Patents

Literature

584results about How to "Realize printing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

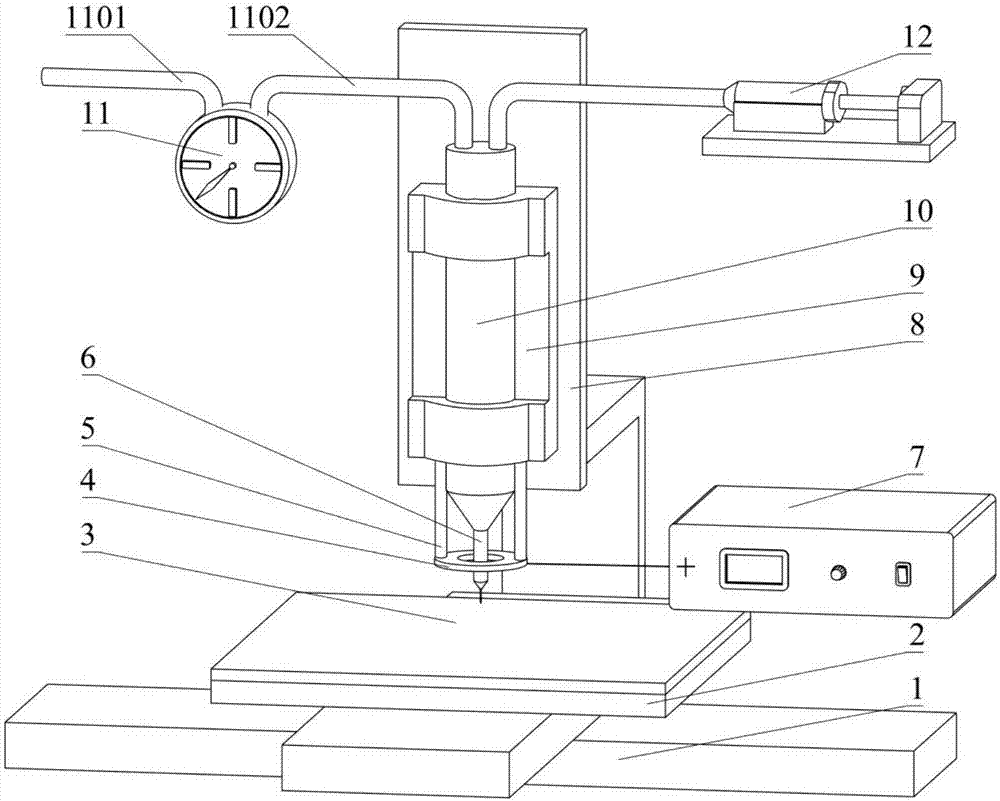

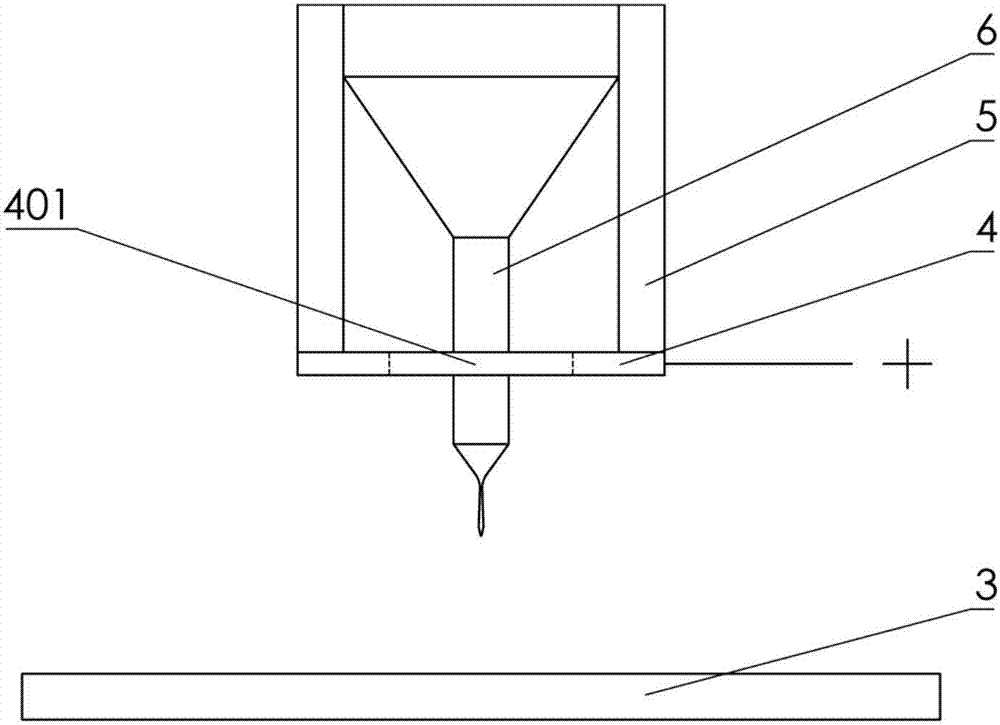

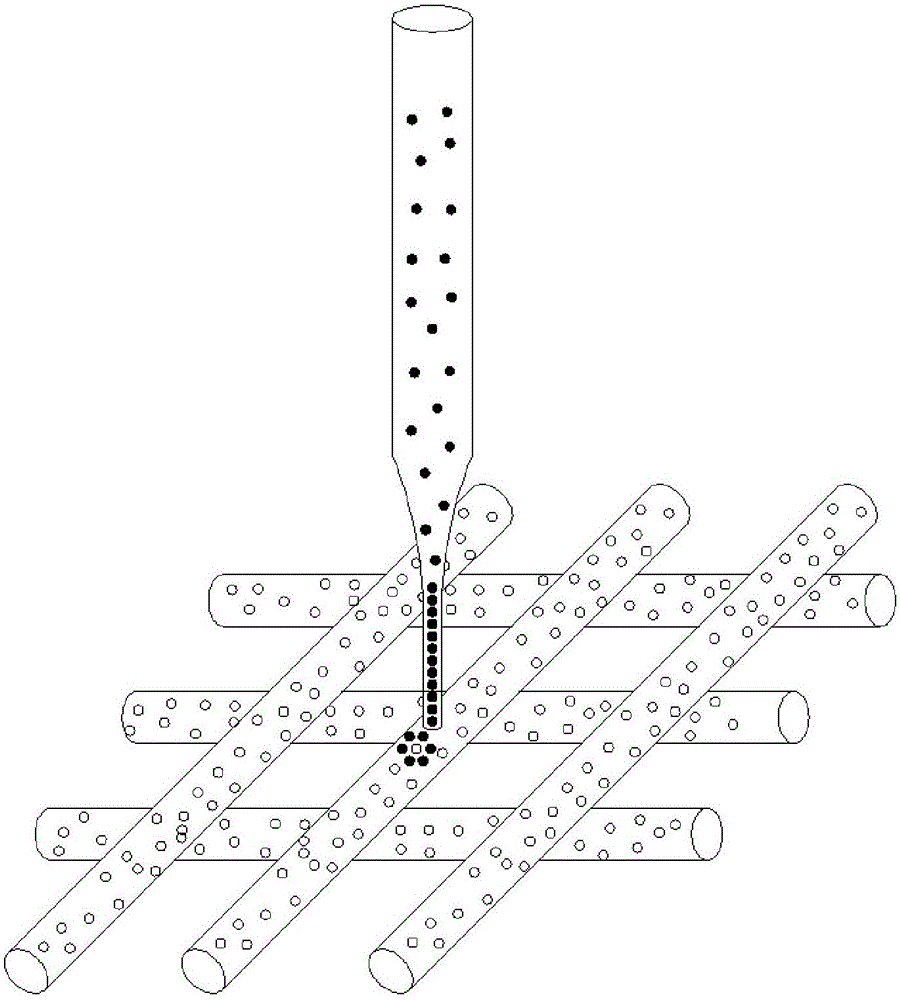

Multi-material multi-scale 3D (3-dimensional) printing device provided with single spray nozzle as well as working method of 3D printing device

ActiveCN105196550ARealize printingReasonable control of macro geometryManufacturing platforms/substratesTransportation and packagingMulti materialSpray nozzle

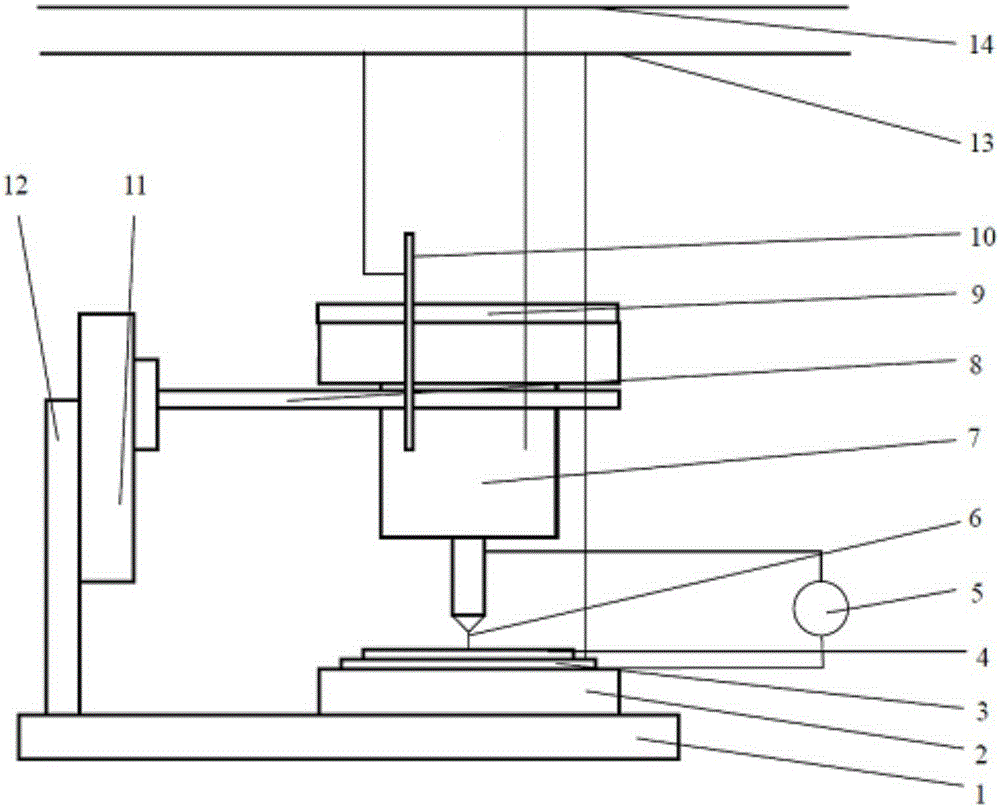

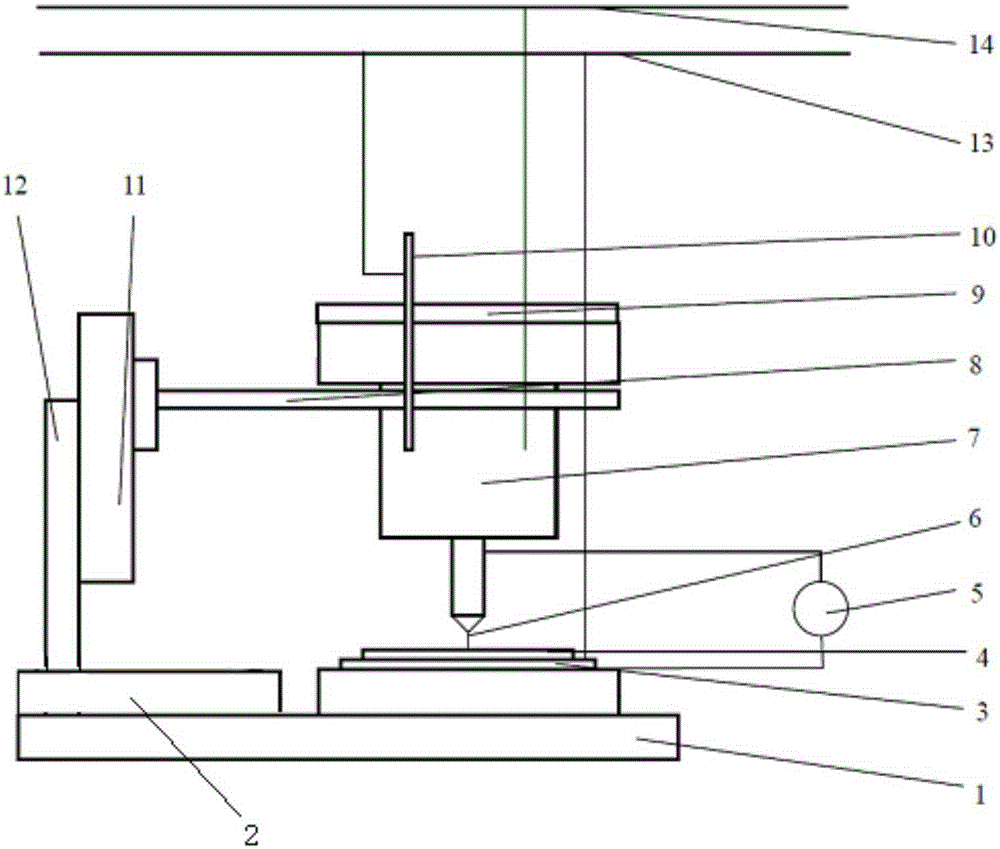

The invention discloses a multi-material multi-scale 3D (3-dimensional) printing device provided with a single spray nozzle as well as a working method of the 3D printing device. The 3D printing device comprises a base, a work table, a bearing table, a substrate, a power supply, the spray nozzle and a bracket, wherein the base is mounted at the bottommost part, the bracket and the work table are mounted above the base, the spray nozzle is mounted on the bracket, the bearing table is fixed on the work table, and the substrate is fixed above the bearing table; an anode and a cathode of the power supply are connected with a nozzle body of the spray nozzle and the bearing table respectively; relative motion between the spray nozzle and the substrate in x, y and z directions is realized by the aid of relative motion between the work table and the bracket. The spray nozzle is provided with a plurality of feed openings connected with different trace feeding pumps, multiple materials are thoroughly mixed under the action of a stirrer after entering the spray nozzle, and multi-material printing is realized. The macroscopic geometrical shape as well as microstructures in an object and on the surface of the object is controlled reasonably, and multi-scale structural integrated manufacture is realized.

Owner:兰红波

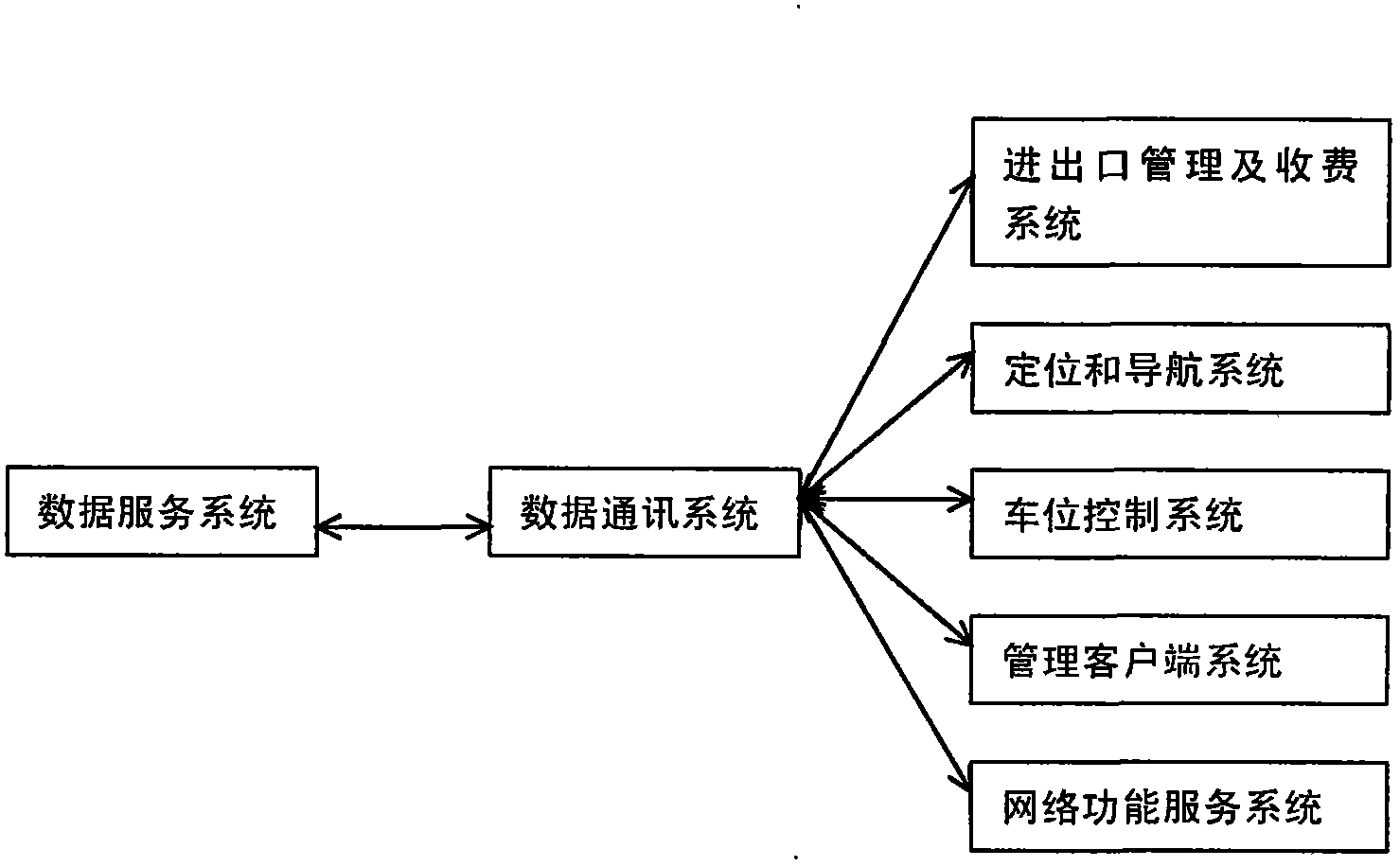

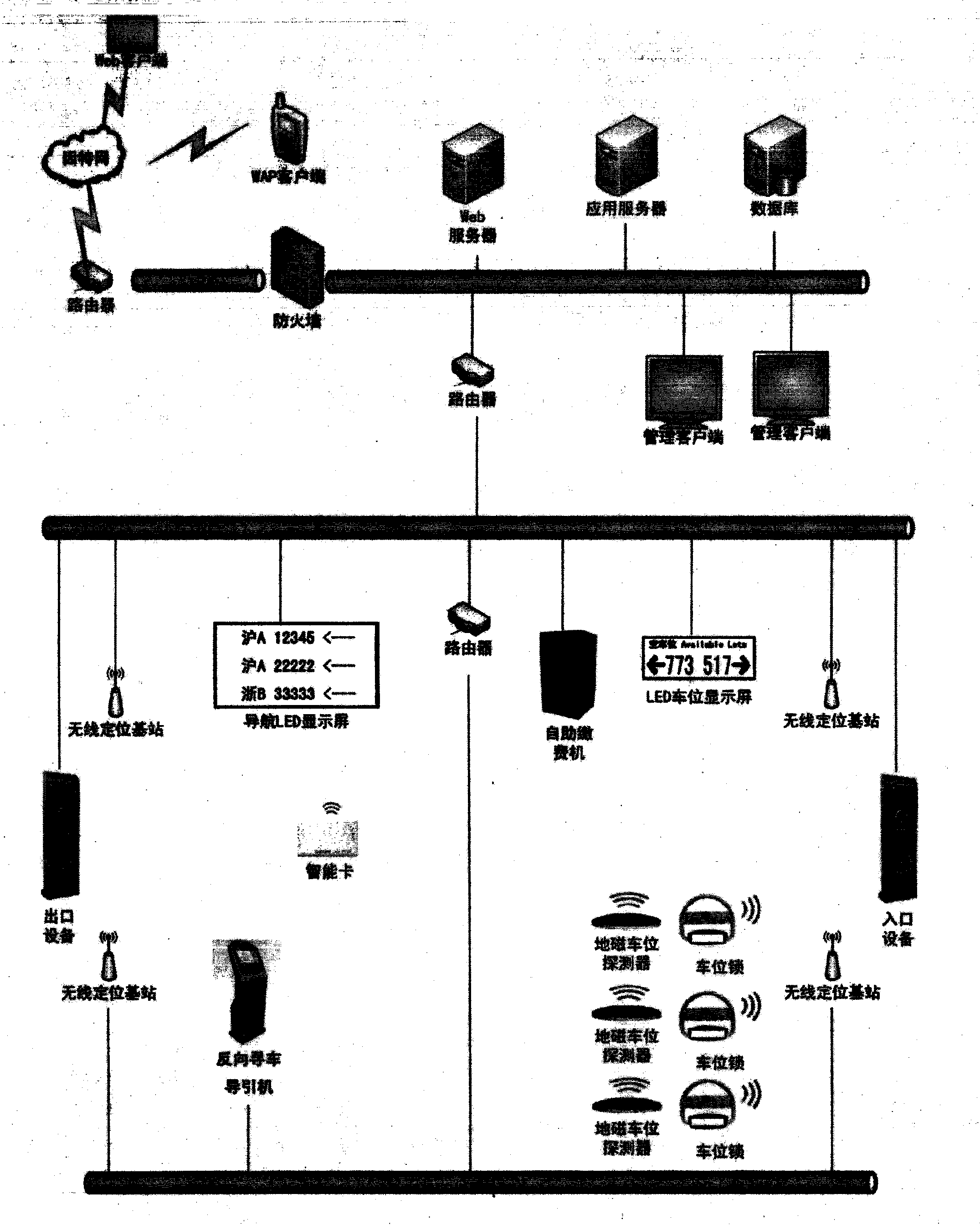

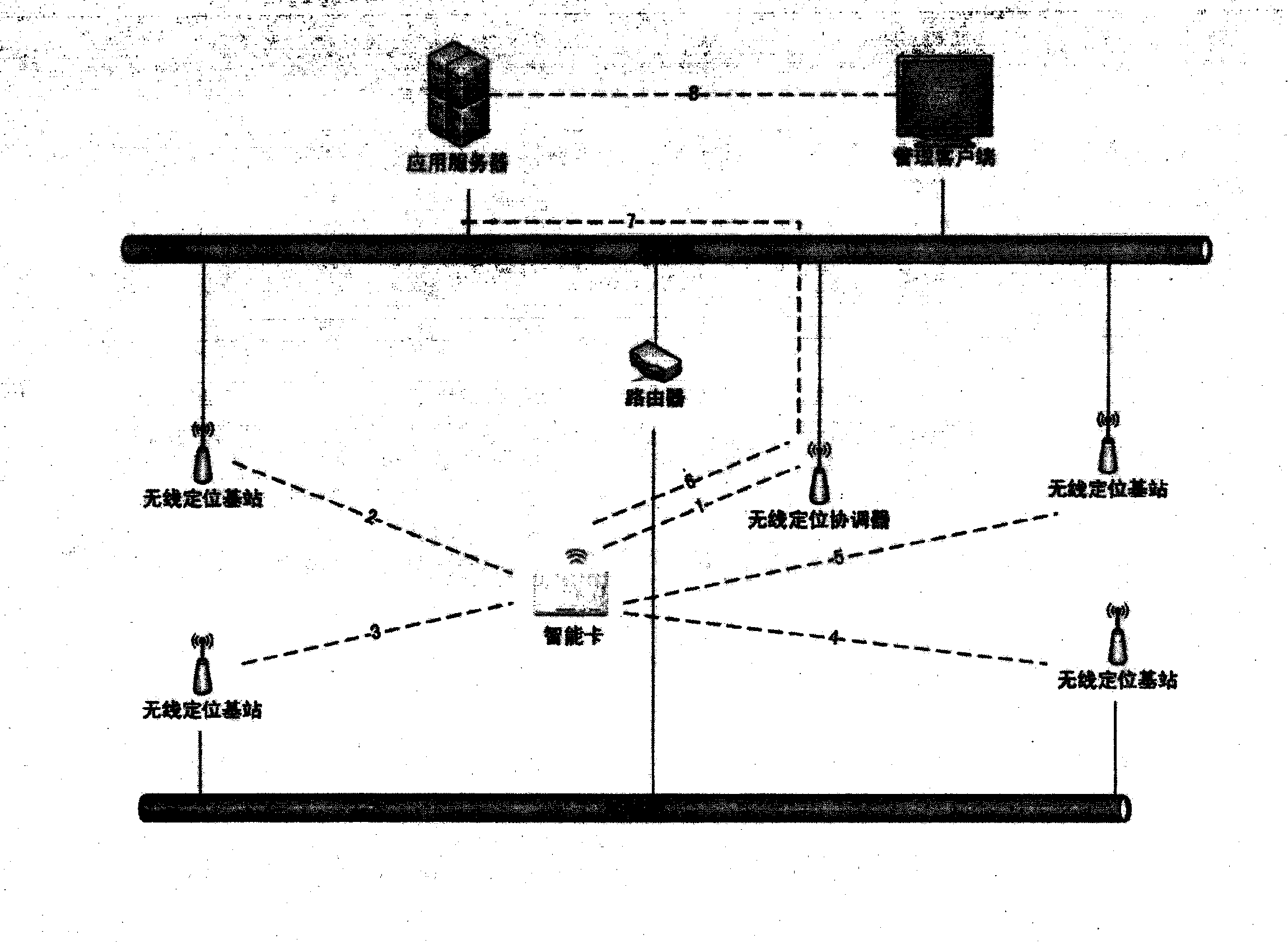

Intelligent parking lot management system and management method

ActiveCN103514641ARealize generationImplement queryTicket-issuing apparatusCommunications systemControl system

The invention provides an intelligent parking lot management system which comprises an entrance and exit management and charging system, a location and navigation system, a parking stall control system, a data communication system, a data service system, an administrative client system and a network function service system. The invention also provides an intelligent parking lot management method which comprises car entrance / exit management, client return and car-search management and car location and navigation methods. According to the invention, intelligent parking lot management automation can be realized, and a parking lot can be managed highly efficiently and accurately. Thus, costs of manpower and material resources are saved greatly.

