Heterogeneous cell three-dimensional printing system and heterogeneous cell three-dimensional printing method

A cell printing and three-dimensional printing technology, applied in biochemical equipment and methods, biological material sampling methods, biomass post-processing, etc., can solve the problems of inability to complete three-dimensional printing of heterogeneous cells, and achieve the effect of efficient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

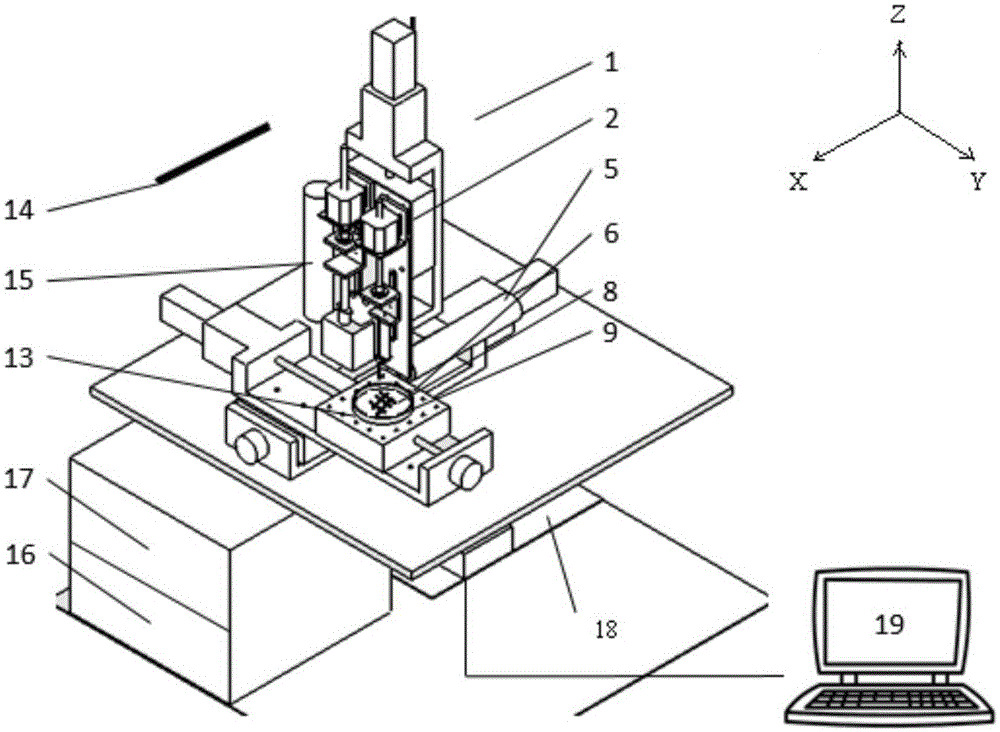

[0039] This embodiment relates to a three-dimensional cell printing system for heterogeneous cells, including a moving platform, an extrusion-type cell printing mechanism and a drop-type cell printing mechanism fixed on the moving platform, an observation unit for observing the cell printing position, and control unit;

[0040] The control unit first controls the extrusion-type cell printing mechanism to complete the printing of the cell hydrogel structure, and then controls the drop-type cell printing structure to complete the printing of a single cell on the cell hydrogel structure; during the printing process, The control unit controls the motion platform to move in the three directions of X, Y, and Z, so as to realize printing at different positions of the extruding cell printing mechanism and the dropping cell printing mechanism.

Embodiment 2

[0042] This embodiment relates to a 3D printing system for heterogeneous cells, the structure of which is as follows figure 1 and figure 2 Compared with Embodiment 1, the difference is that the printing system is placed in the molding chamber 1, and an ultraviolet sterilization lamp 14 is arranged in the molding chamber;

