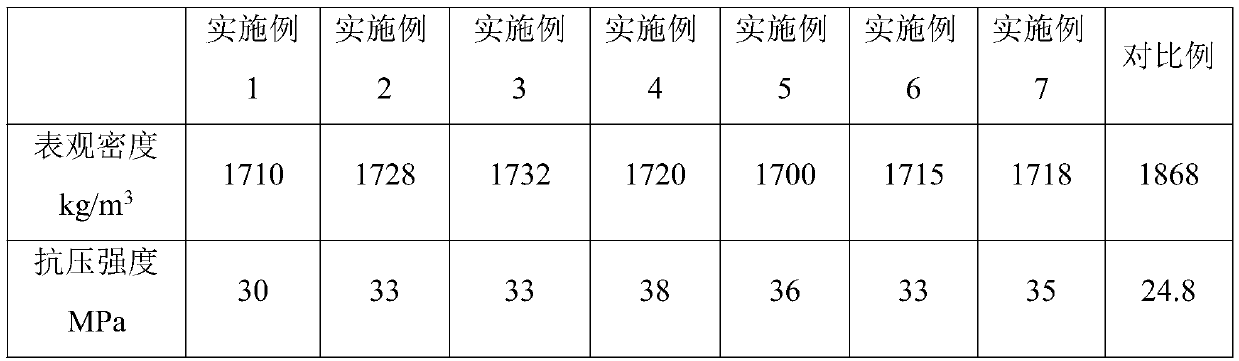

Lightweight high-strength ceramsite concrete as well as preparation method and application thereof

The invention relates to lightweight high-strength ceramsite concrete as well as a preparation method and application thereof, and relates to the field of building materials. The ceramsite concrete iscomposed of the following components in parts by weight: 400 to 530 parts of a cementing material, 420 to 460 parts of coarse aggregate, 650 to 850 parts of fine aggregate, 6.8 to 21 parts of admixtures, and 160 to 220 parts of water, wherein the coarse aggregate is fly ash ceramsite, the fine aggregate is composed of furnace slag and sand, and the admixtures include a polycarboxylic acid water reducing agent and an enhancing agent. The method uses ultra-fine modified fly ash, cement and activated silicon micropowder as the cementing material, the furnace slag and the river sand as the fine aggregate, and the fly ash ceramsite as the coarse aggregate to prepare the lightweight high-strength prefabricated component, and effectively solves the problem of ceramsite concrete layering due to asmall ceramsite density, and the prepared ceramsite concrete has high strength, is convenient for actual construction operation, and effectively uses solid waste, thereby facilitating environmental protection.

Owner:HEFEI UNIV OF TECH +1

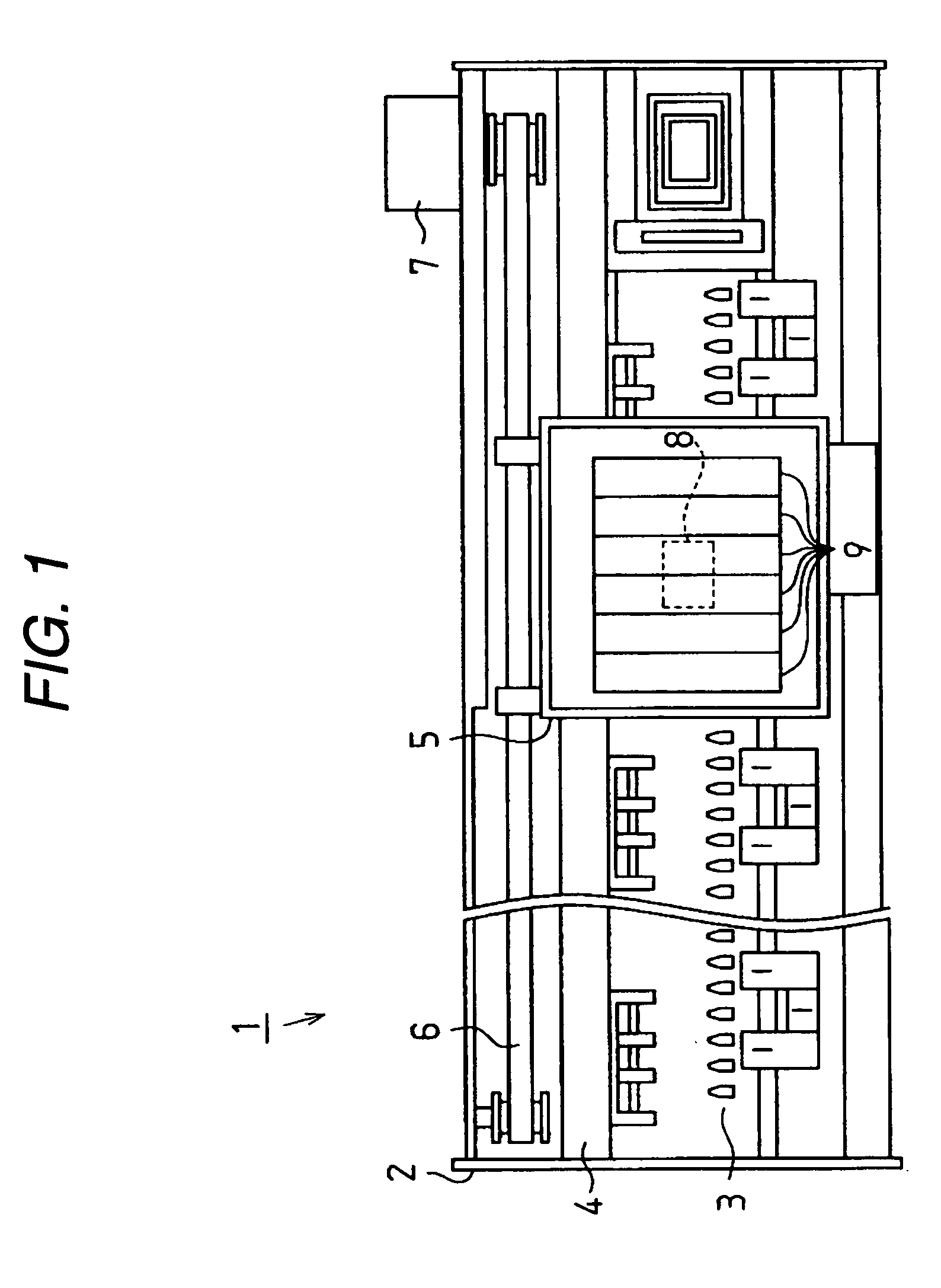

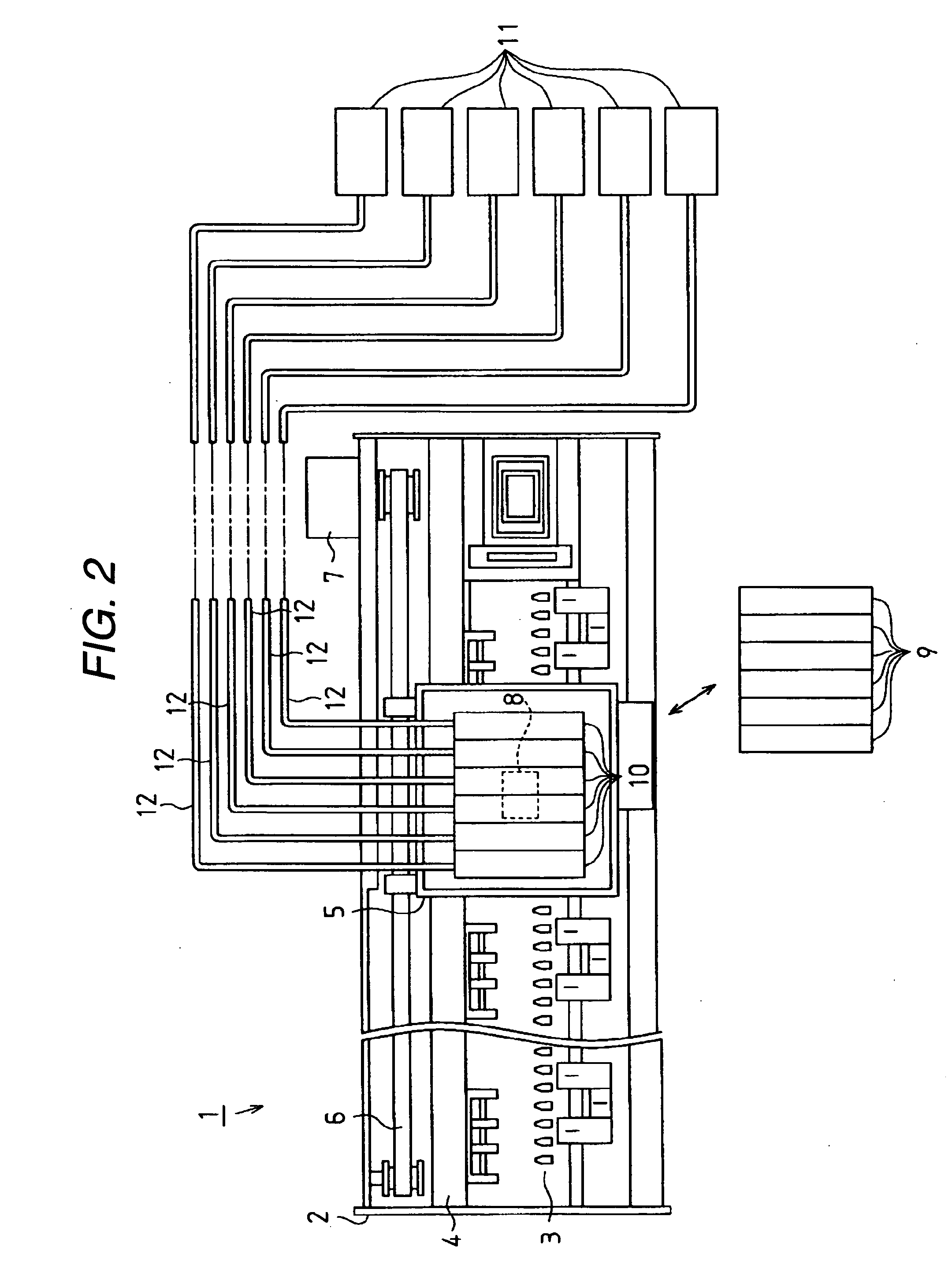

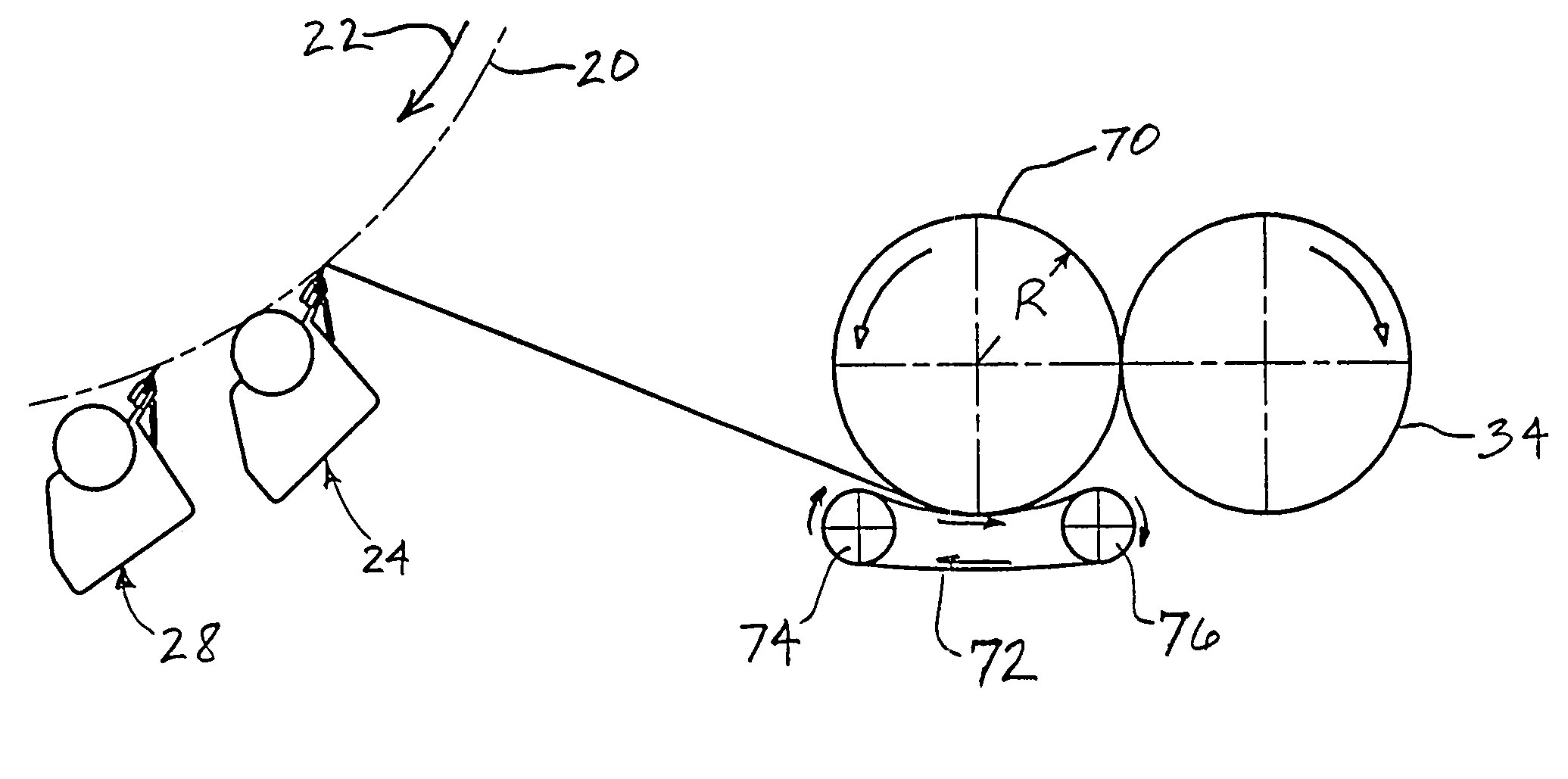

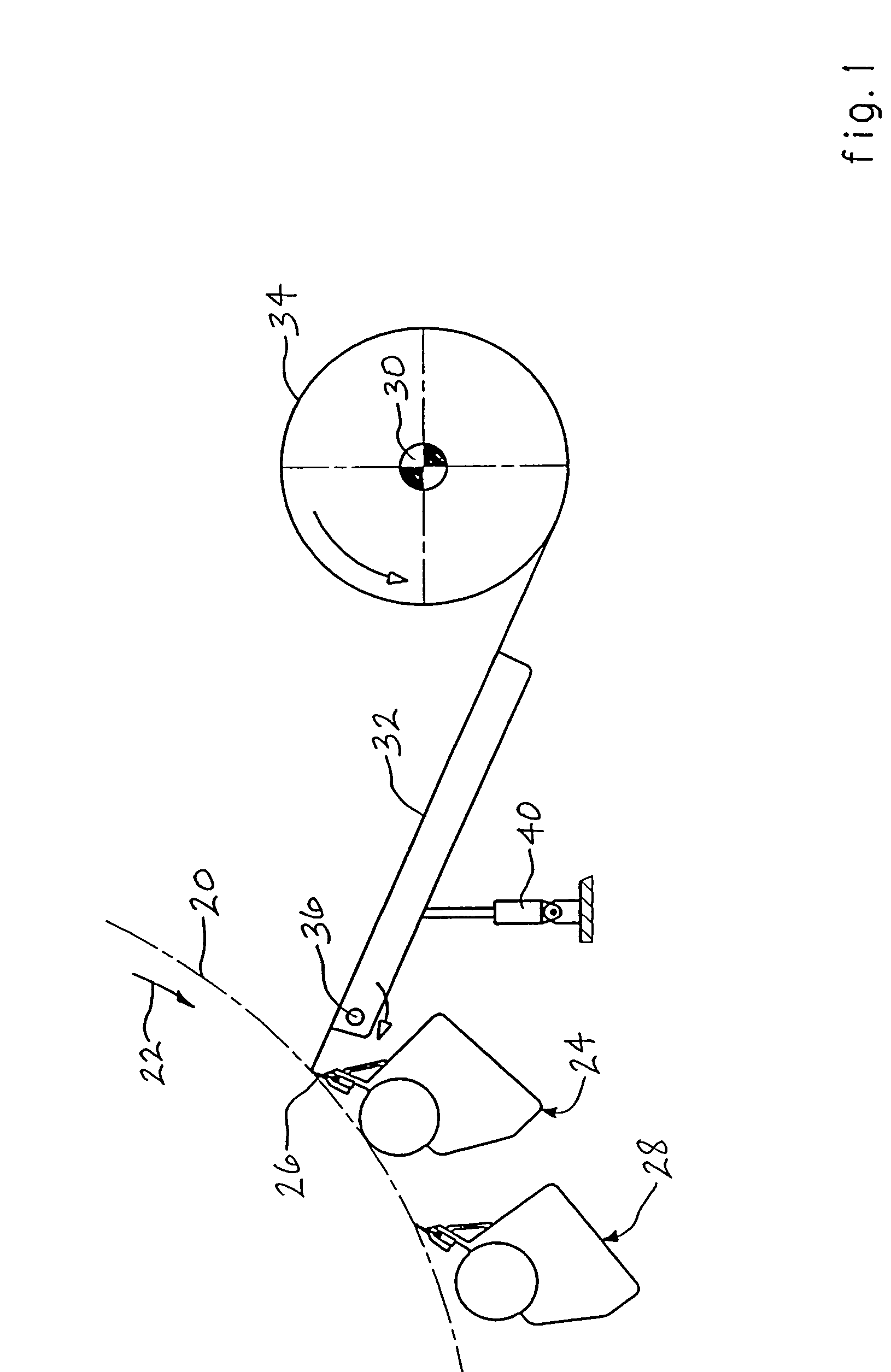

Shortened layout from dryer to reel in tissue machine

InactiveUS7169259B2Eliminate needEasy to controlNon-fibrous pulp additionNatural cellulose pulp/paperEngineeringClose coupling