Owner:YUYAO JINGCHENG HIGH & NEW TECH

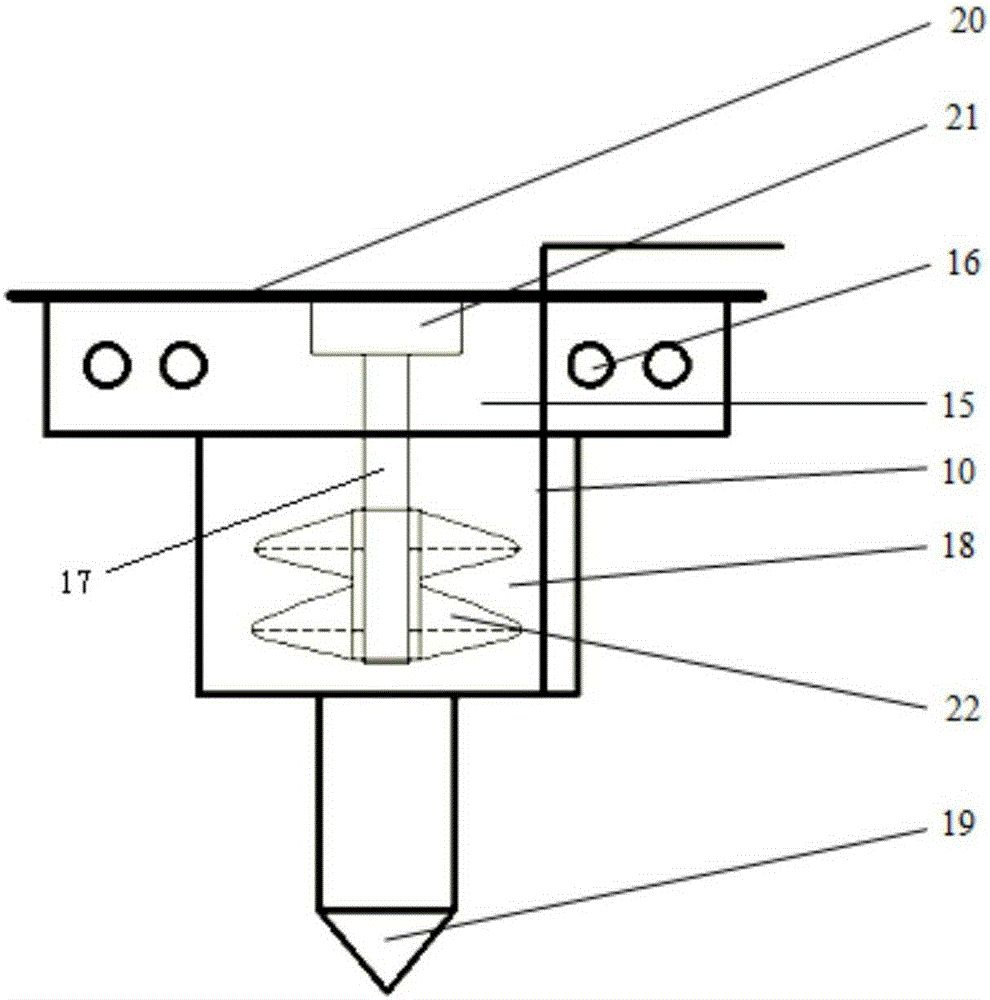

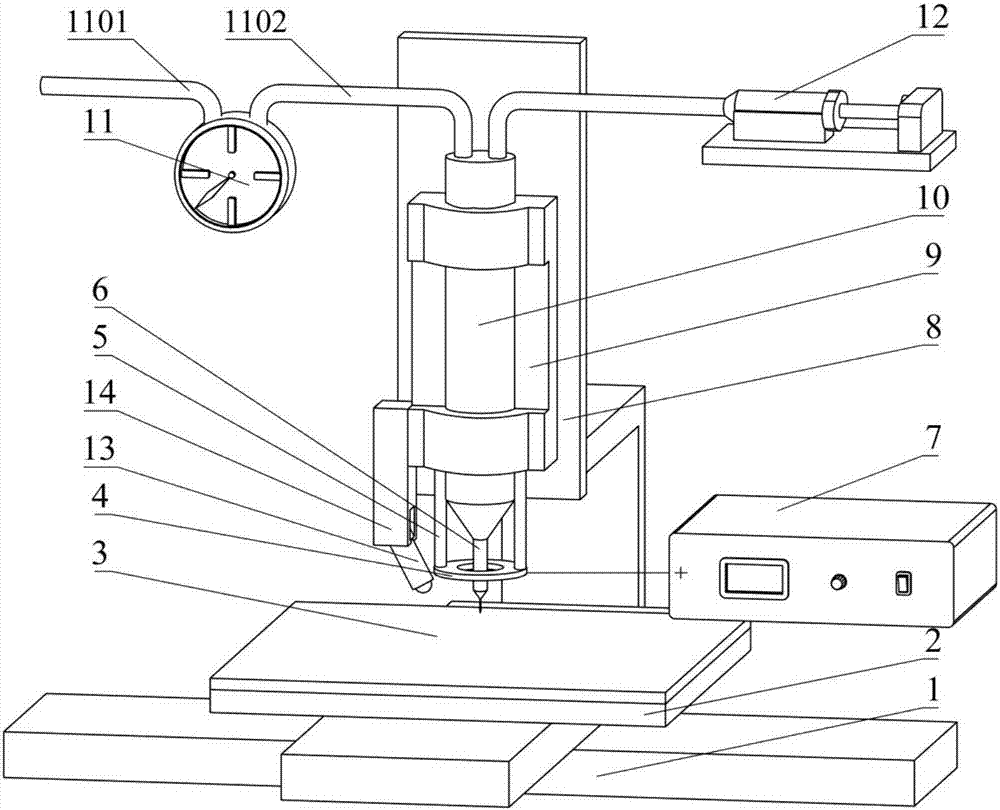

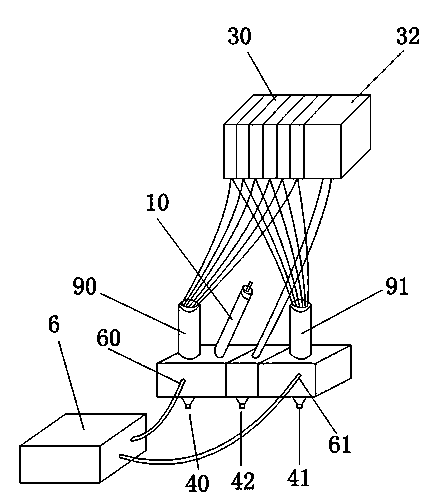

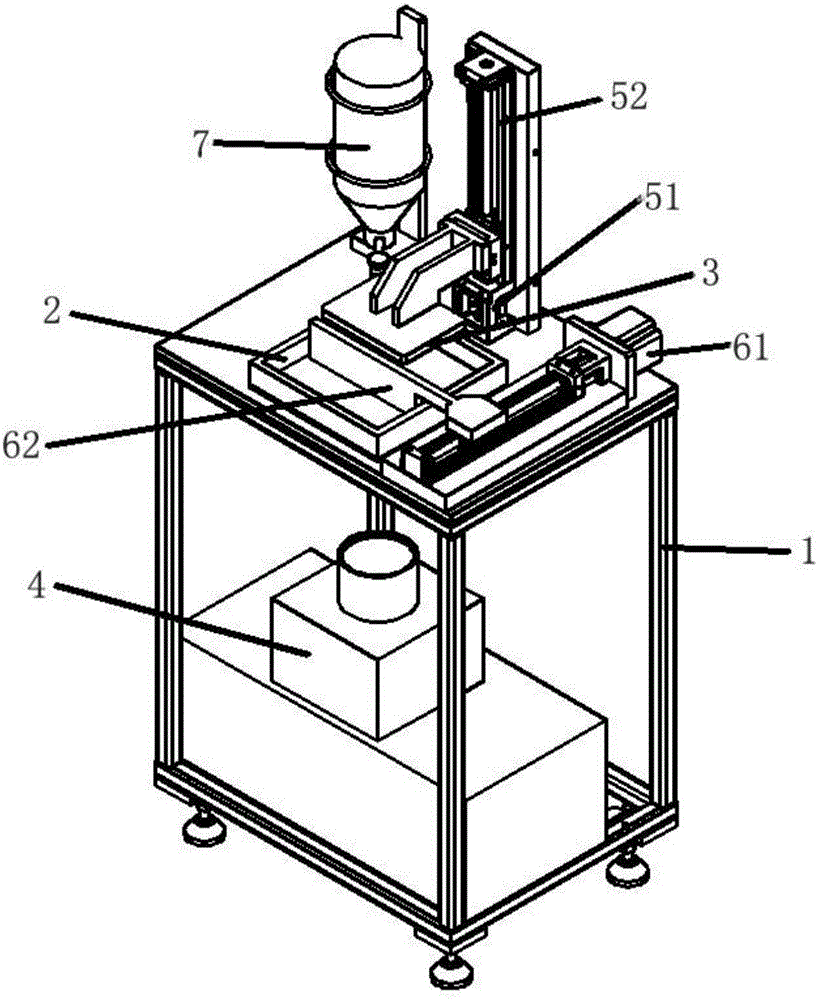

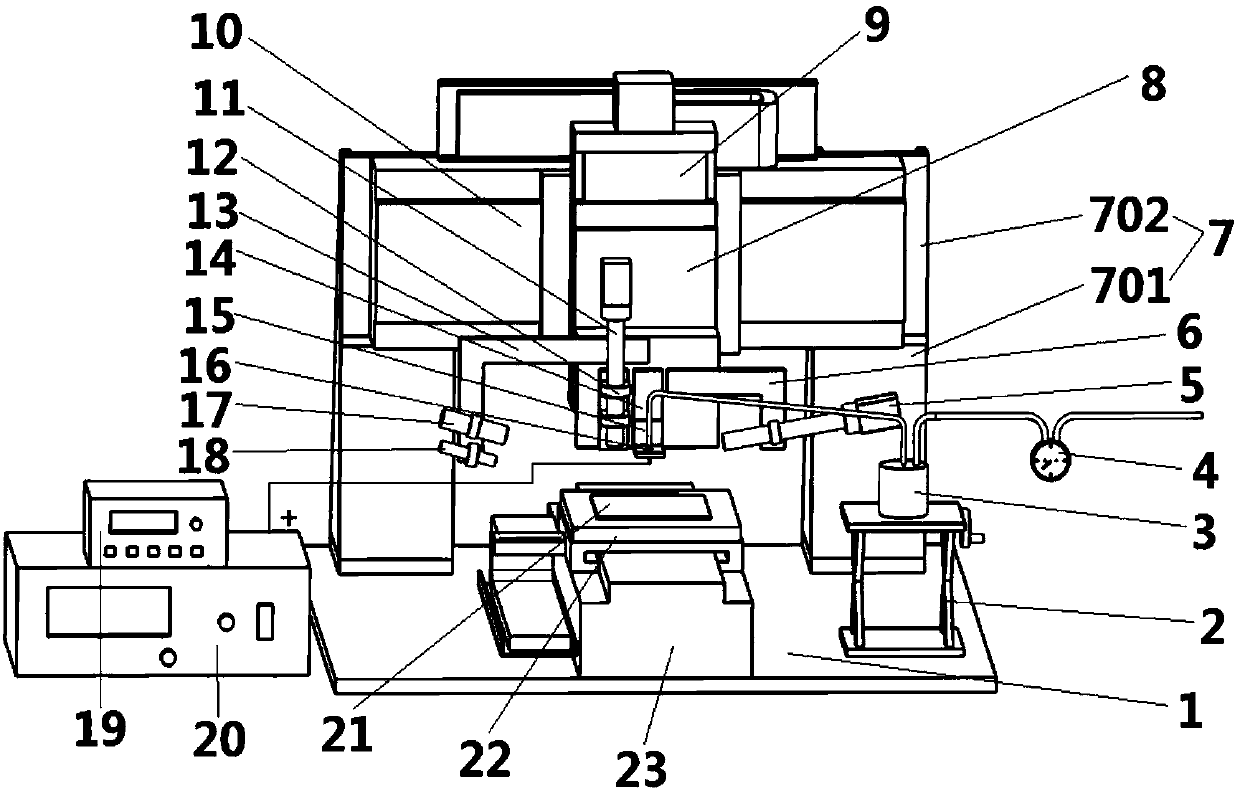

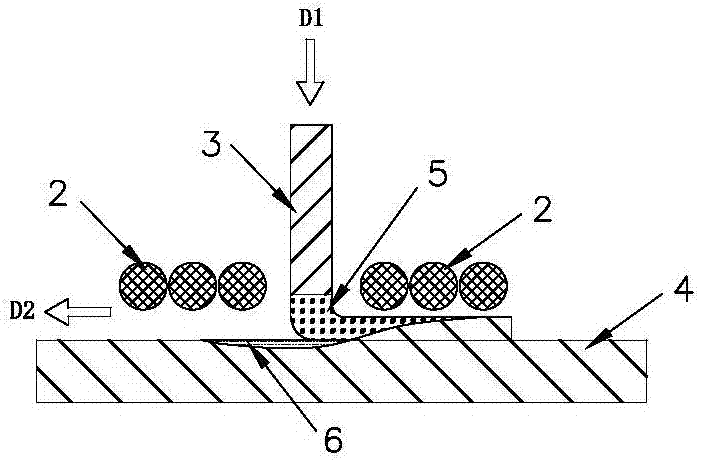

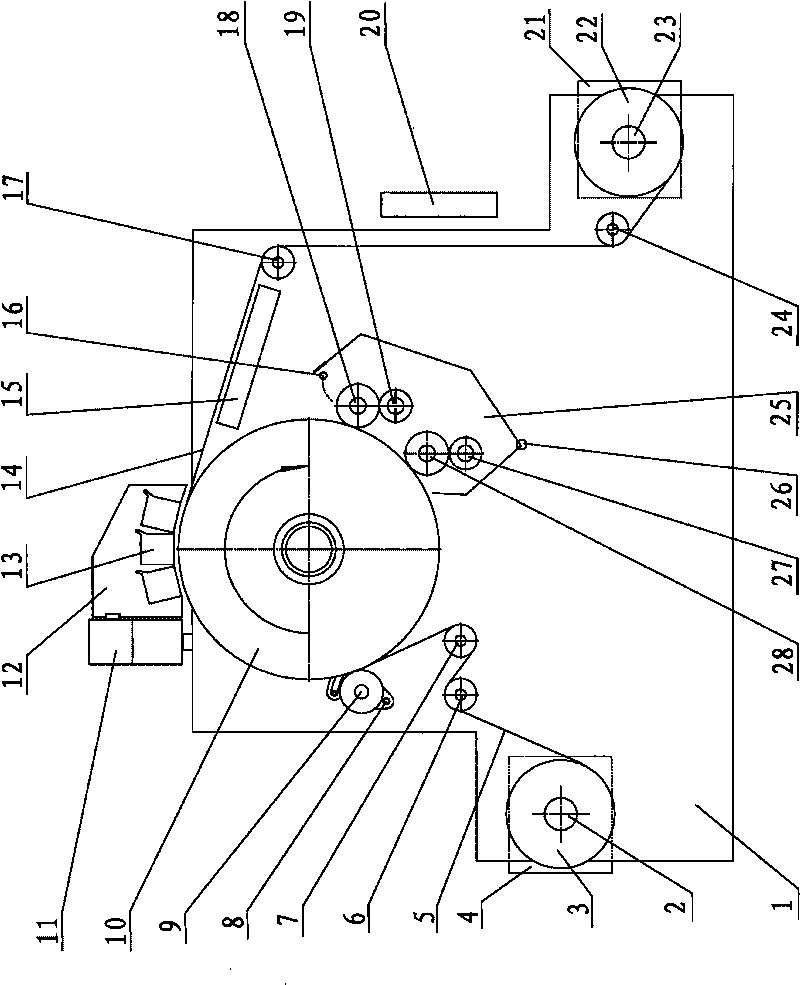

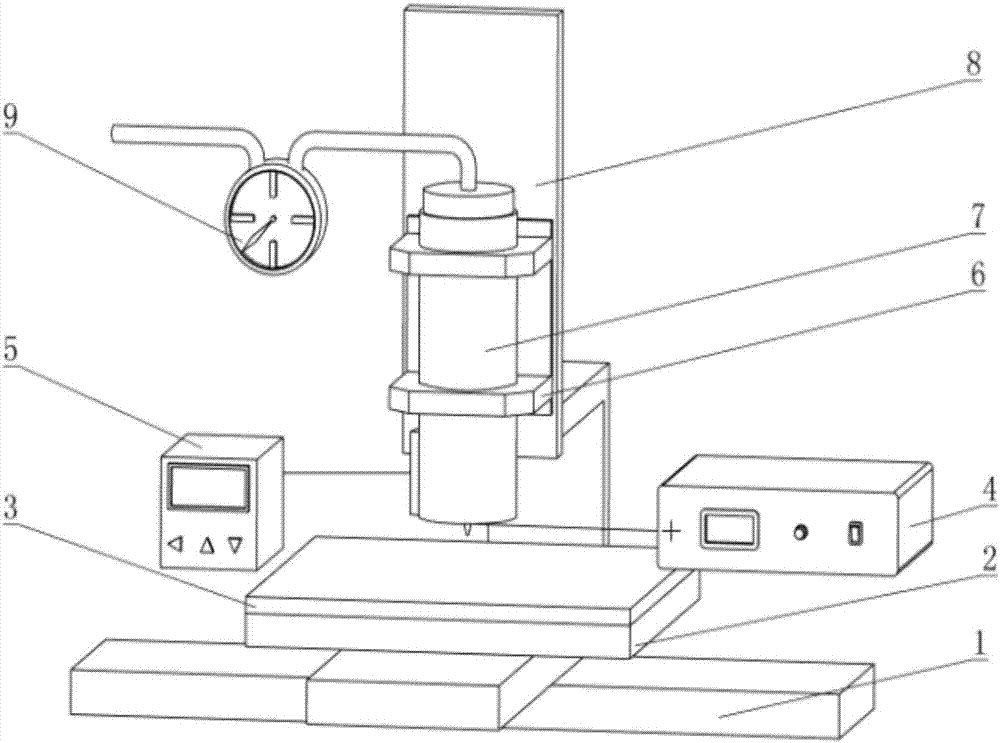

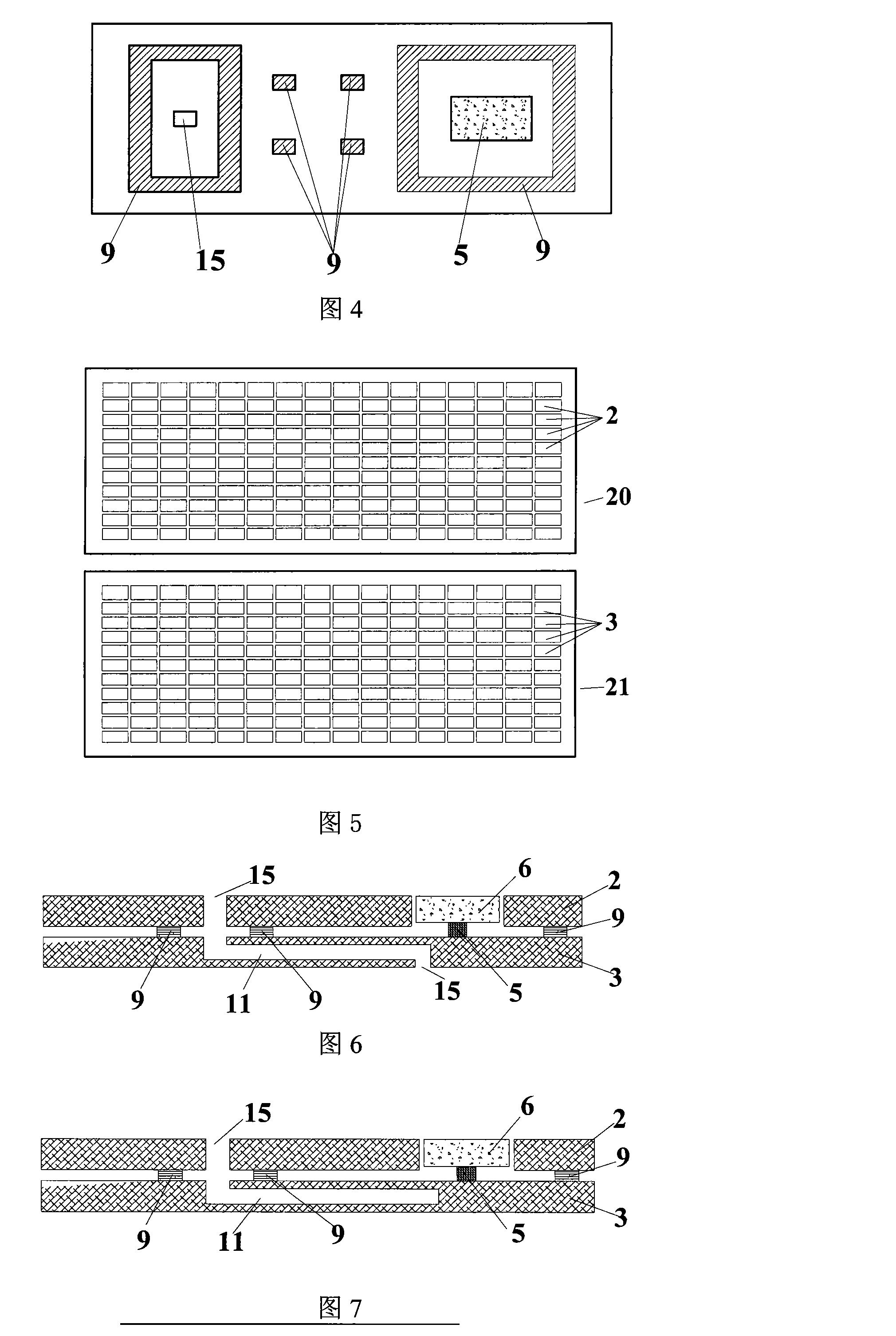

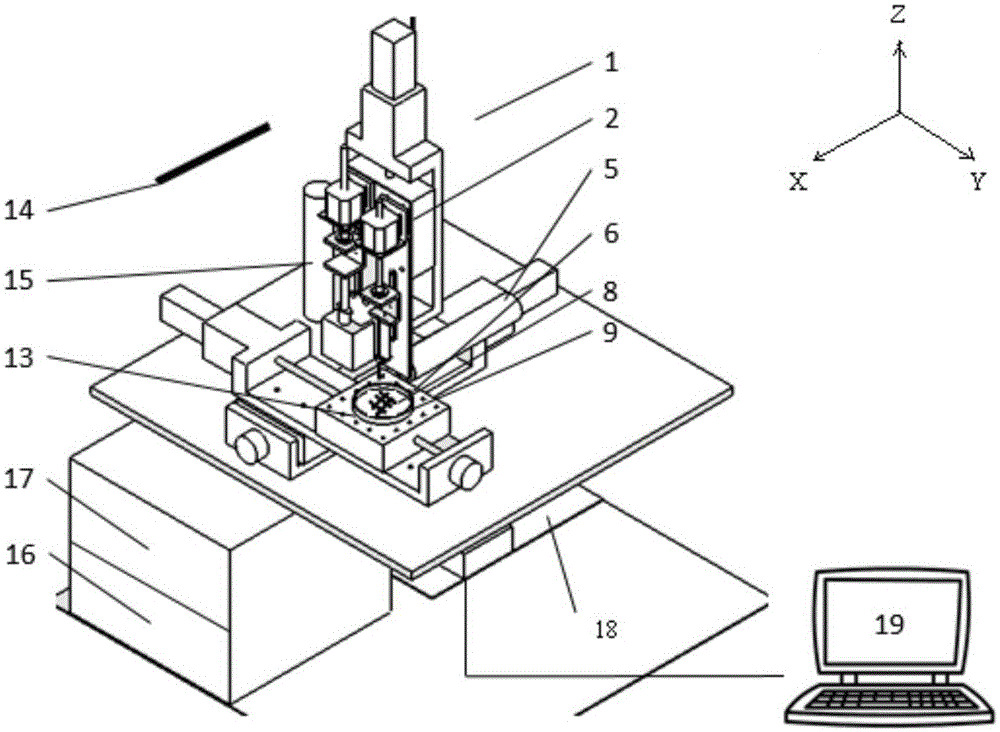

Electric field driving jetting deposition 3D printing device and working method thereof

ActiveCN107214945AStable printingConsider printing accuracyManufacturing driving meansCeramic shaping apparatusMulti materialElectric field

The invention discloses an electric field driving jetting deposition 3D printing device and a working method thereof. The limits of the aspects, such as printing materials, receiving substrates, the resolution, of existing material jetting deposition 3D printing are broken through, especially the multiple-spraying-head technology is combined, and multi-scale multi-material structure integration 3D printing can be realized. According to the technical scheme of the electric field driving jetting deposition 3D printing device, a two-dimensional worktable is included and provided with a printing platform; a receiving substrate is arranged on the printing platform in an adsorbed mode; a jetting unit is arranged on the upper portion of the receiving substrate correspondingly; the jetting unit is connected with a Z-direction worktable and comprises an electric field generating electrode and a printing spraying head; the printing spraying head is arranged in an electric field area formed by the electric field generating electrode; the electric field generating electrode is connected with a positive pole of a high-voltage pulsed power supply; the printing spraying head comprises a nozzle and a storage cylinder which are mutually connected; and the storage cylinder is connected with a back pressure control unit and a printing material supply unit.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

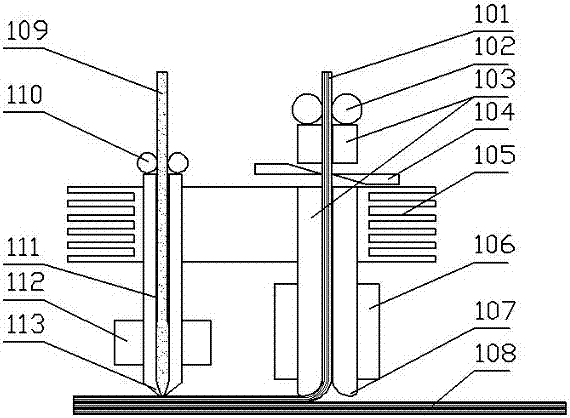

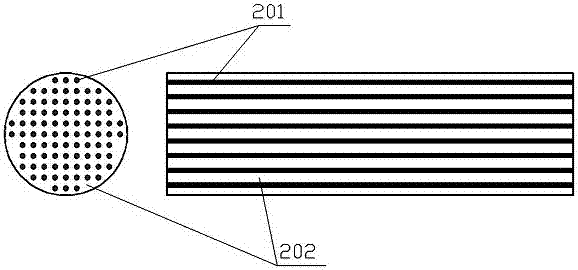

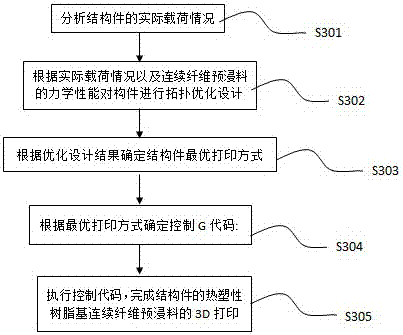

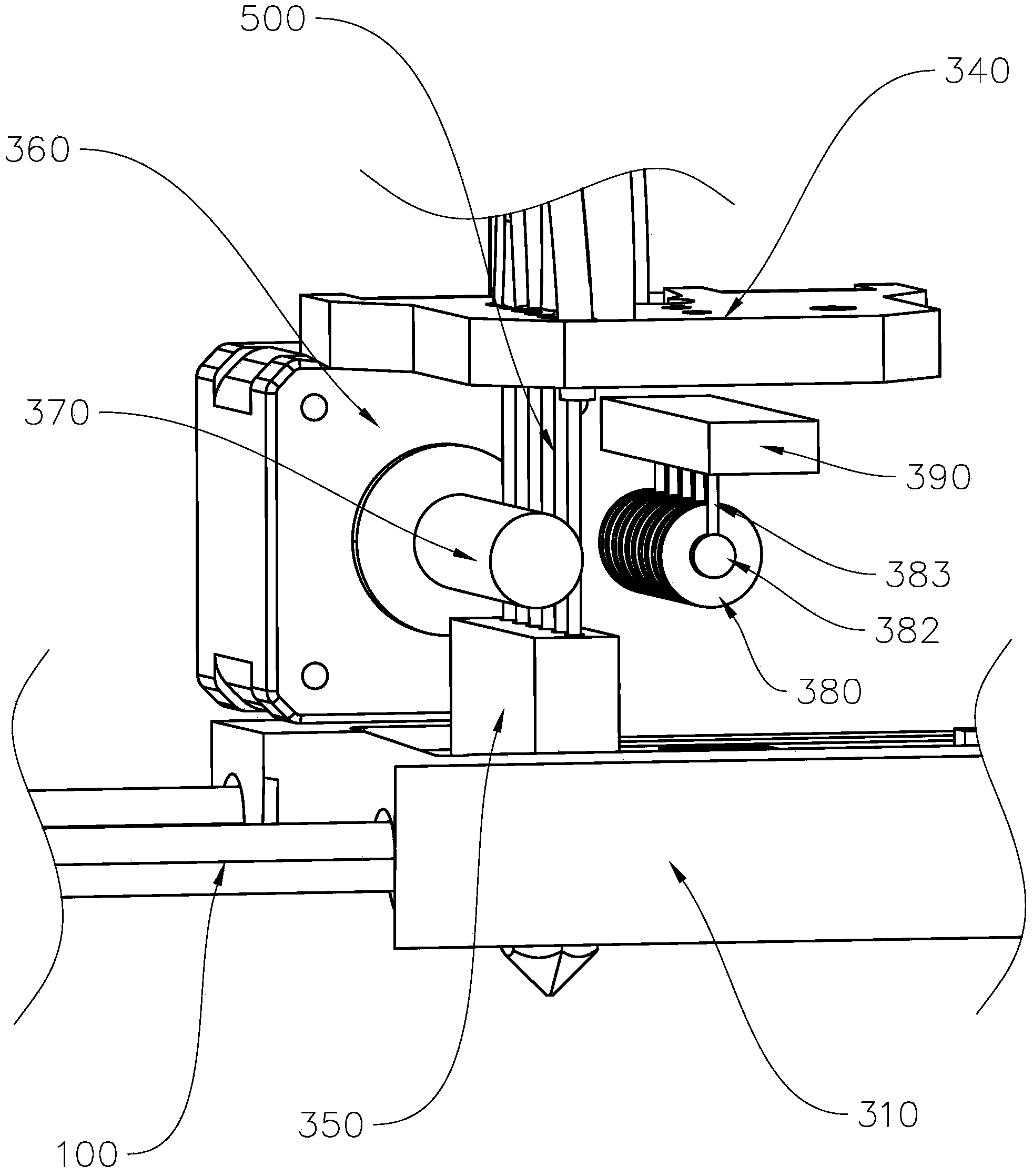

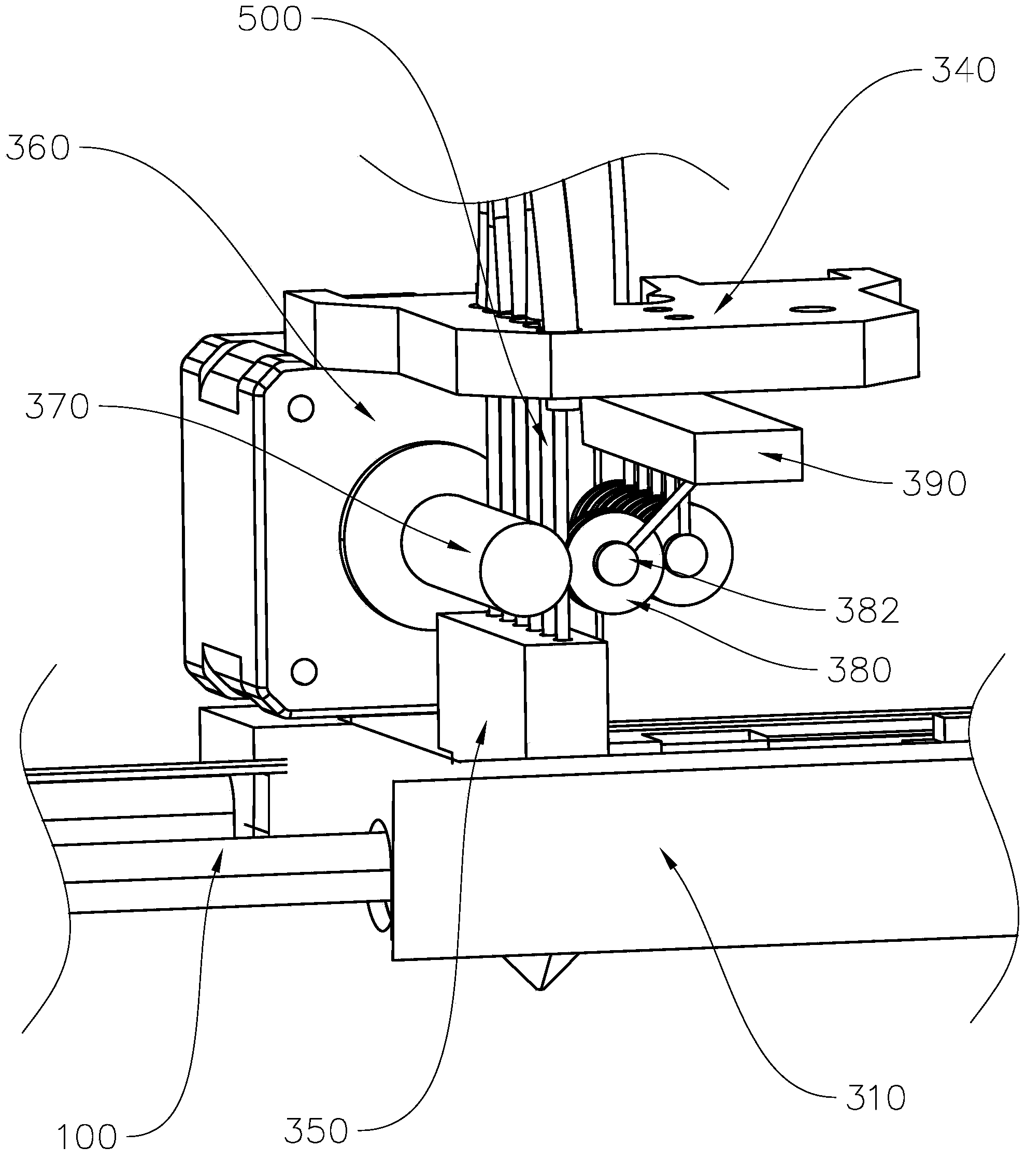

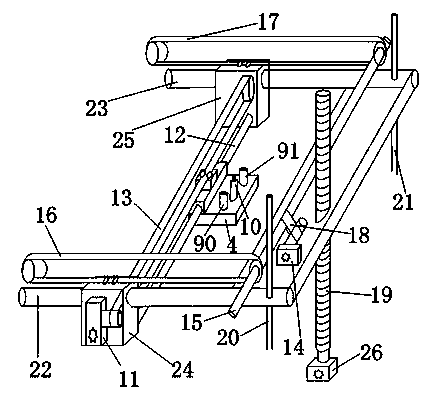

Double-spray-nozzle 3D printing system and method of thermoplastic resin base continuous fiber prepreg material

