Ball bearing cage

A cage and ball bearing technology, applied to bearings, bearing components, shafts and bearings, etc., can solve problems such as abnormal bearing noise, ball bearing damage, cage instability, etc., to save costs and reduce transportation damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

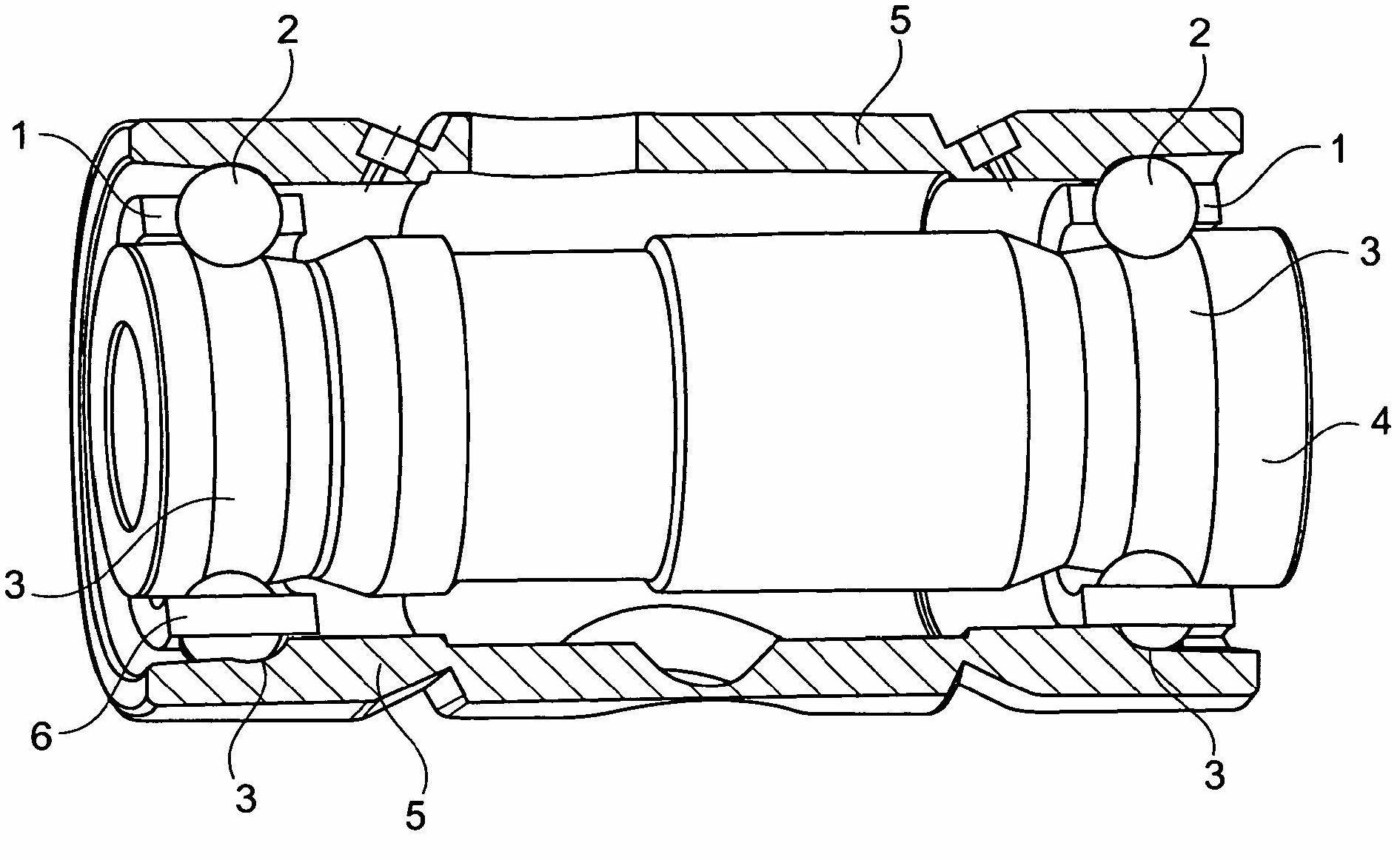

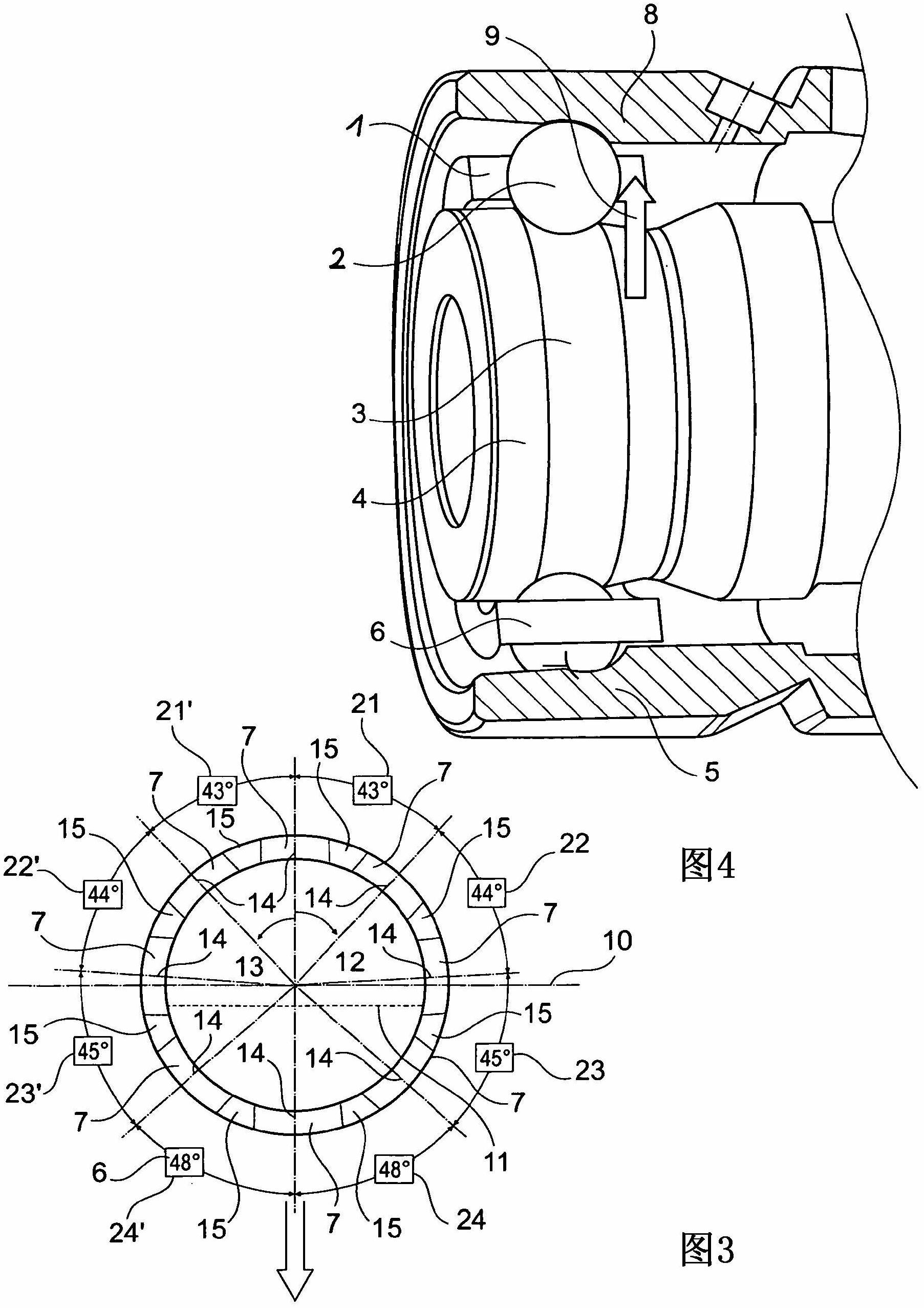

[0029] Depend on figure 1 A cross-section of a rolling bearing arrangement of a shaft bearing in a turbocharger is obtained. The turbocharger has a turbine rotor (not shown) which drives a charging wheel (not shown) of the turbocharger via a rotatably mounted shaft 3 . The fast-rotating shaft 3 is supported via two angular contact ball bearings 1 arranged in an O-shape, which support the shaft 3 relative to a stationary housing or bearing seat 5 .