Owner:METABO PAPER KARLSTAD

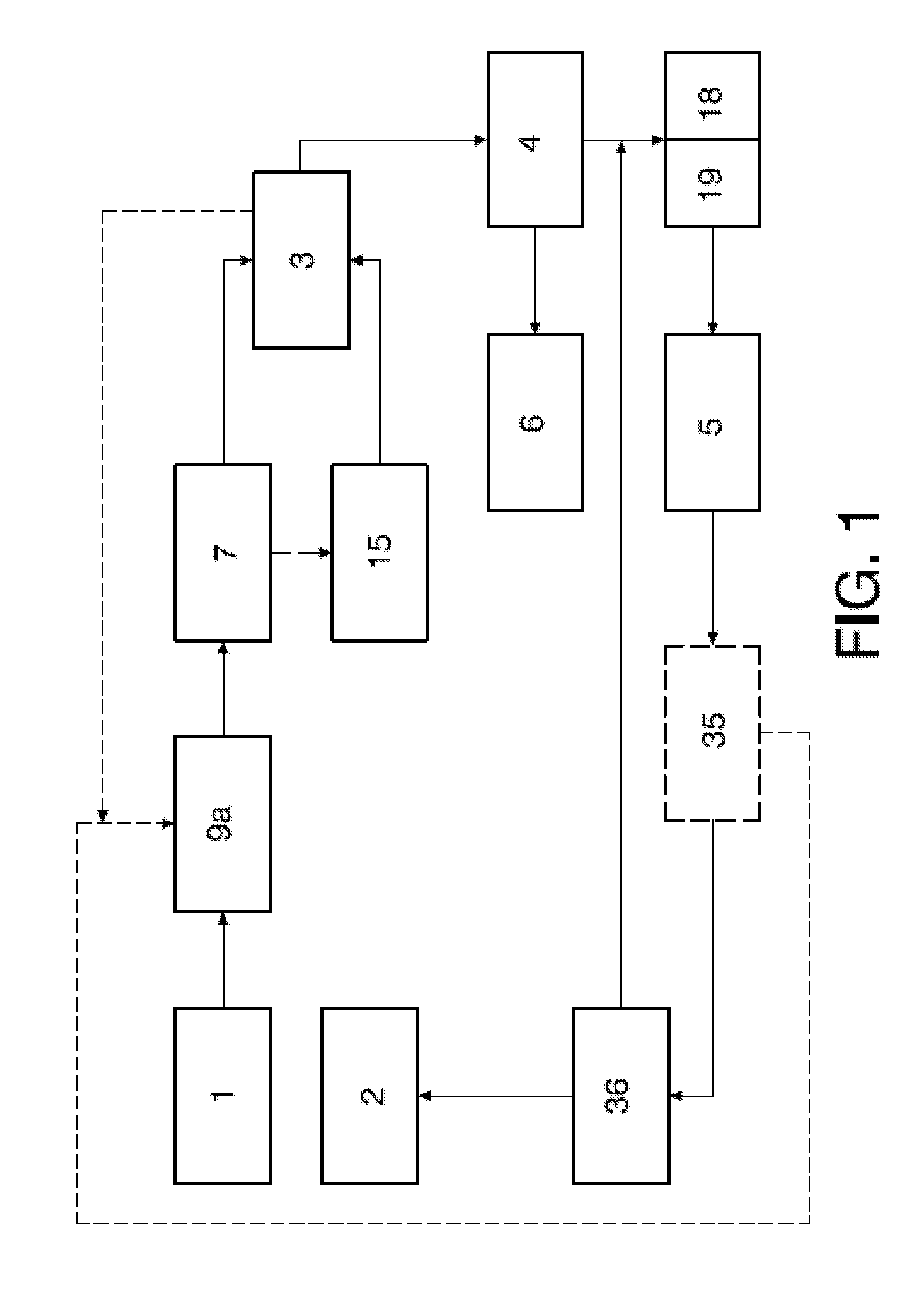

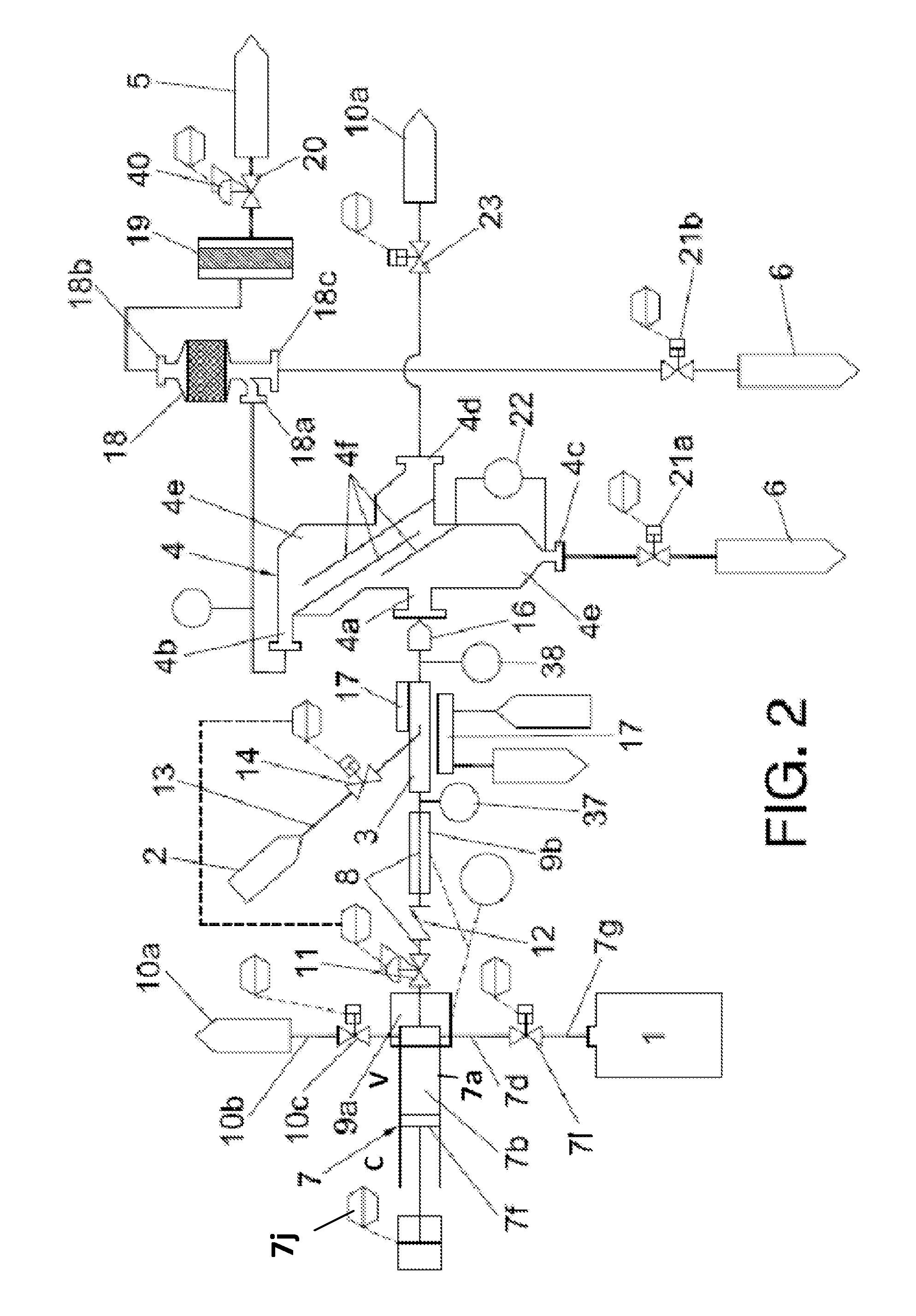

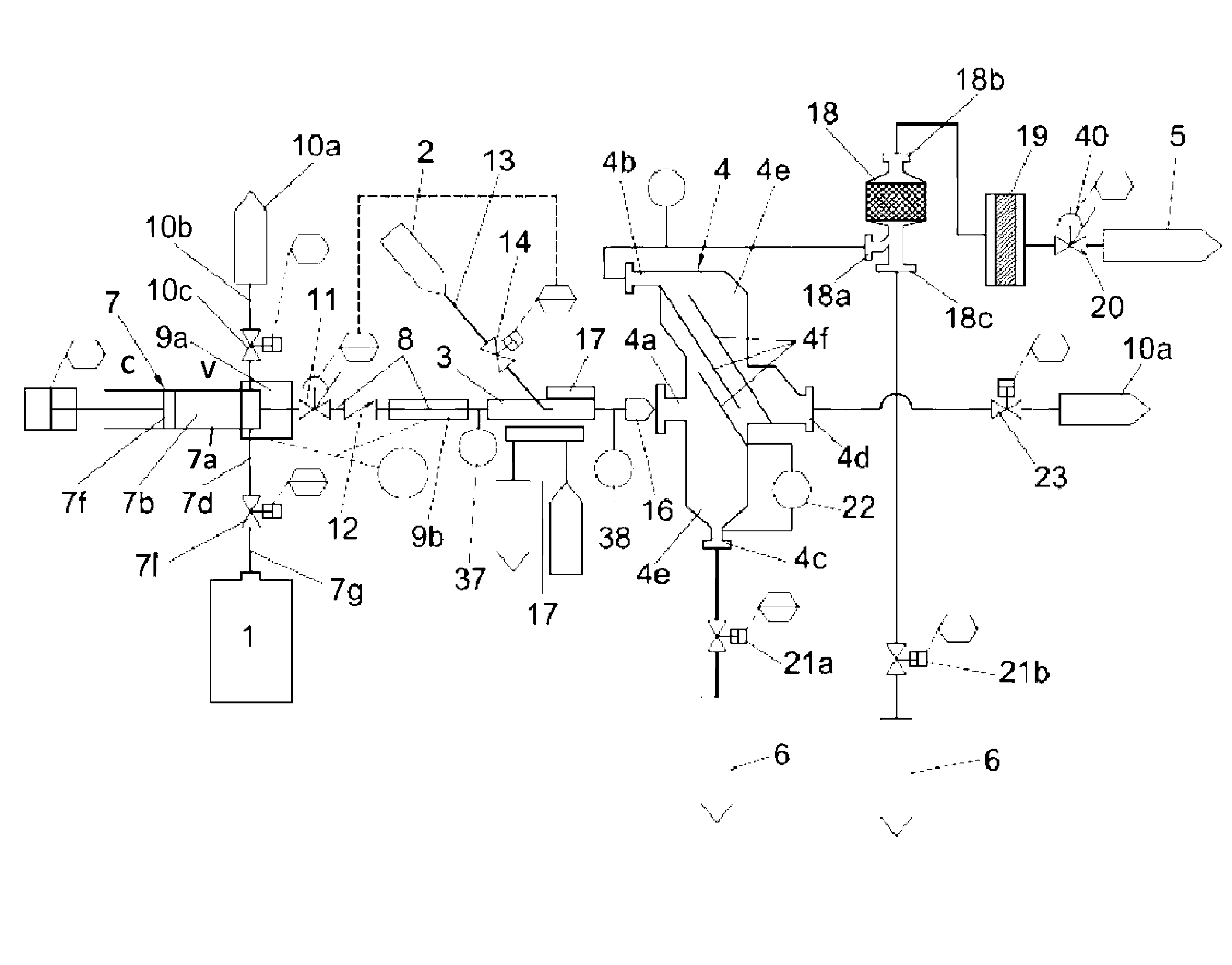

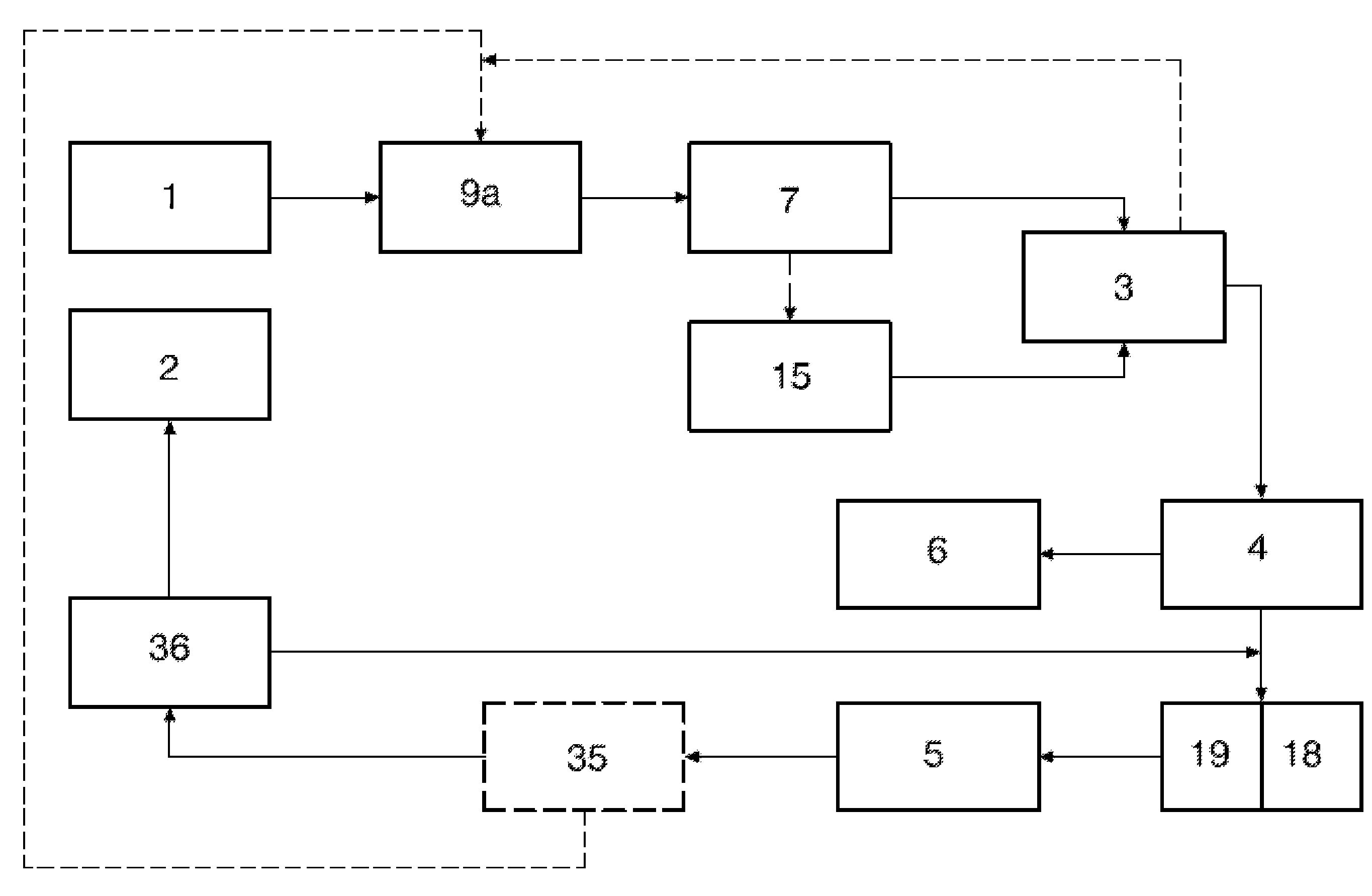

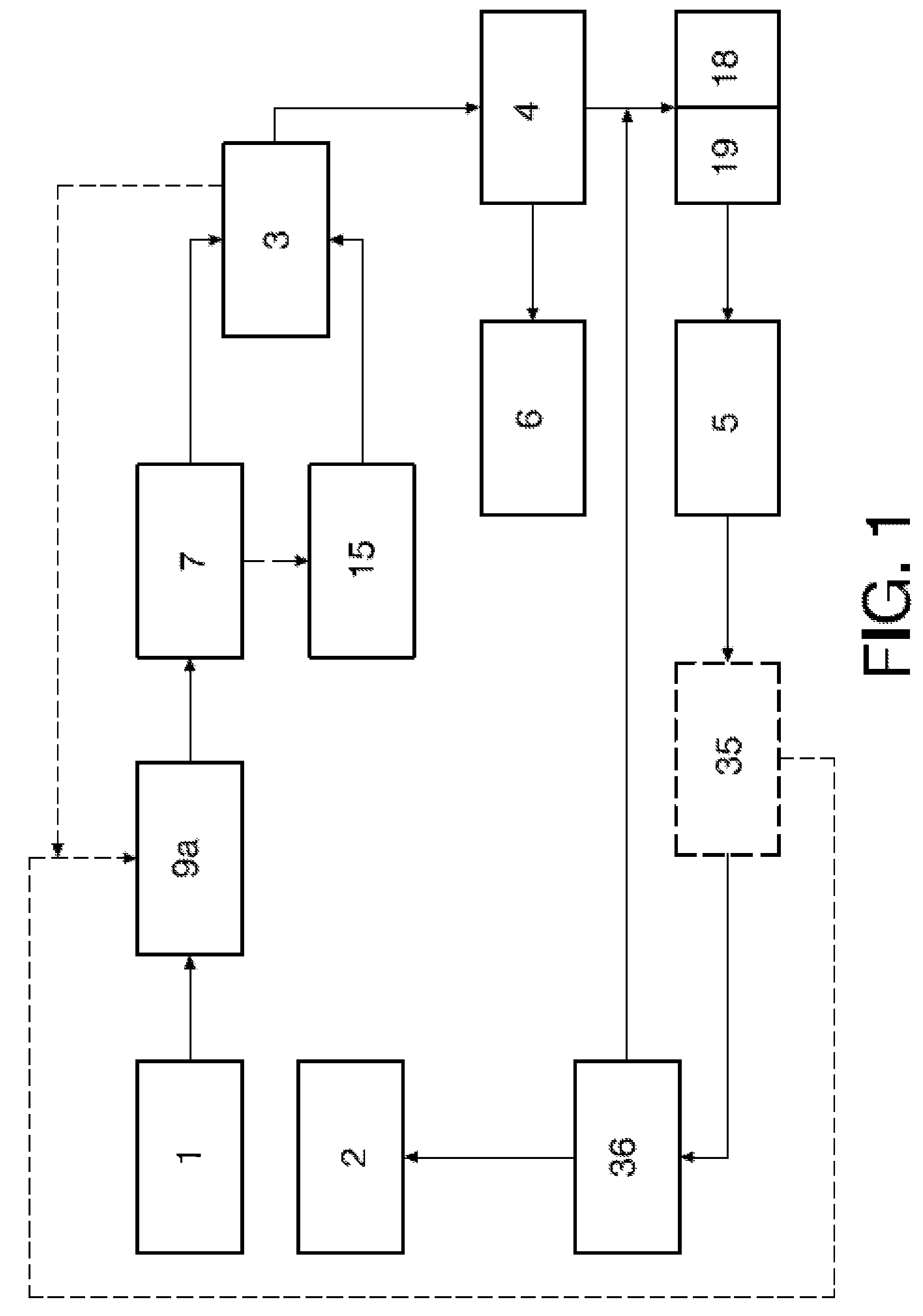

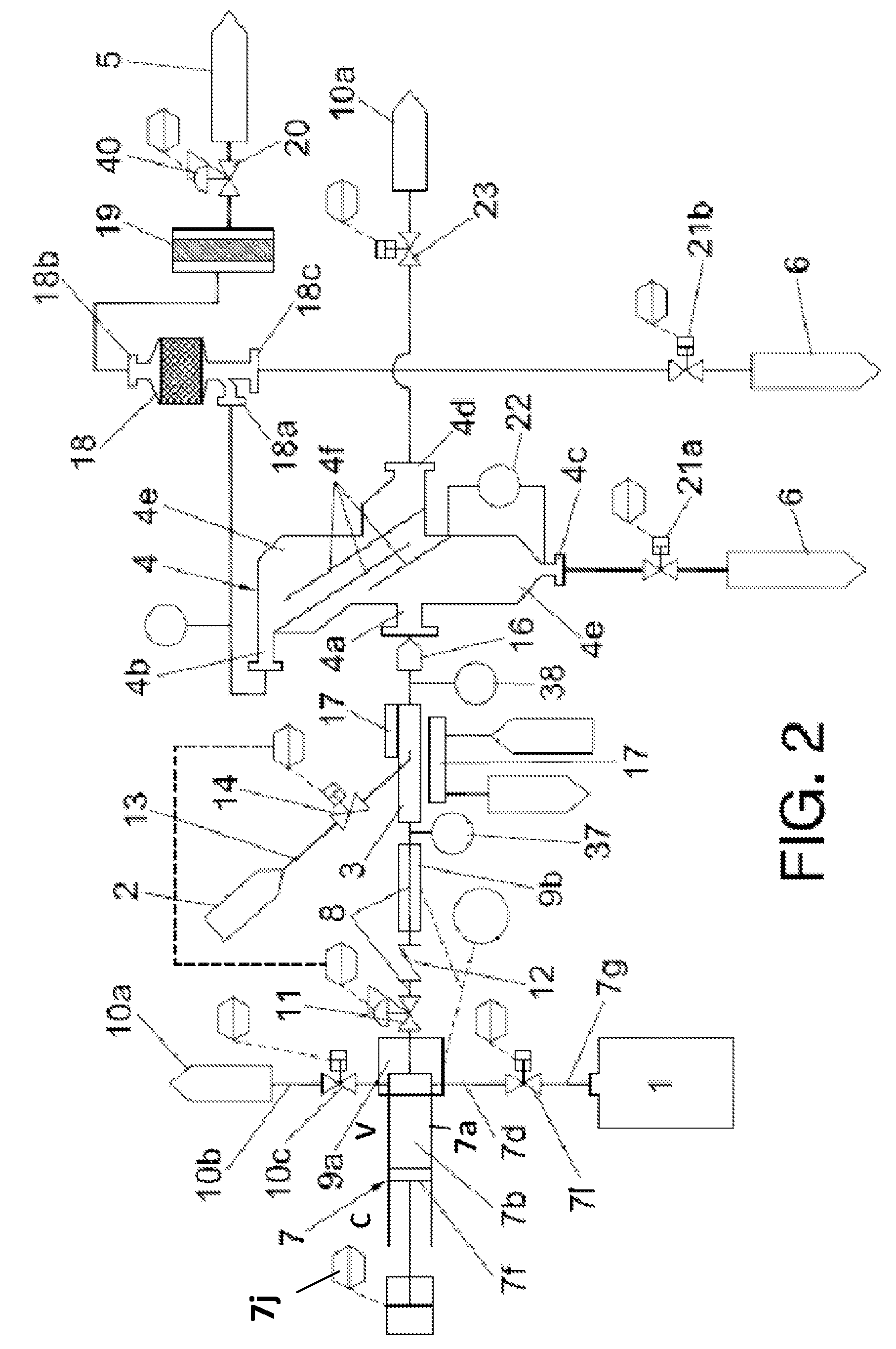

System for controlled on demand in situ hydrogen generation using a recyclable liquid metal reagent, and method used in the system

ActiveUS20130064756A1Increased level of controlImprove performanceReactant parameters controlHydrogen separationAlkaline earth metalLiquid metal

A hydrogen generating system and a method of in situ hydrogen generation controlled on demand capable of reacting an aluminum-free metal reagent composed of at least one of alkali metals, alkaline earth metals, alkali metal alloys and blends including alkali metals, alkaline earth metal alloys and blends including alkaline earth metals and metal alloys including at least one alkali metal and at least one alkaline earth metal, with water to obtain hydrogen and a residual reaction product including metal hydroxide composed of at least one of alkali hydroxides and alkaline earth hydroxide; and separating hydrogen from the residual reaction product; liquefying the metal reagent by heating to obtain liquid metal reagent under vacuum conditions; injecting the liquid metal reagent into a reactor by metal reagent injecting means and simultaneously injecting, by water injection system, a stoichiometric amount of water with respect to the amount of the liquid metal reagent being injected into the reactor such that a controlled metal reagent / water ratio is maintained in the reactor; transferring hydrogen and the residual reaction product from the reactor to separation means; separating hydrogen from the residual reaction product; transferring separated hydrogen to hydrogen receiving means and transferring the residual reaction product to metal hydroxide receiving means, keeping the metal reagent injecting means water injection system, the reactor, the separating means and the hydrogen receiving means free of oxygen by selectively providing a vacuum in the system.