InactiveCN106863772AReduce usageHigh strength3D object support structuresManufacturing data aquisition/processingFiberSpray nozzle

The invention provides a double-spray-nozzle 3D printing system and method of a thermoplastic resin base continuous fiber prepreg material. Double spray nozzles include a thermoplastic resin base continuous fiber prepreg material printing spray nozzle and a thermoplastic pure resin printing spray nozzle. The thermoplastic resin base continuous fiber prepreg material printing spray nozzle has the functions of thermoplastic resin base continuous fiber prepreg material feeding, guiding, clipping, heating and printing compaction, and all functions can be controlled through G codes. By the adoption of the method, the optimal design of a structural part to be printed is conducted according to the practical load condition, then 3D printing of the thermoplastic resin base continuous fiber prepreg material is conducted according to a mechanical optimized structure, and therefore the printed structural part enables thermoplastic resin base continuous fibers to achieve the highest utilization ratio, the consumption of raw materials is reduced, and the processing cost is reduced. In addition, the design of the double spray nozzles can achieve printing of parts with cantilever structures, and the cantilever structure portions can be printed and supported by the use of the thermoplastic pure resin printing spray nozzle.

Owner:SHANGHAI UNIV +1

3D printer and printing method thereof

The invention provides a 3D printer. The 3D printer comprises a rail, a printing head, a heating chamber, a nozzle, filament materials and a line changeover seat, wherein a feeding hole and a discharge hole are formed in the line changeover seat; the inside of the line changeover seat is penetrated so as to form a line guide groove; a motor and a driving roller serve as driving parts; the filament materials are adjacently connected with the driving roller; a controller and driven wheels serve as control parts; at least two driven wheels are two; with action of the controller, one of the driven wheels is adjacently connected with or detached from the driving roller. The 3D printer provided by the invention can finish the printing process of multiple filament materials, randomly switches the filament materials, and is simple in structure and low in cost. The invention further provides a method of using the 3D printer.

Owner:PRINT RITE UNICORN IMAGE PROD CO LTD

Three-dimensional color printing device and method

ActiveCN105500700AImprove printing accuracyFast molding speedAdditive manufacturing apparatusAutomatic controlControl system

The invention discloses a three-dimensional color printing device and method. The three-dimensional color printing device comprises a print area, a feeding system, a nozzle group, a moving mechanism and an automatic control system, wherein the print area is provided with a forming plate and a forming work pool, and the forming plate is provided with a lifting mechanism which is used for drawing a workpiece curing layer; the feeding system comprises a support material feeding box and a solid material feeding box and is used for supplying print raw materials for the nozzle group; the nozzle group comprises at least one solid material nozzle and a support material nozzle, the solid material nozzle is connected with the solid material feeding box of the feeding system through a premixer, and the support material nozzle is connected with the support material feeding box of the feeding system; andthe moving mechanism is provided with motors and guide posts / rods on the X-axis direction, the Y-axis direction and the Z-axis direction and is used for driving the nozzle group for performing mobile printing on the three-dimensional direction. The three-dimensional color printing device has the characteristics of being high in print accuracy and smooth and clean in surface of formed products and can realize color printing and printing of different photosensitive materials.

Owner:QINGDAO ACADEMY OF INTELLIGENT IND

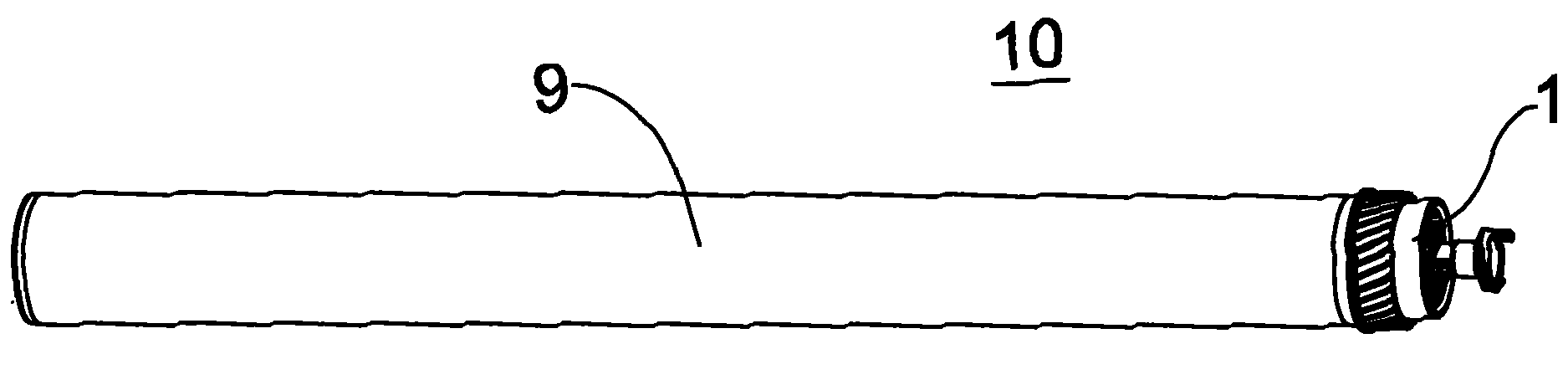

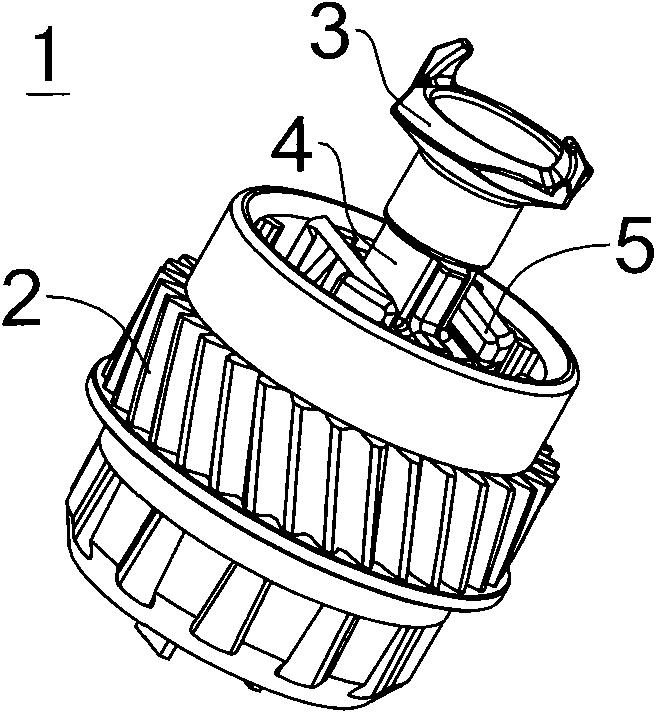

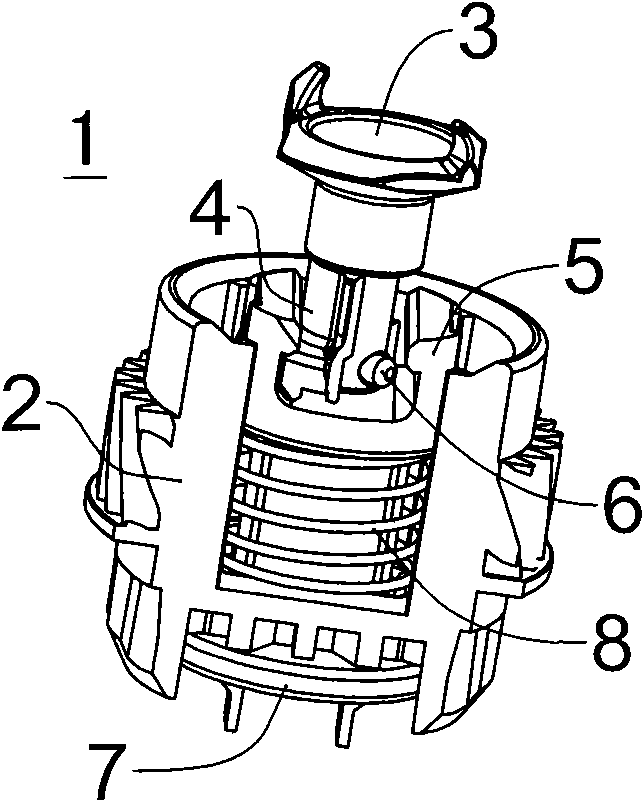

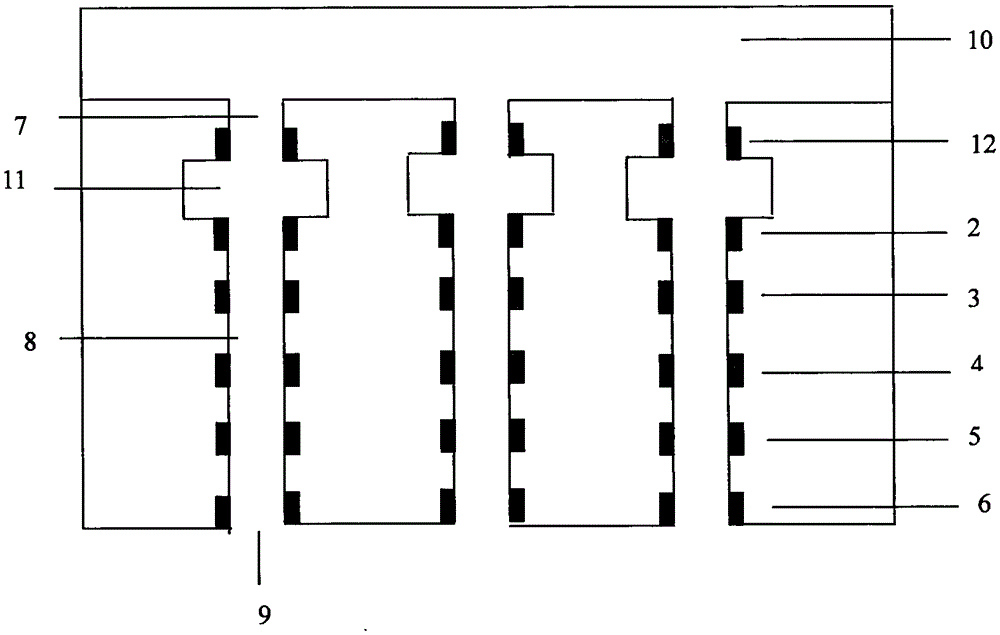

Photosensitive drum driving assembly

ActiveCN101907858AGuaranteed Stability and ReliabilityEasy assemblyElectrographic processEngineeringGear wheel

The invention provides a photosensitive drum driving assembly which comprises a gear wheel and an adjusting assembly, wherein the gear wheel is closely fitted at one end of a photosensitive drum; the adjusting assembly comprises a rotary driving force receiving head which extends out of the gear wheel; the adjusting assembly can be arranged in the gear wheel to move in reciprocating translation relative to the gear wheel along the axial direction of the photosensitive drum and a first direction vertical to the axial direction, and an elastic support part and an axial limit part are arranged between the adjusting assembly and the gear wheel; and the rotation driving force receiving head can be rotatably arranged on the adjusting assembly around the axis per se. Compared with the prior art, the photosensitive drum driving assembly allows simple and convenient assembly, and has stable structure performance; and a processing box in which the photosensitive driving assembly is adopted ensures stable disembarking and stable operation and has reliable performance.

Owner:PRINT RITE UNICORN IMAGE PROD CO LTD OF ZHUHAI

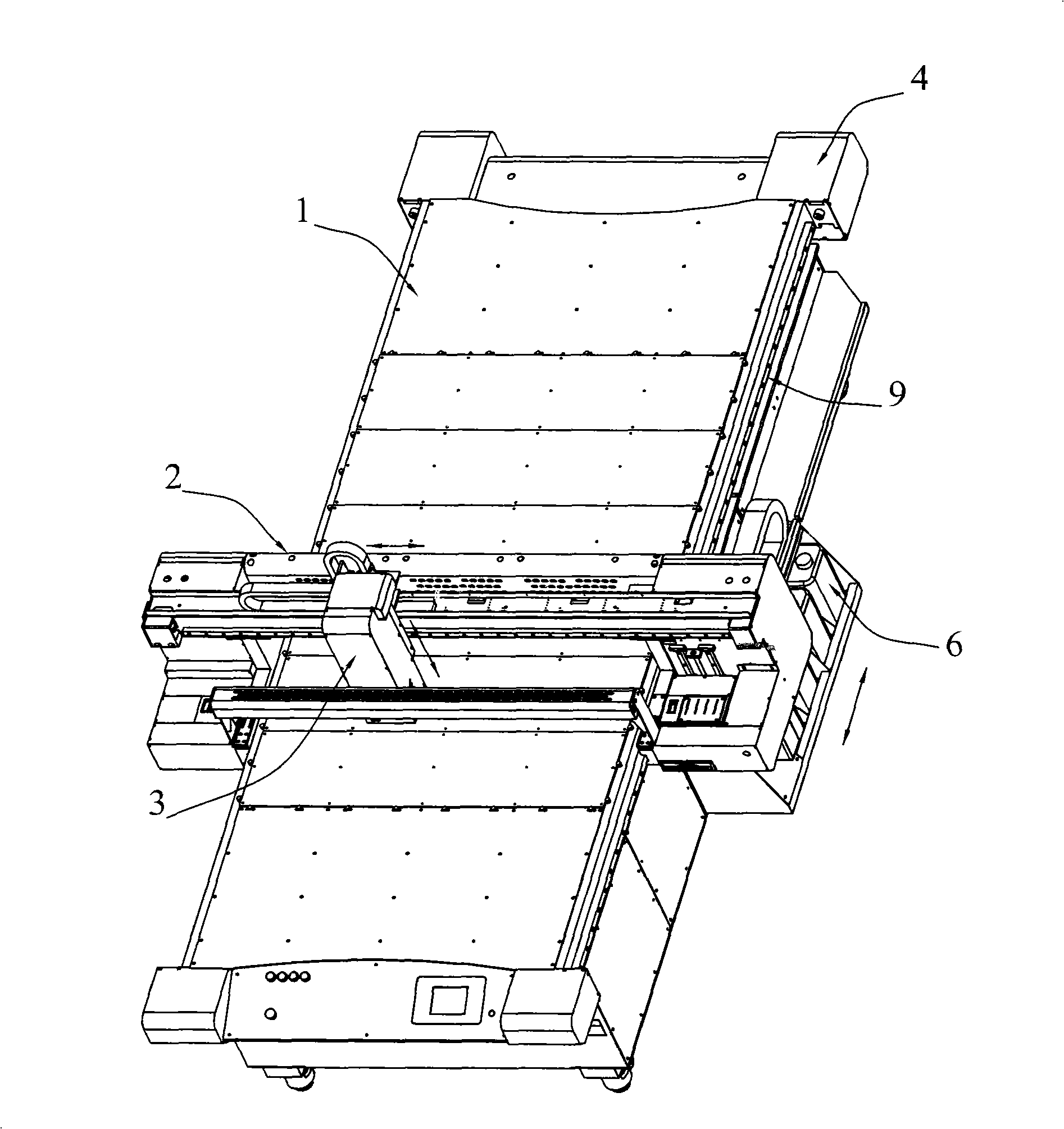

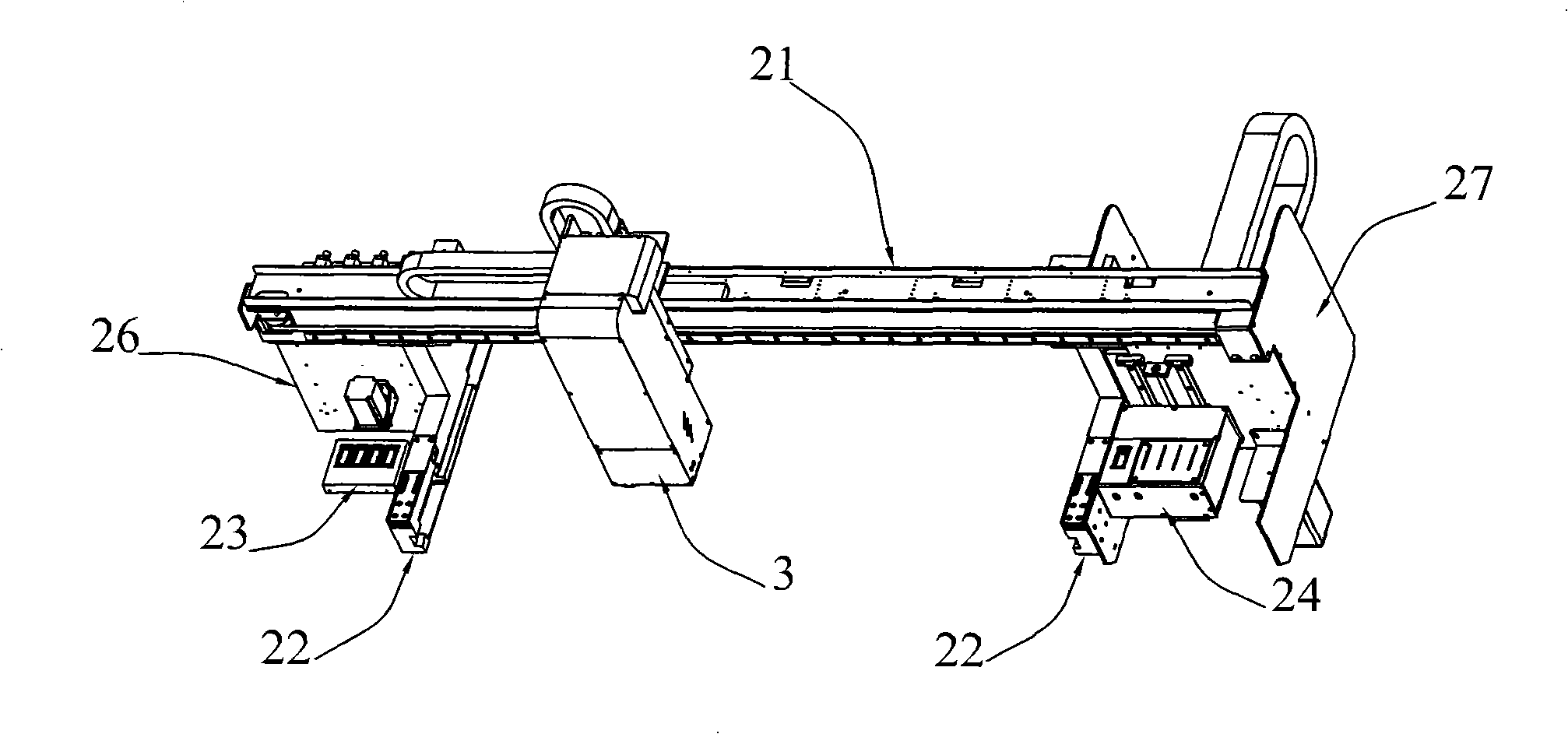

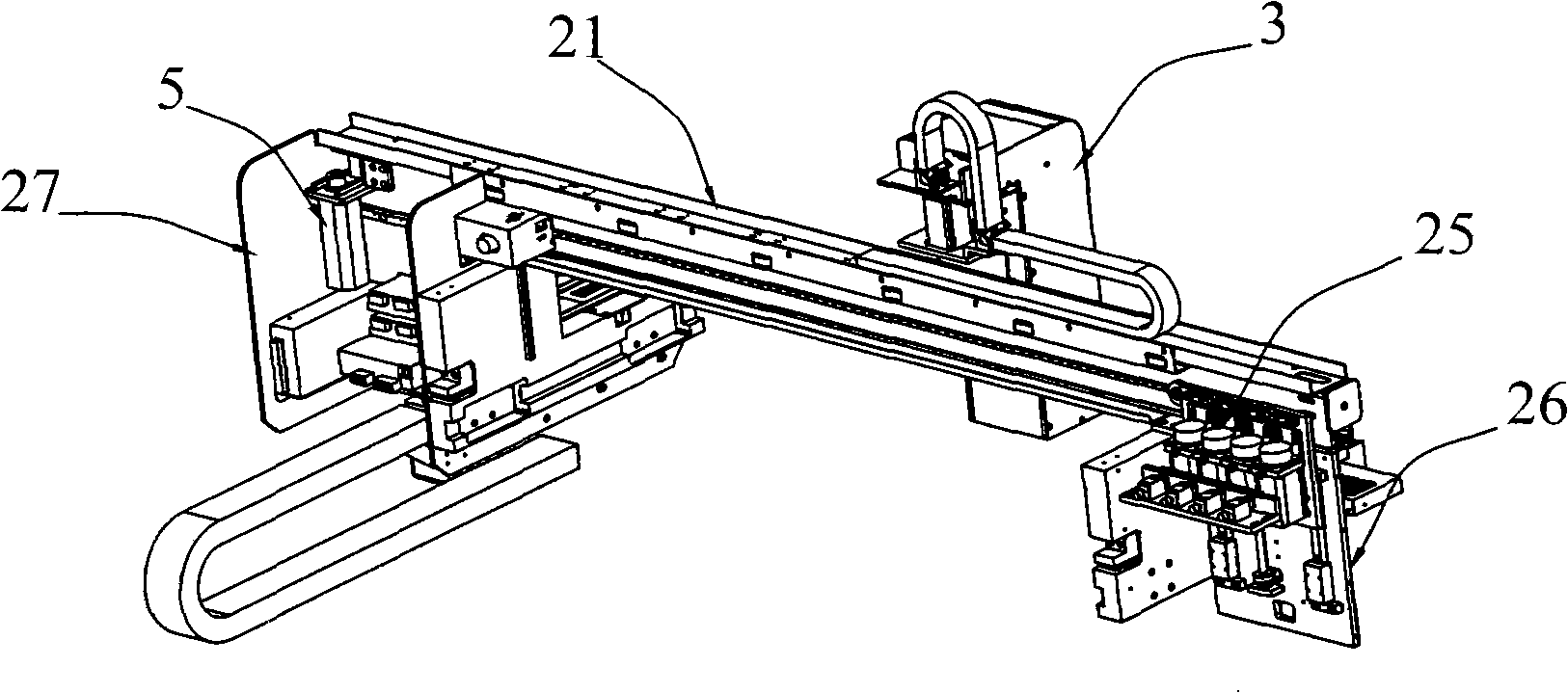

Print mechanism of flat-panel printer

The invention relates to the field of printers, which aims at overcomes the shortages in the prior art and provides a completely novel plate printer printing mechanism with high efficiency and easy control. The plate printer printing mechanism mainly comprises two parts: a jet car and a printing sprinkler, wherein, the jet car is composed of two sliding seats and a crossbeam used for connecting the two sliding seats; the printing sprinkler is arranged on the crossbeam and has two DOFs: left movement and right movement along the crossbeam and lifting vertically to the crossbeam; the sliding seat of the jet car is provided with a transmission box used for driving the printing sprinkler to move to the left side and the right side; the printing sprinkler is internally provided with a lifting mechanism which drives the printing sprinkler to be lifted. The plate printer printing mechanism is arranged on a fixed printing platform, the jet car can longitudinally move along the platform, the printing sprinkler can transversely move along the jet car, thus realizing the planar printing. The height of the printing sprinkler can be freely adjusted; the printing sprinkler is suitable for the products with different thickness, and realizes the printing of solid articles.

