A system for controlled on demand in situ hydrogen generation using a recyclable liquid metal reagent, and method used in the system

一种发生系统、试剂的技术,应用在在高温下液体与气体的反应、氢/合成气生产、氢的生产等方向,能够解决毒性高、回收燃料昂贵、技术复杂等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0171] Embodiment of the invention

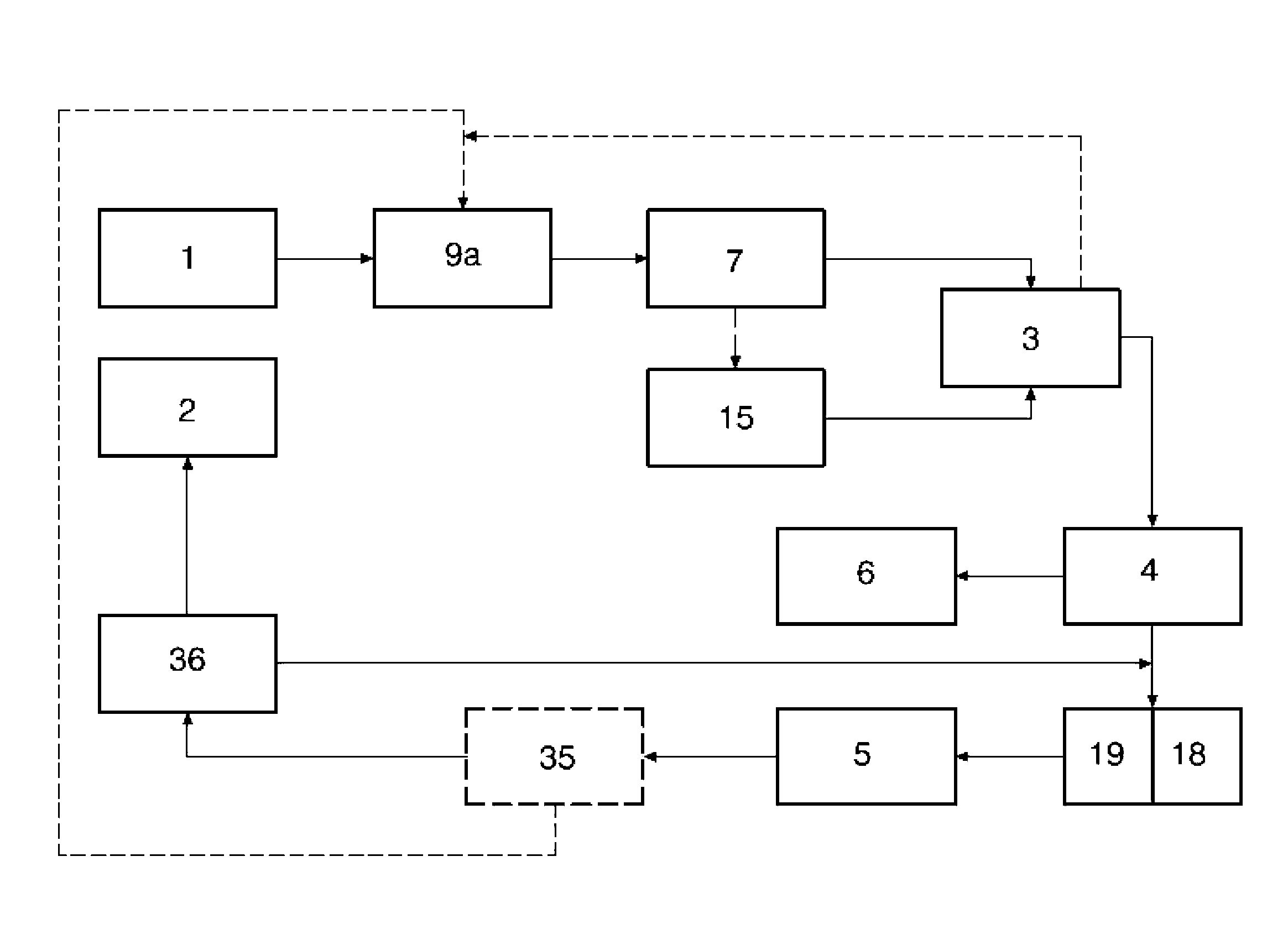

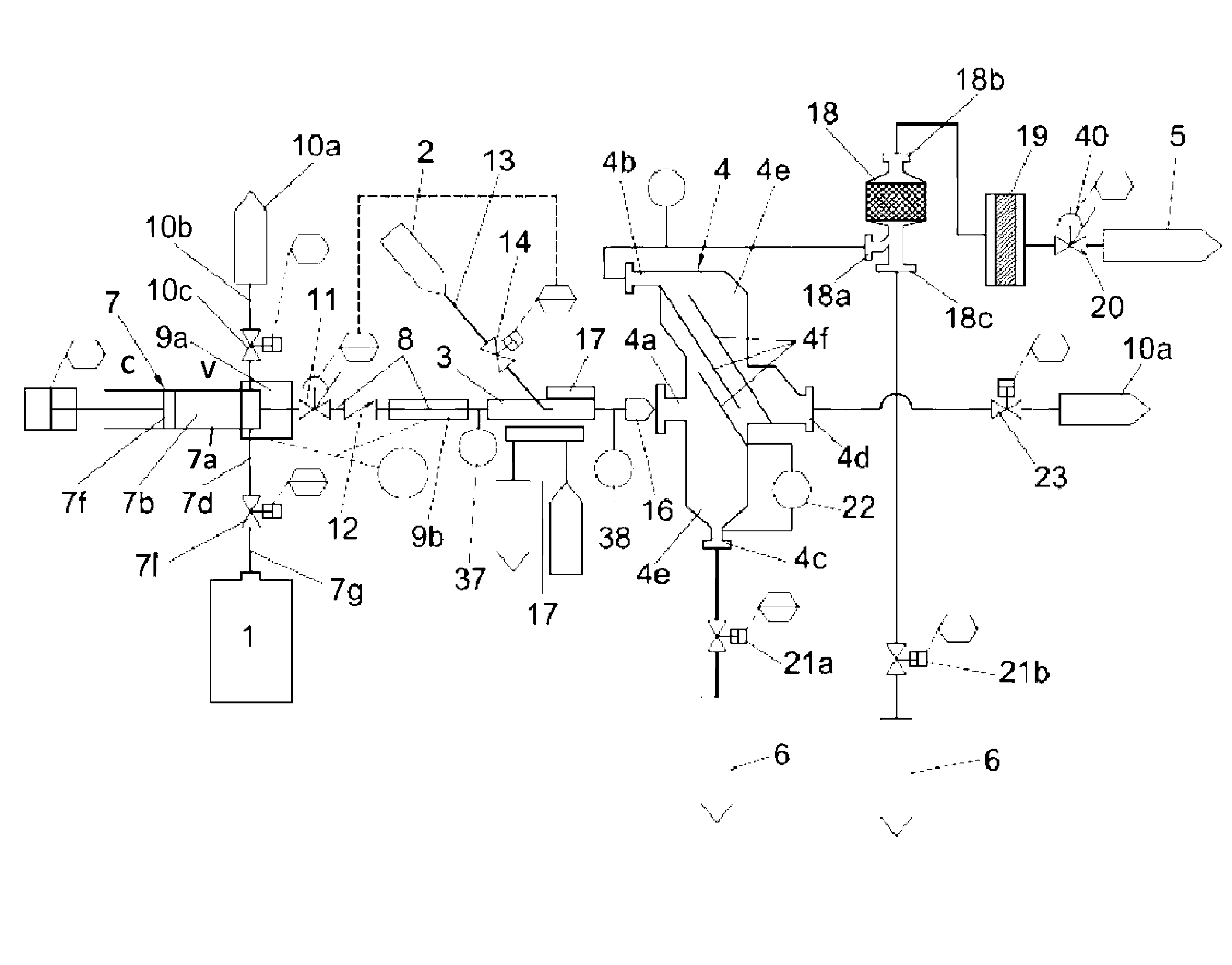

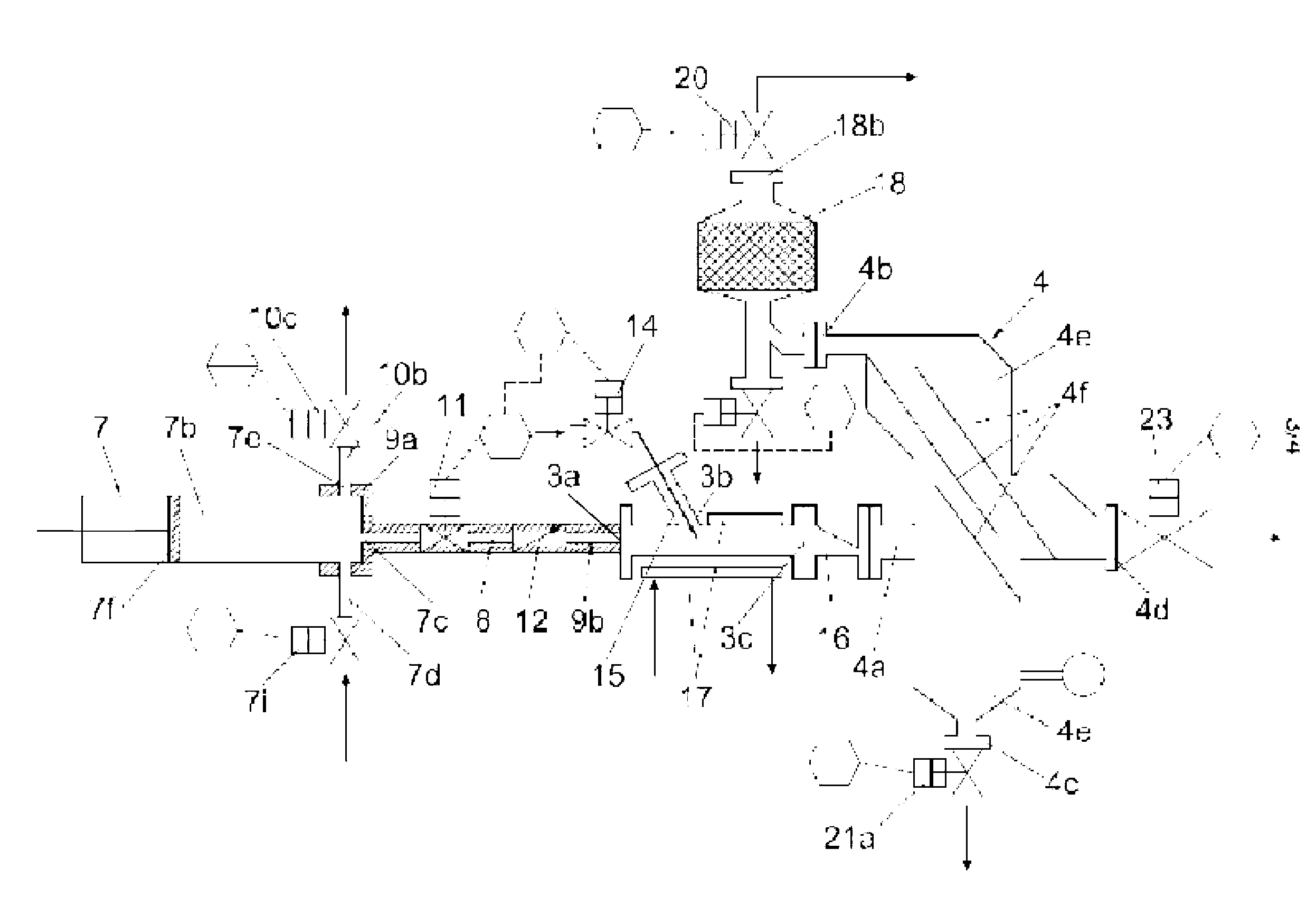

[0172] Figure 1 to Figure 3 Shown are the basic steps and elements of hydrogen generation according to one embodiment of the present invention.

[0173] The basic steps of the described embodiment are as figure 1 shown in , and will be described based on the use of an alkali metal such as lithium or sodium as the first reagent, but the steps can also be followed in a similar manner using alkaline earth metals or alloys of these metals.

[0174] The alkali metal contained in the first storage device 1 is heated to a temperature above its melting point by the first reagent heating device 9a, and the liquefied alkali metal is extruded (preferably using an extruder die of controlled size) using a metal reagent injection device 7 head) into the reactor 3. At the same time, liquid demineralized cold water from the second storage device 2 is also injected into the reactor 3 through the water injection device 15 . The water injection device 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com