Owner:GARRIDO ESCUDERO AMALIO

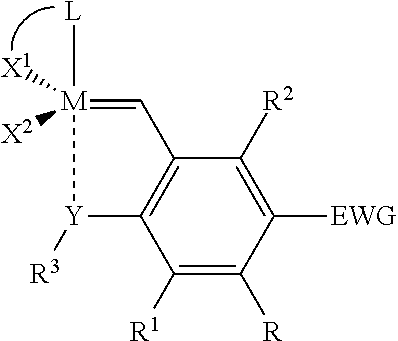

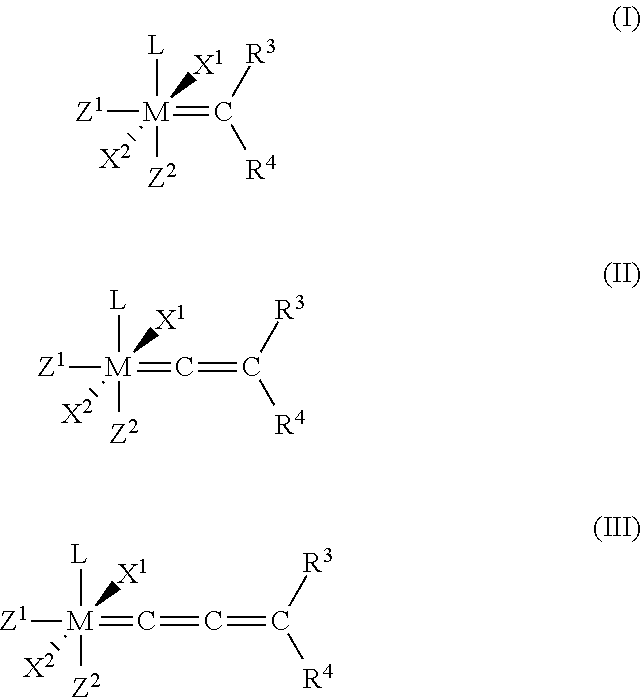

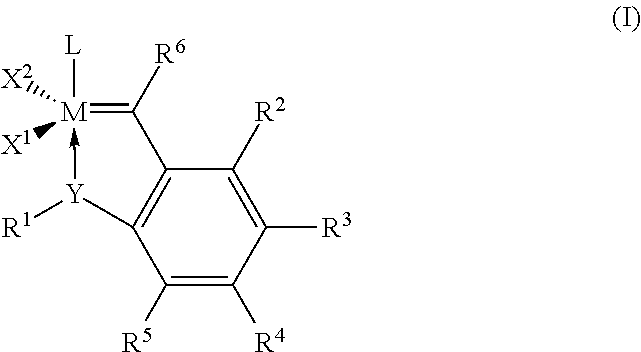

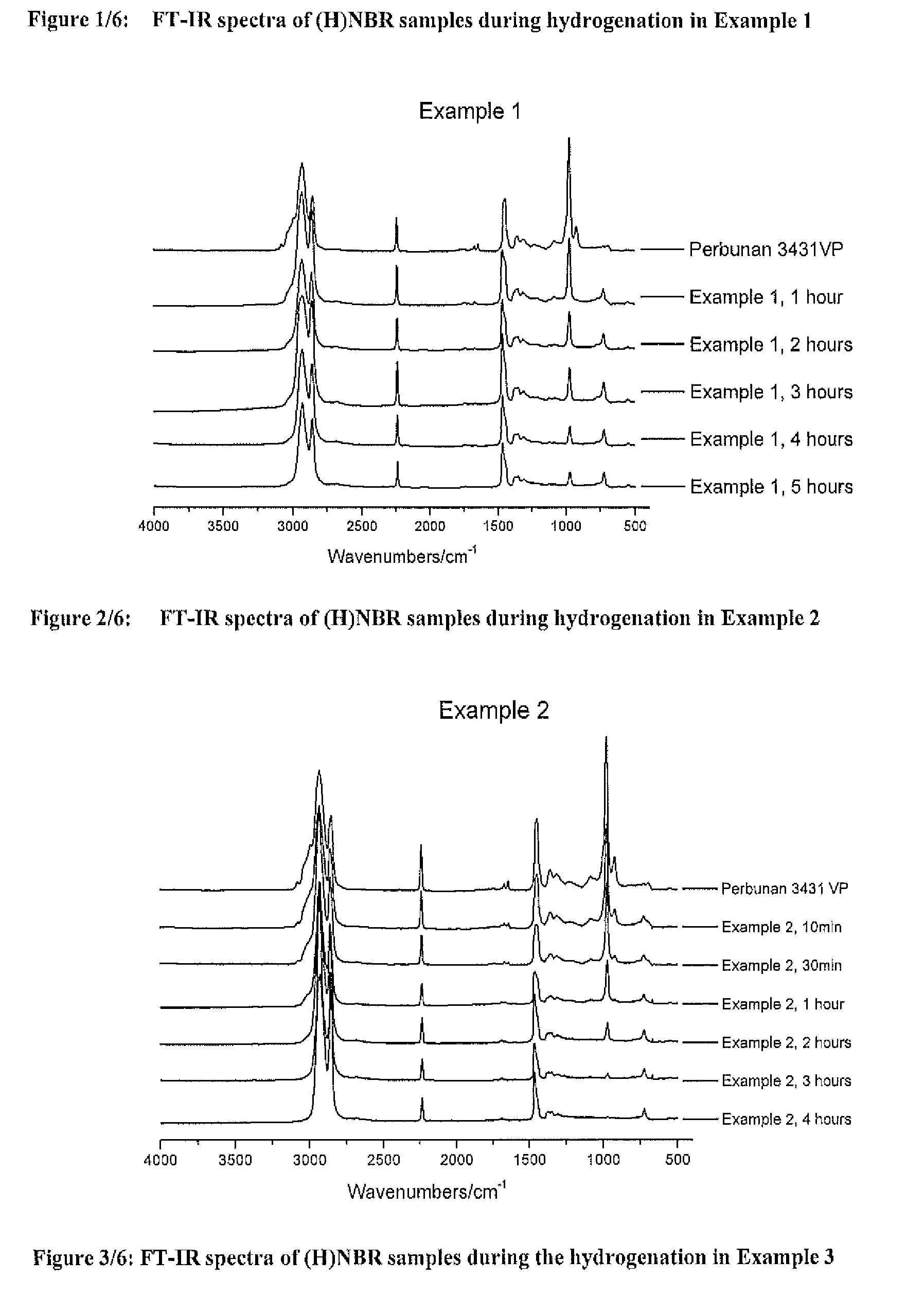

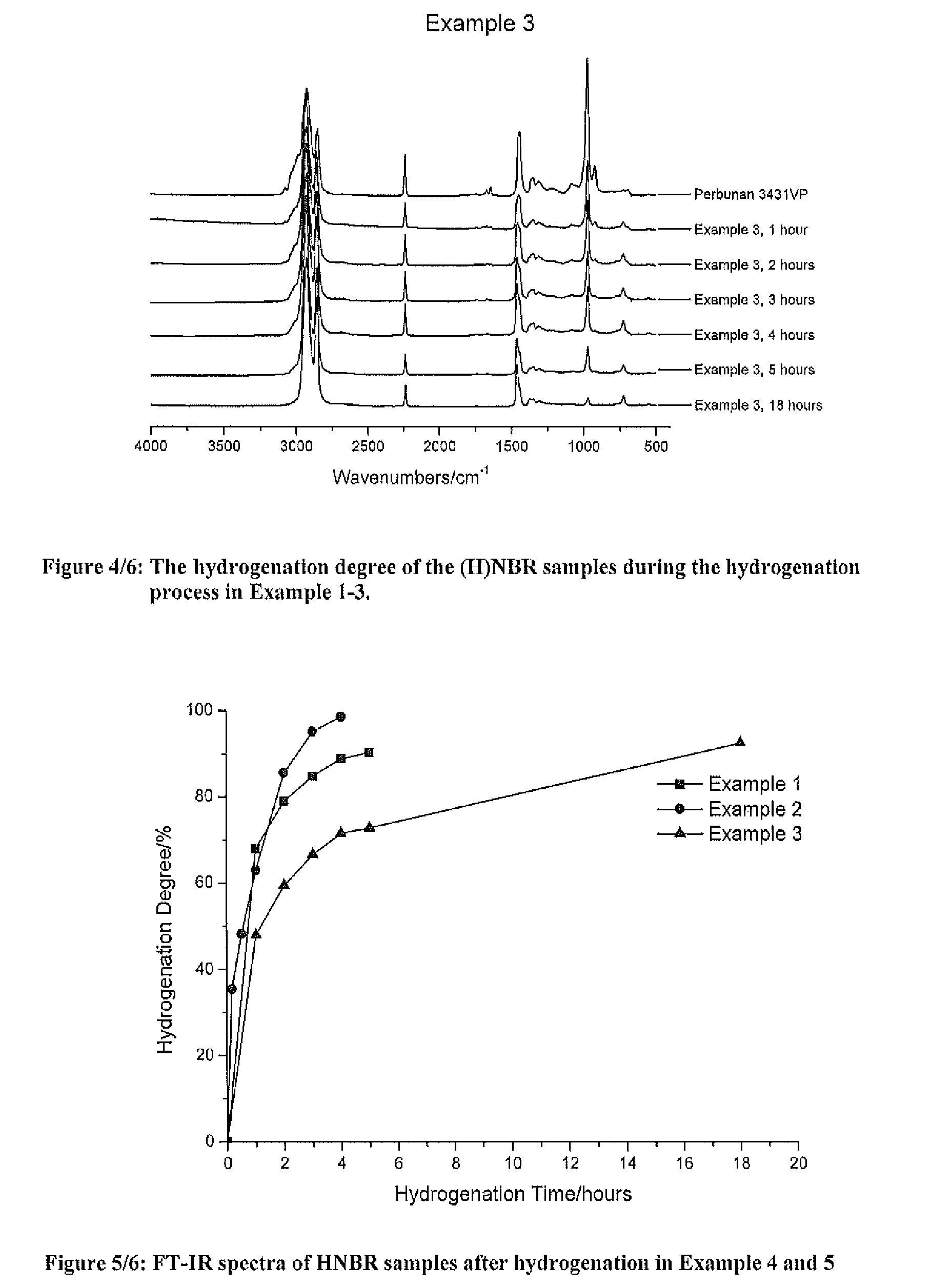

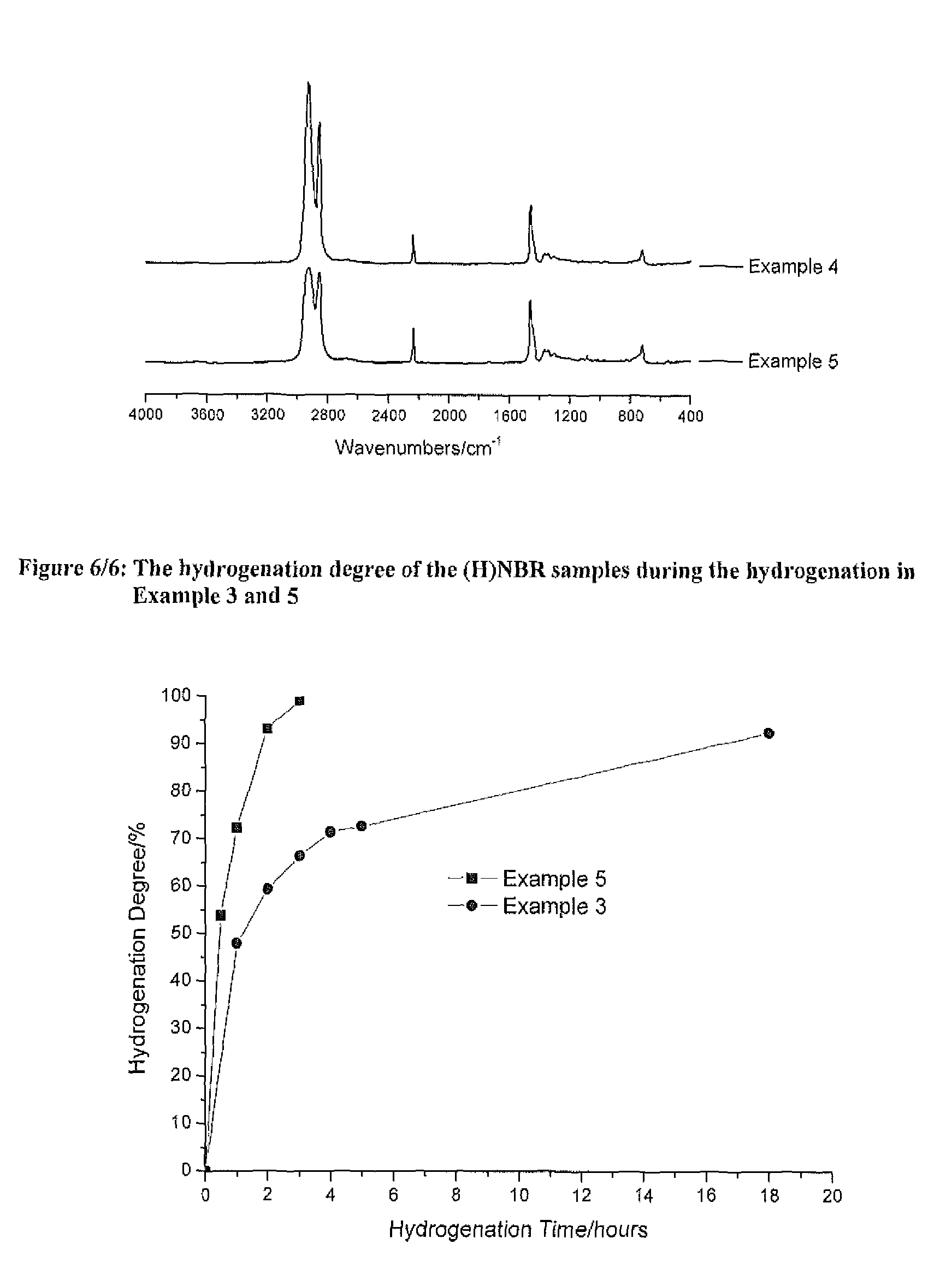

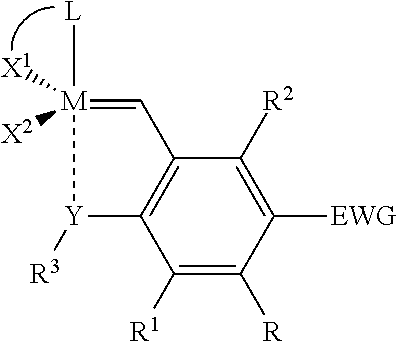

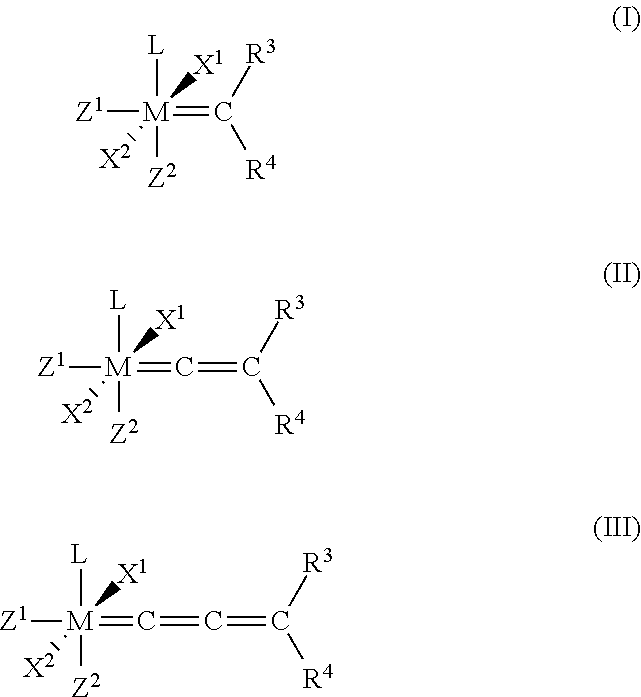

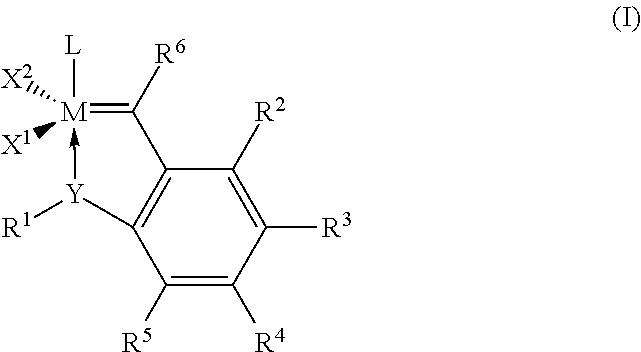

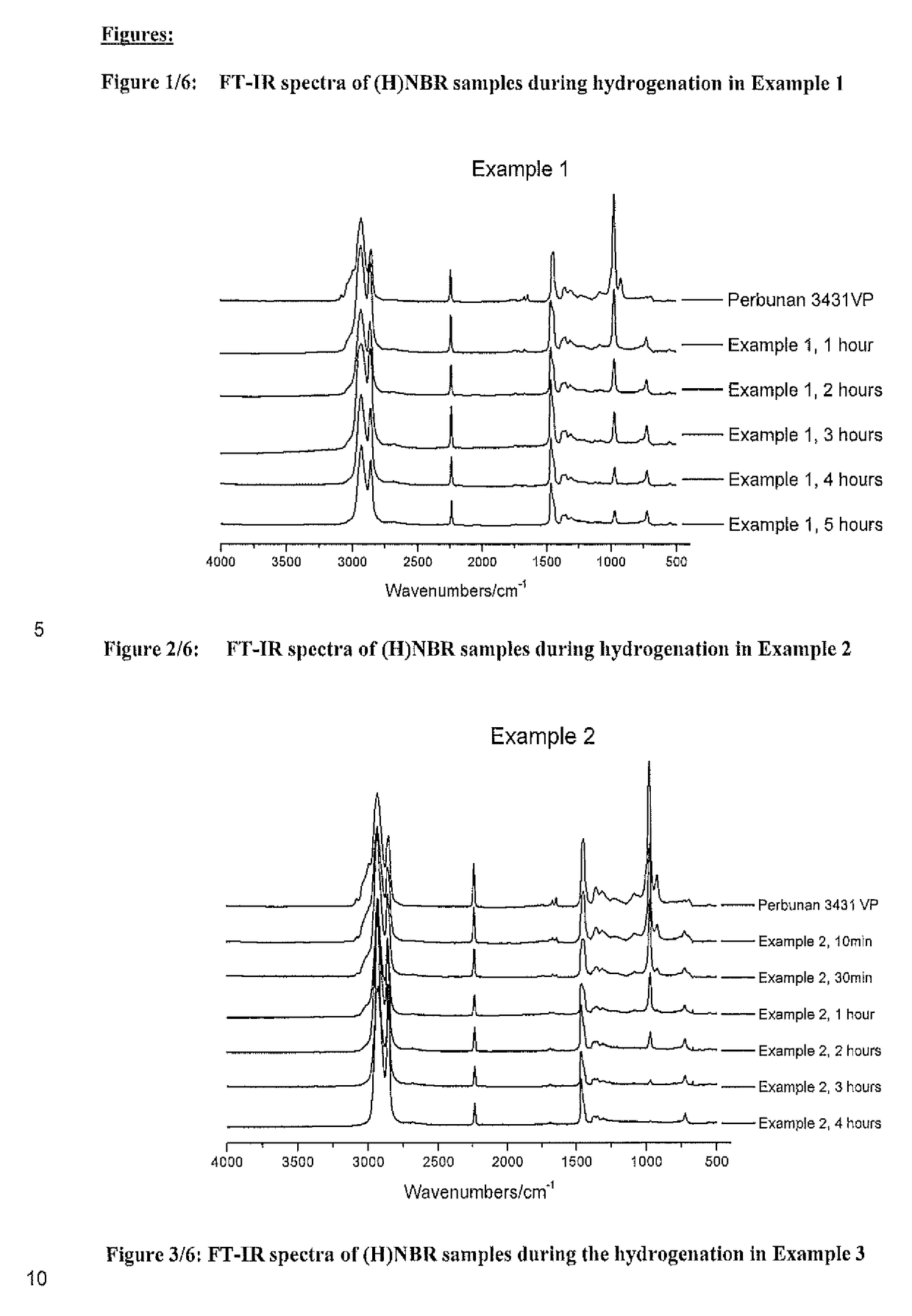

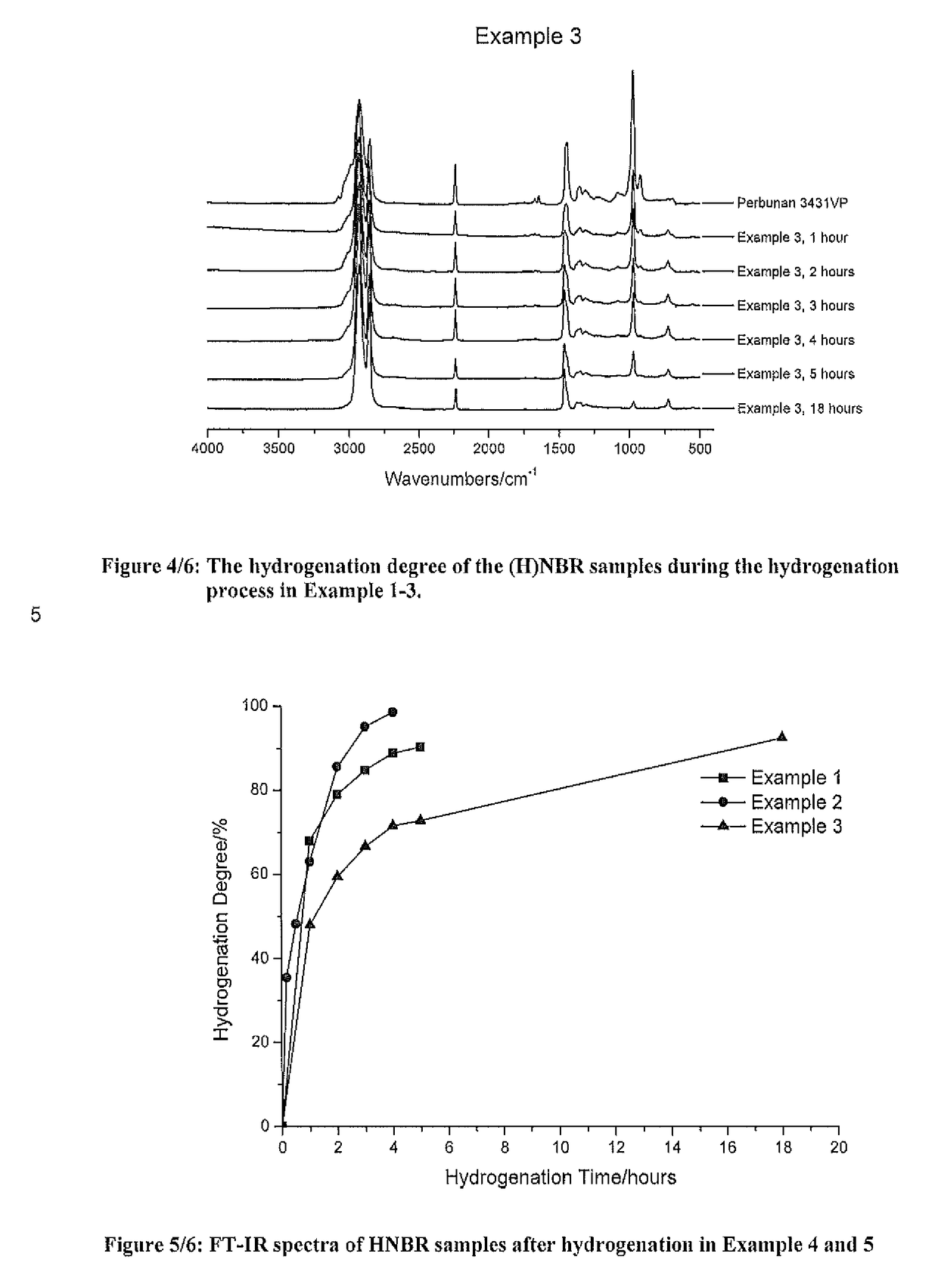

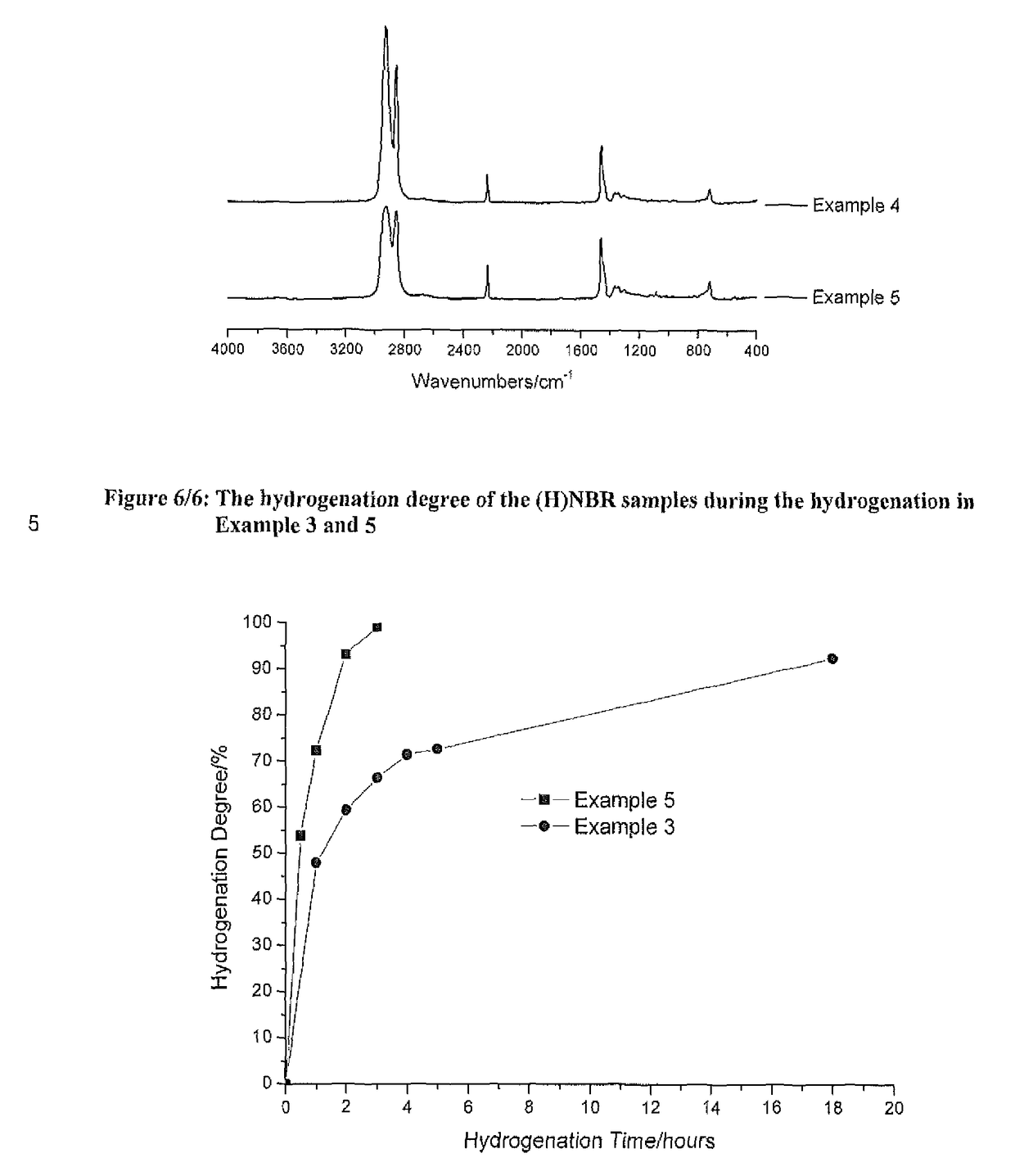

Catalyst compositions and their use for hydrogenation of nitrile rubber

ActiveUS20150166686A1High hydrogenation activityHigh degreeOther chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsNitrile rubberOsmium

Owner:ARLANXEO DEUT GMBH

Catalyst compositions and their use for hydrogenation of nitrile rubber

ActiveUS20140249277A1High hydrogenation activityHigh degreeOther chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsNitrile rubberOsmium

Owner:ARLANXEO DEUT GMBH

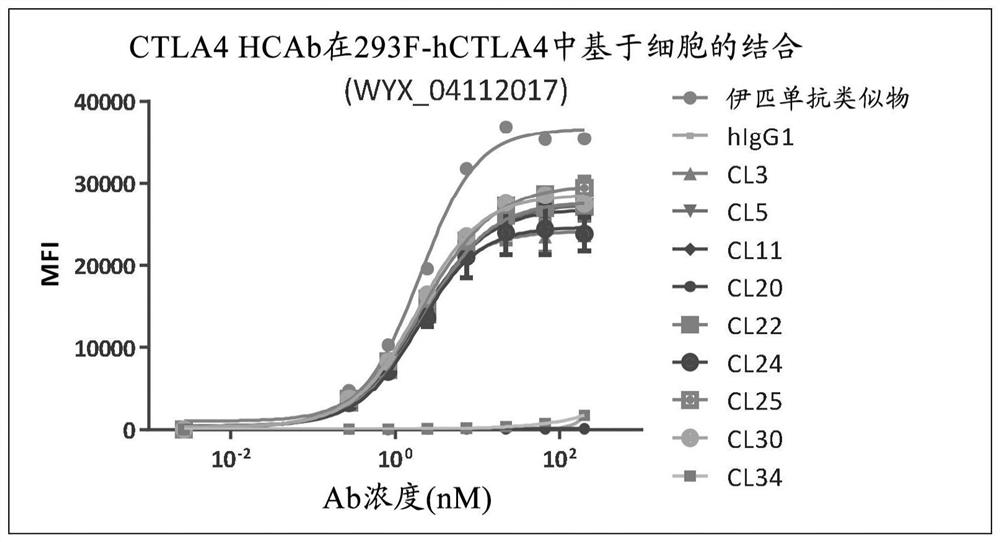

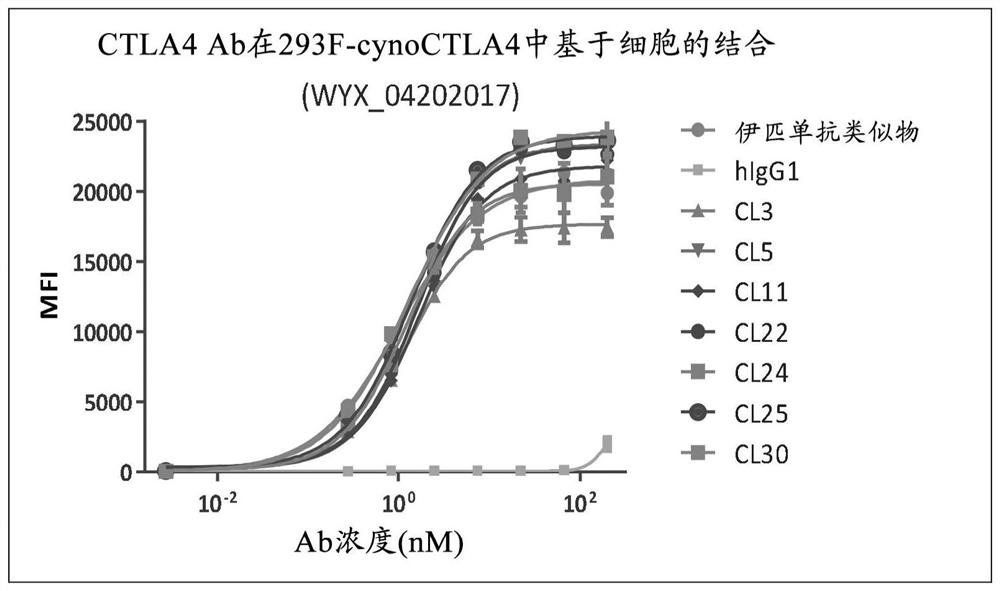

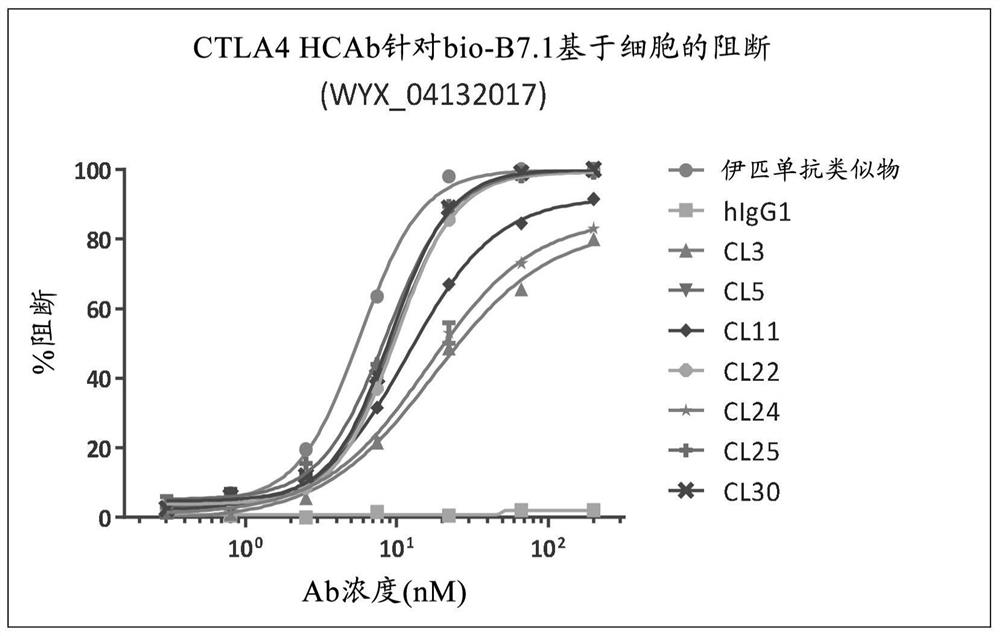

Antibodies binding ctla-4 and uses thereof

ActiveCN111655728AGrowth inhibitionConstant weightImmunoglobulins against cell receptors/antigens/surface-determinantsAntibody ingredientsAutoimmune diseaseAntiendomysial antibodies

Disclosed are isolated monoclonal antibodies, comprising a CD152-binding domain, wherein the antibodies bind specifically to human CD152. Methods of making and using the antibodies to treat diseases including cancers and autoimmune diseases are also provided.

Owner:HARBOUR BIOMED (SHANGHAI) CO LTD

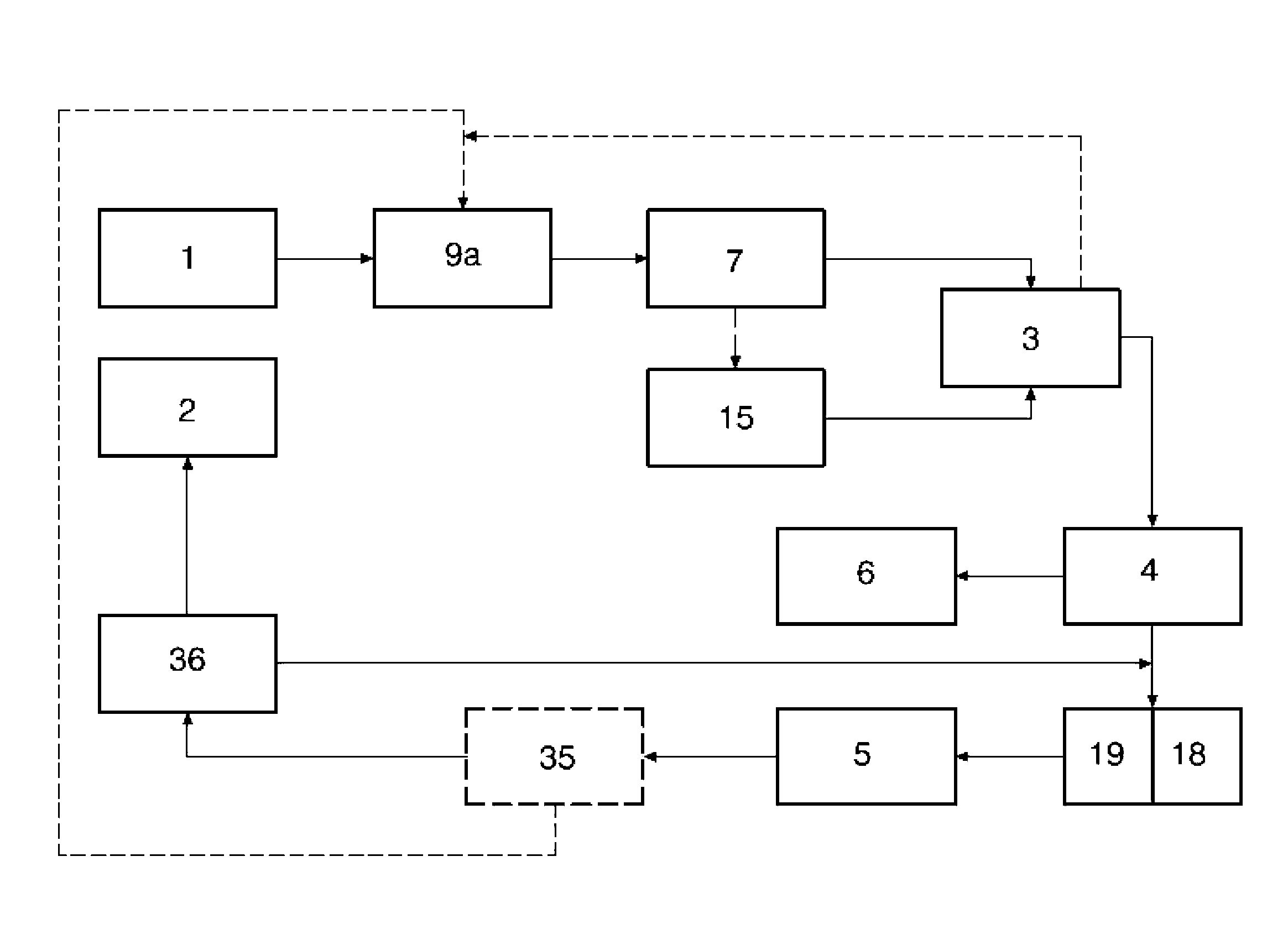

A system for controlled on demand in situ hydrogen generation using a recyclable liquid metal reagent, and method used in the system

InactiveCN102933488AConstant weightReactant parameters controlHydrogen separationAlkaline earth metalMetal alloy

A hydrogen generating system and a method of in situ hydrogen generation controlled on demand capable of reacting an aluminum-free metal reagent selected from alkali metals, alkaline earth metals, alkali metal alloys and blends consisting of alkali metals, alkaline earth metal alloys and blends consisting of alkaline earth metals and metal alloys consisting of at least one alkali metal and at least one alkaline earth metal, with water to