Owner:汤振华

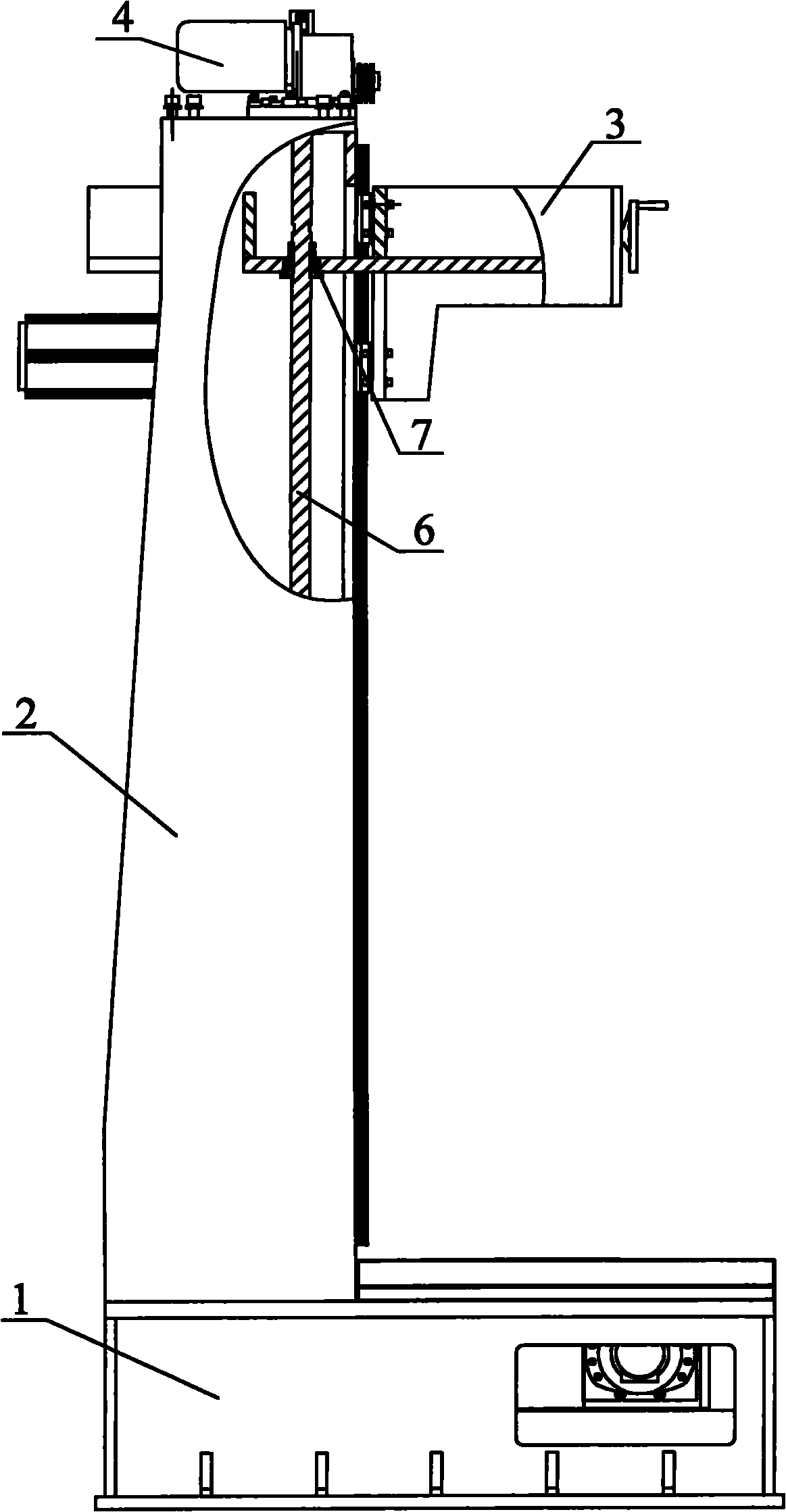

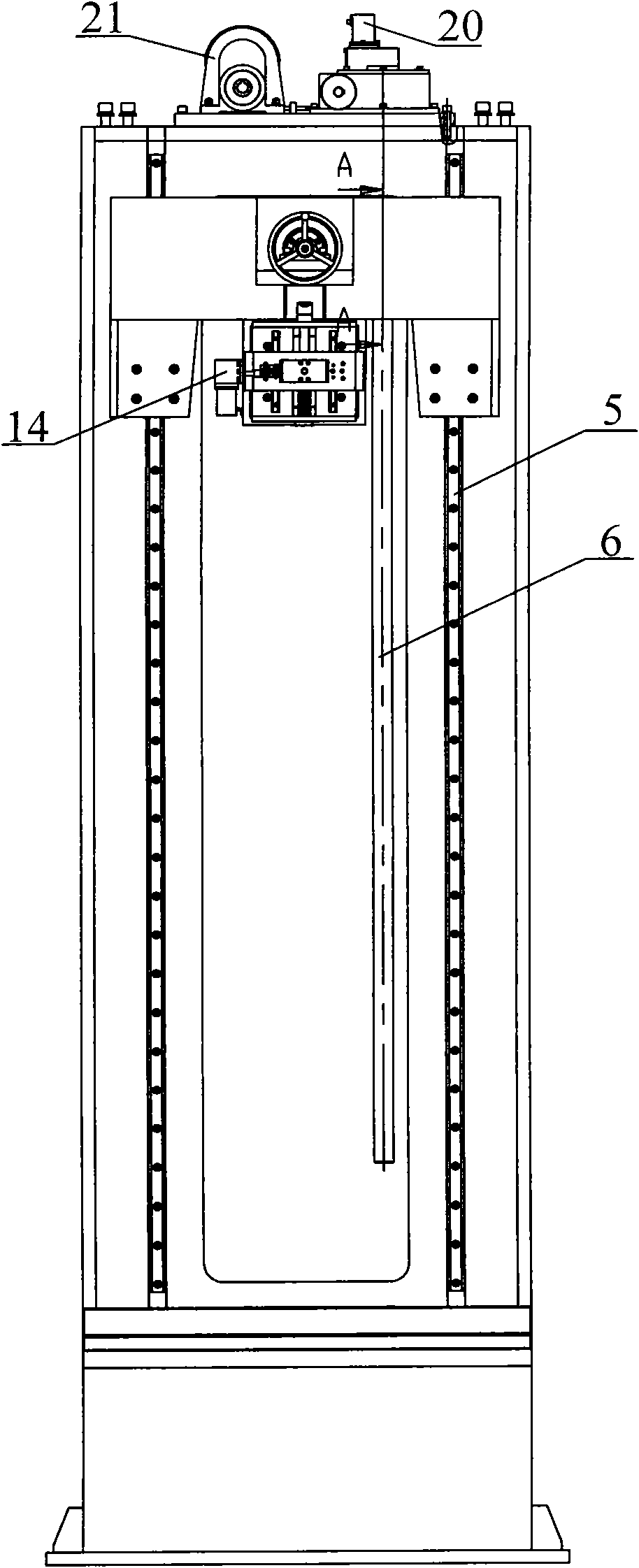

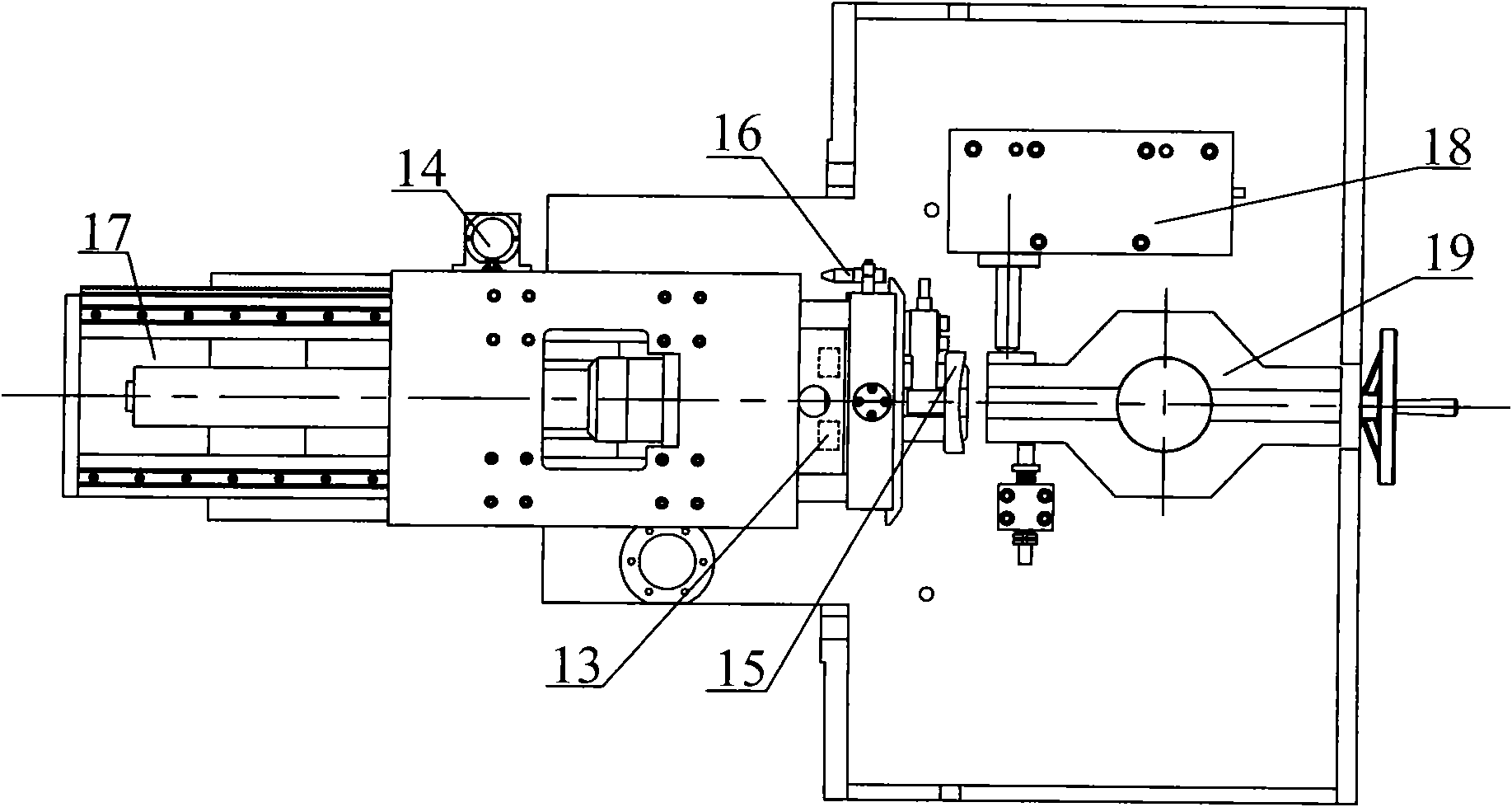

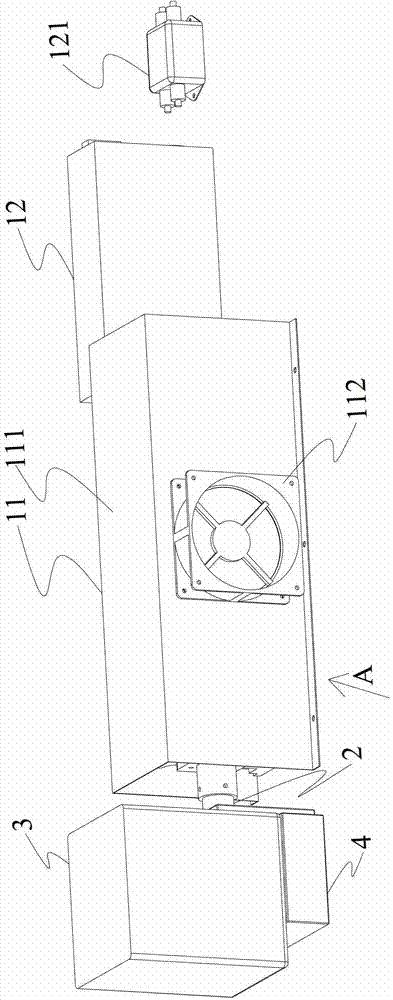

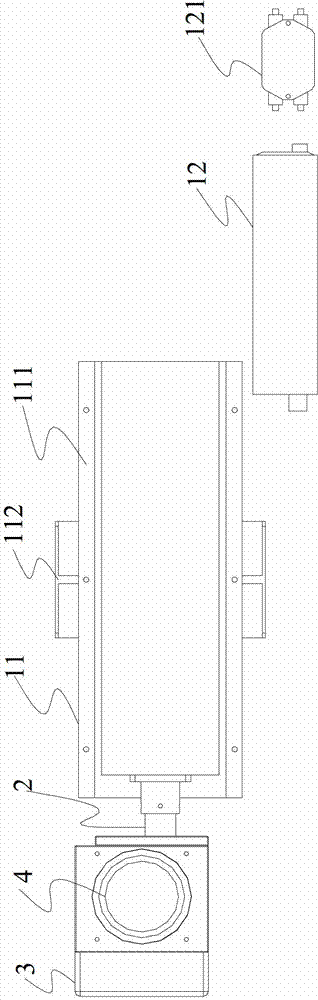

Equipment for testing bending and torsion resisting performances of electrical insulator

ActiveCN101788429AAchieve storageRealize printingMaterial strength using steady bending forcesMaterial strength using steady torsional forcesReducerEngineering

The invention relates to equipment for testing the bending and torsion resisting performances of an electrical insulator. The equipment is characterized in that: the equipment comprises a slewing worktable, an upright post, a cross beam assembly and a lifting driving mechanism; the upright post is vertically fixed above the slewing worktable; the lifting driving mechanism arranged at the top end of the upright post comprises a screw rod, a speed reducer and a lifting coder; the screw rod is connected with a screw rod nut in the upright post, the top part of the screw rod is connected with the speed reducer, a linear guide rail is arranged on the side wall of the upright post, and the cross beam assembly is connected with the upright post by the linear guide rail in a sliding manner; a bending pressure head, a bending load sensor, a bending displacement coder and a torsion block are arranged on the cross beam assembly; a bending oil cylinder is connected at the rear of the bending pressure head, the bending displacement coder is arranged on the bending oil cylinder, a torsion load sensor is arranged on the torsion block, and the position of a groove of the torsion block is corresponding to that of a test piece fixing seat on the slewing worktable. With the characteristics of saving space and being convenient for use, the equipment can accurately detect the bending and torsion resisting performances of the electrical insulator.

Owner:SHANDONG LIANMEI SPRINGS TECH CORP

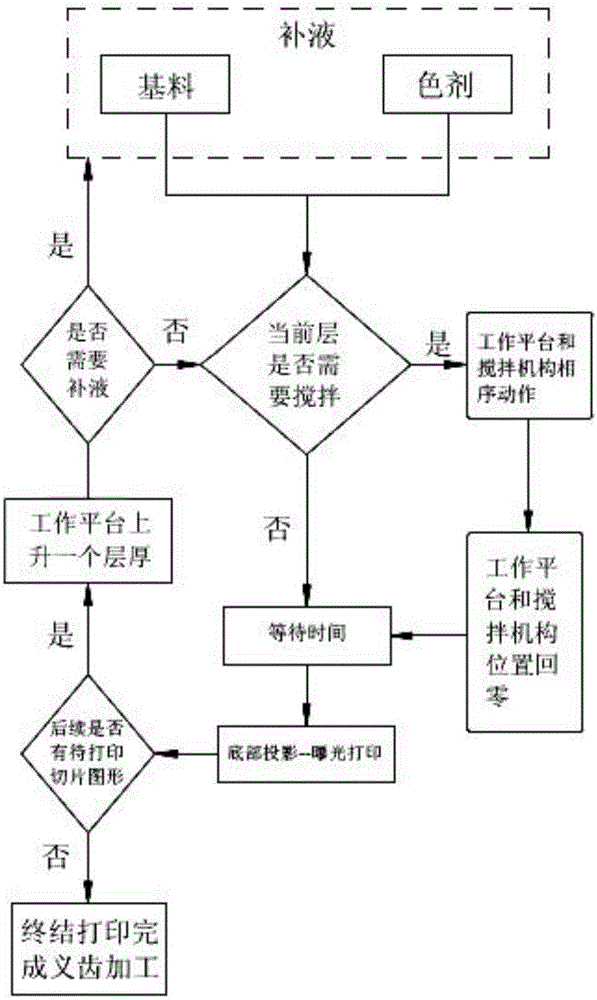

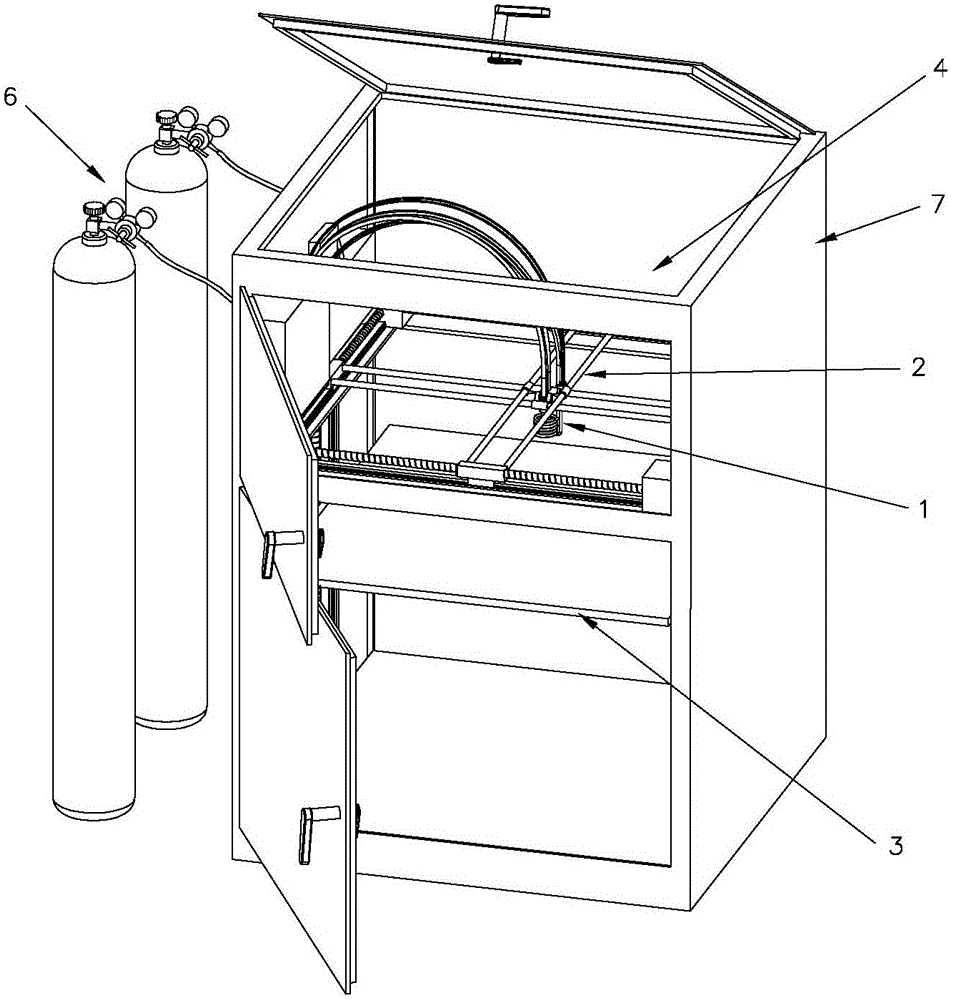

Method and device for ceramic denture 3D printing suitable for light curing molding

ActiveCN106217882AGuaranteed accuracyGuaranteed to mix evenlyAdditive manufacturing apparatusCeramic shaping apparatusData modelLight source

The invention relates to a method and device for ceramic denture 3D printing suitable for light curing molding and belongs to the technical field of tooth making. According to the method, through scanned tooth data and data processing, data of each layer of image after a data model to be printed is sliced are obtained and transmitted to a control system, a liquid supplementing action is controlled through the control system so that the liquid level of a base material can be always kept at the preset height, the base material is configured by photosensitive resin and ceramic powder according to the ratio, and the control system controls completion of stirring of supplemented liquid after liquid supplementing; and a bottom projection manner is adopted for printing, slice images of each layer of image are projected successively, light source exposure is conducted, and curing is completed layer by layer. The method and device have the beneficial effects that the making process is simple, the making efficiency is high, the consumption of materials is low, the making precision is high, and the match is good.

Owner:SHANGHAI UNION TECH

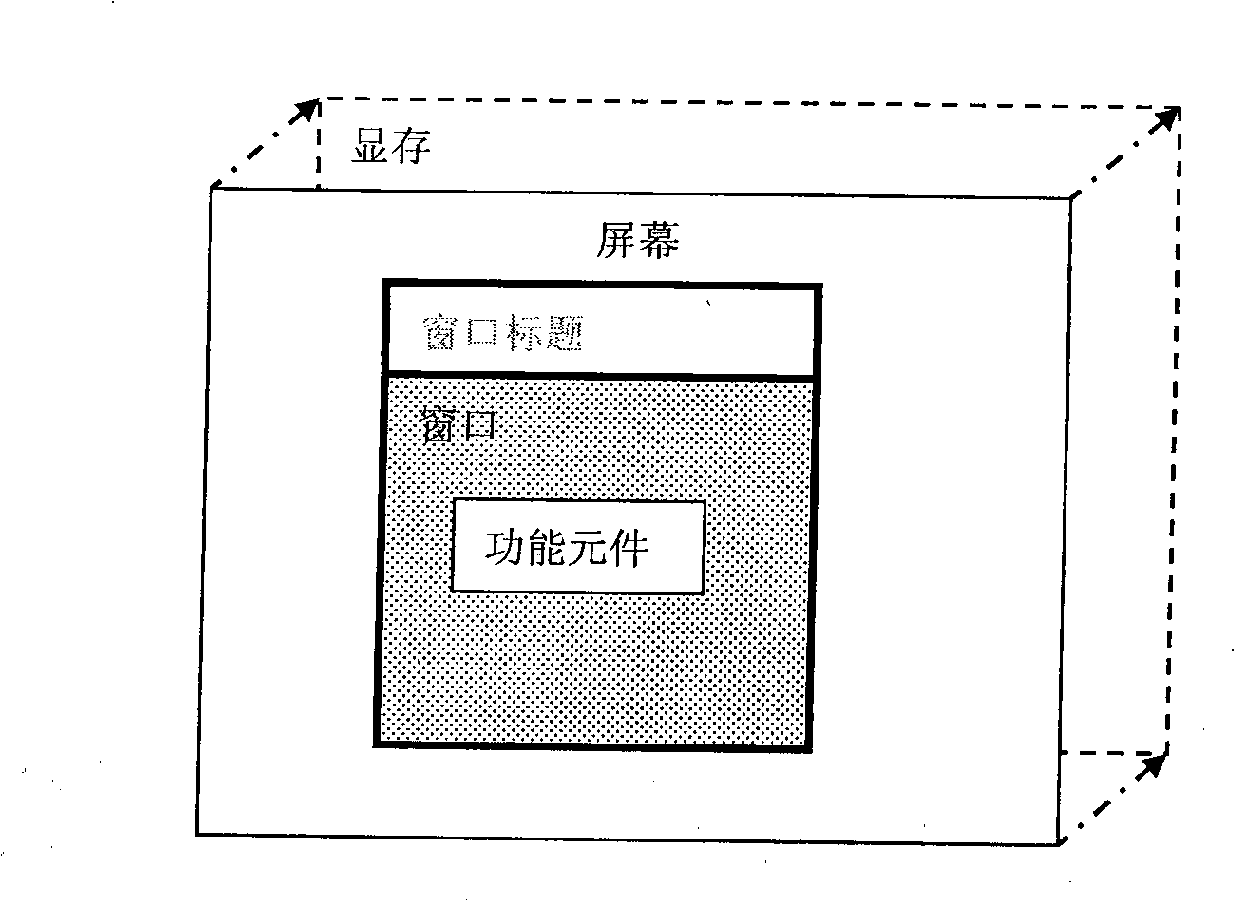

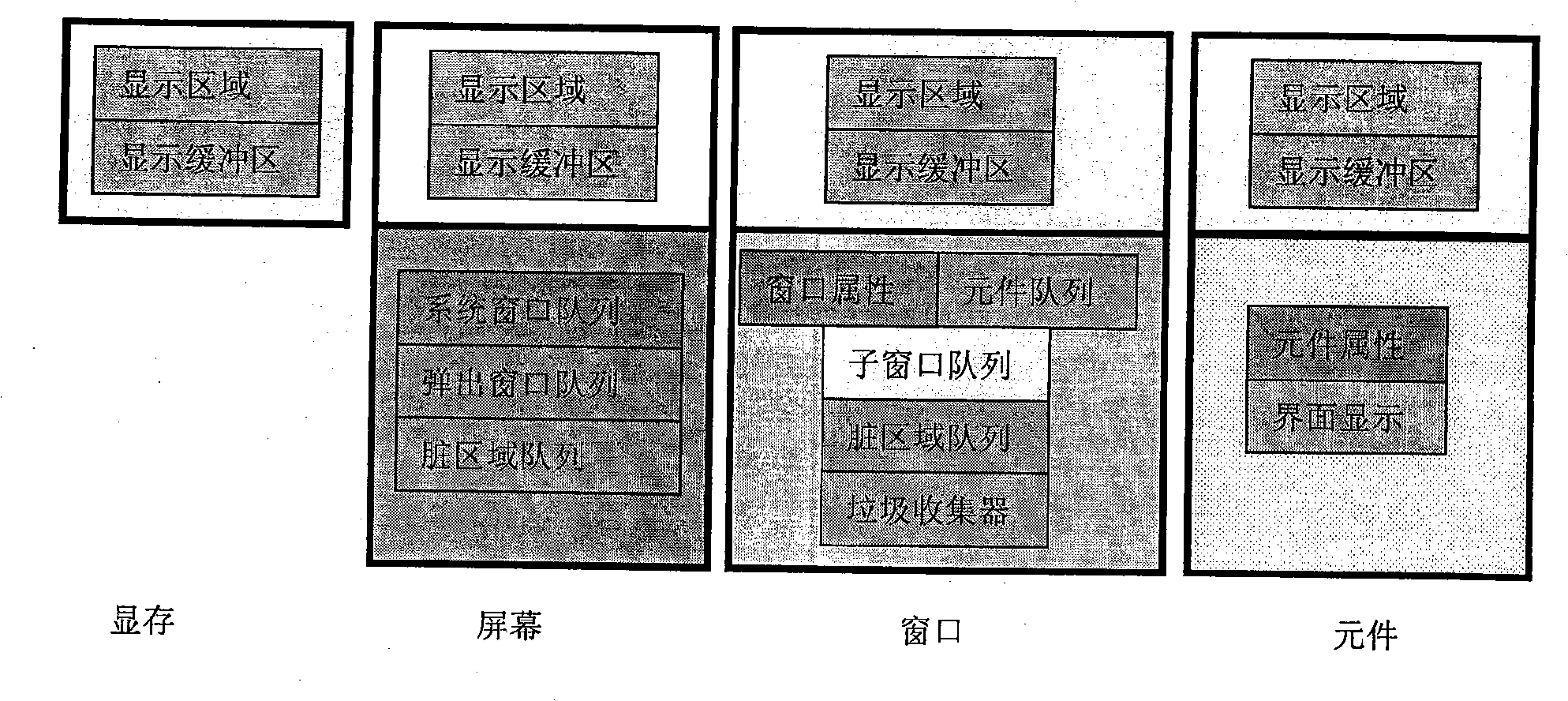

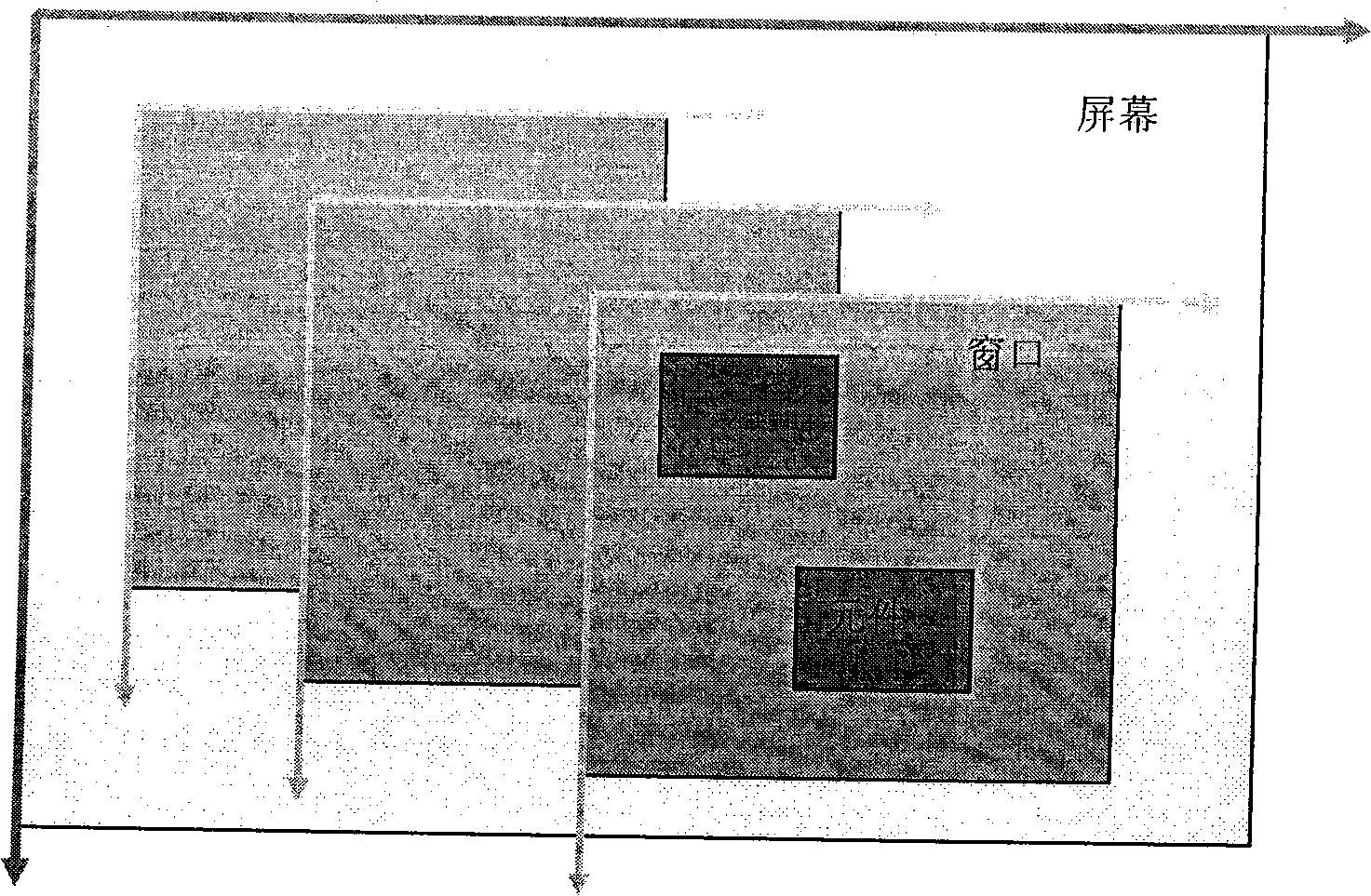

Multi-window manager of embedded graph system

ActiveCN101493751AEasy to transplantImprove portabilitySpecific program execution arrangementsInput/output processes for data processingGraphicsInformation processing

The invention discloses a multi-window managing system and a method used for an embedded system. The system comprises an information processing module for carrying out front-end operation used for processing the user information and outputting the change information of a window basic module area in a dirty area queue way, and a picture refresh module for carrying out back-end operation used for analyzing the transmitted dirty area queue and transmitting newest module area information to a screen display buffer area to complete display refresh. As the invention adopts a layered refresh method and an optimized dirty area queue algorithm to minimize the refresh operation calculation and supports a window junk collector, the invention has higher efficiency; and as a double-buffer display mechanism is adopted, the splash problem in picture refresh is avoided; therefore, the invention has better display effect.

