Digitally-controlled multifunctional inverted arc welding machine

A digital control and digital control system technology, applied in arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of poor parameter stability, poor event management ability, poor flexibility, etc., to meet welding process requirements, dynamic response speed Fast, dynamic range-increasing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is further described, explained and illustrated below in conjunction with specific embodiments.

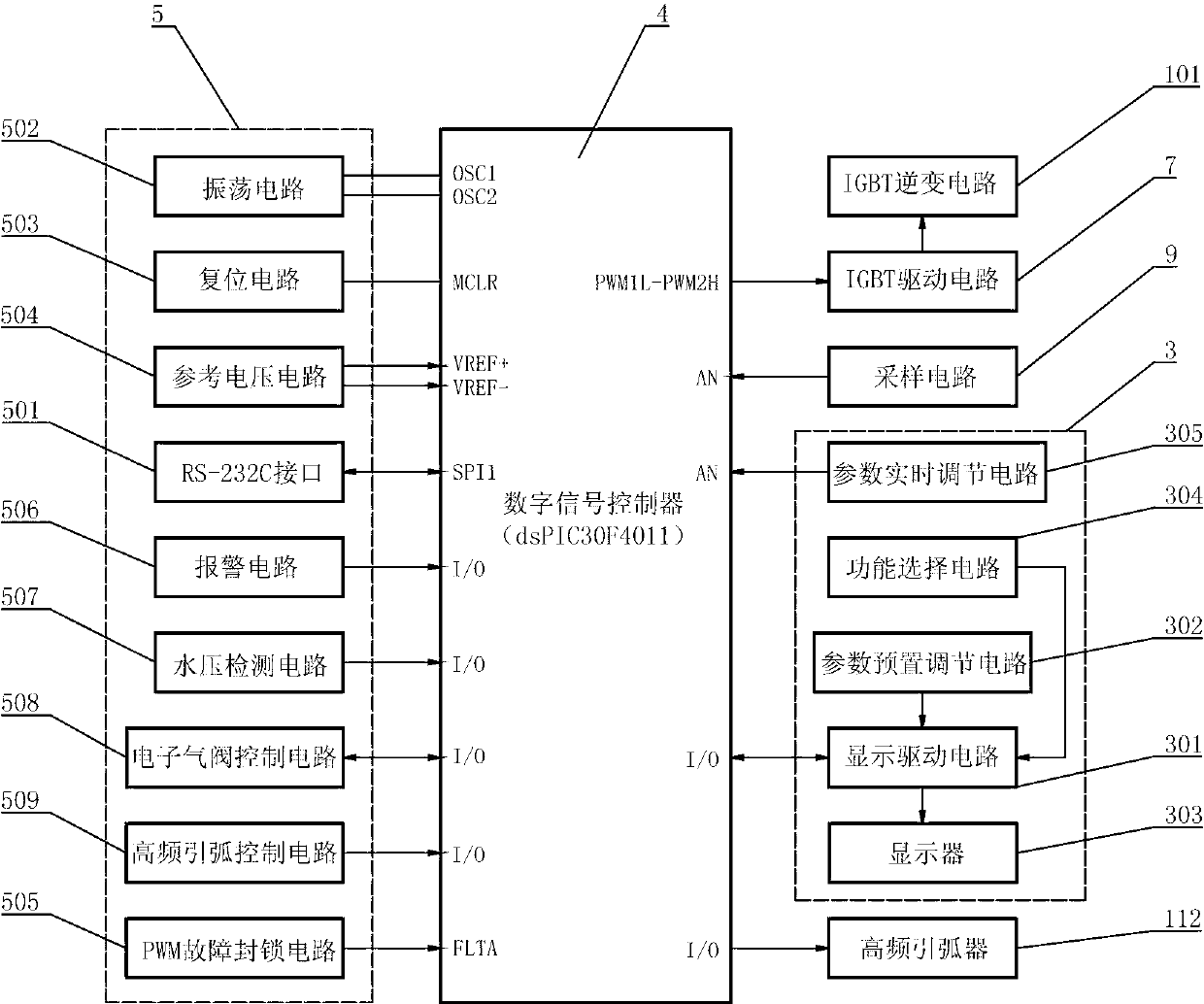

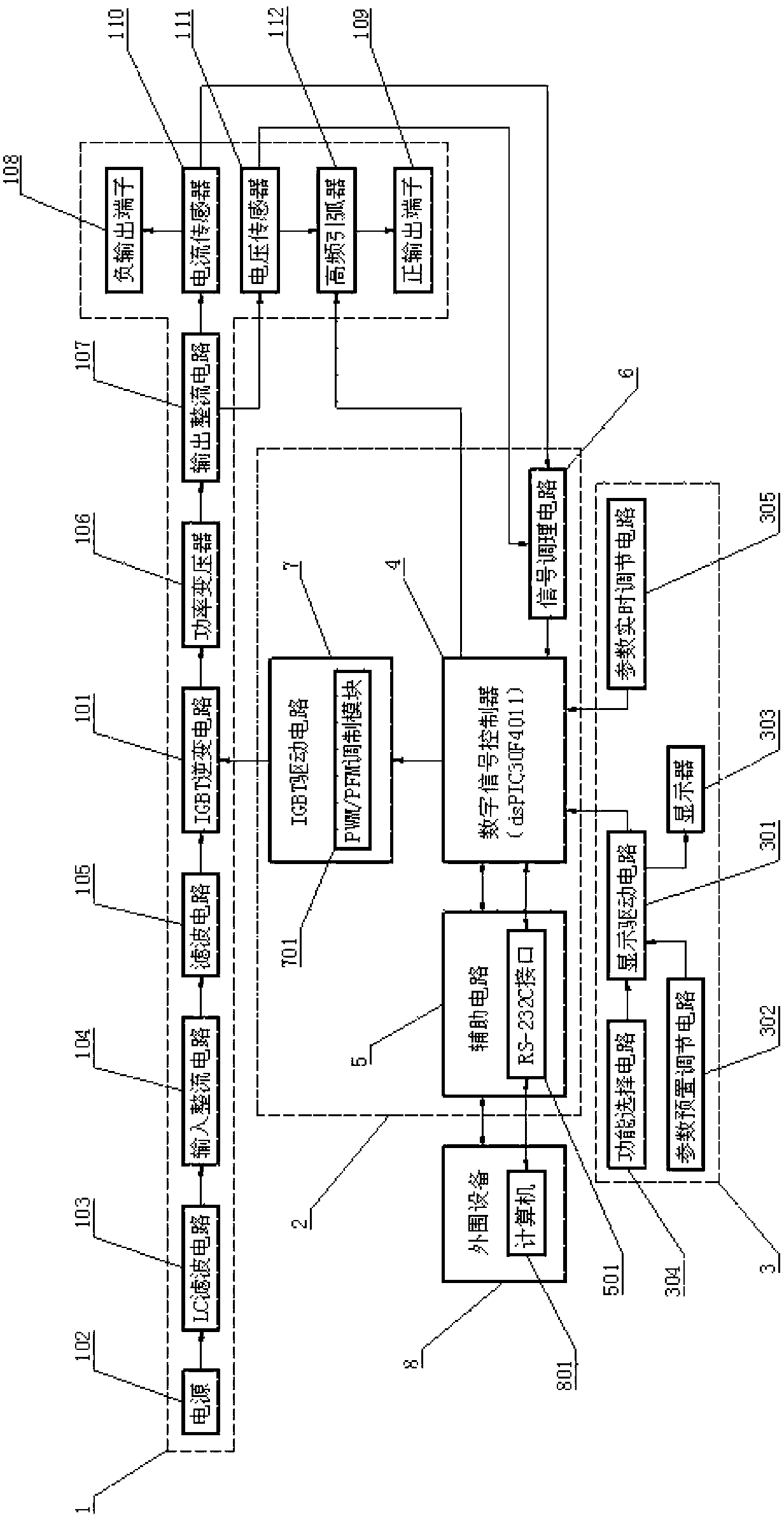

[0025] The digital control multifunctional inverter arc welding machine of the present invention, such as figure 1As shown, it includes a main circuit system 1, a digital control system 2 and a man-machine switching system 3 connected in sequence, and the main circuit system 1 includes an IGBT inverter circuit 101, wherein the digital control system 2 uses a digital signal controller 4 as the core control The unit also includes an auxiliary circuit 5 respectively connected to the digital signal controller 4, a signal conditioning circuit 6 for processing the collected data of the main circuit system 1, and an IGBT drive circuit for driving and controlling the IGBT inverter circuit 101 7; the model of the digital signal controller 4 is dsPIC30F4011, which is connected with the IGBT inverter circuit 101 through the IGBT drive circuit 7, and is used to re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com