obtain hydrogen and a residual reaction product comprising metal hydroxide selected from alkali hydroxides and alkaline earth hydroxide; and separating hydrogen from the residual reaction product; liquefying the metal reagent by heating to obtain liquid metal reagent under vacuum conditions; injecting the liquid metal reagent into a reactor (3) by metal reagent injecting means (7,8) and simultaneously injecting, by water injection system (13, 14, 15), a stoichiometric amount of water with respect to the amount of the liquid metal reagent being injected into the reactor (3) such that a controlled metal reagent / water ratio is maintained in the reactor (3); transferring hydrogen and the residual reaction product from the reactor (3) to separation means (4, 18); separating hydrogen from the residual reaction product; transferring separated hydrogen to hydrogen receiving means (5) and transferring the residual reaction product to metal hydroxide receiving means (6), keeping the metal reagent injecting means (7,8) water injection system (13, 14, 15), the reactor (3), the separating means (4, 18) and the hydrogen receiving means (5) free of oxygen by selectively providing a vacuum in the system.

Owner:阿马利奥·加里多埃斯库德罗

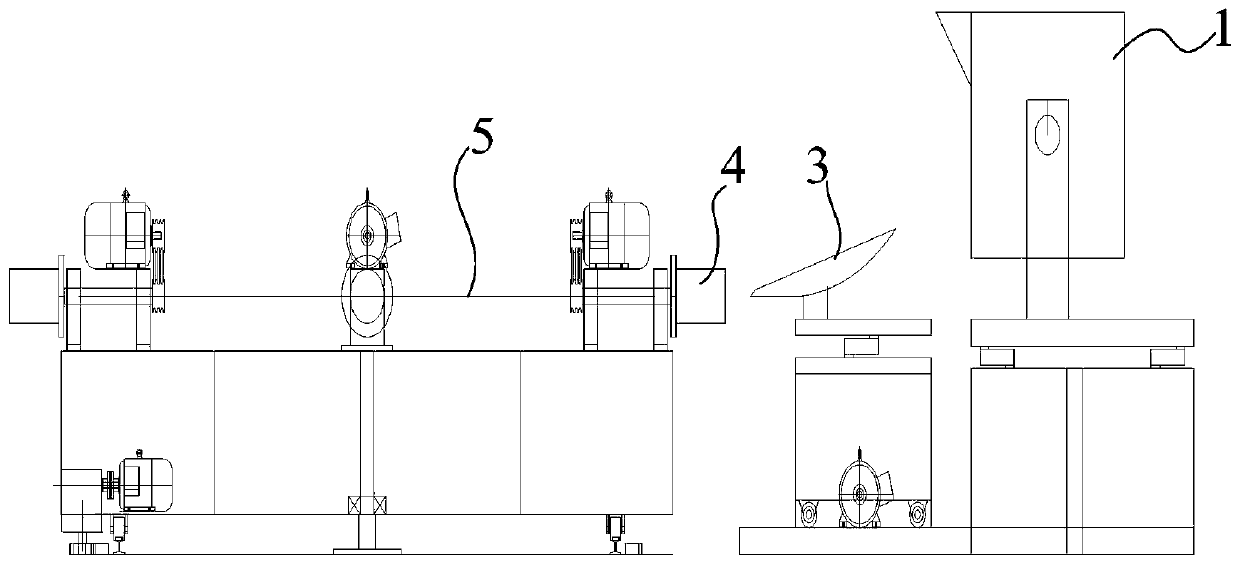

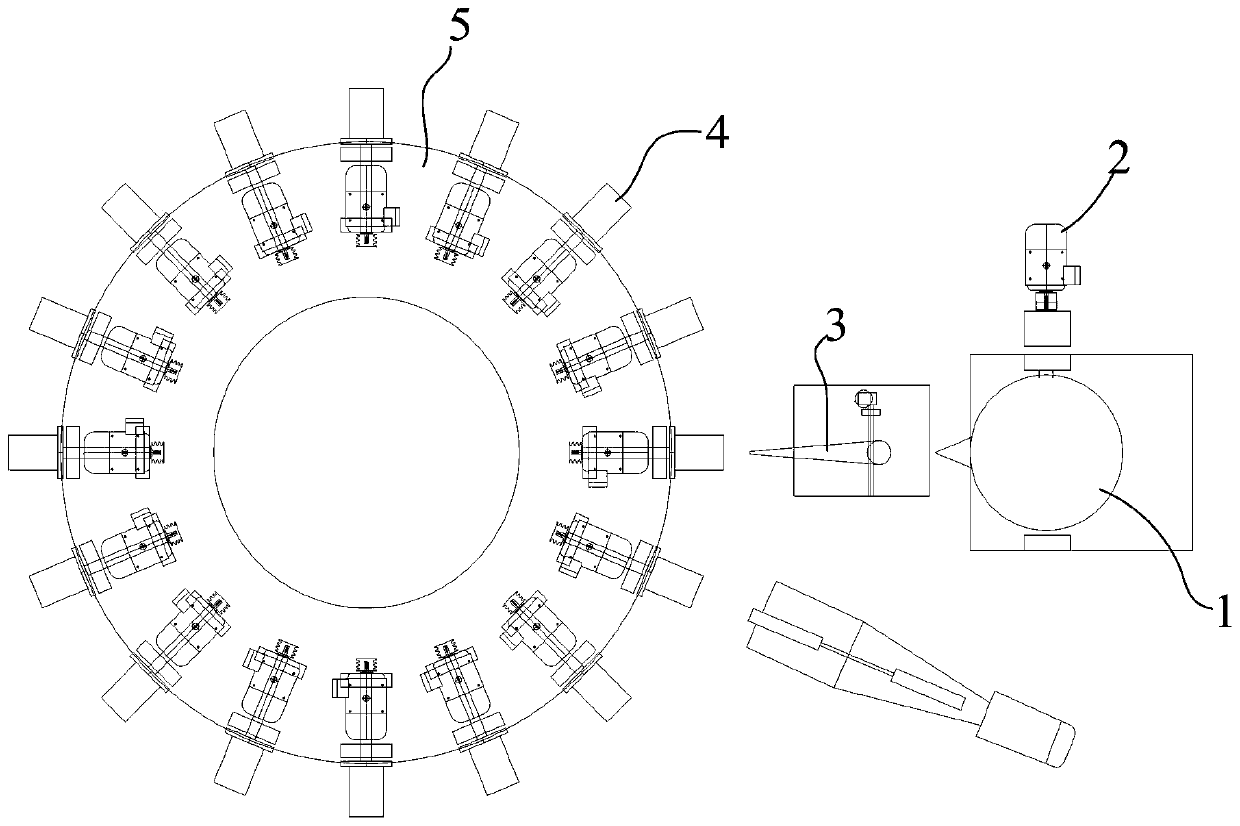

Full-automatic quantitative casting method

ActiveCN111331114AQuality assuranceConstant weightMolten metal supplying equipmentsElectric machineryCasting mold

The invention belongs to the technical field of casting application, and particularly relates to a full-automatic quantitative casting method. The full-automatic quantitative casting method comprisesa large casting ladle, a driving motor used for driving the large casting ladle to rotate and a flow guide groove used for enabling casting liquid to flow to a casting mold, a large casting ladle bearing sensor is arranged on the large casting ladle, and a flow guide groove weighing sensor is arranged on the flow guide groove. According to the full-automatic quantitative casting method, through controlling the inclination speed of the large casting ladle, the weight of the flow guide groove is basically constant, the amount of casting liquid entering a mold is kept stable, the quality of a cast product is ensured, and meanwhile, the method is simple, convenient to operate and suitable for large-scale popularization and use.