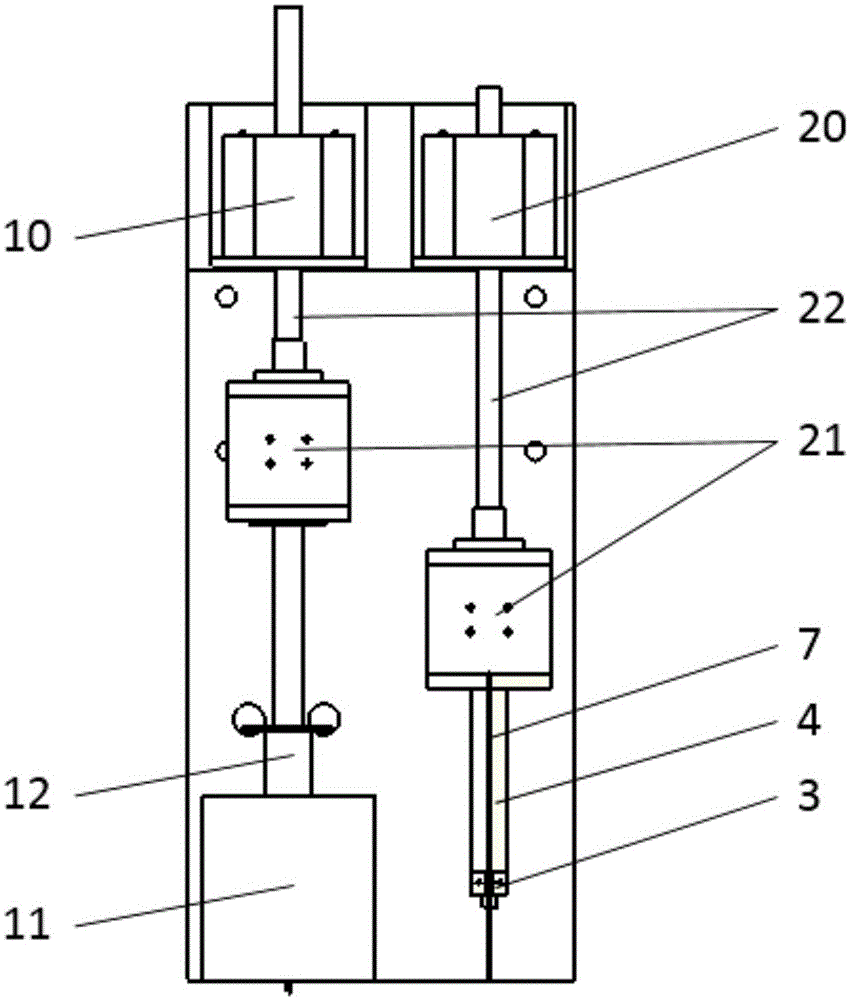

[0043] The extrusion-type cell printing mechanism is fixed on the Z-axis motion platform 2 of the motion platform, and consists of a syringe drive motor 10, a heat preservation sleeve 11, a 1mL syringe and its nozzle 12; the drop-type cell printing mechanism is fine-tuned by position A motor 20, an indenter 21, a piezoelectric ceramic 4, and a drop-type cell printing micro-spray head 7 are all fixed on the Z-axis motion platform 2 through the print head clamping mechanism 3;

[0044] The observation unit includes a horizontal observation microscope 5 arranged on the nozzle clamping mechanism 3 and a vertical observation microscope 15 arranged at the bottom...

Embodiment 3

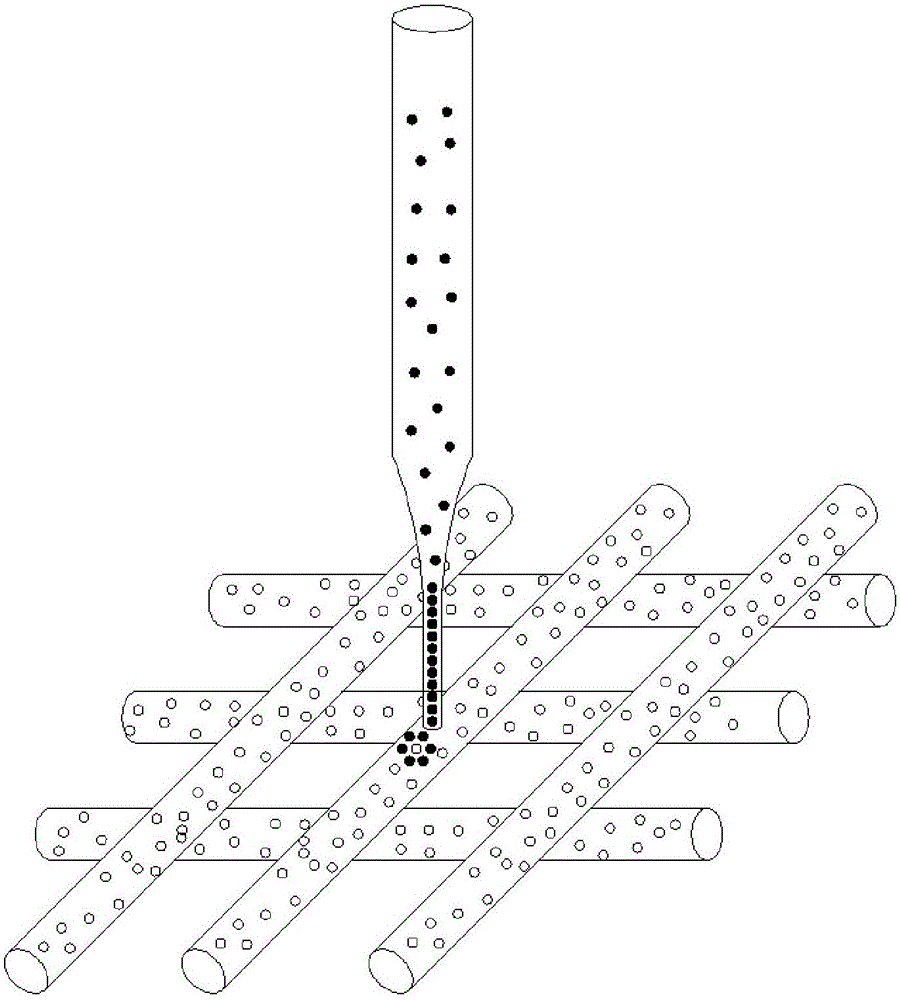

[0048] This embodiment relates to a method for printing a tumor cell model using the heterogeneous cell three-dimensional printing system of the present invention, which is characterized in that it includes the following steps:

[0049] 1) Prepare cell solution for extrusion cell printing. The culture solution containing A549 cells was centrifuged and suspended in the culture medium to reach 4×10 6 / ml cell density. Afterwards, the A549 cell culture solution, 4% sodium alginate solution and 20% gelatin solution were mixed according to the volume ratio of 1:1:1, and the final cell density was 1×10 6 / ml or so.

[0050] 2) Prepare the cell solution for drop cell printing. The A549 cell culture solution was aspirated and diluted so that the final cell density was 5×10 4 / ml. Among them, it is worth noting that the cell density in the cell solution can be adjusted according to the needs of different models, and is not limited to the currently used cell density.

[0051] 3) T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com