[0030] Both the inner raceway 3 and the outer raceway 3 of the two angular contact ball bearings 1 are inserted directly into the shaft 3 or into the bearing housing 5 . Rolling bodies 2 (in this case balls 2 ) are arranged in two ball rows between the respective inner raceway 3 and the associated outer raceway 3 of the two angular contact ball bearings 1 .

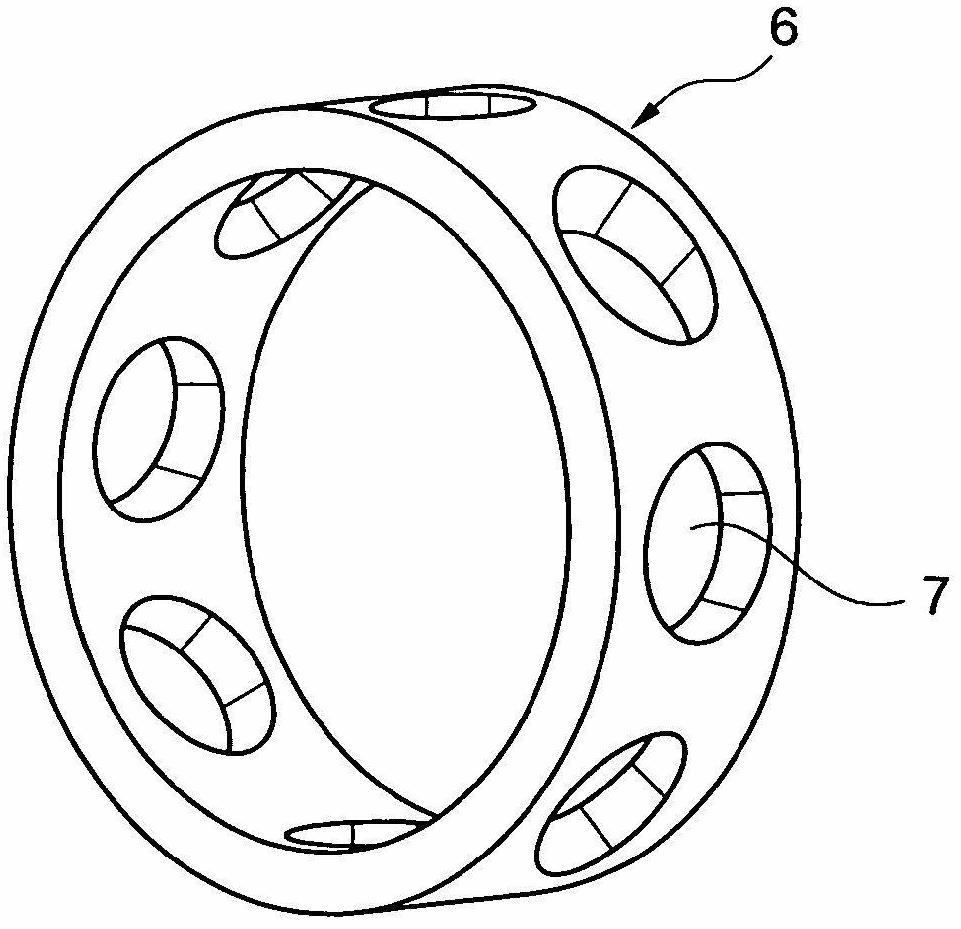

[0031] To hold the balls 2 at a distance, the ball rows of the two angular contact ball bearings 1 are correspondingly arranged in a solid cage 6 (hereinafter referred to as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com