Owner:临清市鑫迈机械有限公司

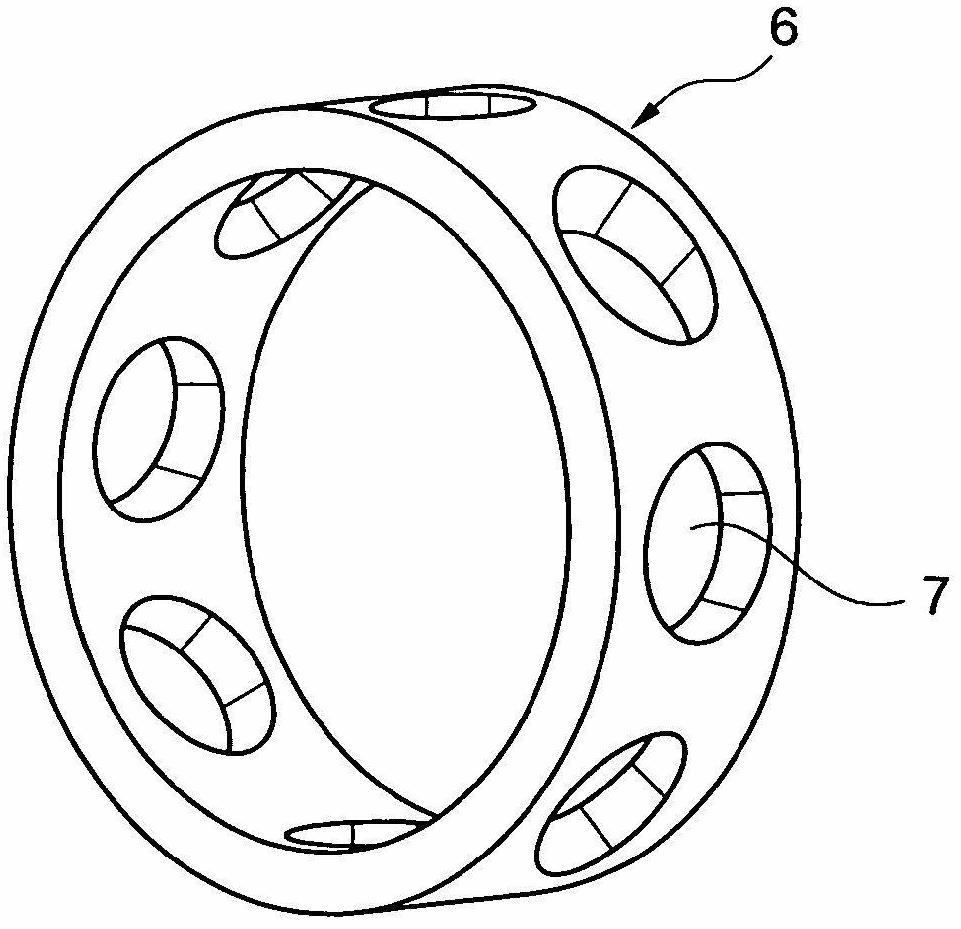

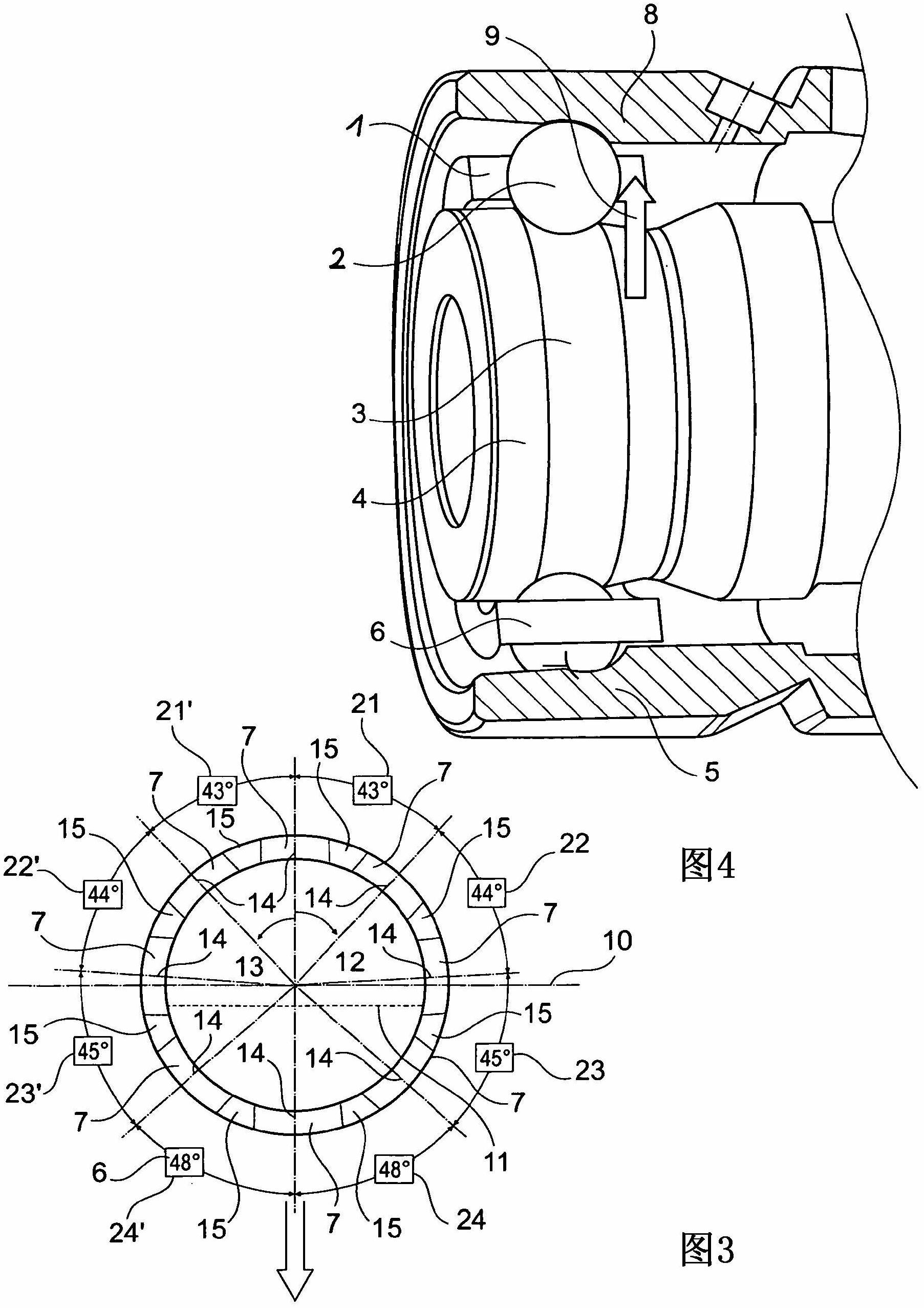

Ball bearing cage

InactiveCN102648358AStop swingAvoid loadRolling contact bearingsShaftsBall bearingClassical mechanics

The invention relates to a ball bearing cage having an annular rolling element retaining body, comprising ball sockets distributed around a circumference of the rolling element retaining body for receiving spherical rolling elements. According to the invention, the ball sockets are distributed around the circumference, such that distances between two adjacent ball sockets increase in a circumferential direction, starting at a smallest distance between two adjacent sockets at least in a circumferential sector.

Owner:SCHAEFFLER TECH AG & CO KG

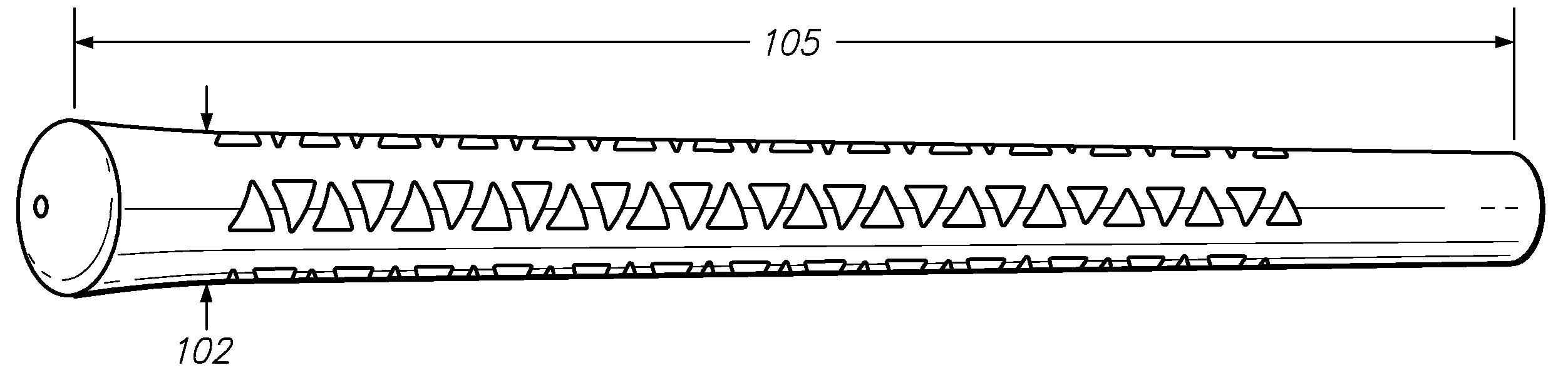

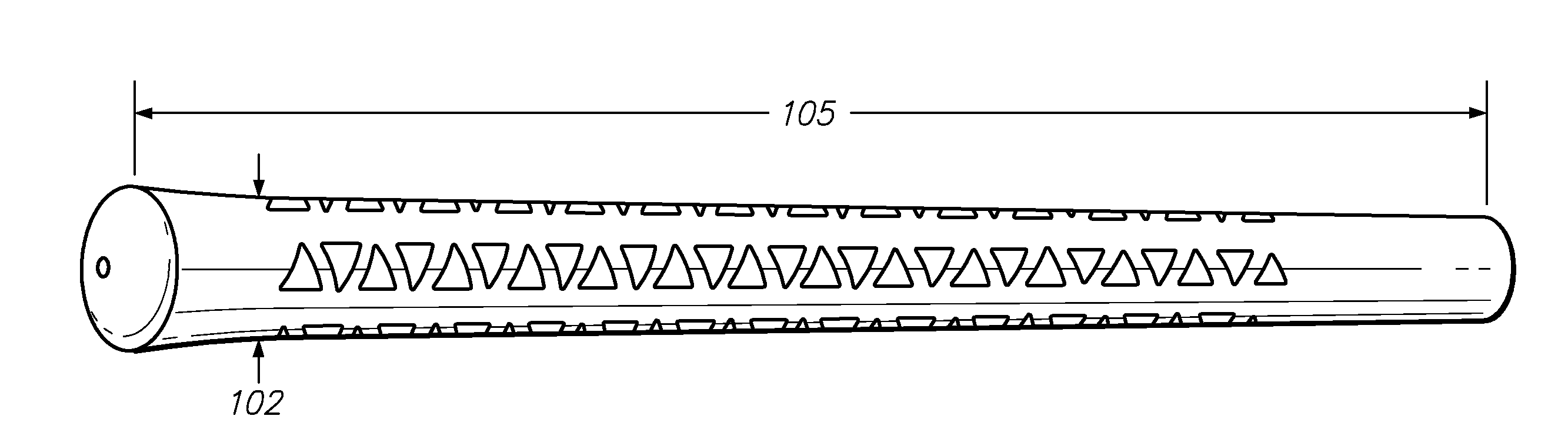

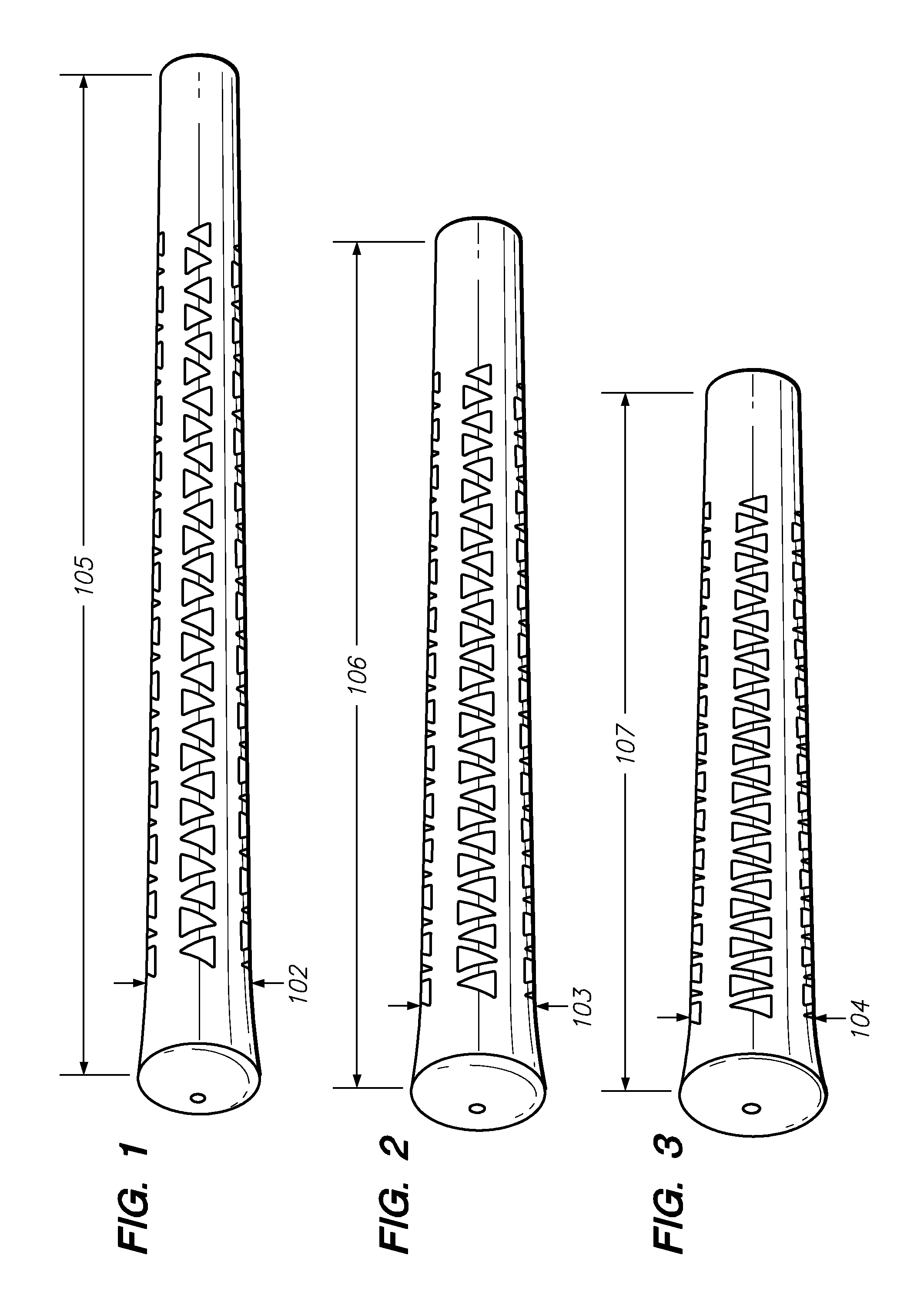

VCM Golf Club Grip System

InactiveUS20090286617A1Maintain balanceBalance weightGolfing accessoriesGolf clubsGolf BallStandard methods

A golf club grip system is presented comprised of golf club grips of identical weights regardless of their grip thickness. The identical weight may be maintained by altering the grip material compound, grip construction method, or by varying the length of the grip along the golf club shaft as the grip width is varied.A set of standardized grip widths is also presented that varies in increments of the thickness of duct tape, thus providing a standard method of adjusting the thickness of a golf club grip on a shaft.The system is designed to permit pre-manufactured golf club grips to be selected by grip thickness and feel, while remaining identically weighted to all other possible thicknesses. This uniform weighting removes the need to adjust club head weight or perform dynamic or static swing weighting after grip thickness is selected.

Owner:VOGES MITCHELL C

System for controlled on demand in situ hydrogen generation using a recyclable liquid metal reagent, and method used in the system

ActiveUS8696936B2Improve the level ofImprove performanceReactant parameters controlHydrogen productionAlkaline earth metalLiquid metal

A hydrogen generating system and a method of in situ hydrogen generation controlled on demand capable of reacting an aluminum-free metal reagent composed of at least one of alkali metals, alkaline earth metals, alkali metal alloys and blends including alkali metals, alkaline earth metal alloys and blends including alkaline earth metals and metal alloys including at least one alkali metal and at least one alkaline earth metal, with water to obtain hydrogen and a residual reaction product including metal hydroxide composed of at least one of alkali hydroxides and alkaline earth hydroxide; and separating hydrogen from the residual reaction product; liquefying the metal reagent by heating to obtain liquid metal reagent under vacuum conditions; injecting the liquid metal reagent into a reactor by metal reagent injecting means and simultaneously injecting, by water injection system, a stoichiometric amount of water with respect to the amount of the liquid metal reagent being injected into the reactor such that a controlled metal reagent / water ratio is maintained in the reactor; transferring hydrogen and the residual reaction product from the reactor to separation means; separating hydrogen from the residual reaction product; transferring separated hydrogen to hydrogen receiving means and transferring the residual reaction product to metal hydroxide receiving means, keeping the metal reagent injecting means water injection system, the reactor, the separating means and the hydrogen receiving means free of oxygen by selectively providing a vacuum in the system.