Owner:上海步科自动化股份有限公司

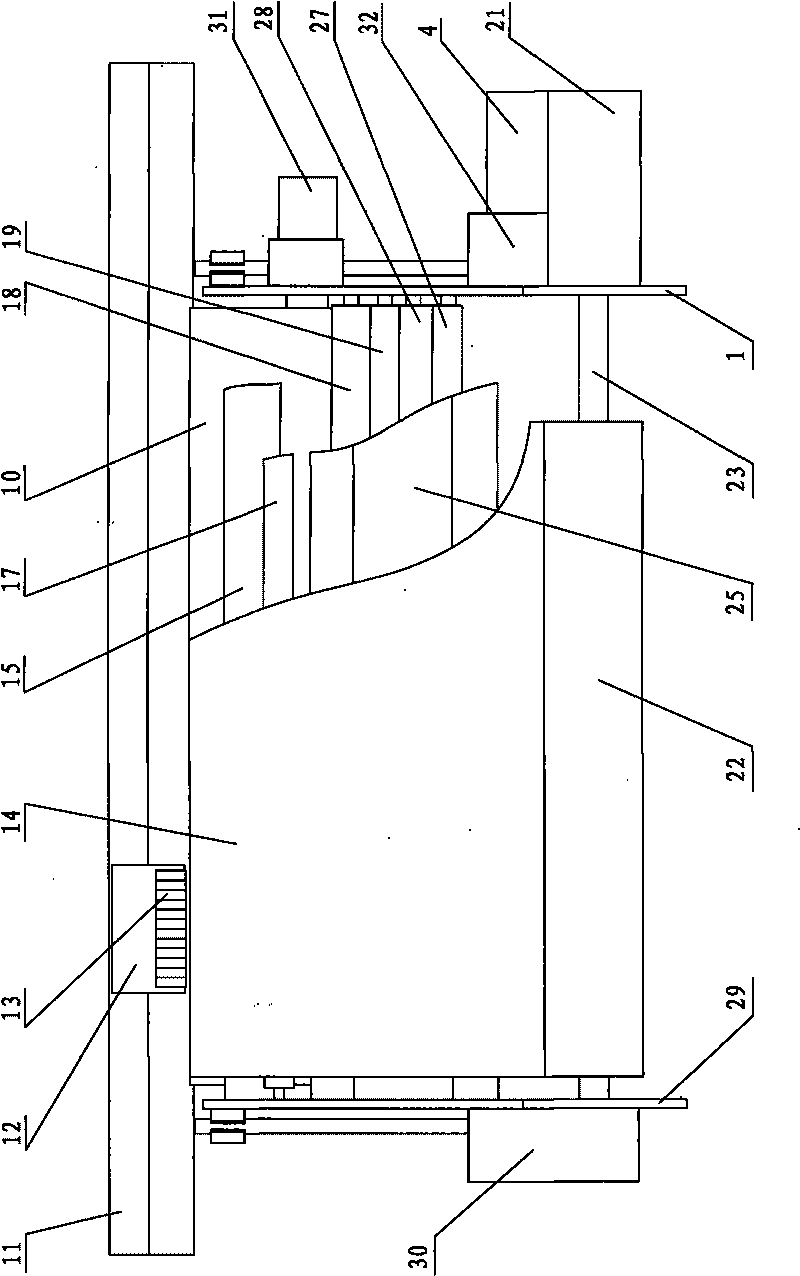

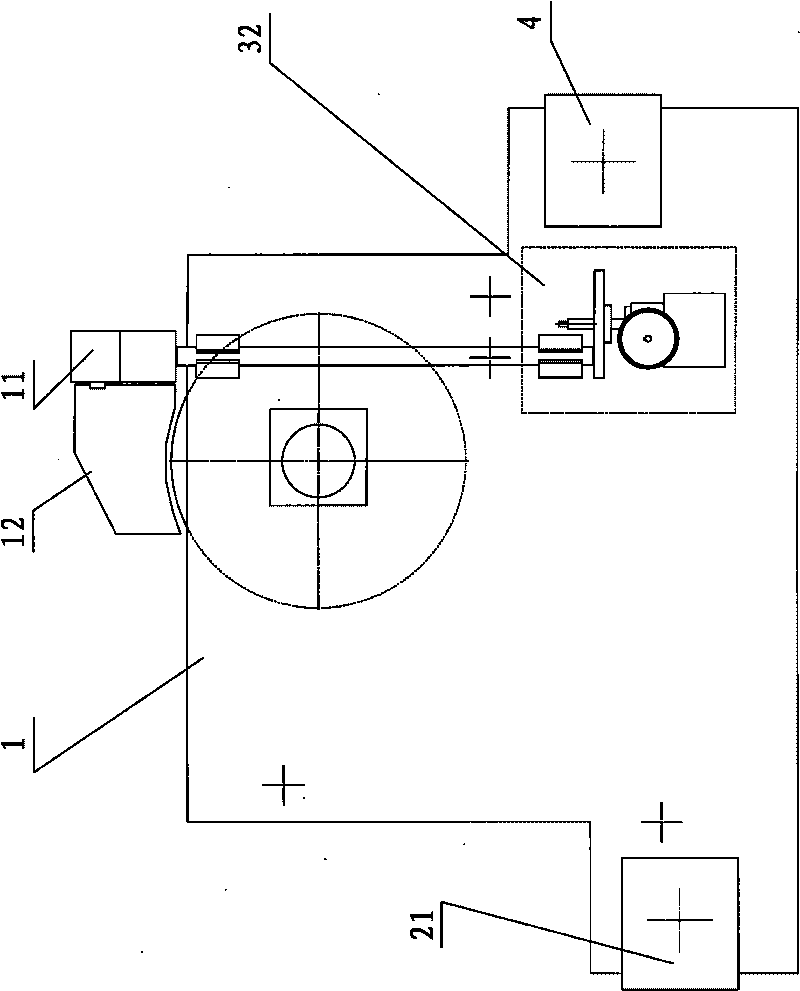

High-precision electric field driven spray deposition 3D printer and working method thereof

PendingCN107932894AHigh frequencyContinuous and stable feedingAdditive manufacturing apparatus3D object support structuresComputer printingImage resolution

The invention discloses a high-precision electric field driven spray deposition 3D printer and a working method thereof, and solves the problems of a traditional 3D printer on multiple aspects of resolution, stability and controllability; high-precision printing of multilayer structures can be realized; the printing process is observed and monitored in real time; and high-precision pattern printing is performed on insulation substrates through electric conducting materials. The high-precision electric field driven spray deposition 3D printer comprises a mounting baseplate; a Y-axle worktable is arranged on the mounting baseplate; a vacuum absorption platform is fixed on the Y-axle worktable; a printing substrate is absorbed on the vacuum absorption platform; a printing nozzle and a vertical observation camera are correspondingly arranged above the printing substrate, and are connected to a Z-axle worktable; the Z-axle worktable is fixed on an X-axle worktable; a squint observation camera is correspondingly arranged on one side of the printing nozzle; an LED light source and a far infrared curing light source are correspondingly arranged on the other side of the printing nozzle; theprinting nozzle communicates with a storage bottle; and the storage bottle is arranged on a lifting table.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

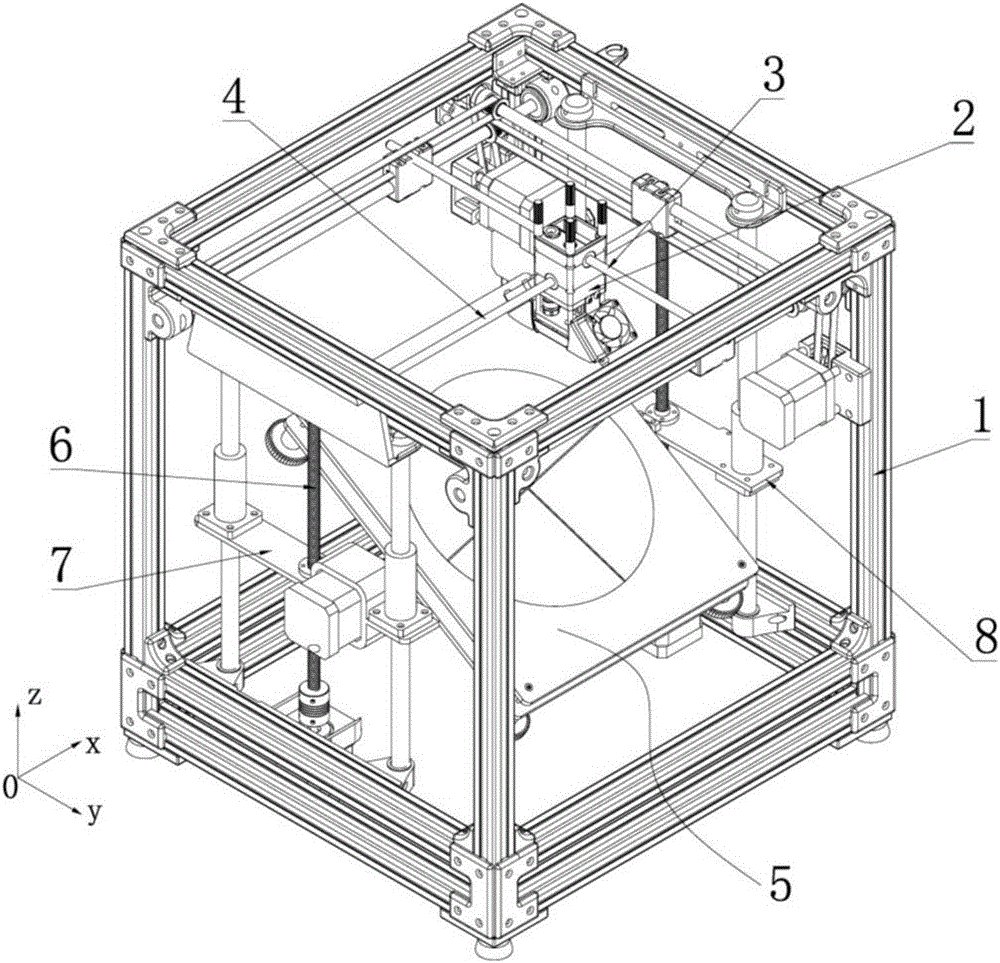

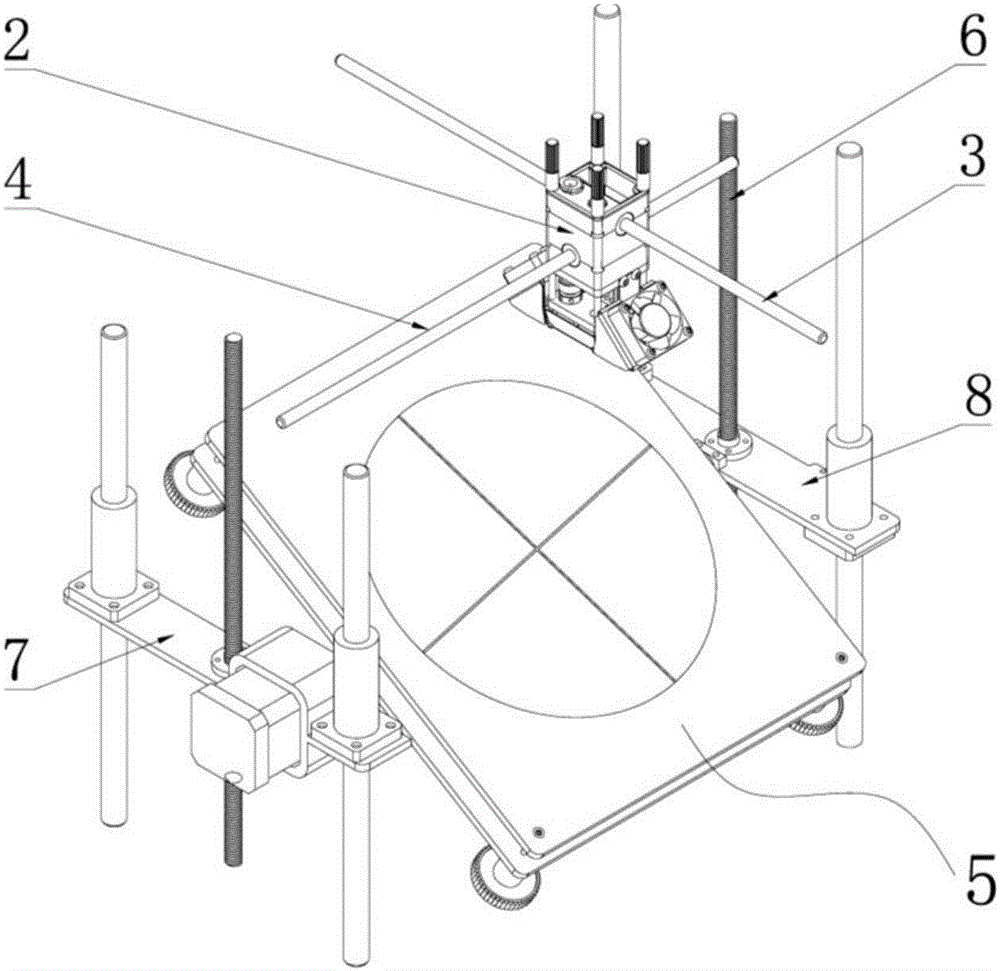

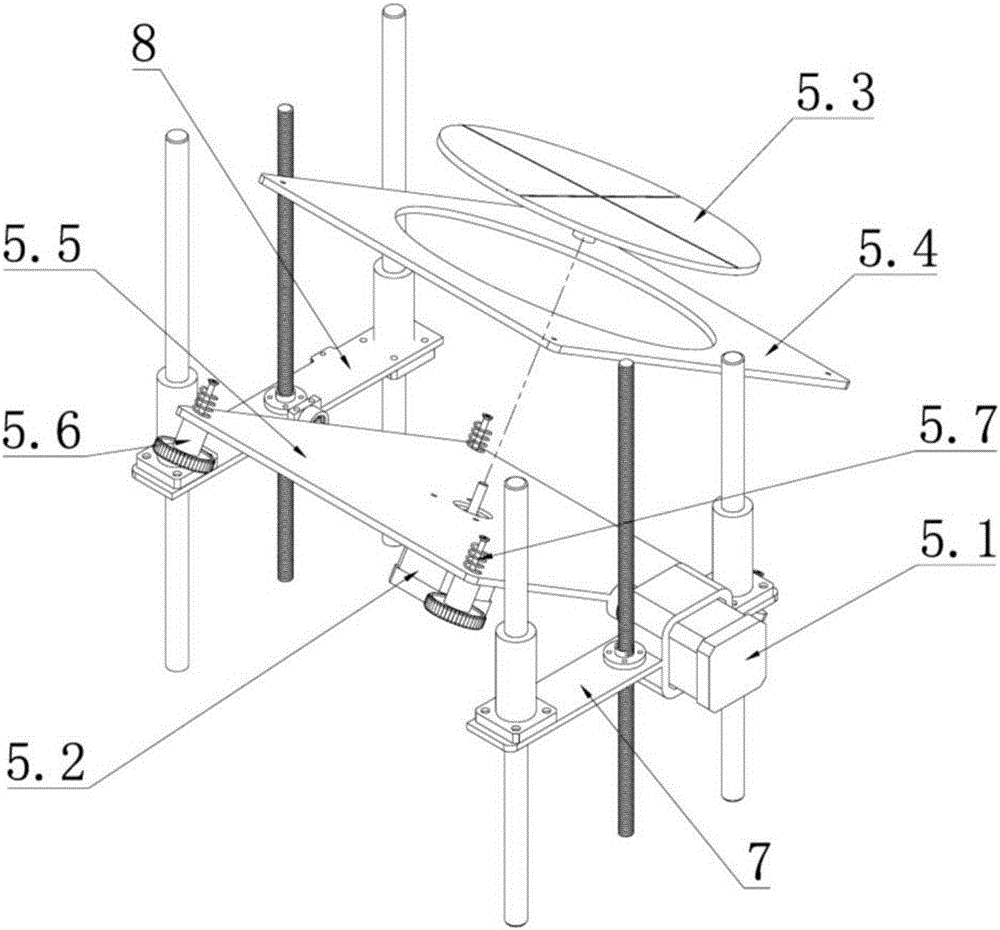

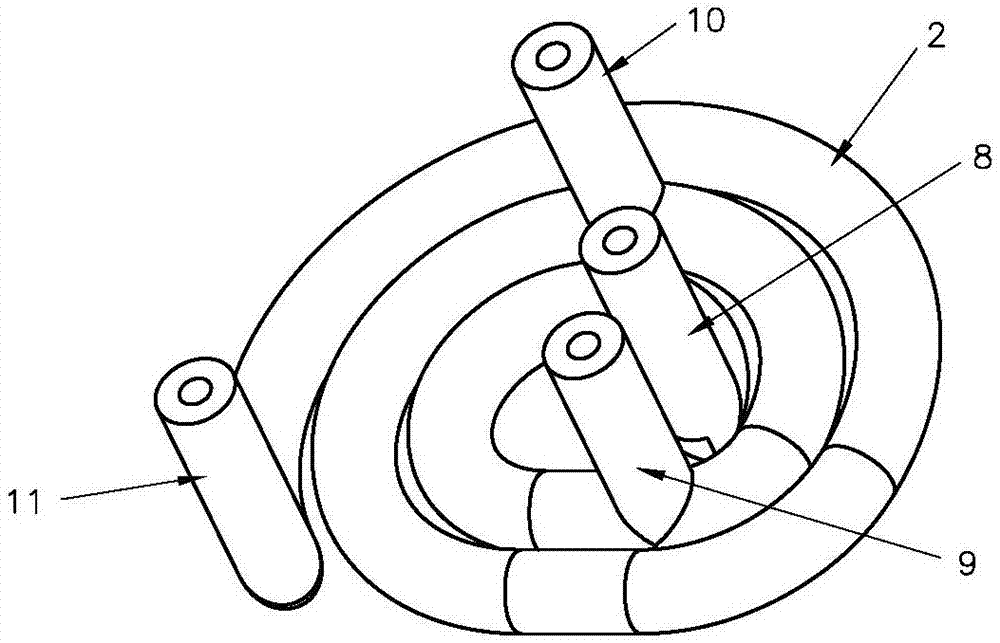

Double-rotating-shaft 3D printing platform

InactiveCN106239918ARealize printingImprove one-shot molding rateAdditive manufacturing apparatusBall screwEngineering

The invention discloses a double-rotating-shaft 3D printing platform capable of completing printing of the lateral side parts of components. According to the double-rotating-shaft 3D printing platform, by means of two stepping motors, a working table can be driven to rotate around the vertical axis of the working table itself and can pitch and incline up and down around the horizontal central axis of the platform during rotation; and on the other hand, the 3D printing platform is driven by a ball screw to rise and fall along the Z axis, and therefore precise and complete printing of the lateral side parts of the printed parts is achieved. The double-rotating-shaft 3D printing platform is simple in structure, reasonable in design and convenient to control, no supporting materials need to be added during printing, the pretreatment and aftertreatment procedures required by conventional printers are reduced, the quality of printed pieces is improved, and the application field of printers of the type is expanded.

Owner:HUBEI UNIV OF TECH

Three-dimensional printing method

ActiveCN106965421AImprove the bonding force between layersImprove structural strengthManufacturing heating elementsCeramic shaping apparatusBinding forceElectromagnetic induction

The invention discloses a three-dimensional printing method. According to the main process of the three-dimensional printing method, fused raw materials are placed in a forming area adopted by a three-dimensional printing device, the fused raw materials are accumulated and converted into a printed body in the forming area, and the fused raw materials are accumulated on the basis of the printed body until an object to be printed is formed. The three-dimensional printing method is characterized in that in the process of accumulating the fused raw materials, the portion, where the fused raw materials are to be accumulated, of the printed body is fused or softened through an electromagnetic induction heating manner, and / or the portion, where the fused raw materials are being accumulated, of the printed body is fused or softened. The three-dimensional printing method has the beneficial effects that the interlayer binding force of the printed body is high, and the structural strength of the printed body is high; a detachable auxiliary supporting body can be generated synchronously so that printing of a complicated structure can be achieved; an equipment structure is simple; a large-sized component can be printed; the three-dimensional printing method is suitable for multiple types of materials, and three-dimensional printing of electrically-conducive materials such as metal, metal ceramics and plastics mixed metal power can be achieved; cost is low; and the three-dimensional printing method has the substantial improvement.

Owner:NANJING TAITAO INTELLIGENT SYST CO LTD

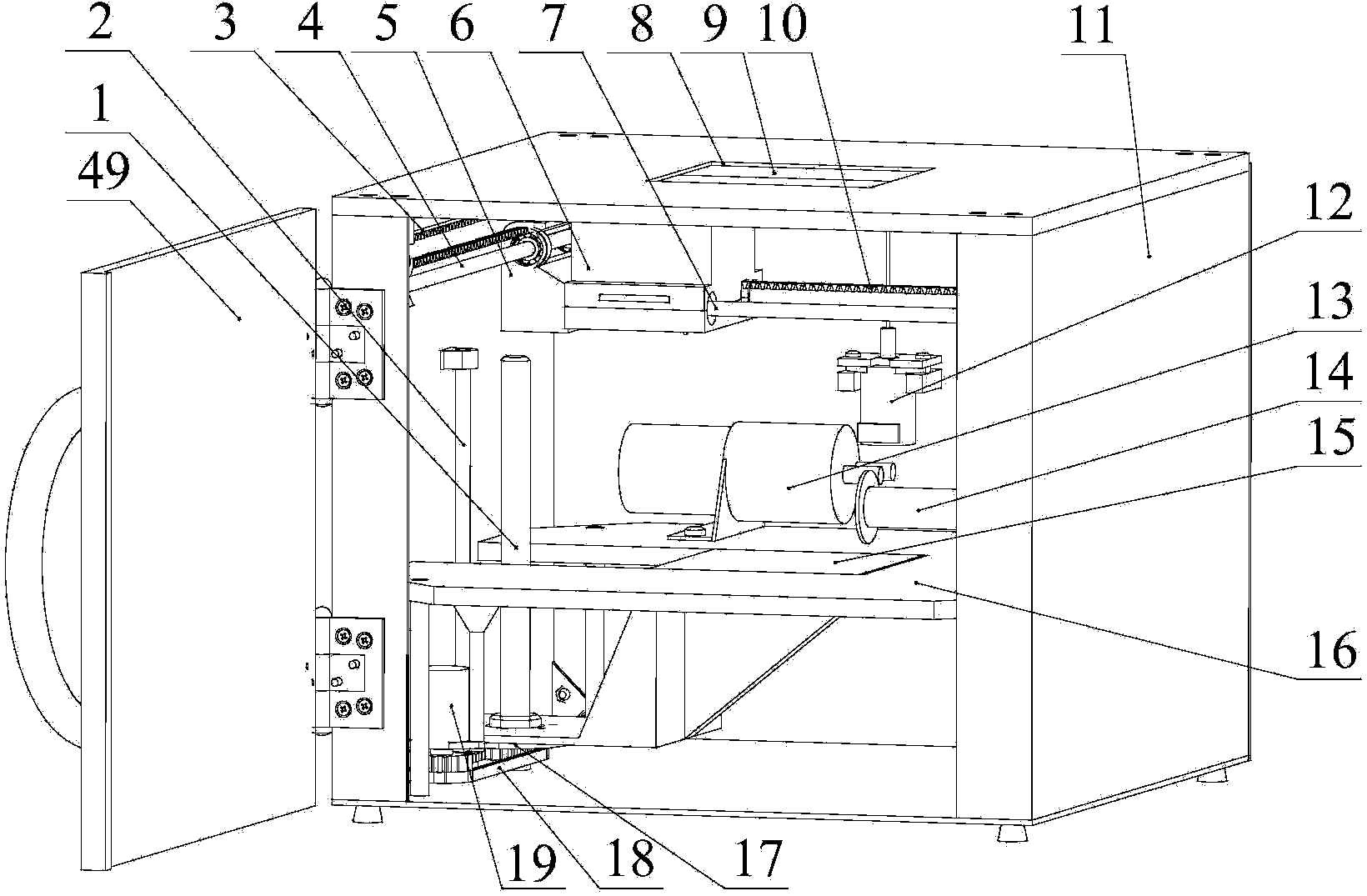

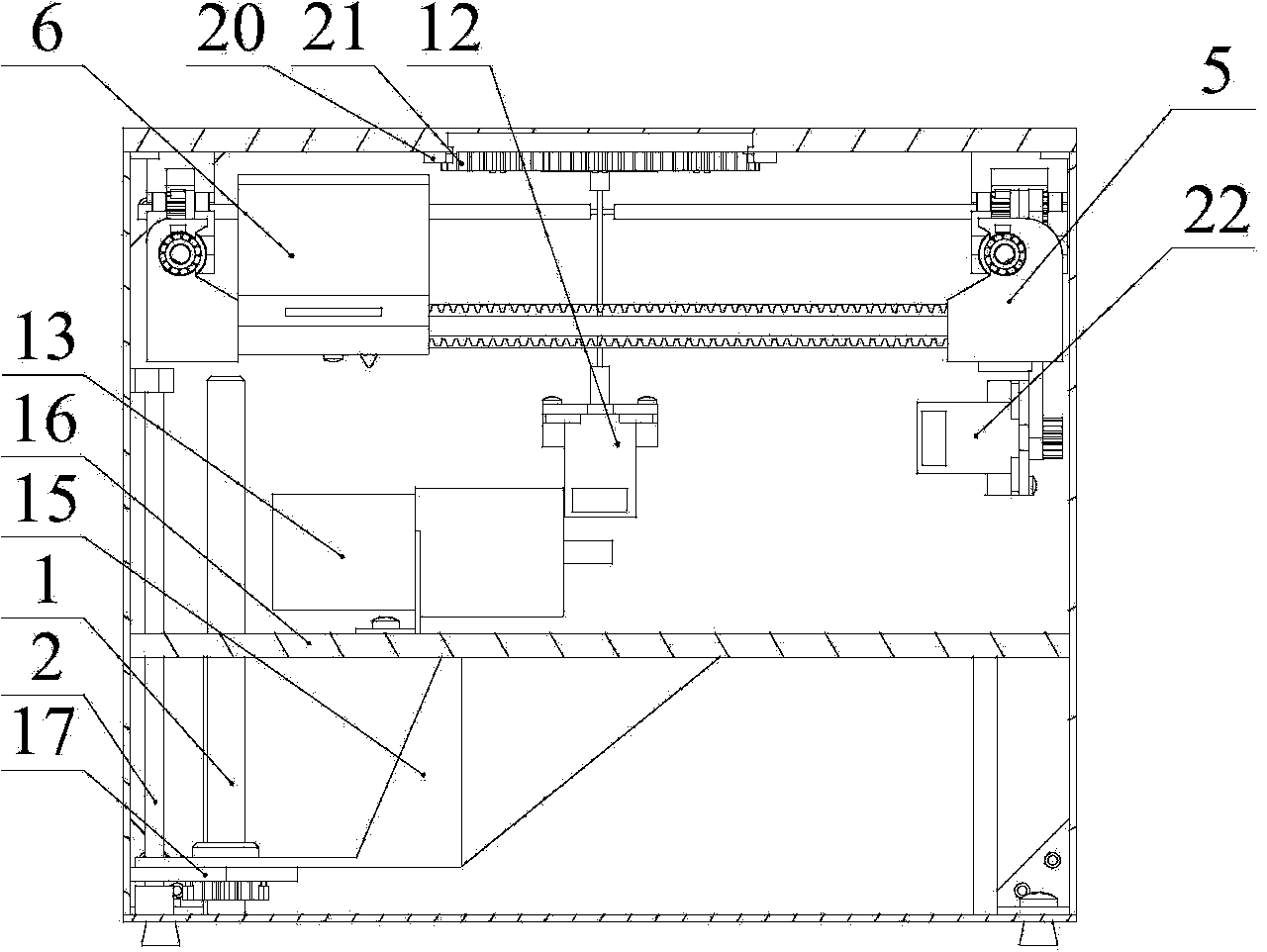

Digital ink-jet textile printing machine

InactiveCN101722723AEasy to processRealize printingTypewritersPower drive mechanismsTextile printerEngineering

The invention relates to textile printing equipment, in particular to a digital ink-jet textile printing machine capable of personalized jet printing. The digital ink-jet textile printing machine comprises a main driving roller used as a driving roll, a material feeding device, a material receiving device, a guide rail unit and a nozzle set unit, wherein the main driving roller, the material feeding device and the material receiving device are rotatably arranged between two parallel wall plates; the material receiving device and the material feeding device are respectively arranged at both sides of the main driving roller and parallel to the main driving roll; the guide rail unit is arranged on the wall plates at both sides with synchronous lifting; and the nozzle set unit is arranged above the main driving roller and can be arranged on the guide rail unit in a reciprocating way. The digital ink-jet textile printing machine has the advantages of good synchronism, high jet printing precision, wide jet printing material breadth, no pollution of jet printing materials and devices, long service life, wide application range, and the like.

