Processing technology of canned sweet corn

A technology of sweet corn canning and processing technology, which is applied in the direction of food science, etc., can solve the problems of the overall quality reduction of canned food and the influence of brand reputation, and achieve the effect of overall weight balance, improvement of quality and reputation, and improvement of overall quality and brand reputation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

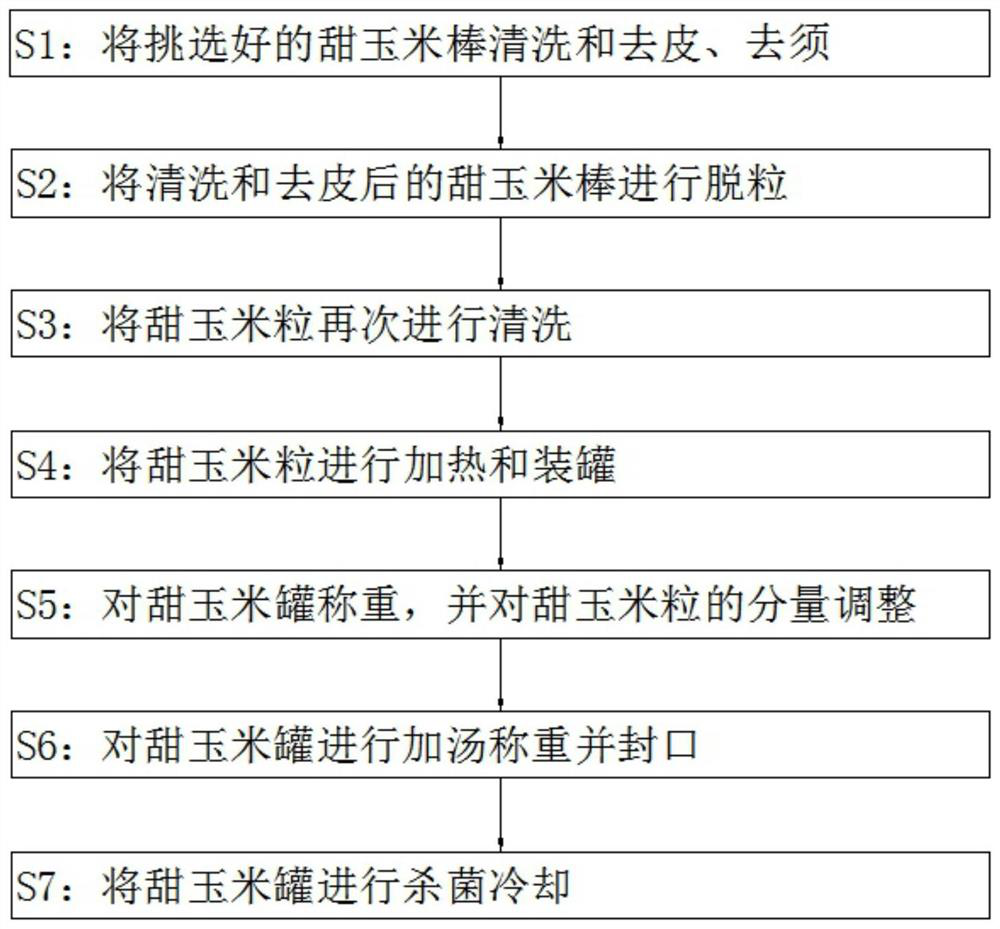

[0028] refer to figure 1 , a kind of canned sweet corn processing technology, comprises the following steps:

[0029] S1: cleaning and peeling the selected sweet corn cobs;

[0030] S2: Threshing the sweet corn cobs after cleaning and peeling;

[0031] S3: washing the sweet corn kernels again;

[0032] S4: heating and canning the sweet corn kernels;

[0033] S5: weighing the sweet corn tank, and adjusting the weight of the sweet corn kernels;

[0034] S6: adding soup to the sweet corn jar, weighing and sealing;

[0035] S7: The sweet corn jar is sterilized and cooled.

[0036] In this embodiment, in S1, the sweet corn cobs are cleaned through the cleaning tank, and the sweet corn cobs are collided with each other by the stirring mechanism to achieve the cleaning effect, and then the outer skin and the tassels of the sweet corn cobs are removed by the peeling and beard removal mechanism.

[0037] In this embodiment, in S2, the sweet corn cobs are transmitted one by one in...

Embodiment 2

[0044] refer to figure 1 , a kind of canned sweet corn processing technology, comprises the following steps:

[0045] S1: cleaning and peeling the selected sweet corn cobs;

[0046] S2: Threshing the sweet corn cobs after cleaning and peeling;

[0047] S3: washing the sweet corn kernels again;

[0048] S4: heating and canning the sweet corn kernels;

[0049] S5: weighing the sweet corn tank, and adjusting the weight of the sweet corn kernels;

[0050] S6: adding soup to the sweet corn jar, weighing and sealing;

[0051] S7: The sweet corn jar is sterilized and cooled.

[0052]In this embodiment, in S1, the sweet corn cobs are cleaned through the cleaning tank, and the sweet corn cobs are collided with each other by the stirring mechanism to achieve the cleaning effect, and then the outer skin and tassels of the sweet corn cobs are removed by the peeling and beard removal mechanism.

[0053] In this embodiment, in S2, the sweet corn cobs are transmitted one by one in an o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com