Owner:GARRIDO ESCUDERO AMALIO

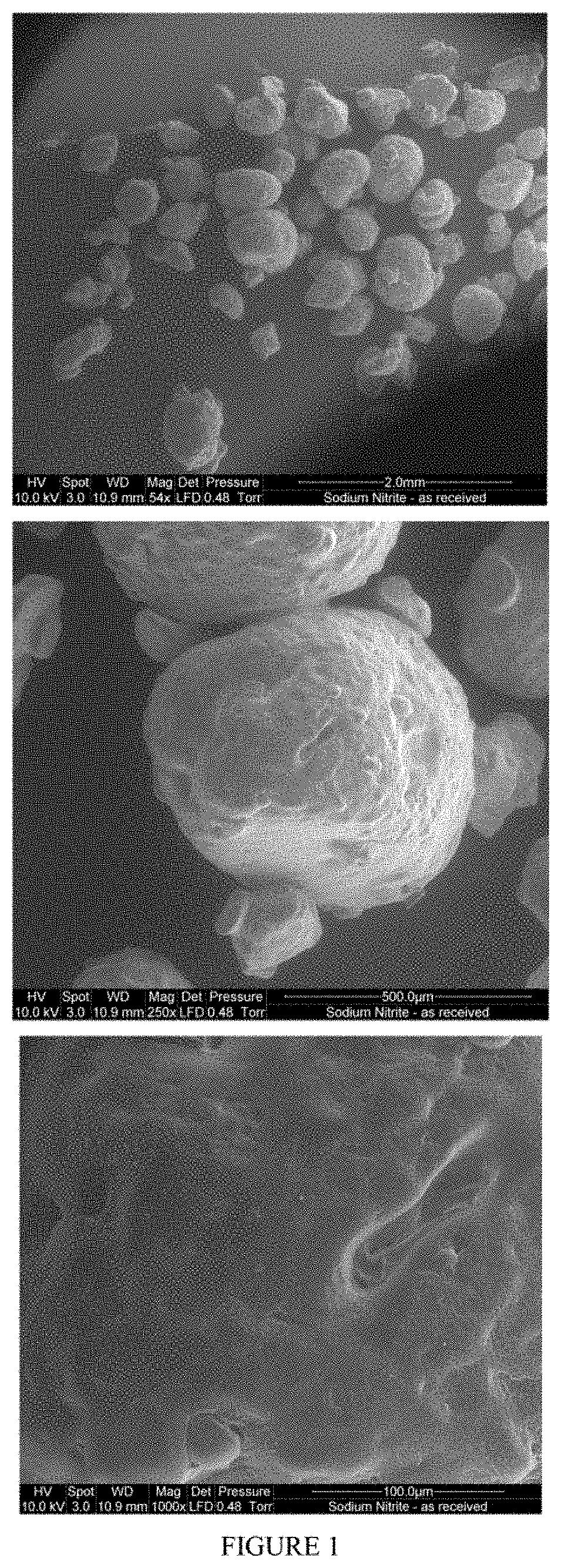

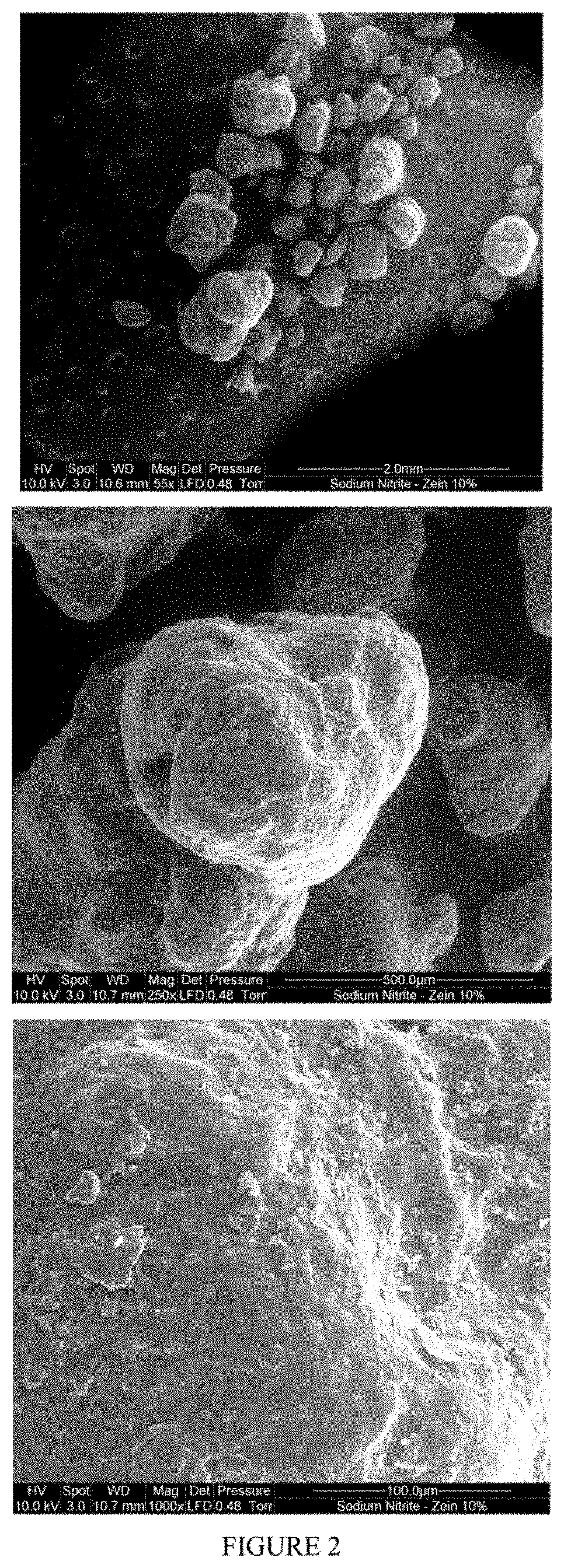

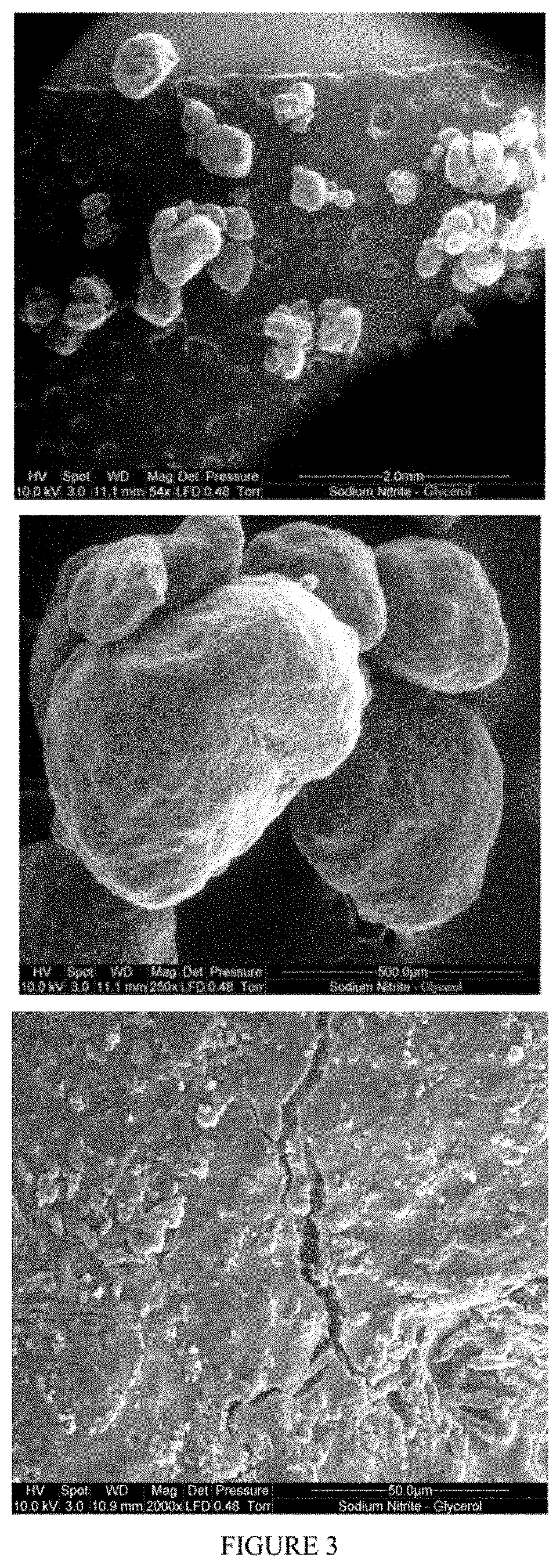

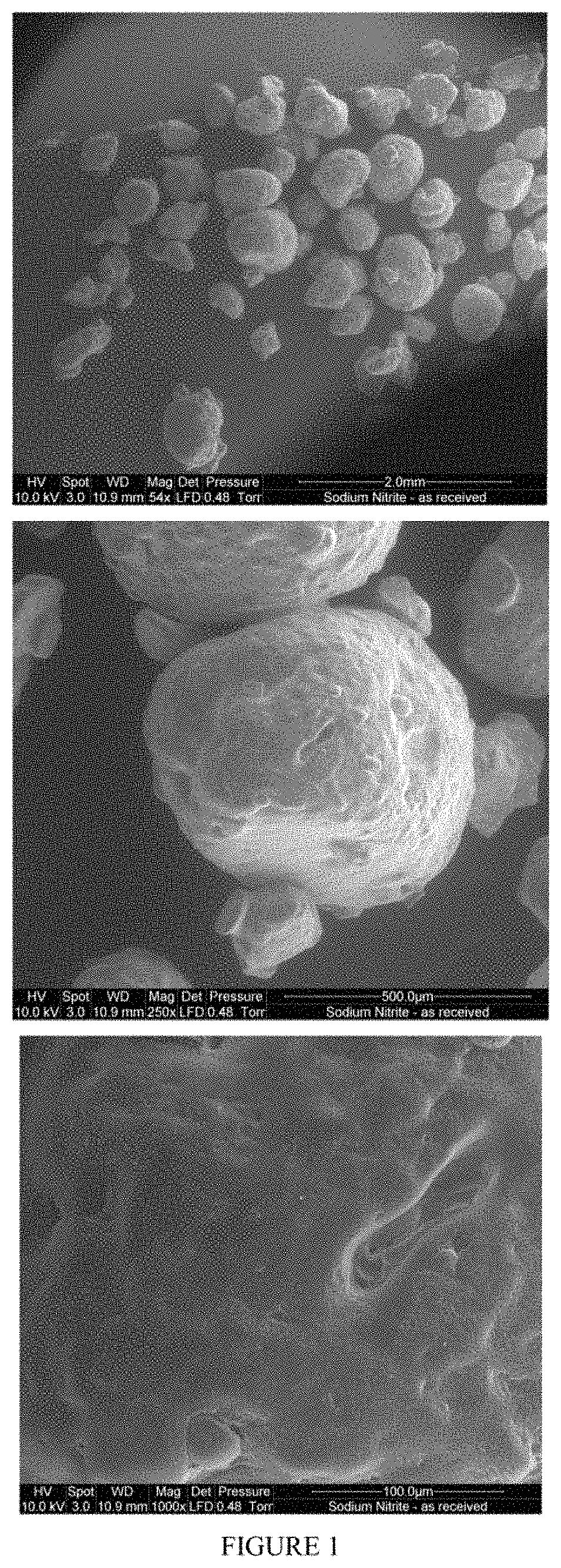

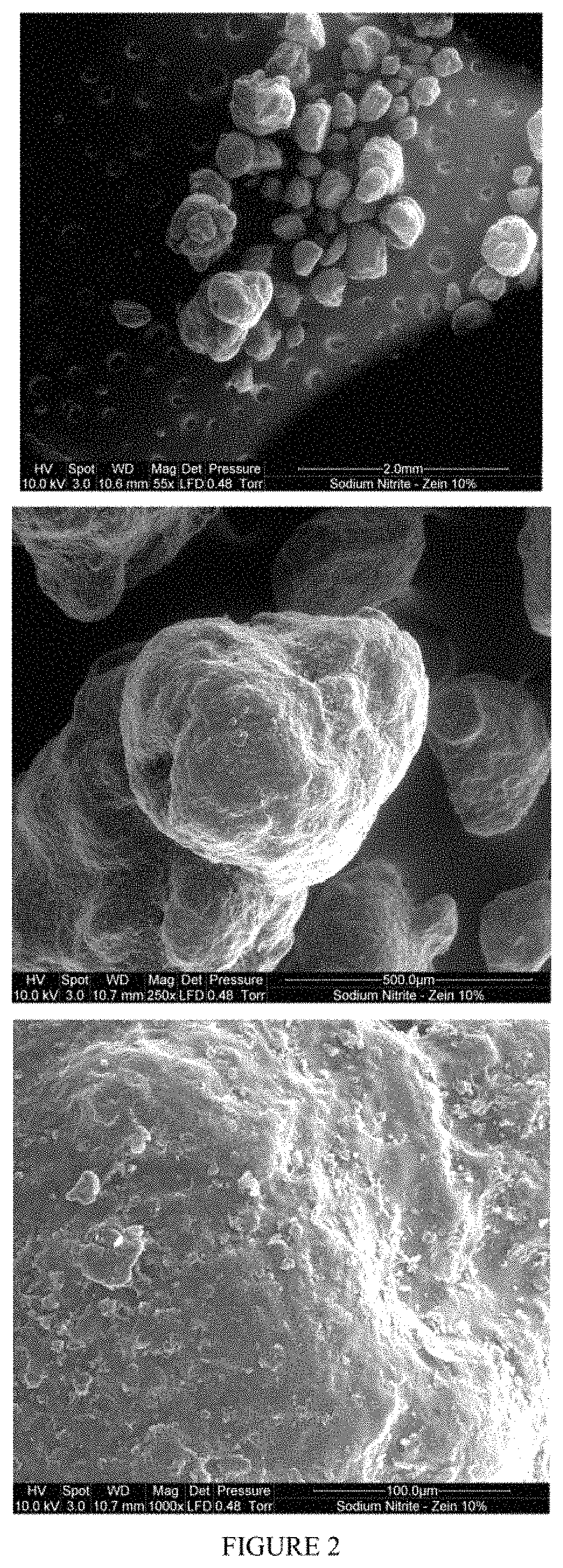

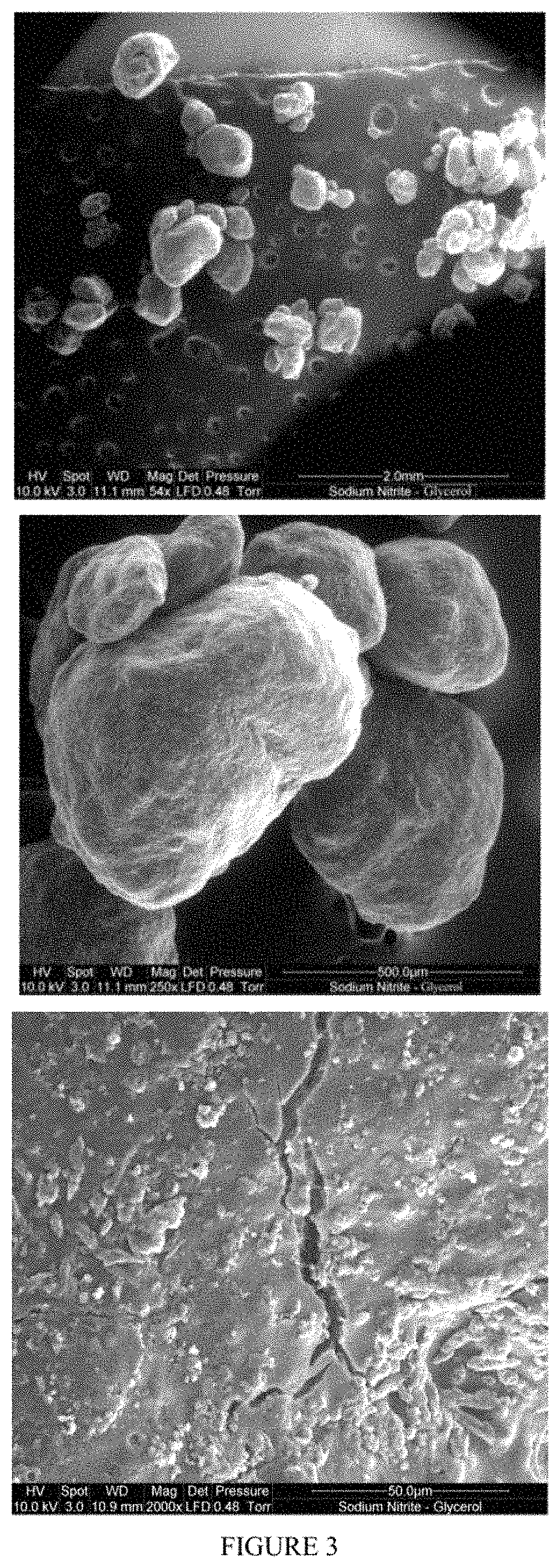

Nitrite microencapsulation, and uses of microencapsulated nitrite in the manufacture of pest baits

ActiveUS20200077646A1Improve delivery formImprove stabilityBiocideAnimal repellantsBiotechnologyAnimal science

Owner:STAPLES LINTON +1

VCM Golf Club Grip System

A golf club grip system is presented comprised of golf club grips of identical weights regardless of their grip thickness. The identical weight may be maintained by altering the grip material compound, grip construction method, or by varying the length of the grip along the golf club shaft as the grip width is varied.A set of standardized grip widths is also presented that varies in increments of the thickness of duct tape, thus providing a standard method of adjusting the thickness of a golf club grip on a shaft.The system is designed to permit pre-manufactured golf club grips to be selected by grip thickness and feel, while remaining identically weighted to all other possible thicknesses. This uniform weighting removes the need to adjust club head weight or perform dynamic or static swing weighting after grip thickness is selected.

Owner:VOGES MITCHELL C

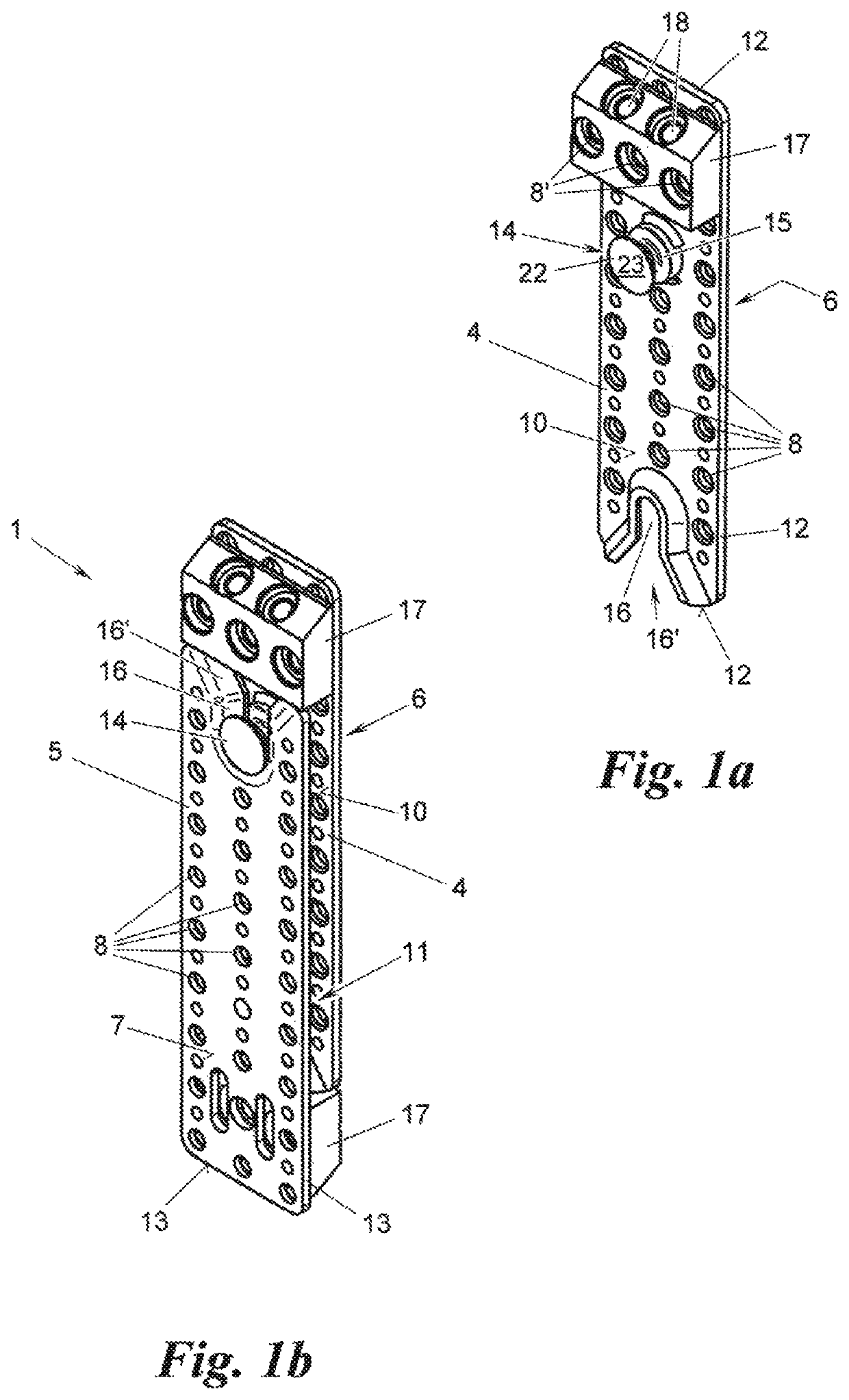

Connector for two workpieces

The present disclosed subject matter relates to a connector for two workpieces, which are in particular made of wood. The connector comprises a first and a second fitting which may be mounted on one of the workpieces each by their one side and may be anchored to one another by their other sides, and which each have a circumferential edge between their one and other side. At least the first fitting has a projection with an undercut on its other side and the second fitting has a slot, starting from its edge and corresponding to the undercut, for anchoring the projection. At least one of the fittings has a protrusion on its other side and running transverse to the direction of the slot for resting of the edge of the other fitting when the projection is in the position anchored in the slot.