Owner:梁健

Metal three-dimensional printing method and equipment thereof

ActiveCN105880598AHigh strengthImprove the bonding force between layersAdditive manufacturing apparatusMolten casting coatingElectrical resistance and conductanceUltimate tensile strength

The invention discloses a metal three-dimensional printing method and equipment thereof. The metal three-dimensional printing method comprises the following steps that melted and flowable metal or softened and flowable metal is put into a molding area used by three-dimensional printing equipment; after not having the flowability, the melted and flowable metal or the softened and flowable metal is converted into printed and molded metal; the melted and flowable metal or the softened and flowable metal is accumulated based on the printed and molded metal until an object to be printed is molded; the object to be printed is formed by the accumulated printed and molded metal. The key characteristics of the metal three-dimensional printing method disclosed by the invention lie in that during molding, binding force between layers and binding force between pixel points are changed in a manner of resistance radiation, and a printing area for performing resistance radiation can be set; a metal part generated by the metal three-dimensional printing method disclosed by the invention is high in strength, high in density, and high in molding accuracy; molding process of each pixel point is monitored; a dismountable assisting bracket can be synchronously generated; a large-scale part can be printed; the equipment is simple in structure and low in cost. The metal three-dimensional printing method and the equipment thereof disclosed by the invention have a substantive progress.

Owner:NANJING TAITAO INTELLIGENT SYST CO LTD

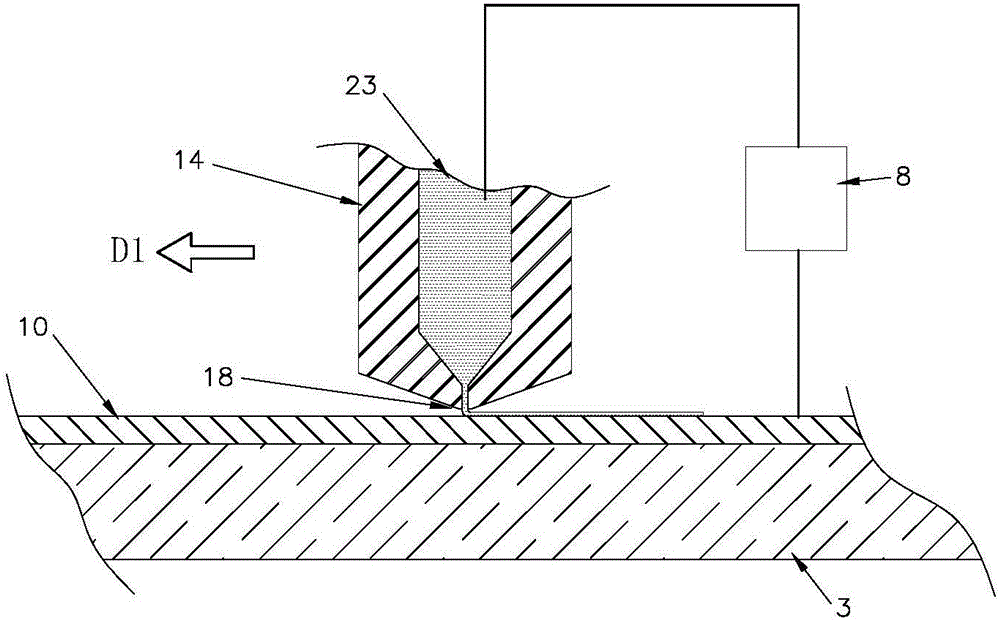

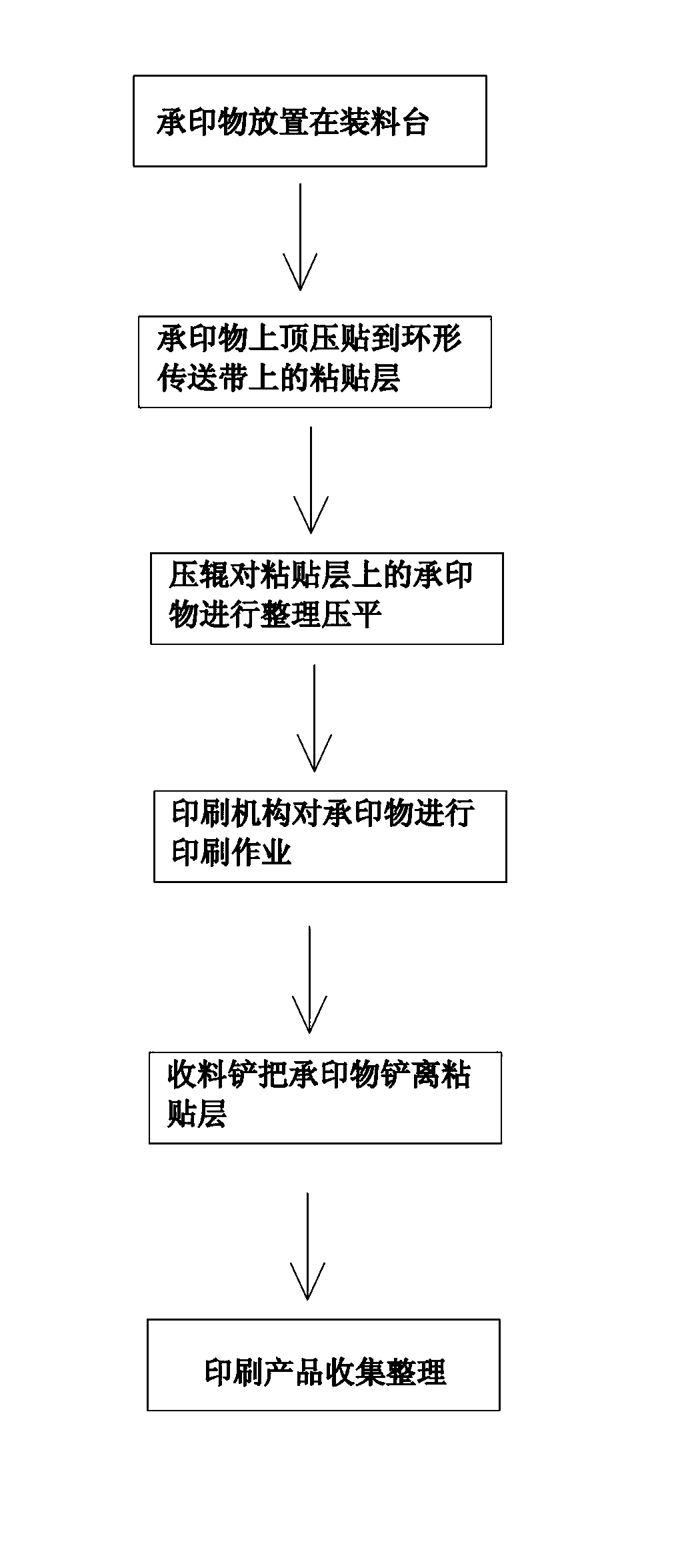

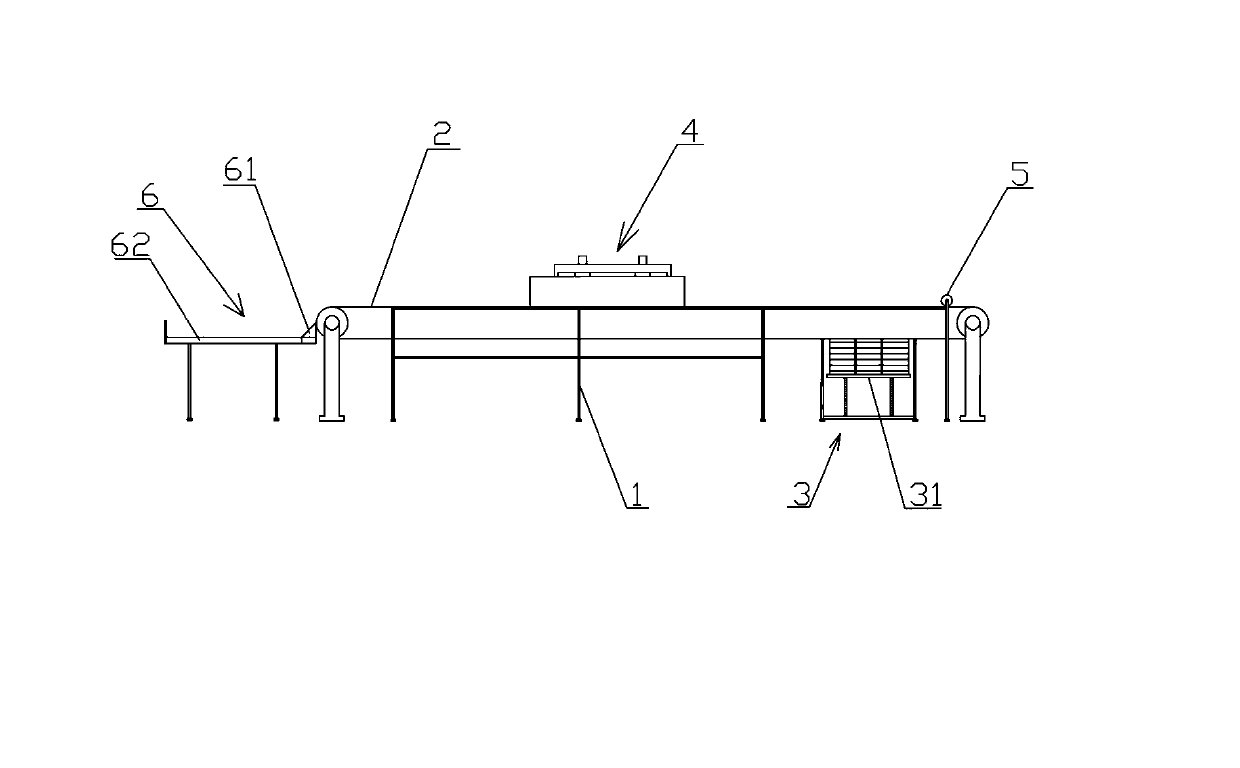

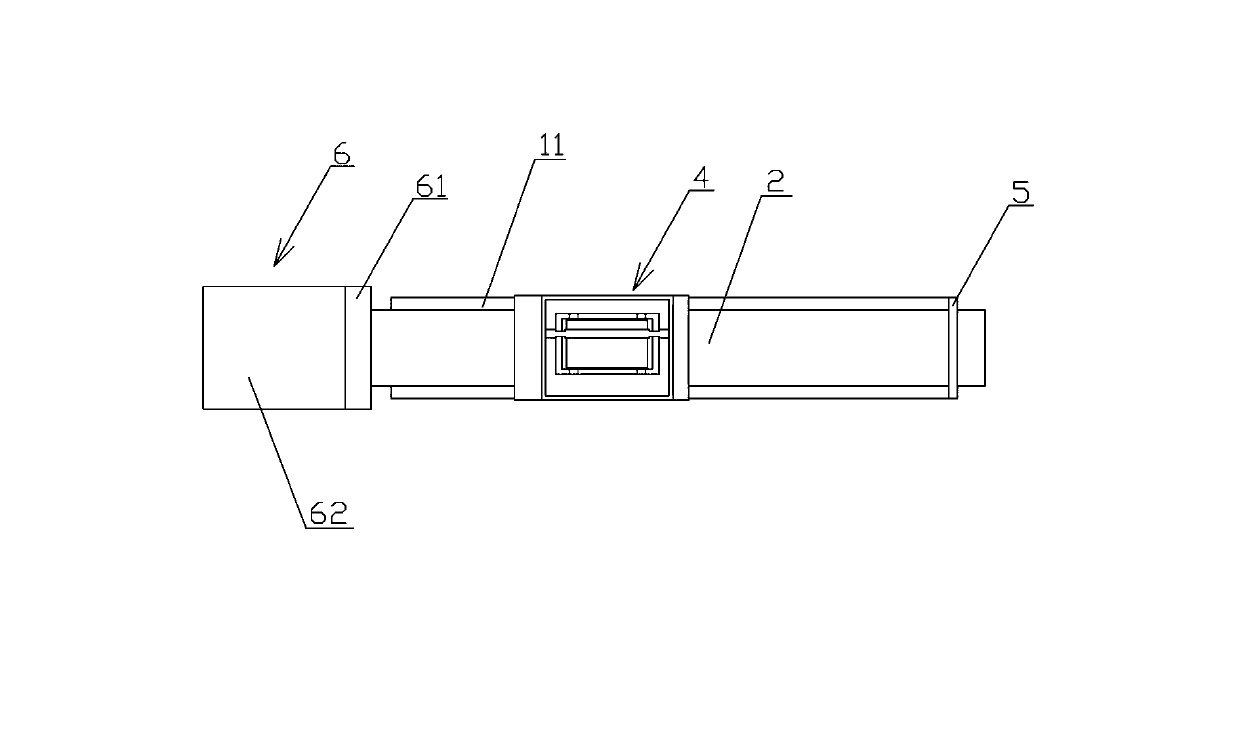

Automatic printer for vamp

The invention discloses an automatic printer for a vamp. The automatic printer comprises a combined rack body on which a working platform is arranged, wherein an annular conveyor belt and a driving device of the conveyor belt are arranged on the combined rack body, and an adhesion layer with changeable adhesion strength is coated on the surface of the annular conveyor belt; a material feeding mechanism is arranged below the combined rack body and is used for upwards propping against a printed object to press and adhere the printed object on the adhesion layer; and a printing mechanism is arranged above the combined rack body and is used for printing the printed object. According to the automatic printer for the vamp, which is disclosed by the invention, firstly the printed object is temporally adhered on the annular conveyor belt to be arranged and flattened and then is printed, secondly the printed object is automatically shoveled out of the annular conveyor belt by a material collection shovel, and finally product collection processing is carried out; and therefore, through the new conveying and printing operation manner, the printing precision and the printing quality of a printing mechanism are improved.

Owner:BLACK GOLD STEEL AUTOMATION TECH FUJIAN

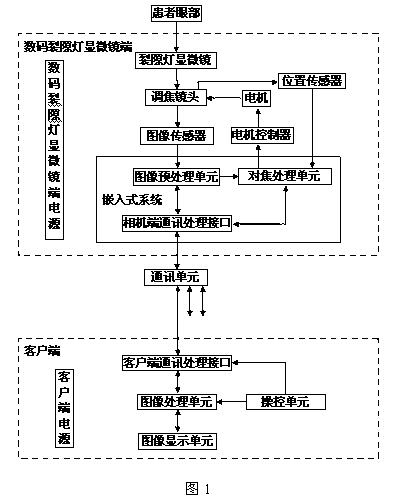

Electronic recording and remote diagnosis digital slit lamp system and method

InactiveCN102727175ARealize remote expert consultationImprove inspection qualityTelemedicineMedical automated diagnosisCommunication unitSlit lamp

The invention discloses an electronic recording and remote diagnosis digital slit lamp system and a method, relates to the field of optical instruments and remote communication control, and aims to solve the problem about electronic recording, reproduction and remote diagnosis based on an image of a slit lamp. The electronic recording and remote diagnosis digital slit lamp system comprises an eye part of a patient, a digital slit lamp microscope end, a communication unit and a plurality of clients, wherein the digital slit lamp microscope end irradiates the eye part of the patient; the digital slit lamp microscope end, the communication unit and the clients are sequentially connected with one another so as to transmit pathological information of the eye part of the patient; and the clients remotely process and reproduce the pathological information of the eye part of the patient in the form of an image and can remotely control the digital slit lamp microscope end through the communication unit to acquire optical information of the eye part of the patient. The system and the method are mainly used for performing electronic recording, reproduction and remote diagnosis on the image of the slit lamp.

Owner:SHANGHAI MEDIWORKS PRECISION INSTR CO LTD

Fluorescent paint used for reinforcing infrared light

InactiveCN103468044AExtended service lifeLow costAlkali metal silicate coatingsLuminescent paintsUltraviolet lightsCcd camera

A fluorescent paint used for reinforcing infrared light comprises an infrared long afterglow luminescent material, diluent, binding agent and a fluorescence staining substance, and is characterized in that the infrared long afterglow luminescent material is mixed with the diluent to form a fluorescent solution containing the infrared long afterglow luminescent material, the fluorescent solution and the binding agent are evenly mixed to form fluorescent binding agent, and the fluorescent binding agent is combined with the fluorescence staining substance. The fluorescent paint used for reinforcing infrared light absorbs ultraviolet light in sunlight and releases near-infrared light for a long time at night. The near-infrared light can be sensitively detected by an existing CCD camera. The fluorescent paint used for reinforcing infrared light can form a static infrared light-emitting environment background when painted on fencings, walls, cloth, trees and the ground. The fluorescent paint used for reinforcing infrared light has the advantages of being stable, free of toxin, environmentally friendly, low in cost, simple to use and the like, thereby being capable of being widely applied to the fields of security monitoring, night target infrared displaying, dynamic tracking without heat source, anti-fake fluorescent materials and the like.

Owner:SHANGHAI KEYAN PHOSPHOR TECH

Copper alloy powder 3D printing method

InactiveCN105880594A3D printing realizedRealize printingAdditive manufacturing apparatusIncreasing energy efficiencyMicrometerGalvanometer

The invention discloses a copper alloy powder 3D printing method. The method comprises the steps that 1, copper alloy powder is weighed, screened and dried; 2, three-dimensional CAD model processing is carried out; 3, the dried copper alloy powder is poured into a powder tank, an SLM forming machine is prepared and carries out pretreatment on a base plate, the base plate and a scraper are installed, and powder is preset and laid; 4, a laser head is controlled by a galvanometer scanning system to act, the power of the laser head is 200-500 W, the scanning velocity V is 50-300 mm / s, the scanning distance is 0.07-0.09 mm, the powder laying thickness d is 20 micrometers, and the laser spot diameter is 120-140 micrometers. By selecting laser wavelength, powder and other data and carrying out annealing heat treatment after molding, the technical problems that laser molding of copper alloy is difficult and copper is likely to be cracked after being molded due to high heat conductivity and high light reflectivity are solved.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

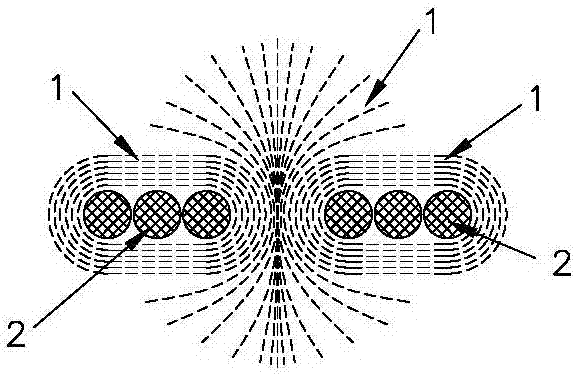

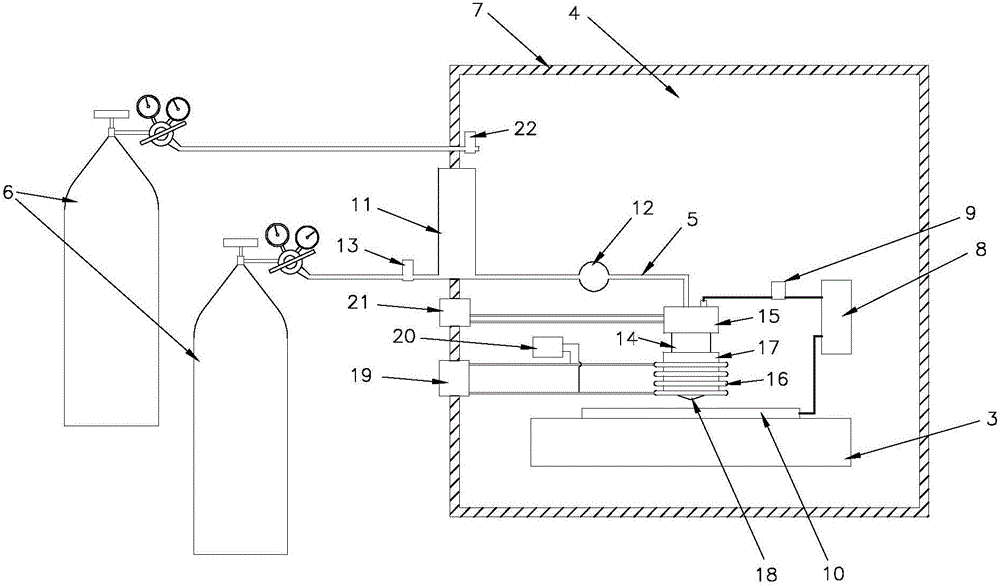

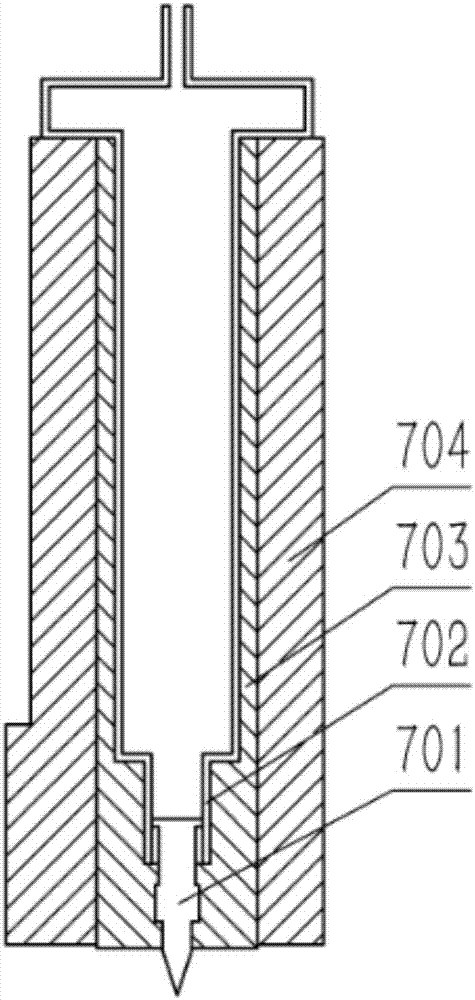

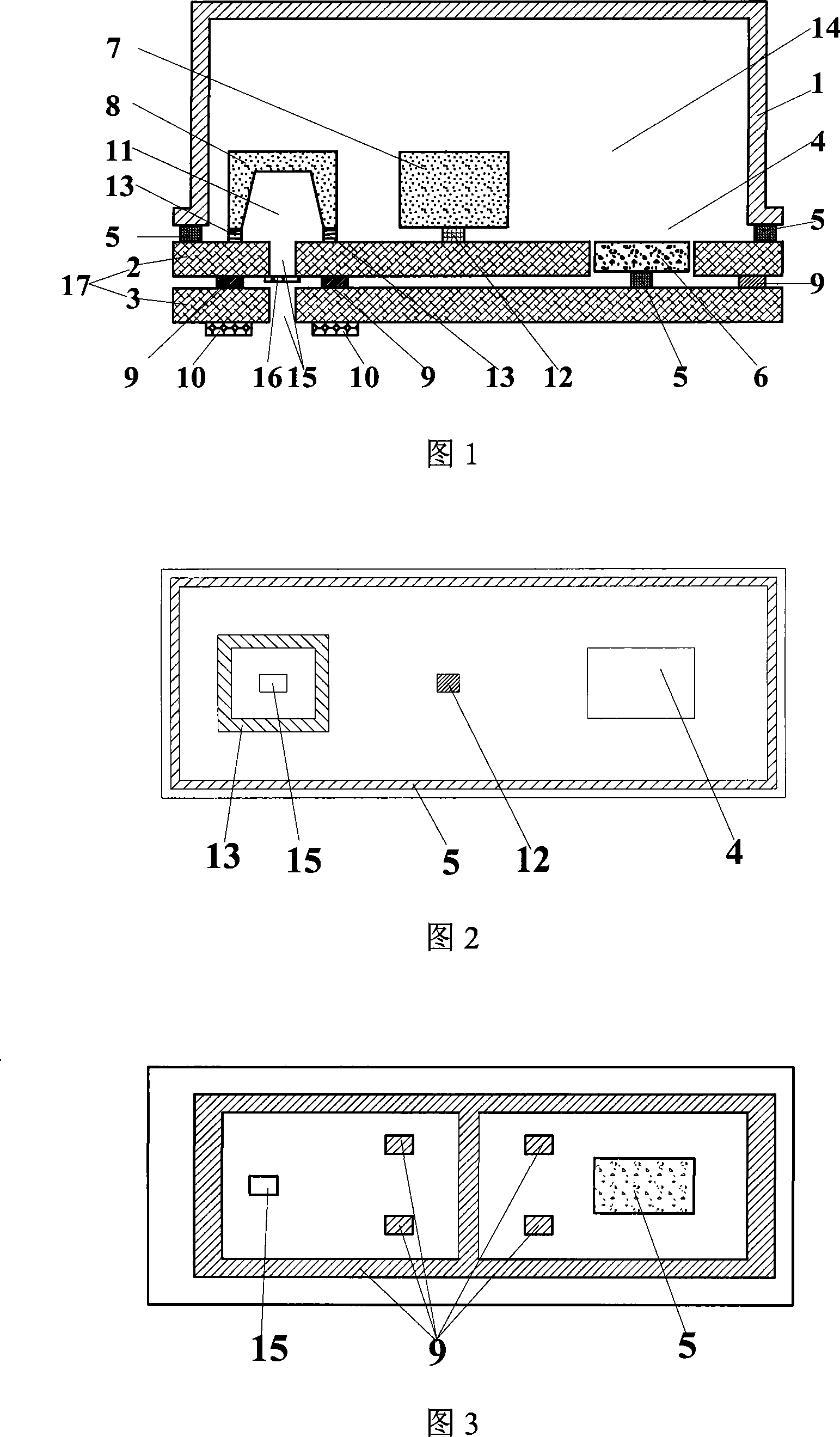

Molten jetting deposition 3D printing device driven by electric field, and working method thereof

InactiveCN107160685AAvoid cloggingEvenly heatedManufacturing heating elements3D object support structuresScale structureHigh pressure

The invention discloses a molten jetting deposition 3D printing device driven by an electric field, and a working method thereof. The problems that the molten droplet jetting 3D printing accuracy is low, the printing materials are limited and the micro-scale structure printing is hard to achieve are solved, and the high-accuracy and high-efficiency macro / micro-scale manufacturing of complex 3D structures using thermal phase transition and thermoplastic polymer materials and composite materials is achieved. According to the technical scheme, the 3D printing device comprises a two-dimensional stage which is provided with a printing bed, and an insulating thermal-conductive substrate is attached to the printing bed; a jetting unit is arranged above the insulating thermal-conductive substrate, and connected to a Z-axis workbench; the jetting unit comprises a print head comprising a nozzle and a material storage barrel which are connected to each other, and the print head is connected to the anode of a high-voltage pulse power supply; the nozzle is a musashi conductive nozzle; the material storage barrel is connected to a backpressure control unit; and a heater is sheathed outside the print head, and connected to a temperature control unit.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

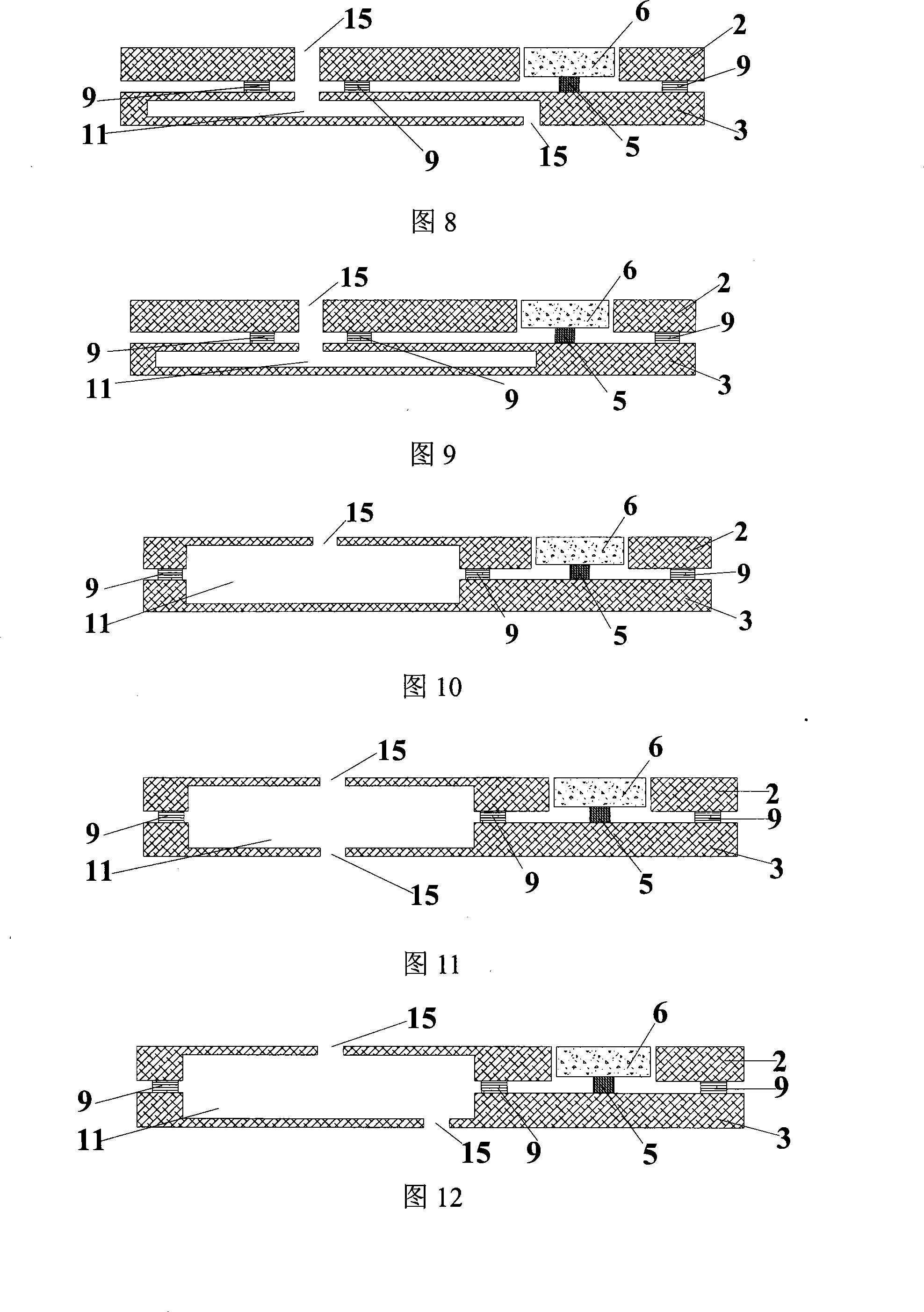

A silicon capacitance microphone and its making method

ActiveCN101237719AControl thicknessSimple structureElectrets selectrostatic transducerElectrostatic transducer microphonesCapacitanceTransducer

The invention discloses a silicon electret condenser microphone and a method for making the same. The silicon electret condenser microphone comprises a shell, an acoustic transducer chip, an IC device, other passive components and a substrate, wherein the shell and the substrate are fixed together and form a cavity, and the shell and / or the substrate is provided with sound inlets; the acoustic transducer chip, the IC device and other passive components are positioned in the cavity and are respectively fixed and electrically connected with the substrate; the substrate is provided with an output end bond pad; an acoustic cavity is formed between the acoustic transducer chip and the substrate, and the substrate has a first mounting surface and a second mounting surface, with the acoustic transducer chip and the IC device fixed on the first mounting surface, and the other passive components fixed on the second mounting surface. The silicon electret condenser microphone in the technical proposal of the invention has two mounting surfaces for mounting elements, with the other passive components arranged on the second mounting surface and, the acoustic transducer chip and the IC device arranged on the first mounting surface, thereby realizing full page printing and improving the production efficiency.

