Laser optical path guiding system of laser sinter molding equipment

A laser sintering molding and guiding system technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of dust easily setting inside the machine, adverse effects of light path, and high light energy loss, etc. and cooling, improving collimation, and the effect of short optical path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

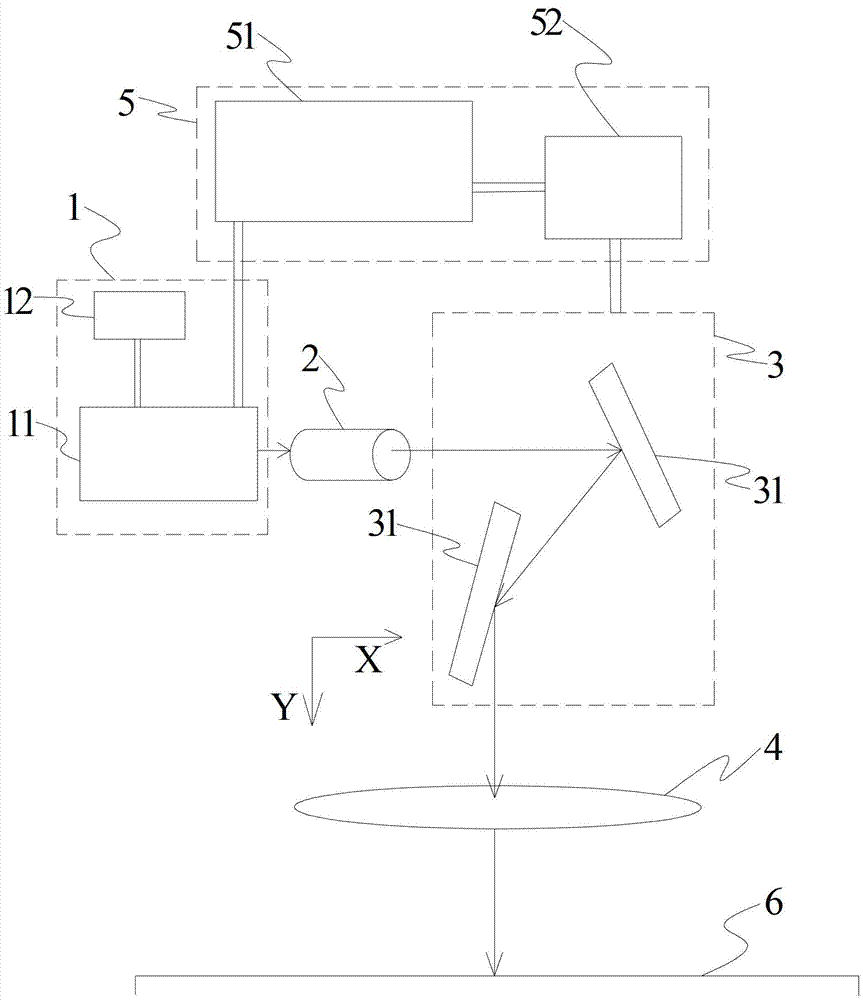

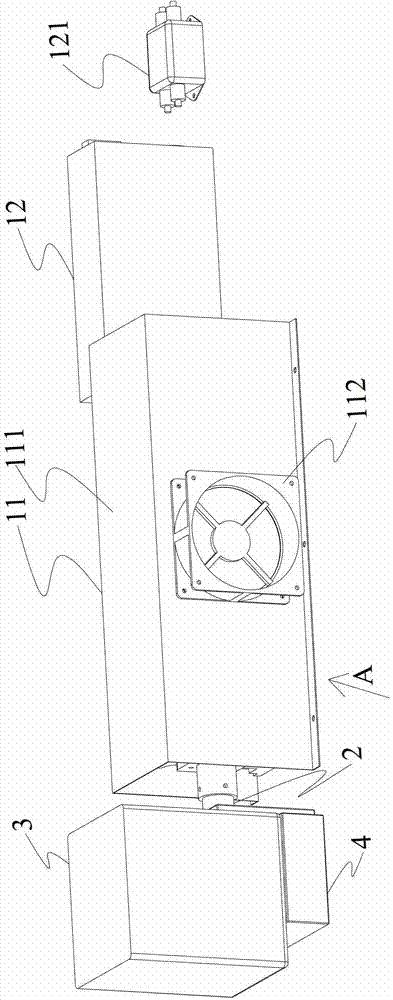

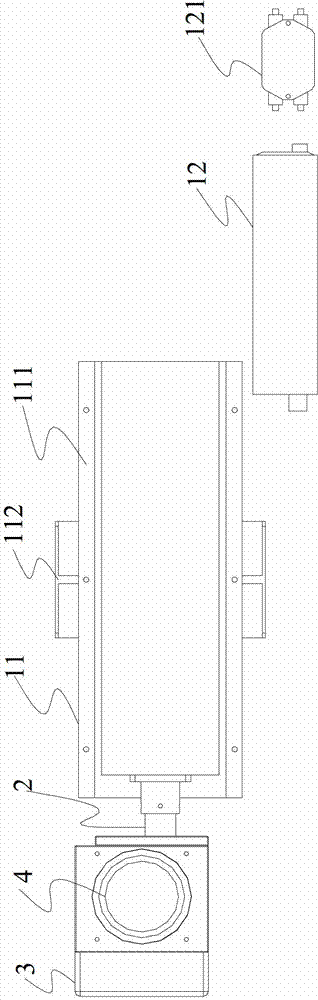

[0032] Such as Figure 1 to Figure 3 The laser optical path guiding system of the laser sintering molding equipment of the shown embodiment includes a laser source 1, a beam expander 2 matched with the laser source, a scanning galvanometer device 3 matched with the beam expander 2 and a scanning galvanometer The flat-field focusing lens 4 connected to the device 3; the laser sintering molding equipment is provided with a molding platform 6, and the flat-field focusing lens 4 is arranged at a position matched with the molding platform 6.

[0033] The laser source 1, the beam expander 2 and the scanning galvanometer device 3 are distributed along the X-axis direction, the flat-field focusing lens 4 and the scanning galvanometer device 3 are distributed along the Y-axis direction; the laser light emitted by the laser source 1 is first along the X-axis After being shot out, the direction is changed by the scanning galvanometer device 3, and shot to the forming platform 6 along the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com