Owner:KNAPP GMBH

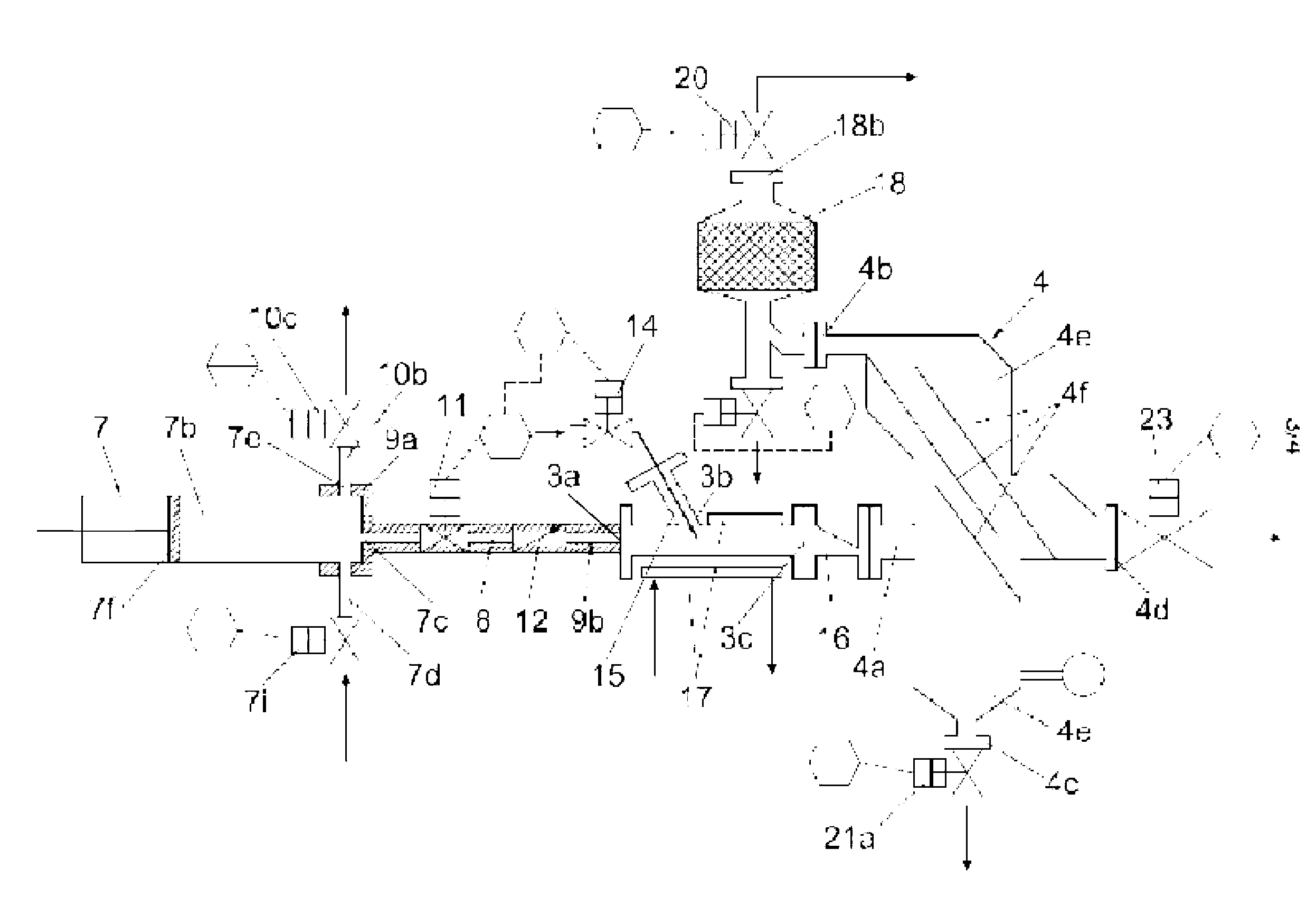

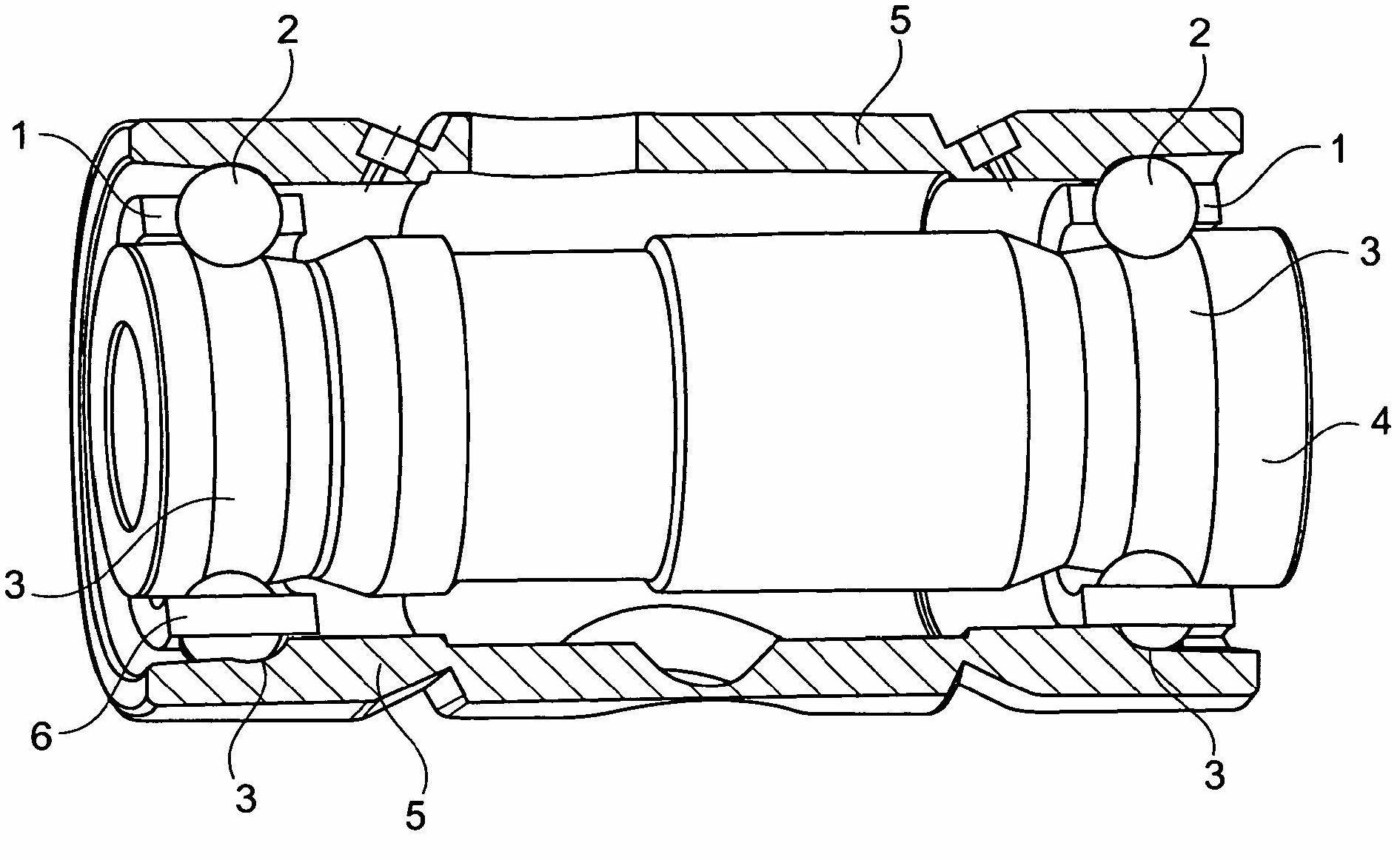

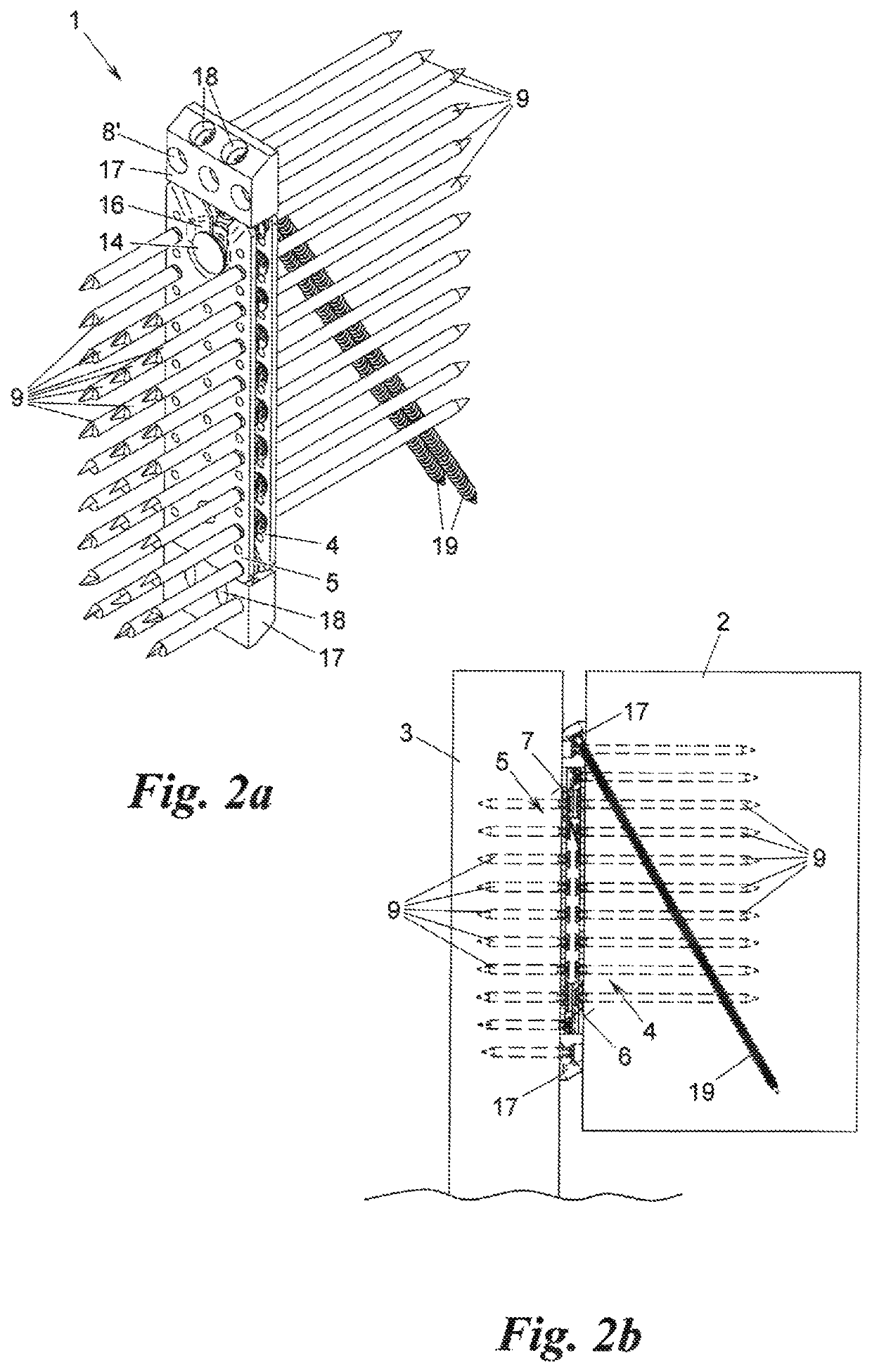

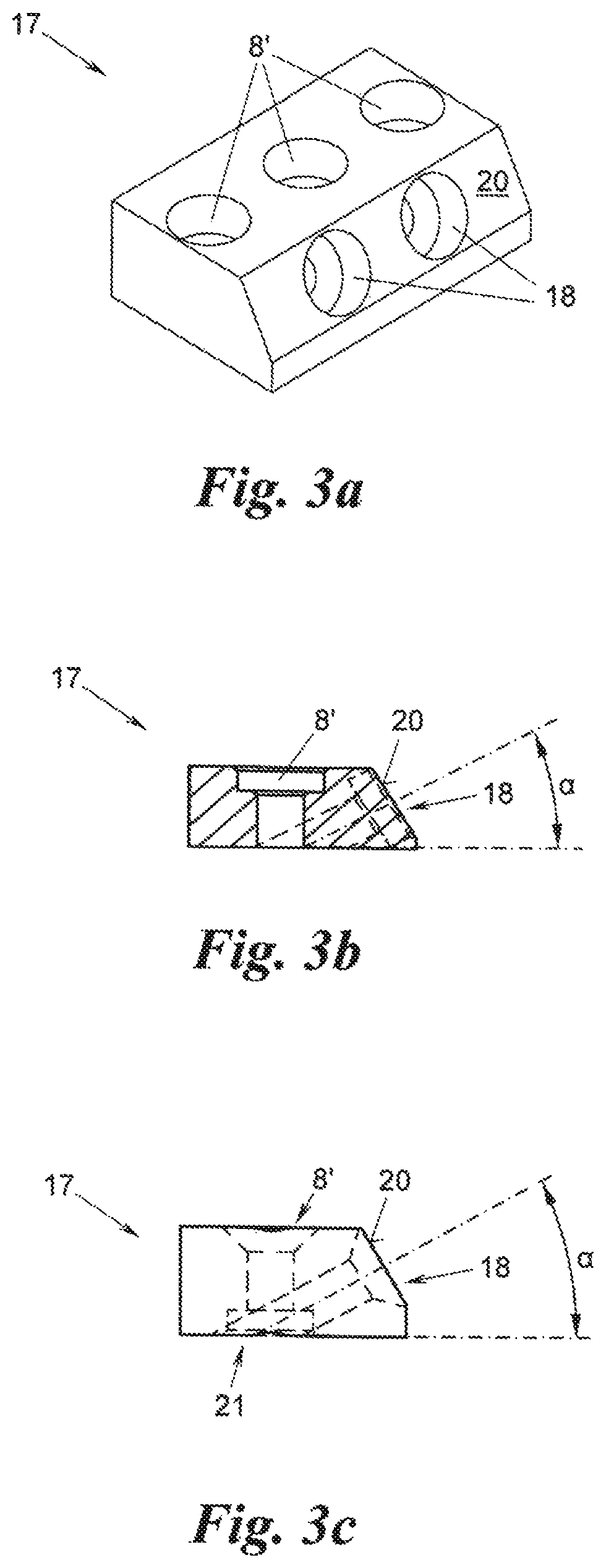

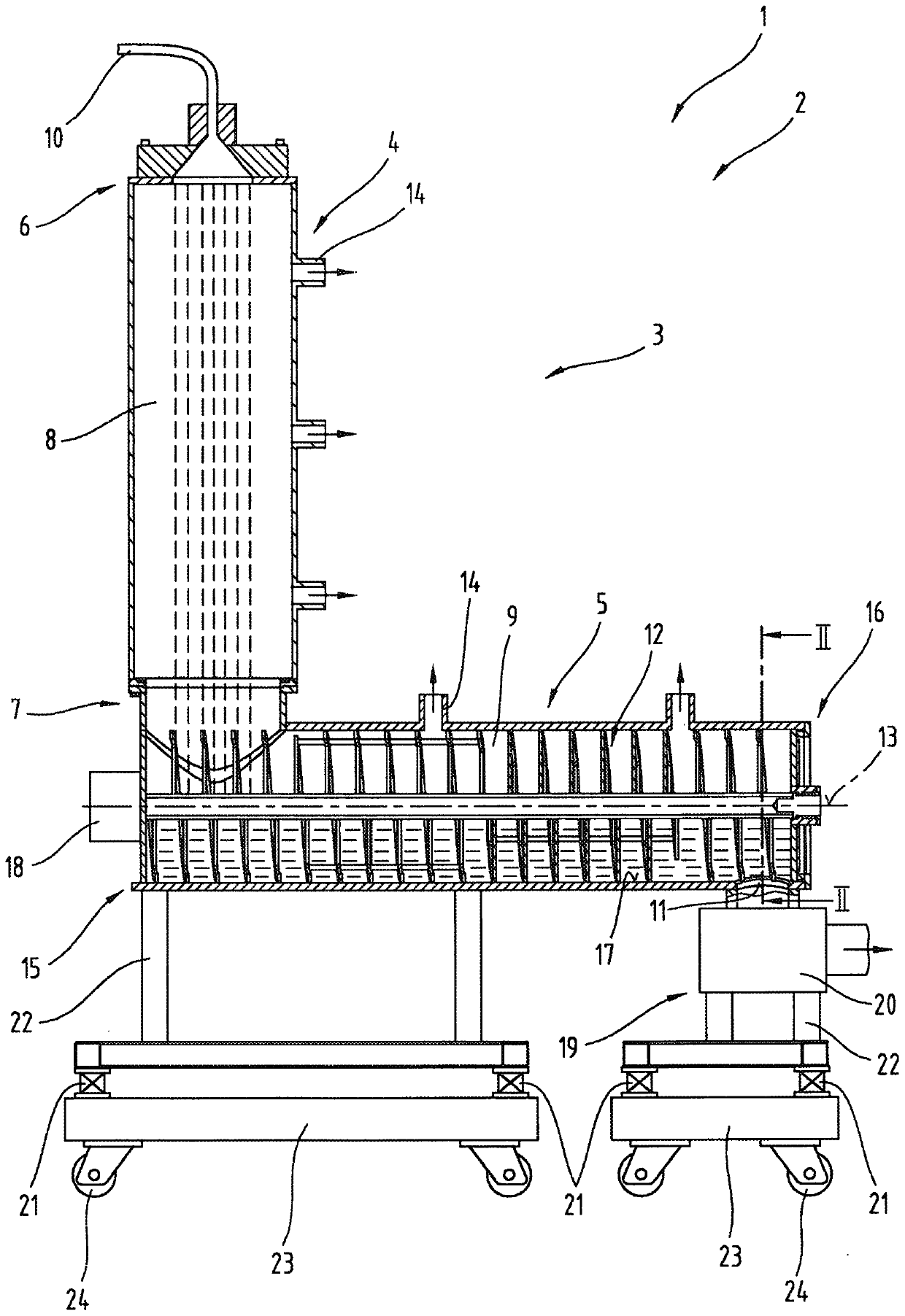

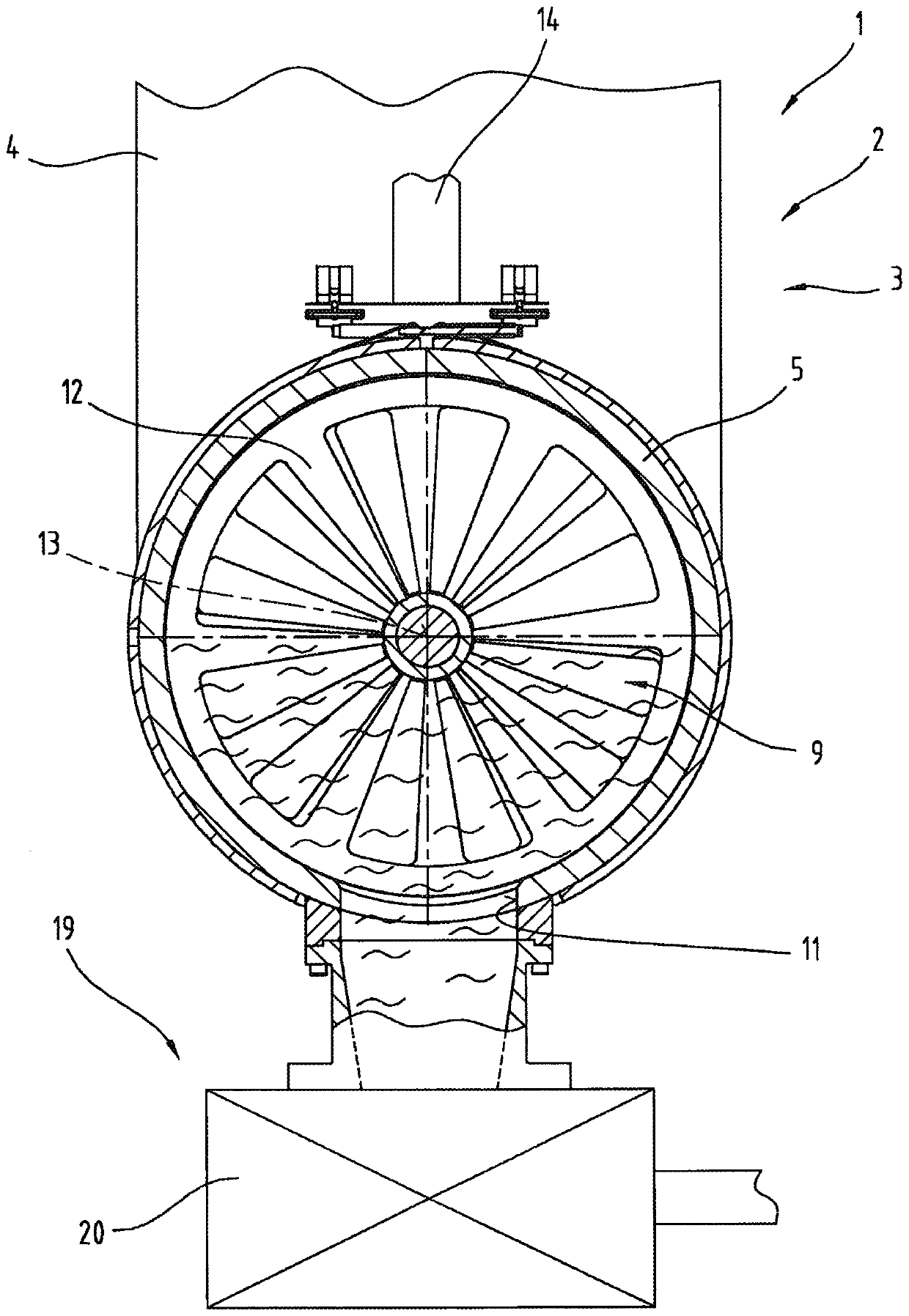

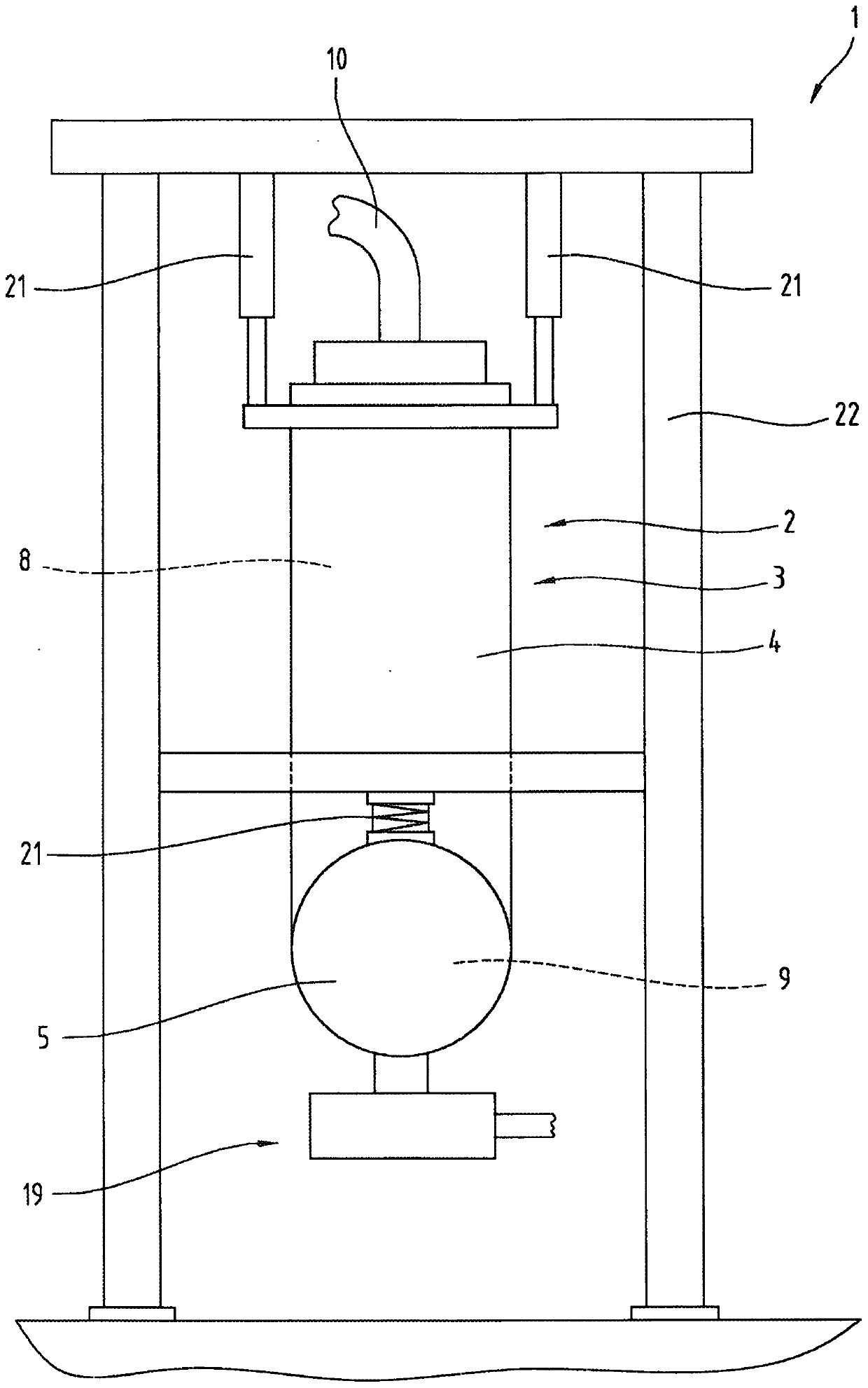

Installation and method for treating a plastic melt

InactiveCN110774472AAchieving Intrinsic ViscosityAchieve strengthRotary stirring mixersTransportation and packagingRotational axisEngineering

The invention relates to an installation (1) and a method for treating a plastic melt, comprising a reactor (2) that has a reactor housing (3) consisting of first and second reactor housing parts (4,5); a mixing element (12) being arranged in the second reactor housing part (5) and mounted thereupon so as to rotate about a rotational axis (13); and said reactor, together with a discharge device (19) and with at least one weighing device (21) connected between these, being supported on a contact area.

