VCM Golf Club Grip System

a golf club and grip technology, applied in the field of golf club grip replacement systems, can solve the problems of labor-intensive installation of custom grips, up to an hour of time for custom grip installation, etc., and achieve the effect of maintaining the balance of overall swing weight and club weight, constant grip weight, and constant texture and feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

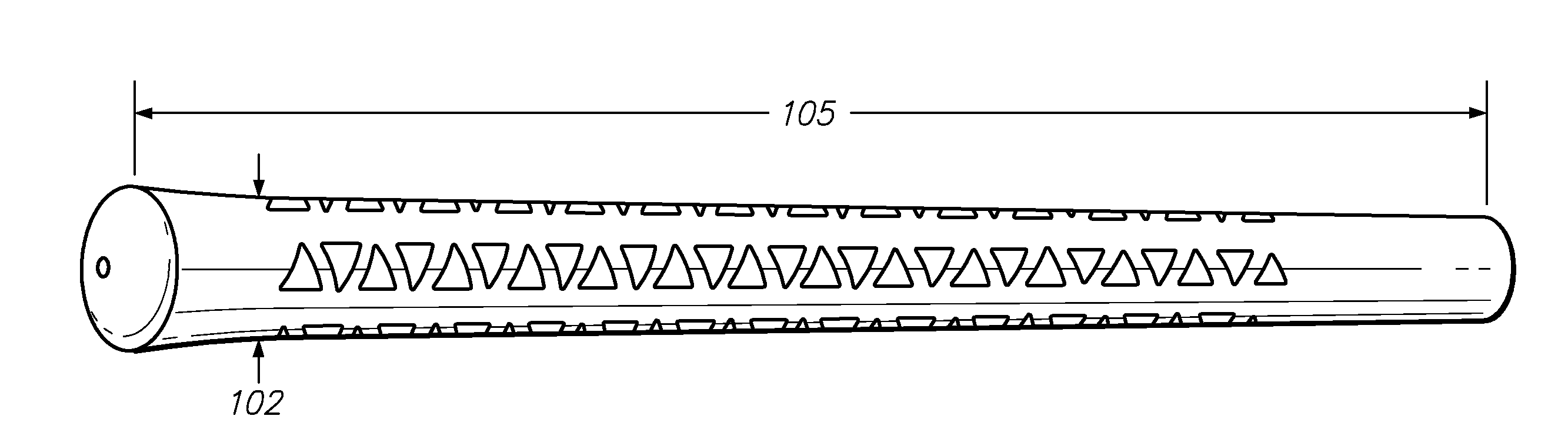

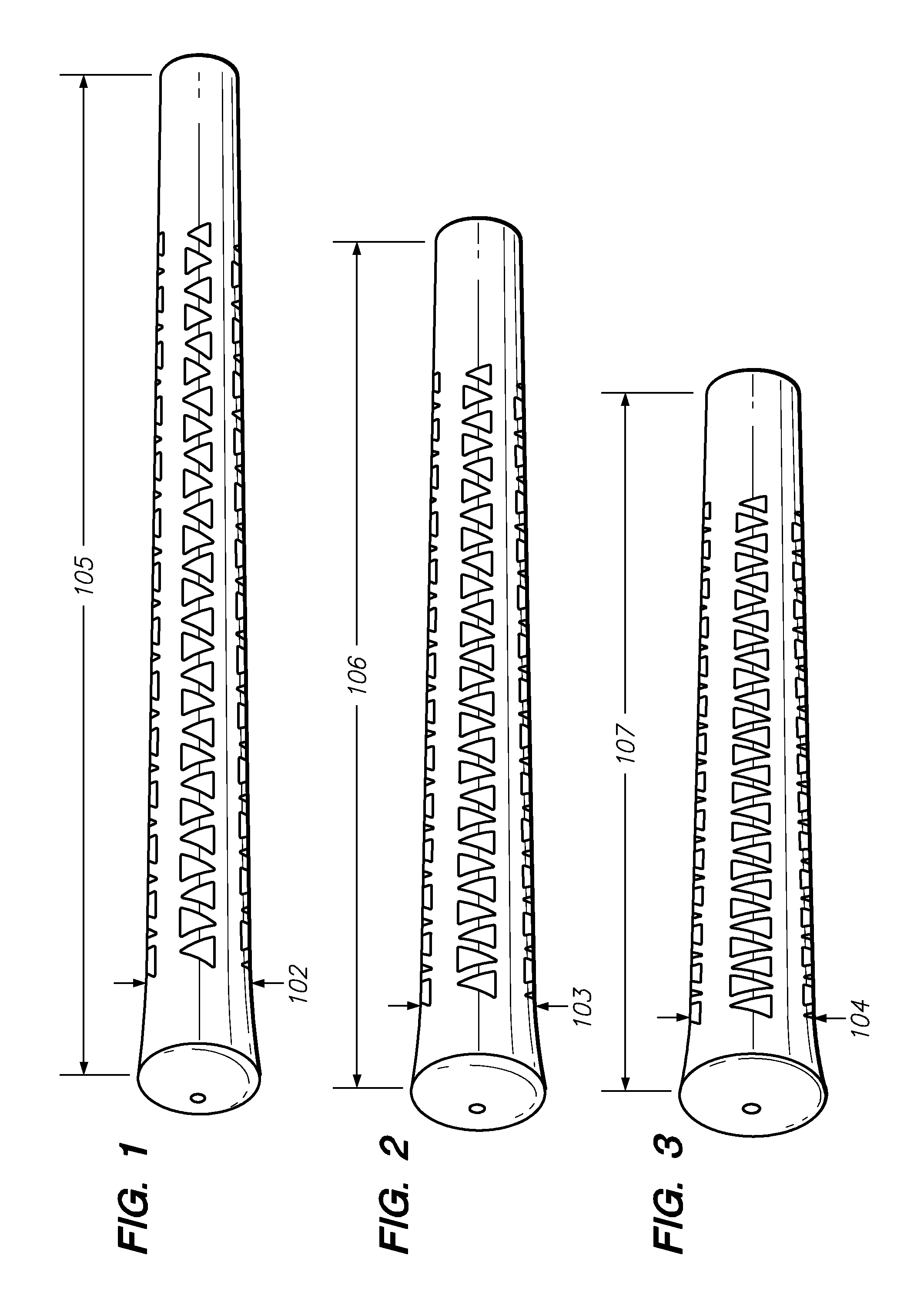

[0019]The present invention is comprised of a set of identically-weighted golf club grips 101 that have varying widths 102, 103, 104. In an alternate embodiment, the volume of the grips is identical, as the thinner width grip 102 is longer on the club shaft than the thicker grips 104, each having in this embodiment commensurately varying lengths 105, 106, 107. In FIGS. 1, 2, and 3, the grip lengths are exaggerated for emphasis, and are not representative of the true lengths of the invention.

[0020]The golf club grip 101 of this invention is comprised of a proprietary blended material, in the preferred embodiment a soft plastic or rubber compound, but may in alternate embodiments include a polymer, leather, or synthetic compound. The weight of the grips in the set comprising the present invention will be chosen in the range of 50 to 54 grams for the preferred embodiment of the invention and maintained throughout the grip set. Alternate embodiments will be in the weight range of 40 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com