Owner:SHENZHEN HORN AUDIO

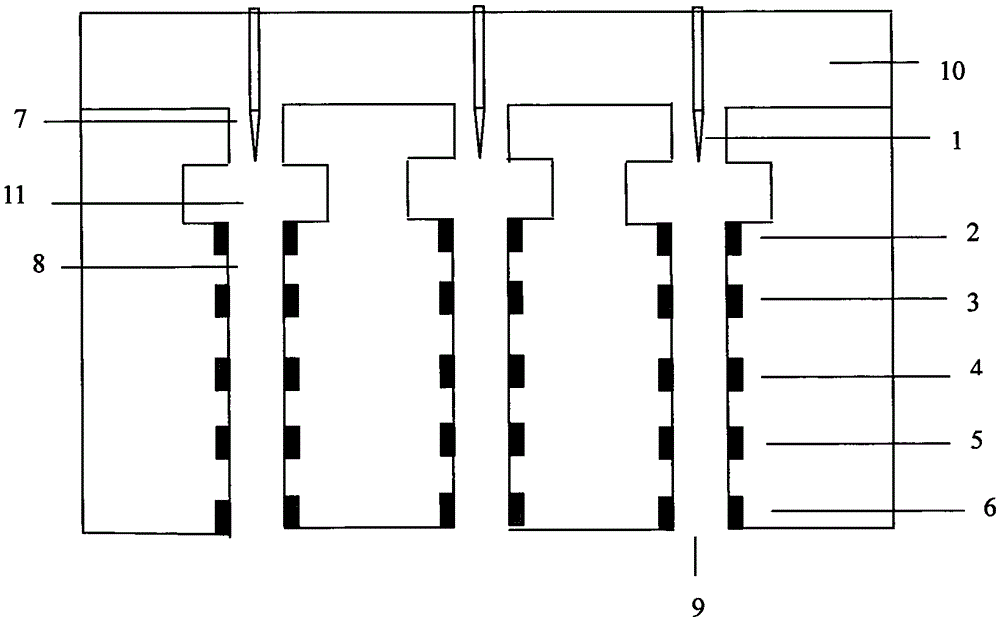

Electrofluid ink jet printing spray in array and logic control method

PendingCN106799891ARealize printingControlling the Jet Thinning ProcessOther printing apparatusJet flowElectric field

The invention discloses an electrofluid ink jet printing spray in array and a logic control method and relates to the technical field of electrofluid ink jet printing. The spray is provided with ink boxes and N independent nozzle systems which are in array arrangement and correspond to the ink boxes. Each independent nozzle system includes a material-in hole, a spray hole, and a channel between the material in hole and the spray hole. The channel is provided with a plurality of electrodes thereon. The method includes the following steps: powering the plurality of electrodes with logic control, applying an electric field to a jet flow with logic control, by regulating the voltages of the electrodes, adjusting the intensity, level, and direction of the electric field, controlling the size, direction and times of the force-bearing of the jet flow. In this way, the logic electric field can effectively control the process of the refining of the jet flow, increases the precision of the refining of the jet flow, not only realizes printing at nanometer, and realizes the adjustment of the diameter of the jet flow according to needs, and is advantaged by high spraying precision and high efficiency.

Owner:深圳市富彩三维技术有限公司

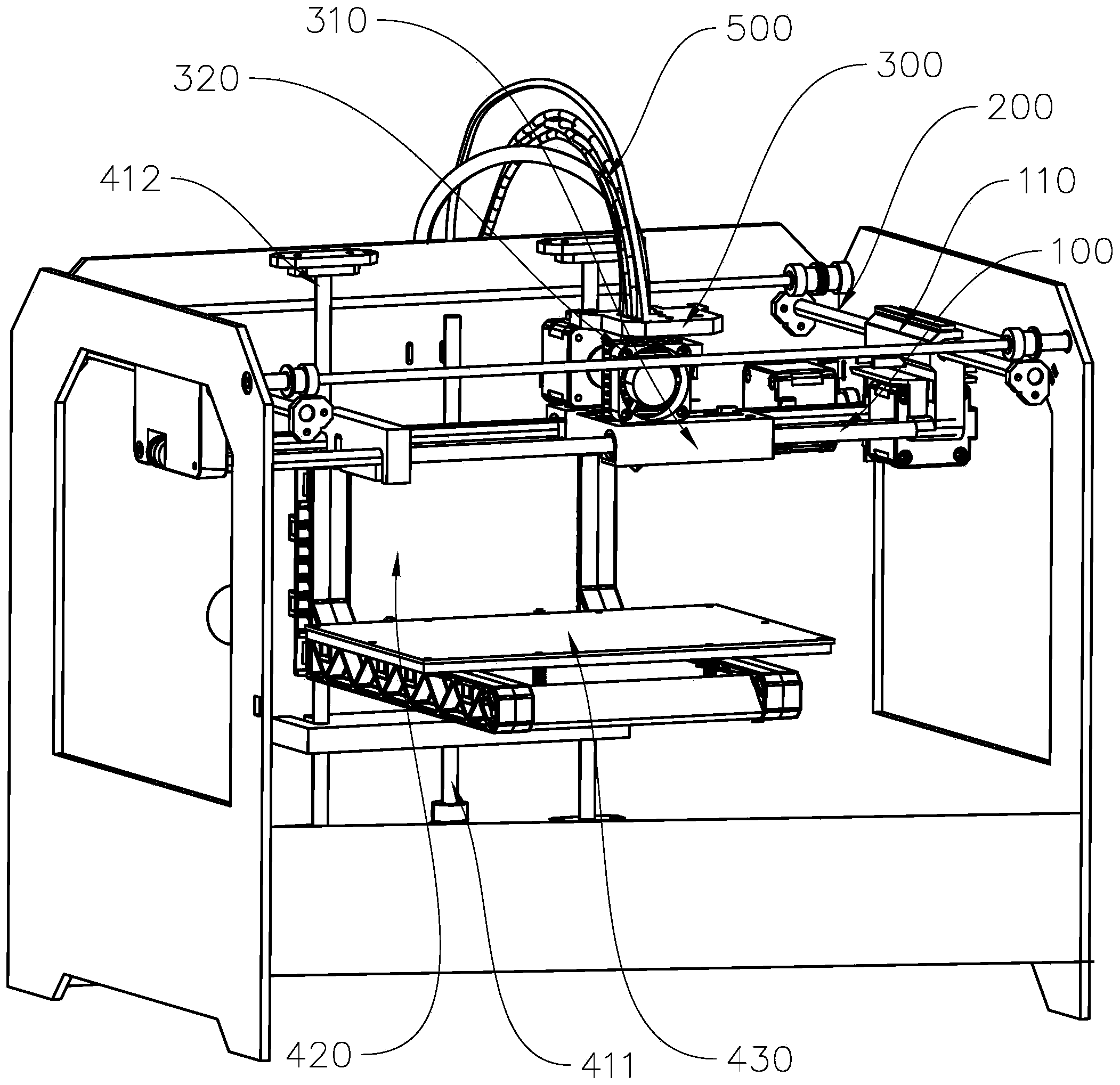

Rapid molding apparatus

ActiveCN104385594AStrong applicabilityReduce dependencyAdditive manufacturing apparatusSurface plateRapid prototyping

The invention discloses a rapid molding apparatus. The apparatus comprises a box body, the bottom of the box body is provided with a printing panel which can lift along the Z axis, a printing head and a moving mechanism for driving the printing head to move along the X axis and the Y axis are arranged above the printing panel in the box body, the printing head is detachably arranged on the moving mechanism, and the top of the box body is provided with an opening for the printing panel to lift out of the box body, and a movable skylight for shielding the opening. The printing head is detachably arranged on the moving mechanism, so a user can select a corresponding print head as required, so the printing of a variety of materials is realized, and the applicability is strong; the printing panel is paved with a silica gel membrane, and the lifting mechanism can automatically send products out of the box body after printing is completed, so the products can be very conveniently taken from the work panel; and the shell of the printing head is clamped and fixed to a fixing piece, and is detachably mounted on an Y-axial slide rail, so the user can replace the printing head as needed, and the applicability is strong.

Owner:ZHEJIANG UNIV

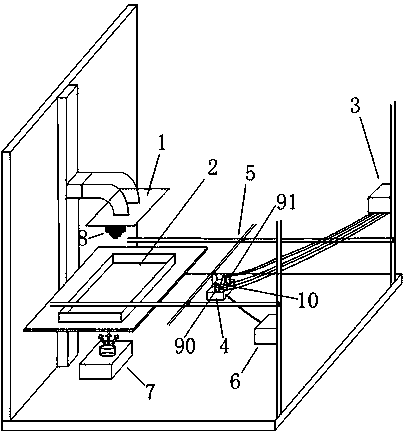

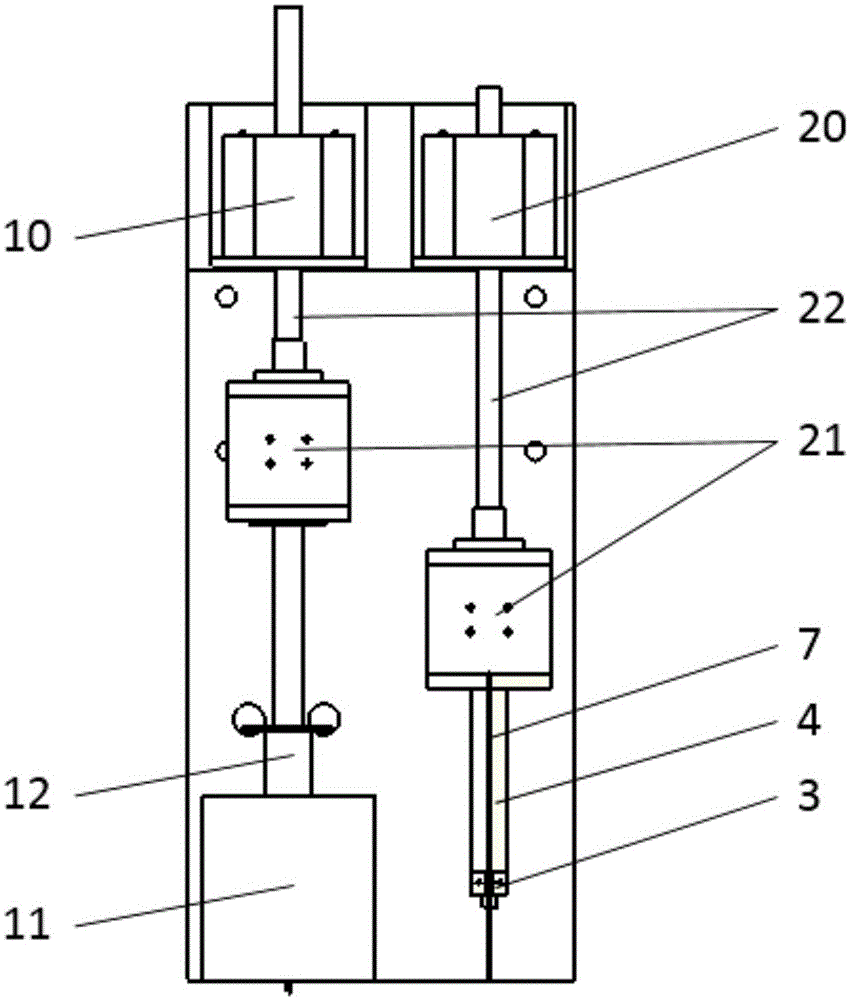

Heterogeneous cell three-dimensional printing system and heterogeneous cell three-dimensional printing method

ActiveCN106399078ARealize printingRealize fixed-point printingBioreactor/fermenter combinationsAdditive manufacturing apparatusComputer printingCluster cell

The present invention relates to a heterogeneous cell three-dimensional printing system, which comprises a moving platform, an extruded cell printing mechanism fixed on the moving platform, a dropping-off type cell printing mechanism fixed on the moving platform, an observation unit for observing and feeding back the cell printing condition, and a control unit, wherein the control unit controls the extruded cell printing mechanism to complete the three-dimensional cell hydrogel structure printing, and then controls the dropping-off type cell printing mechanism to complete the printing of single or multiple cells on the three-dimensional cell hydrogel structure. According to the present invention, the micro-extrusion type printing technology and the dropping-off type cell printing technology based on the alternating hysteresis force driving are integrated, such that the efficient construction of the macroscopical cell clusters is ensured, the construction of the microenvironment of the microcosmic single cell near the cluster cells is ensured, the in vitro heterogeneous cell model construction method integrating the efficiency and the precision is created, and the system and the method have important pathology and pharmacology application potential.

Owner:TSINGHUA UNIV

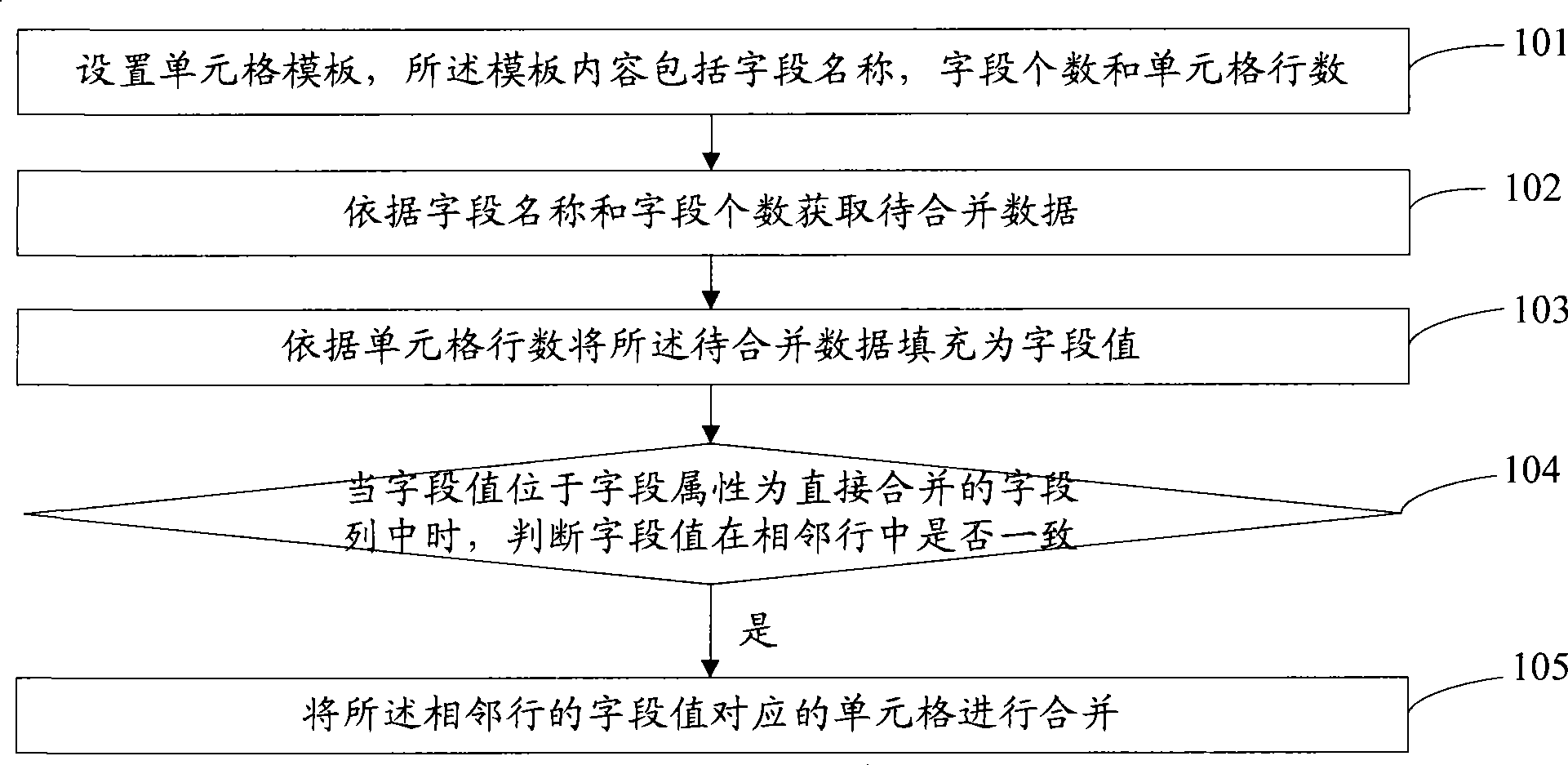

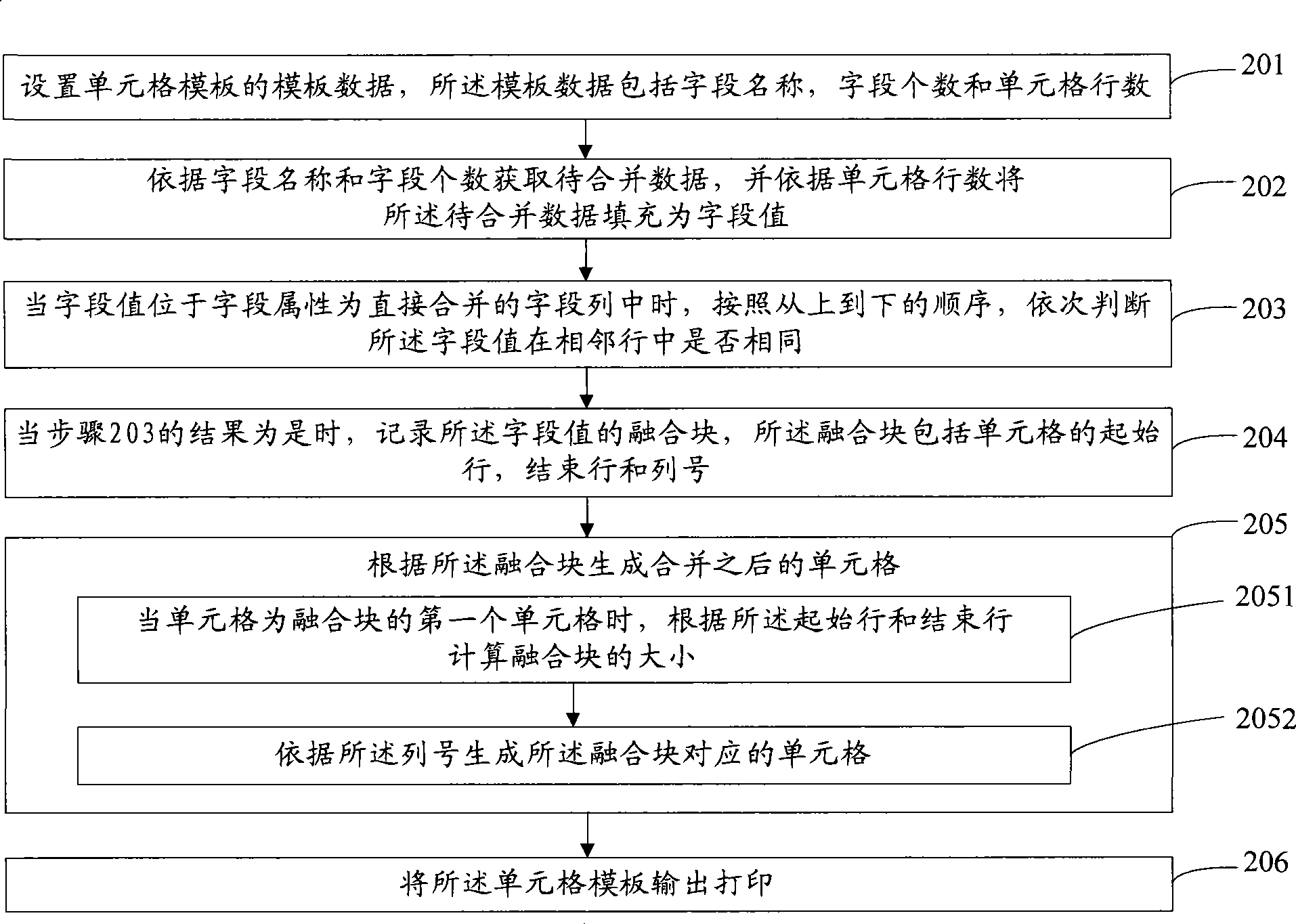

Method and apparatus for combining cells

InactiveCN101388028ARealize the mergerRealize printingSpecial data processing applicationsTime costComputer science

The invention provides a method of merging cells and a device. The method comprises steps of firstly setting a cell template which includes a field name, field numbers and cell row numbers, then obtaining to-be-merged data according to the field name and the field numbers, filling the to-be-merged data with field values according to the cell row numbers, determining the consistency of the field values in adjacent rows when the field values are located in a field column with field attribute of direct merging, and if positive, merging the cells corresponding to the field values in the adjacent rows. By using the method, the problem of extremely tedious maintenance for developers during cell mergence, thereby saving great time cost for the developers.

Owner:KINGDEE SOFTWARE(CHINA) CO LTD

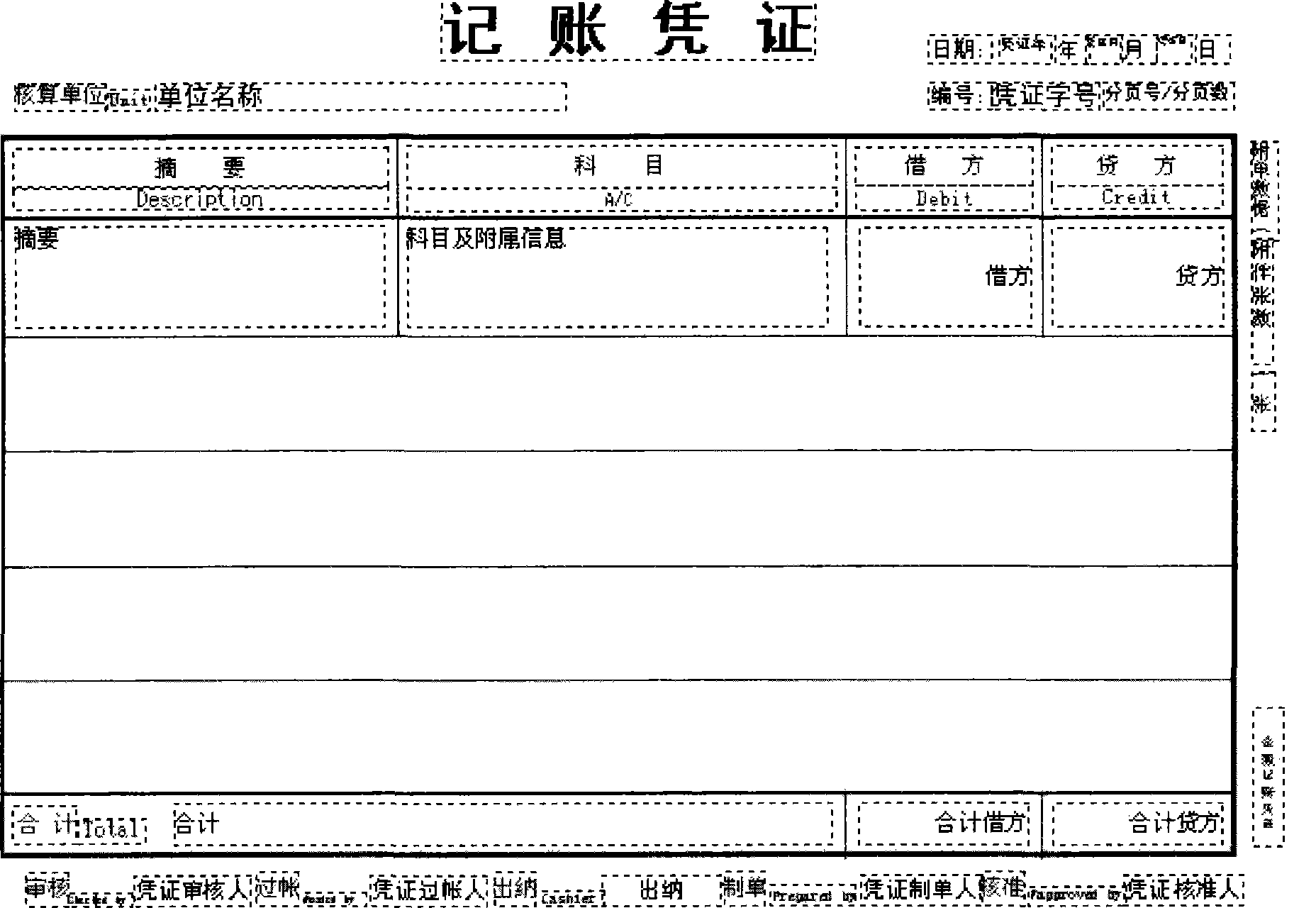

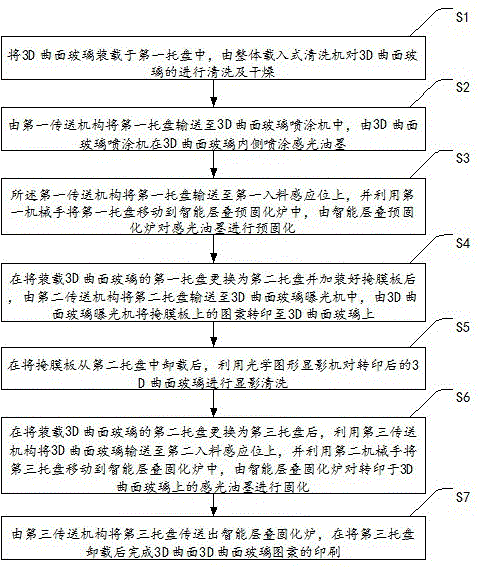

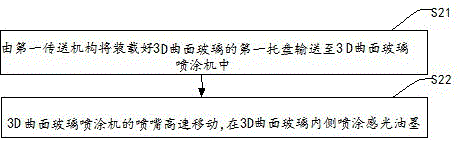

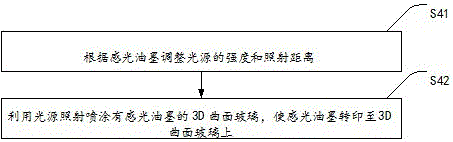

Printing method and device of 3D curved glass pattern

InactiveCN106827845ACreate pollutionRealize printingDuplicating/marking methodsTypewritersManipulatorPrinting ink

The invention discloses a printing method and device of a 3D curved glass pattern. The method comprises the following steps: washing and drying 3D curved glass by an overall load type washing machine; spraying photosensitive printing ink on the inner side of the dried 3D curved glass by a 3D curved glass spray coater; moving a first tray in an intelligent stack-up precuring furnace by a first manipulator, and precuring the photosensitive printing ink by the intelligent stack-up precuring furnace; loading the treated 3D curved glass in a second tray, additionally mounting a masking plate, and transferring the photosensitive printing ink onto the treated 3D curved glass by a 3D curved glass exposure machine; unloading the masking plate from the second tray, and utilizing an optical pattern developing machine to perform development washing for the 3D curved glass transferred with the photosensitive printing ink; and curing the photosensitive printing ink transferred onto the 3D curved glass by an intelligent stack-up curing furnace. Through the adoption of the method disclosed by the invention, the printing of the 3D curved glass pattern is realized, the yield rate in production is guaranteed, and besides, the method has the advantages of low process cost and high production capacity.

