Equipment for testing bending and torsion resisting performances of electrical insulator

An insulator and bending technology, which is used in the field of equipment for testing the bending and torsional performance of power insulators, can solve the problems of large deformation, occupying space, and cost of insulators, meeting test requirements, high angle detection accuracy, and detection data. precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the utility model are further described below in conjunction with the accompanying drawings:

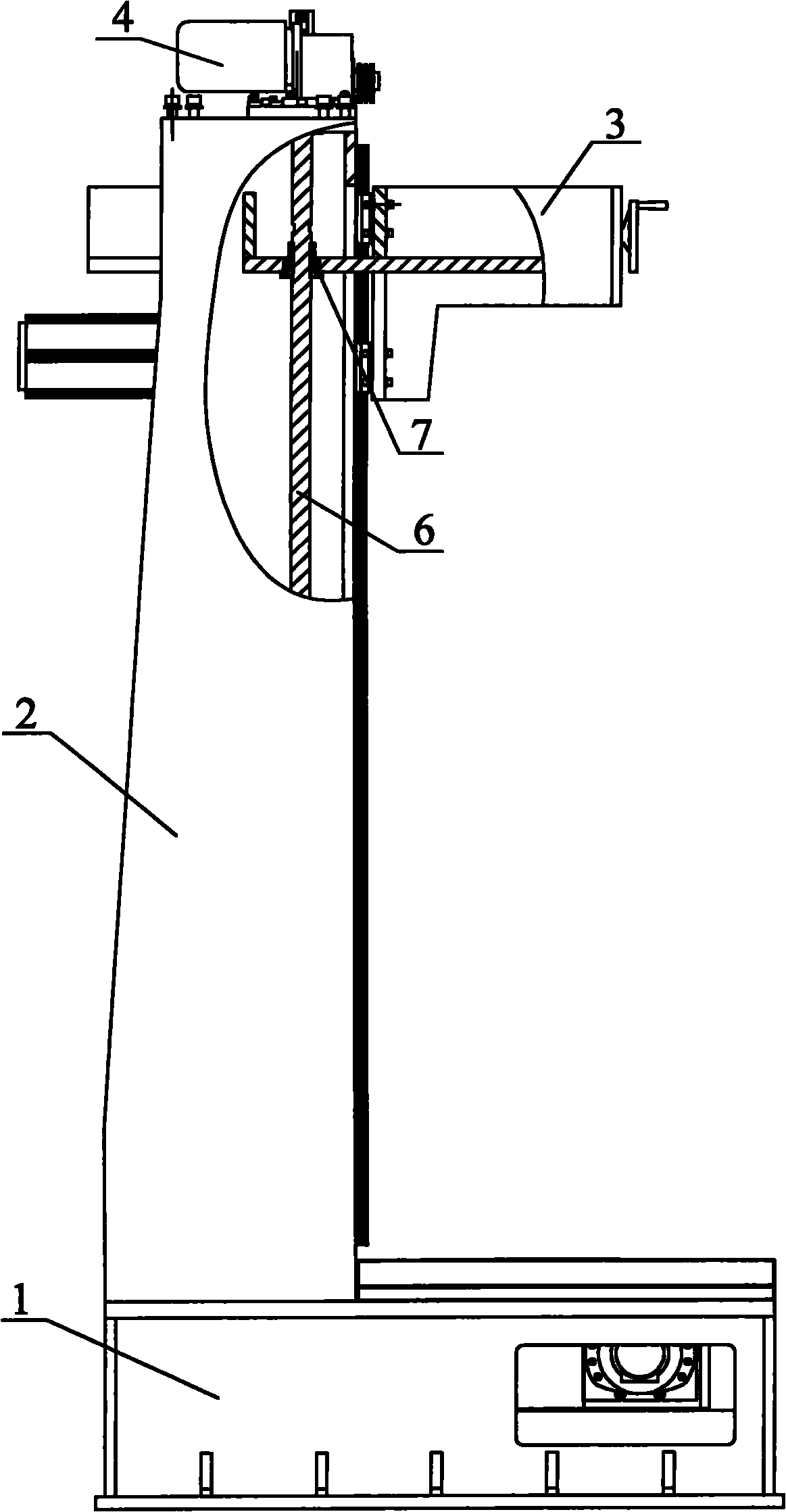

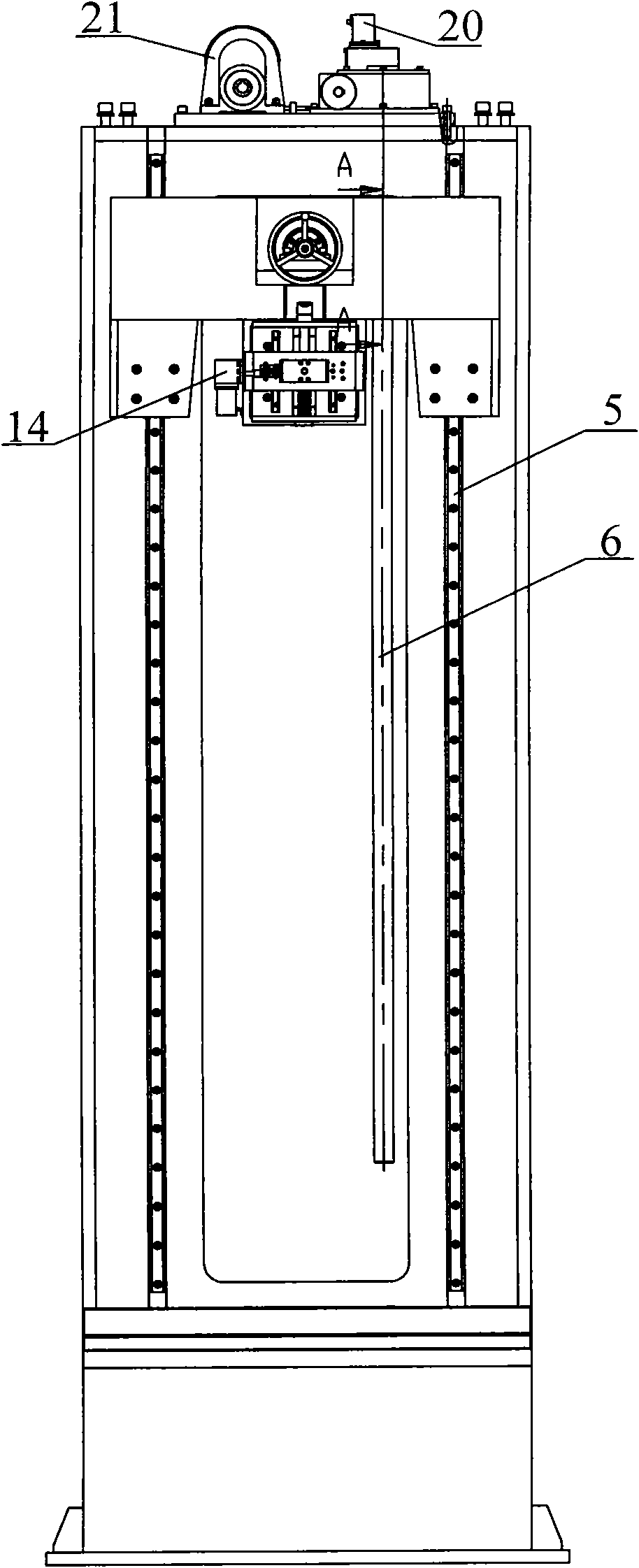

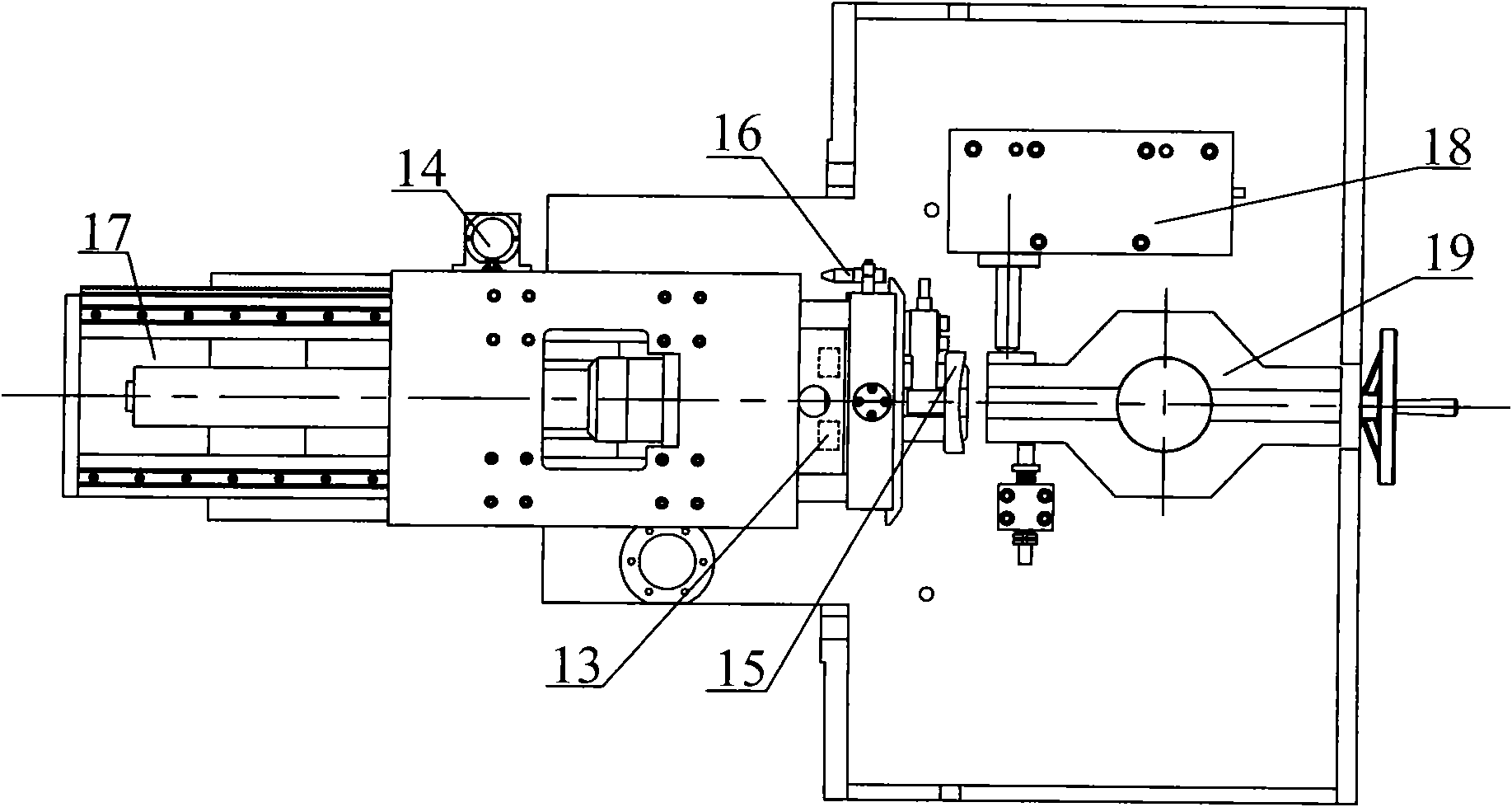

[0018] Such as figure 1 , 2 As shown, a device for testing the bending and torsional performance of power insulators is mainly composed of four parts: a rotary table 1, a column 2, a beam assembly 3 and a lifting drive mechanism 4. The rotary table 1 is located at the bottom of the equipment, and a rotary mechanism is provided therein. The column 2 is vertically fixed above the rotary table 1. The top of the column 2 is equipped with a lifting drive mechanism 4. The lifting drive mechanism 4 includes a lead screw 6, a reducer 21 and The lifting encoder 20, the lead screw 6 is connected with the lead screw nut 7 in the column 2, the top of the lead screw 6 is connected with the reducer 21, the side wall of the column 2 is provided with a linear guide rail 5, and the beam assembly 3 is connected to the column through the linear guide rail 5 2 sliding connection,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com