Owner:NEXT GENERATION RECYCLINGMASCHEN

Catalyst compositions and their use for hydrogenation of nitrile rubber

ActiveUS9598506B2Constant weightImprove hydrogenation activityOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsNitrile rubberOrganic chemistry

Owner:ARLANXEO DEUT GMBH

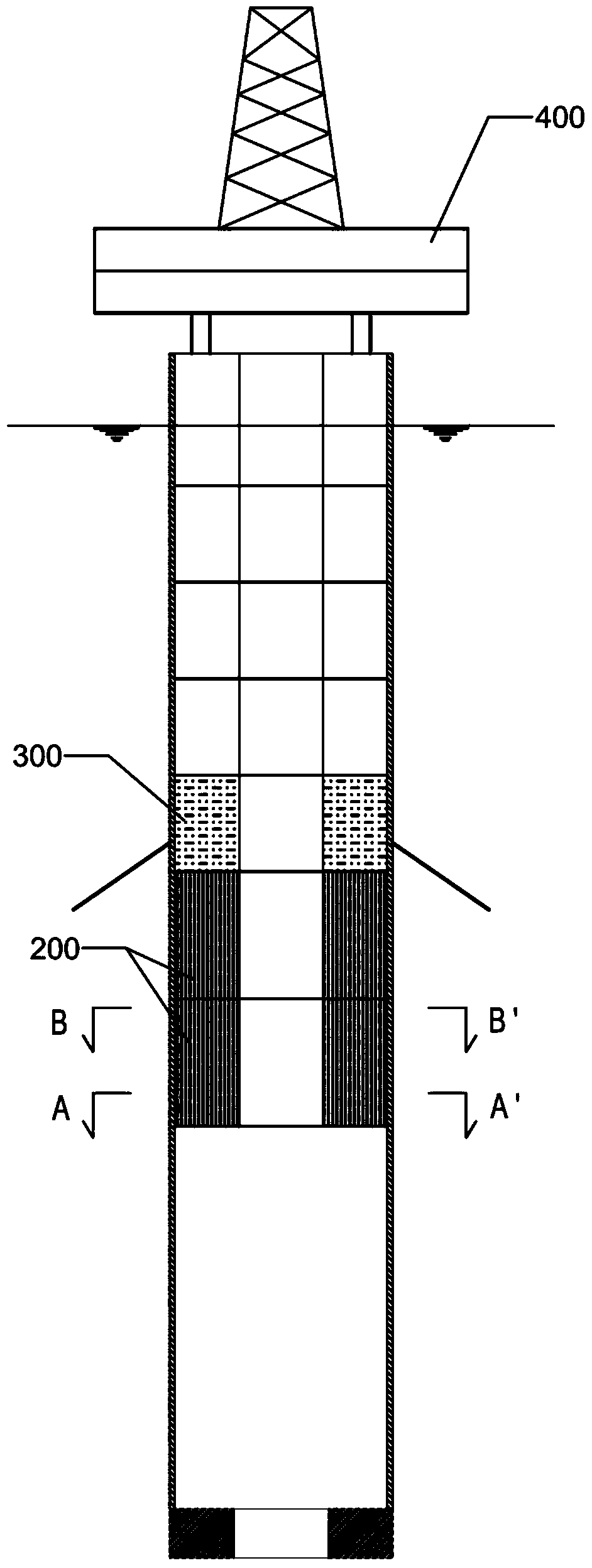

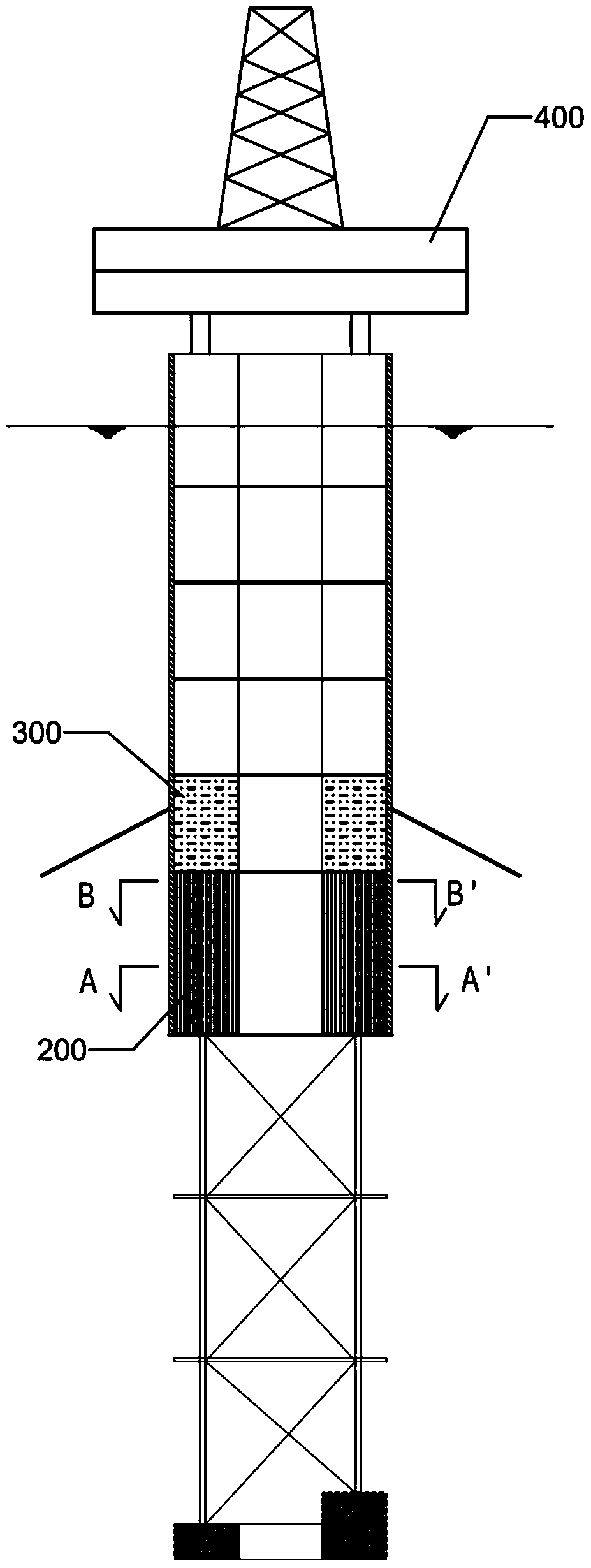

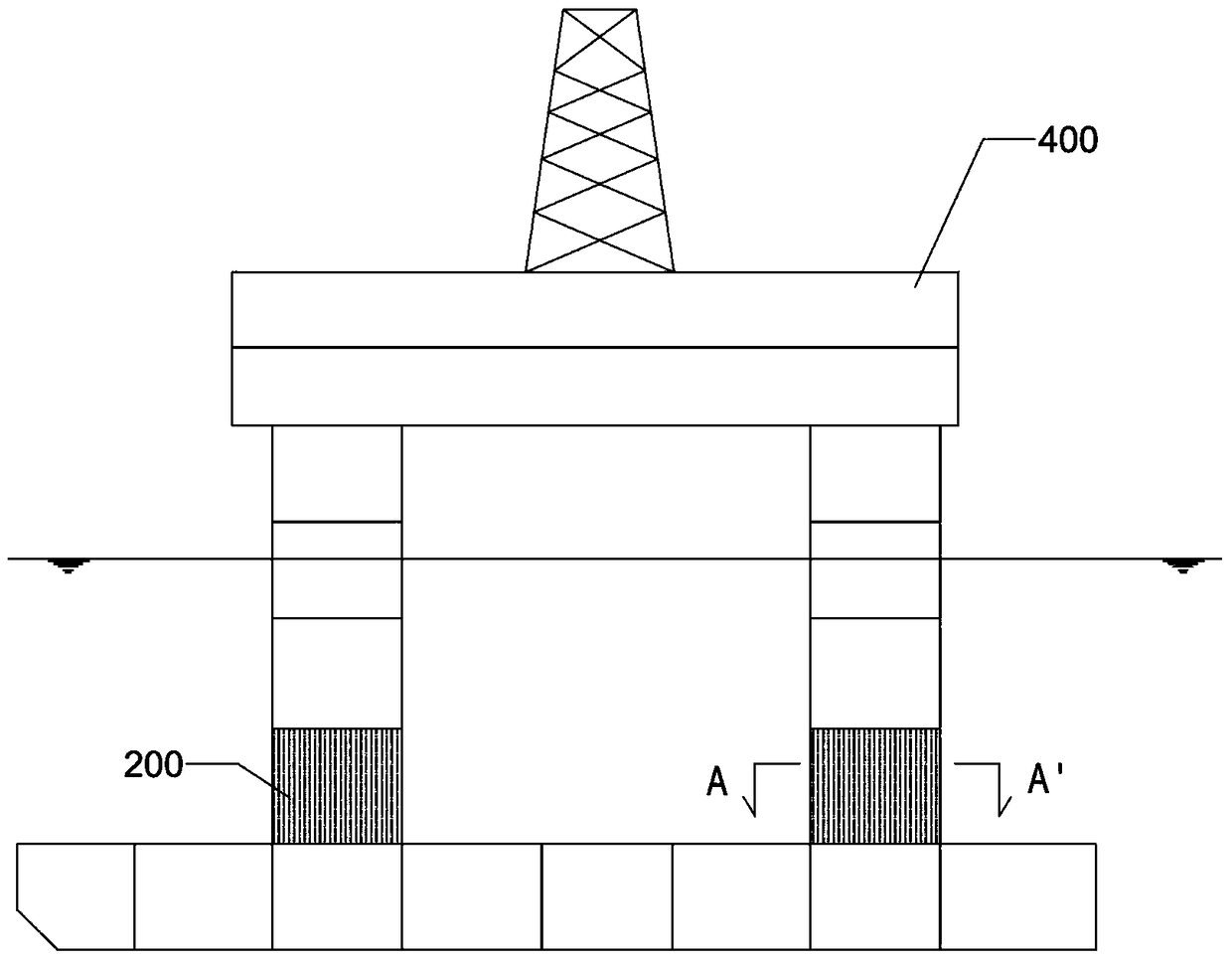

Deepwater floating oil and gas platform using underwater flexible storage device

InactiveCN105501406BSitting on the bottom of the weight change is smallImprove stabilityWaterborne vesselsFloating buildingsLoading unloadingWater pipe

Owner:TIANJIN XISHENG TECH DEV CO LTD

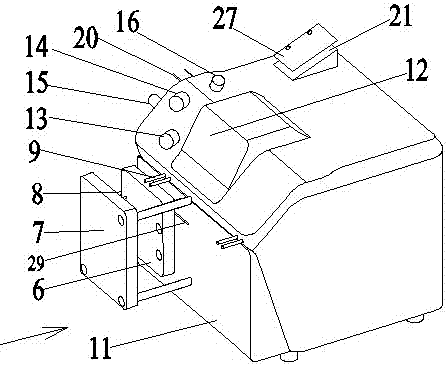

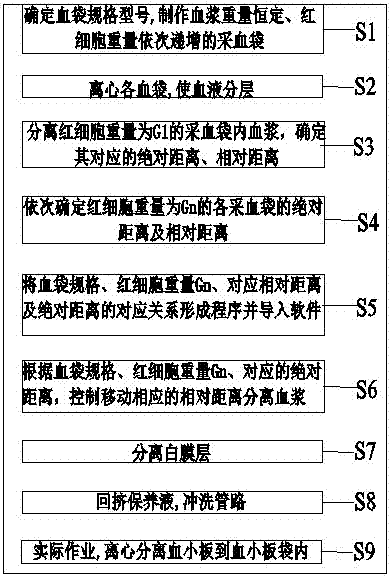

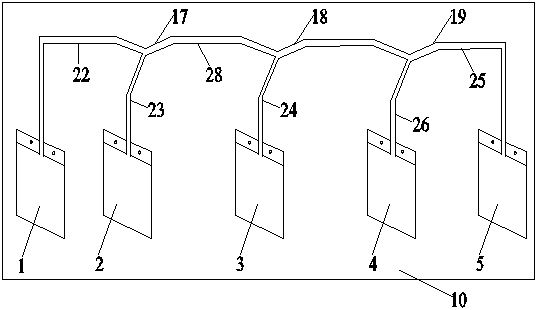

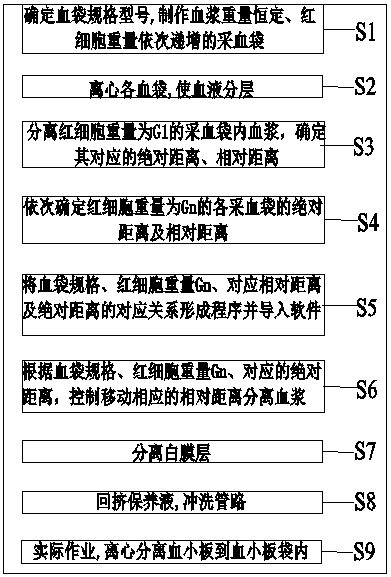

Platelet quantitative separation method applied to automatic blood component separator

ActiveCN107080869AConstant weightOther blood circulation devicesMedical devicesBlood Collection TubeBlood component separator

The invention discloses a platelet quantitative separation method applied to an automatic blood component separator and can provide a more optimized operation method for platelet separation. The automatic blood component separator comprises a front extrusion plate, a hanging arm, a heat sealing head and an inductive head. The separation method comprises the following steps: centrifuging series of blood collection bags containing constant plasma weight D and different red blood cell weight Gn, extruding the blood collection bags to enable a red blood cell level to reach an inductive head position, recording a front extrusion plate moving distance as an absolute distance Hn, setting extruded plasma volume D1 (D1=D-E) according to the platelet quantity demanded E, sequentially enabling the front extrusion plate to continuously extrude all the blood collection bags till the D1 volume of plasma is extruded, recording a change value relative distance delta n of each of the blood collection bags corresponding to the moving distance at the moment and enabling a corresponding relation among the blood bag specification, the absolute distance and the relative distance to form a program to guide into software for invoking during separation operation. The platelet quantitative separation method disclosed by the invention has the benefits that prepared platelet products are consistent in weight, and the platelet density difference is smaller.

Owner:深圳市爱康生物科技股份有限公司

Catalyst compositions and their use for hydrogenation of nitrile rubber

ActiveUS9605088B2Constant weightImprove hydrogenation activityOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsNitrile rubberOrganic chemistry

Owner:ARLANXEO DEUT GMBH

A quantitative platelet separation method applied to an automatic blood component separator

ActiveCN107080869BConstant weightOther blood circulation devicesMedical devicesBlood Collection TubeBlood component separator

Owner:深圳市爱康生物科技股份有限公司

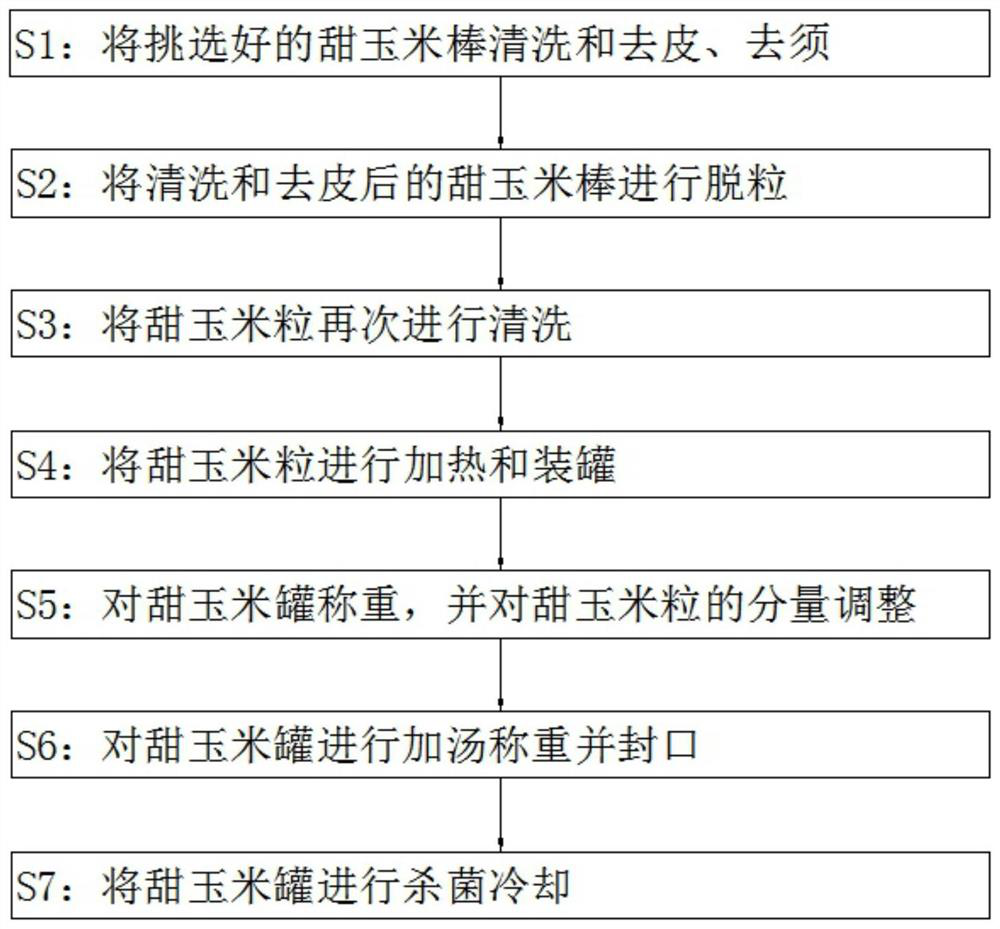

Processing technology of canned sweet corn

PendingCN113229451AWeight is fast and more accurateConstant weightFood scienceAgricultural scienceAgricultural engineering

The invention belongs to the field of processing of canned corn, particularly relates to a processing technology of canned sweet corn, and aims to solve the problems that the overall quality of the canned sweet corn is reduced and the brand public praise is affected due to the fact that the overall weight of the existing canned sweet corn is relatively balanced but the weight of sweet corn kernels in the canned sweet corn is often greatly different. According to the scheme, the method comprises the following steps: S1, cleaning selected sweet corn cobs, and removing peels and stigmas of the sweet corn cobs; S2, threshing the cleaned and peeled sweet corn cobs; S3, cleaning the sweet corn kernels again; S4, heating and canning the sweet corn kernels; S5, weighing the sweet corn tank, and adjusting the amount of the sweet corn kernels; S6, adding soup into the sweet corn tank, weighing, and sealing; and S7, sterilizing the sweet corn cans and cooling. The overall weight of the sweet corn cans can be balanced, meanwhile, the proportion of corn kernels and soup in the cans is uniform, and the overall quality and brand public praise of the cans are improved.

Owner:信丰润丰食品有限公司

Nitrite microencapsulation, and uses of microencapsulated nitrite in the manufacture of pest baits

ActiveUS10624338B2Improve delivery formImprove stabilityBiocideAnimal repellantsBiotechnologyAnimal science

Owner:STAPLES LINTON +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com