Owner:TRANS POTENT MECHATRONICS SHENZHEN

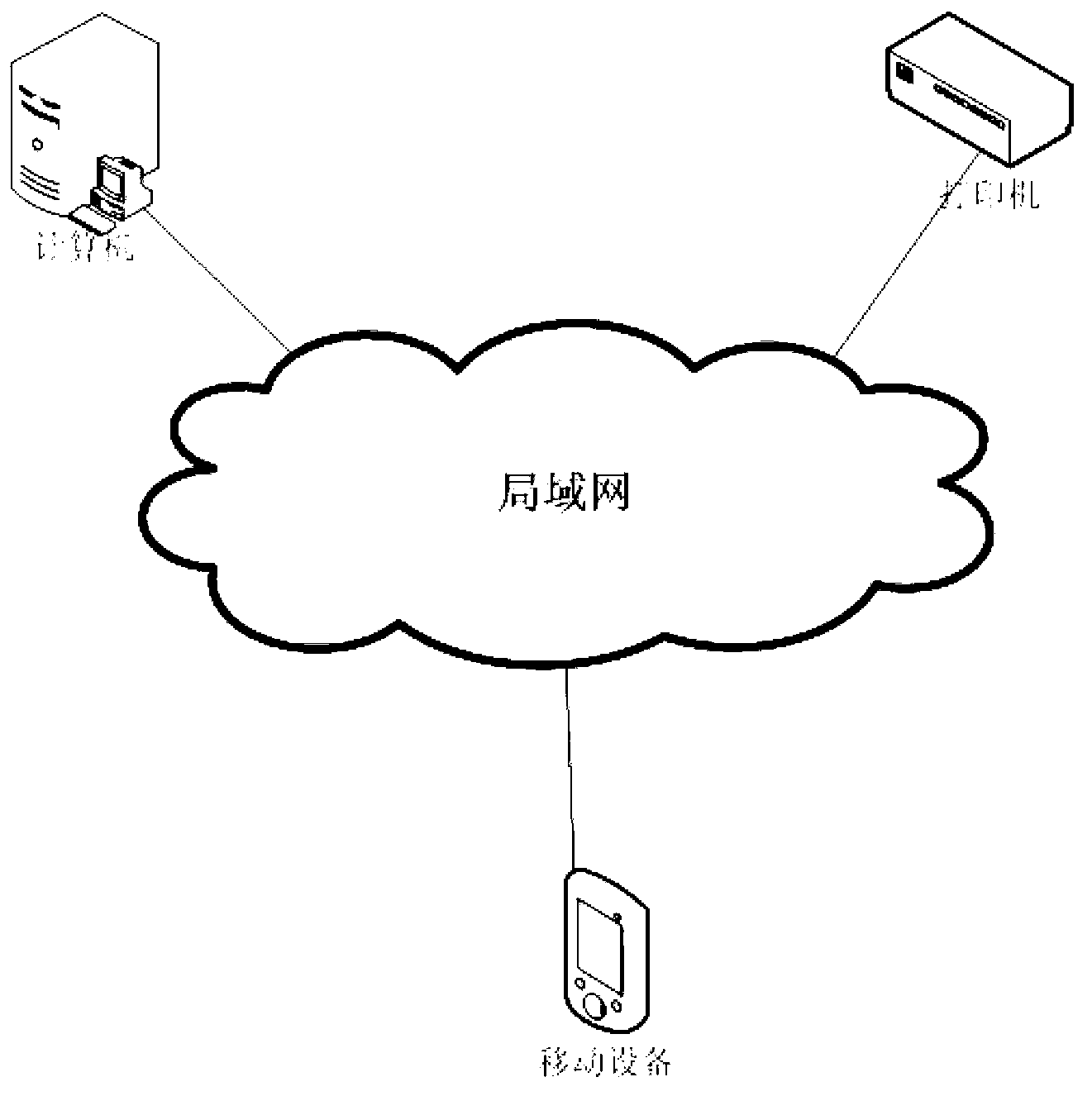

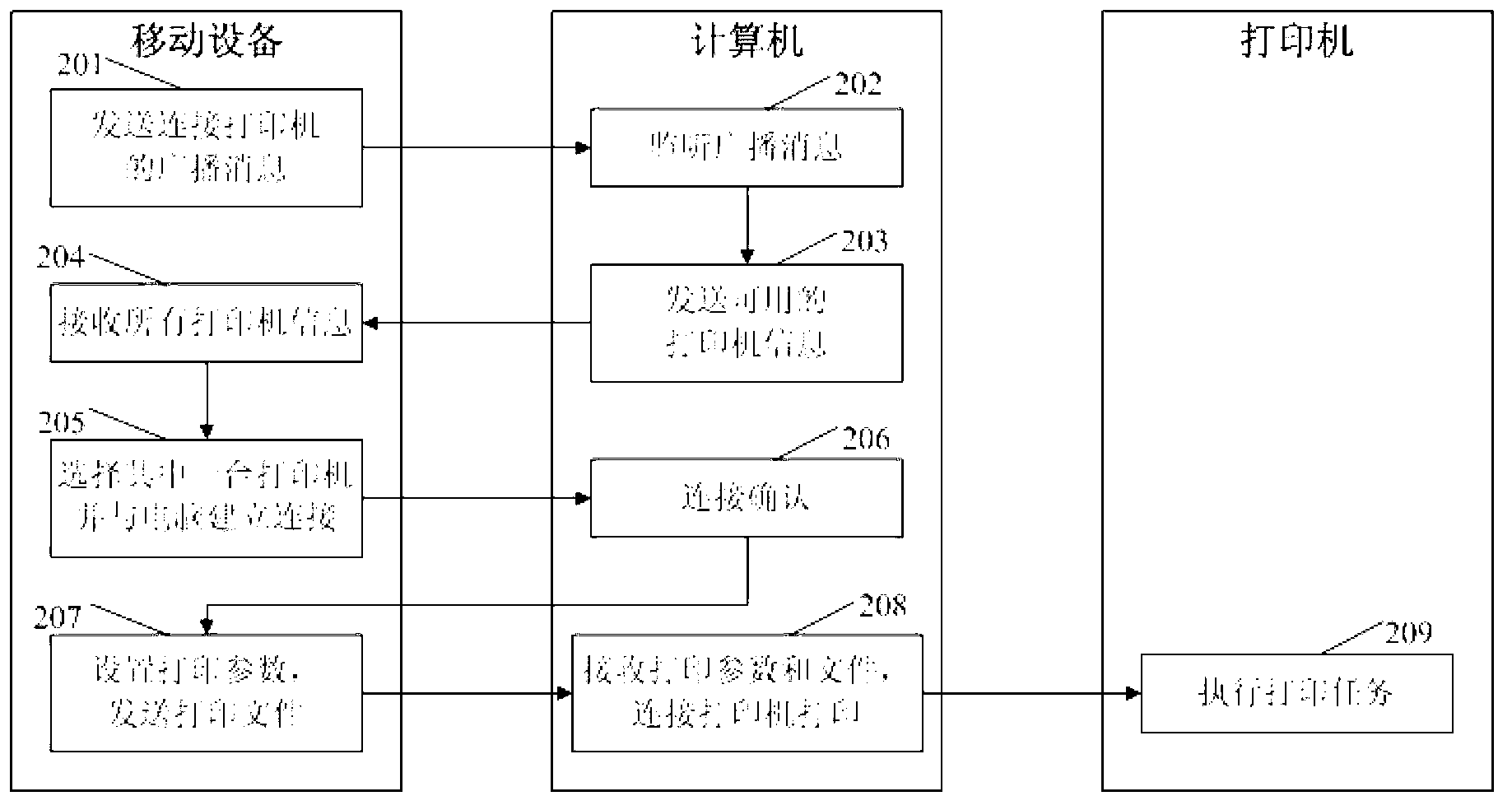

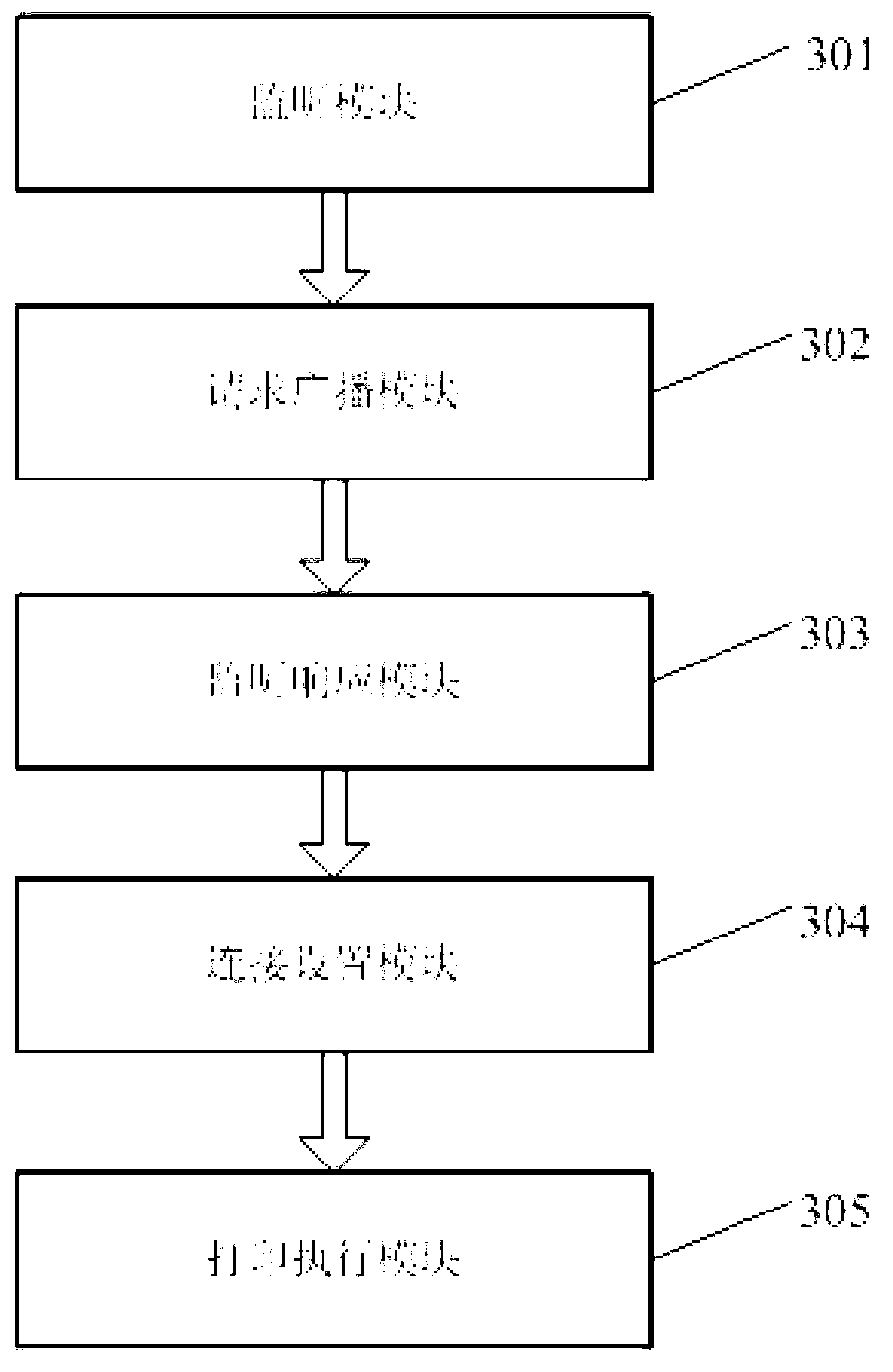

Method and system for realizing printing of mobile device

InactiveCN103179120ARealize monitoringInterconnectionSpecial service provision for substationDigital output to print unitsMobile deviceBroadcasting

The invention discloses a method and a system for realizing printing of a mobile device. The method comprises the following steps of: monitoring a broadcast message of a printing request by installing monitoring software at a computer; when the mobile device needs to print, transmitting the broadcast message of the printing request to a local area network; when the printing request is monitored by a computer, transmitting all the currently-connected printer messages to the mobile device; selecting one printer from all printers by the mobile device, building connection with the computer, and transmitting the selected printer, printing documents and setting printing parameters to the computer; and after the parameters are received by the computer, connecting the printer selected by the mobile device, and setting and printing the printing documents according to the printing parameters. According to the invention, the monitoring and the interlinking of the computer and the mobile device in a local area network are realized, the printing request of the mobile device is monitored by the computer, the printing task of the mobile device is completed, and the printing of the mobile device is realized without needing to purchase new equipment, so that the cost can be saved.

Owner:TIANWEN DIGITAL MEDIA TECH BEIJING

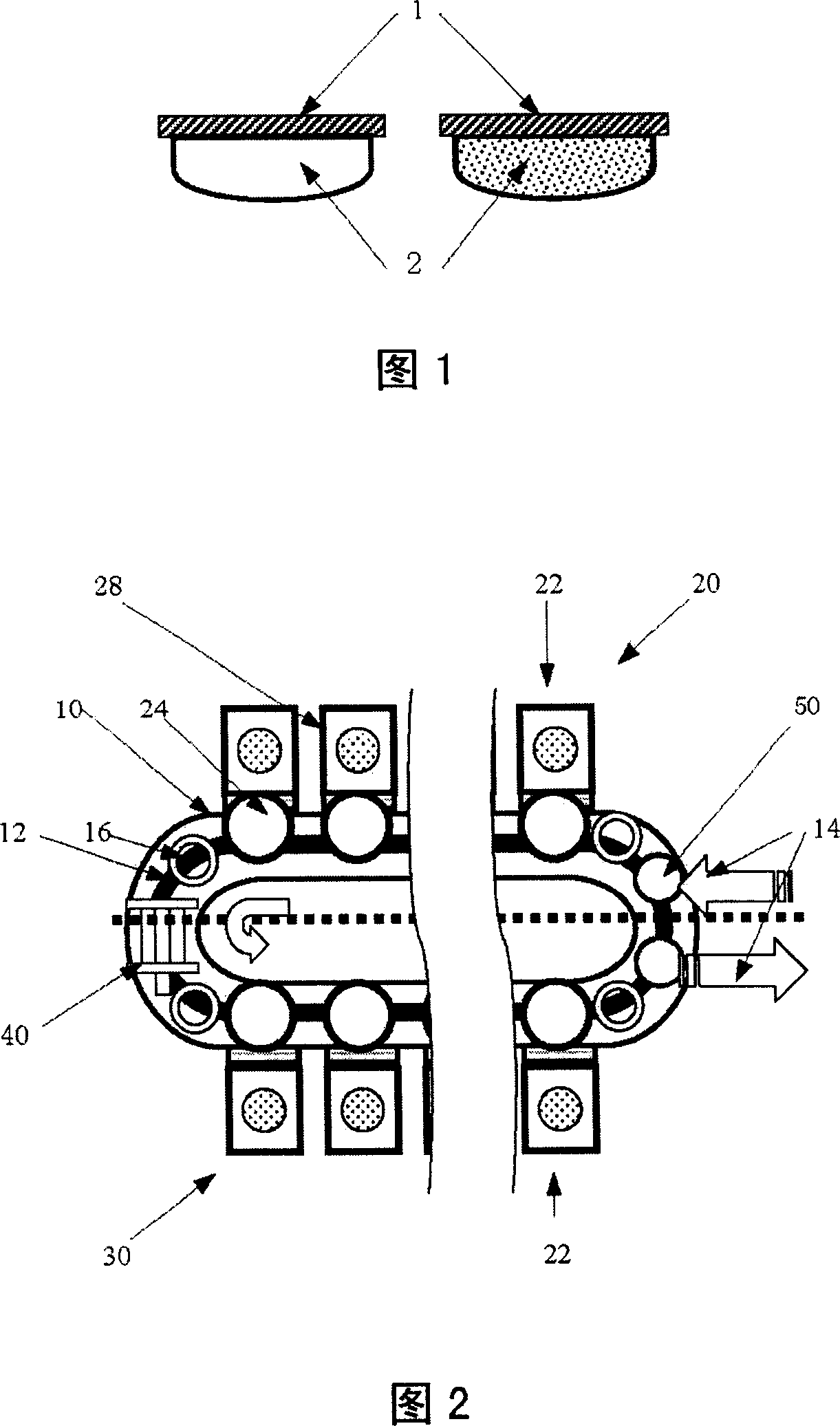

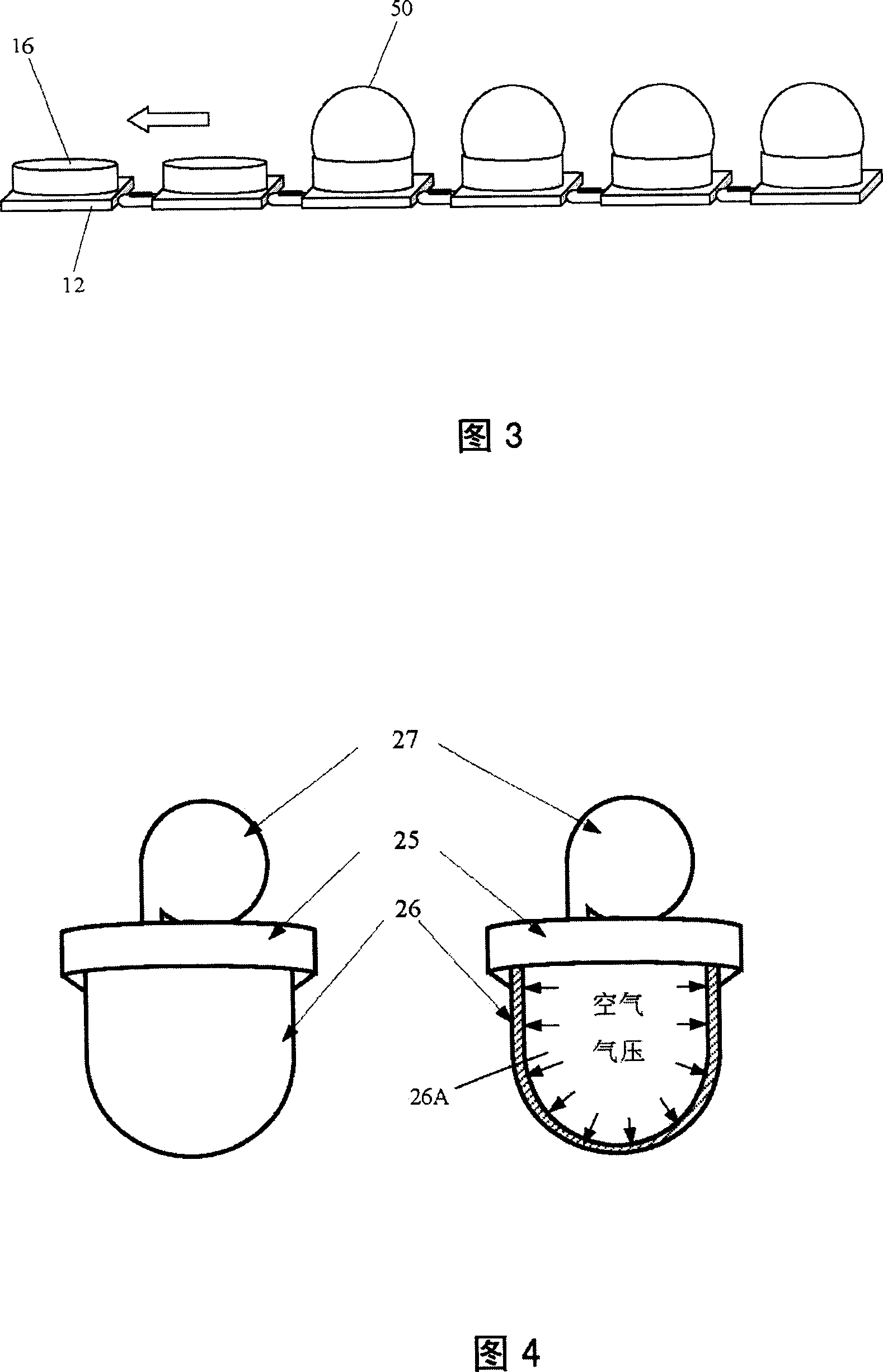

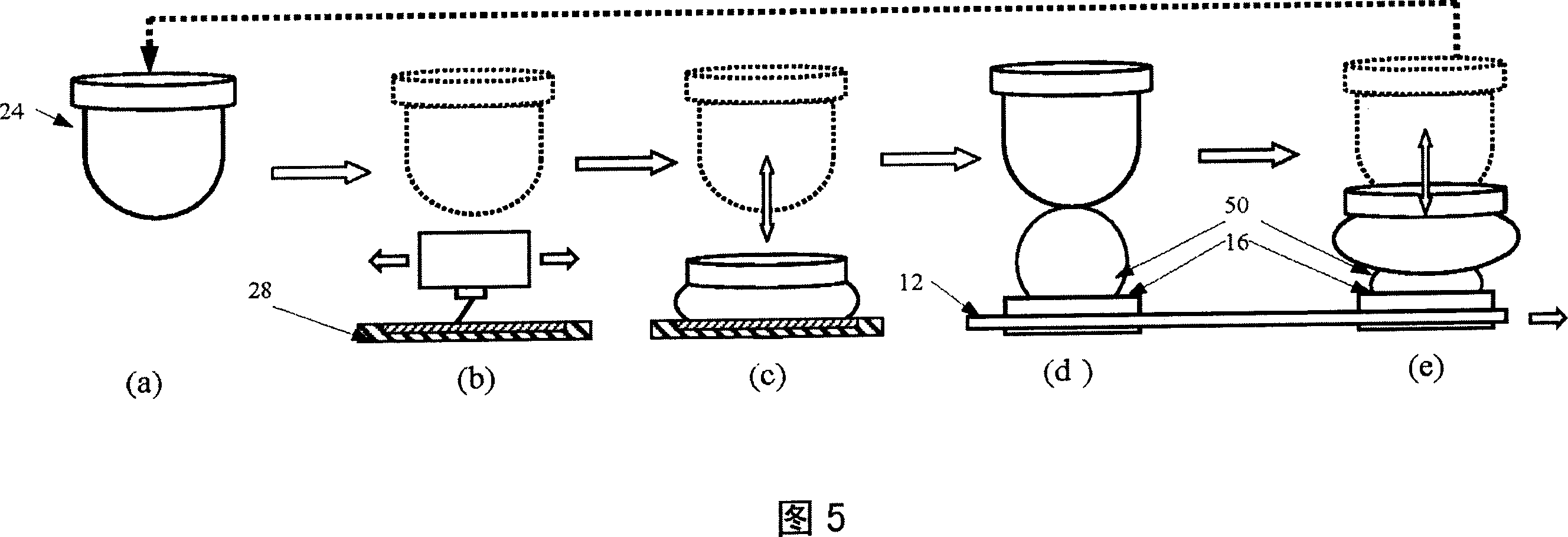

Spherical/special-shaped product all-print printing process and apparatus

InactiveCN101007475ARealize efficient continuous productionRealize printingRotary pressesOther printing apparatusColor printingAbnormal shaped

A spherical / heteromorphic products all-printed equipment is used for printing the whole spherical / heteromorphic products. It is characterized by, it includes a transmission frame, conveyer belt installed on the transmission frame, upper and lower semi-surface printing areas installed on conveyer belt and the turn-over device installed on the interface part of upper and lower semi-surface printing areas; the conveyer belt is equipped with products input and output channels and many transmission discs with gaps each other; the upper and lower semi-surface printing areas respectively includes at least one single color printing device, each single color printing device consists of a flexible air pressure jelly mould head installed below the transmission disc and a printing gravure installed below one side of transmission disc. The spherical / heteromorphic products all-printed method includes: processing at least single color printing of the upper semi-surface of spherical / heteromorphic products through using the flexible air pressure jelly mould head; turning over the spherical / heteromorphic products 180degree through a turn-over device; processing at least single color printing of the lower semi-surface of the product through using the flexible air pressure jelly mould head.

Owner:SHANGHAI INNOVATIVE TOYS

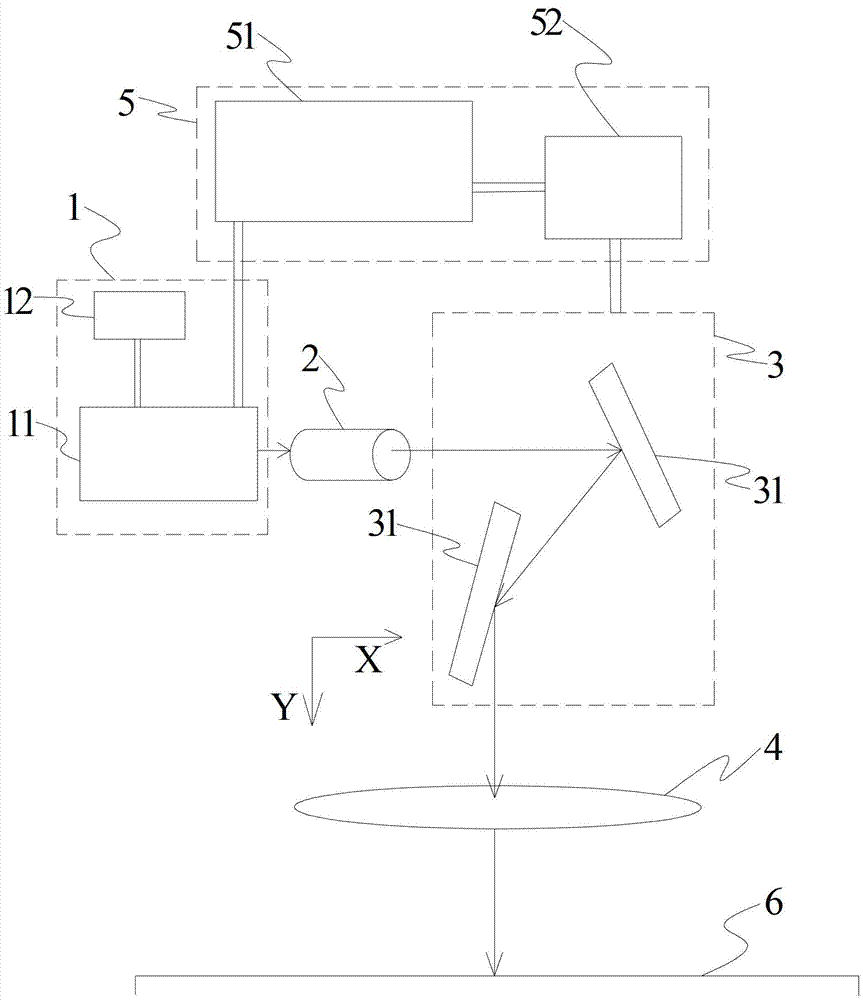

Laser optical path guiding system of laser sinter molding equipment

InactiveCN103111756ARealize printingCompact structureIncreasing energy efficiencyLaser beam welding apparatusBeam expanderLight energy

The invention discloses a laser optical path guiding system of laser sinter molding equipment. The laser optical path guiding system of the laser sinter molding equipment comprises a laser source, a beam expander matched with the laser source, a scanning galvanometer device matched with the beam expander and a flat field focusing lens connected with the scanning galvanometer device. The laser sinter molding equipment is provided with a molding platform, a focal plane of the flat field focusing lens is overlapped with the molding platform, and the focus point of the lens is arranged at the center of the molding platform. Due to the mentioned structure, not only can printing of a three-dimensional component be achieved very well, but also each optical component can be connected into a whole without clearances, drifting of light beams is avoided, at the same time dust and vibration are prevented. In addition, protection of optical elements like the galvanometers and the like is considered. The laser optical path guiding system is compact in structure, short in optical path, small in light energy consumption, and convenient to debug.

Owner:余振新

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com