Three-dimensional color printing device and method

A three-dimensional printing and color technology, applied in the direction of additive processing, etc., can solve the problems of complex models that cannot be printed in color and hollowed out, and achieve the effects of improved printing accuracy, high printing accuracy, and convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

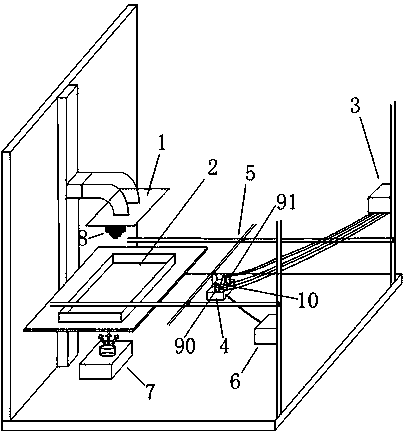

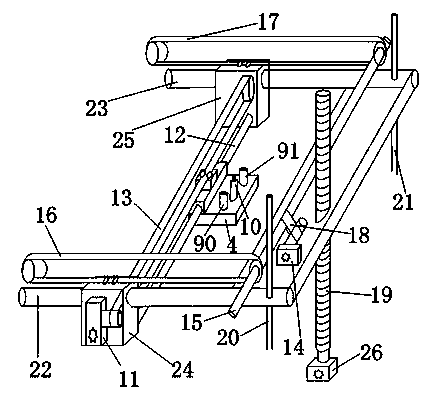

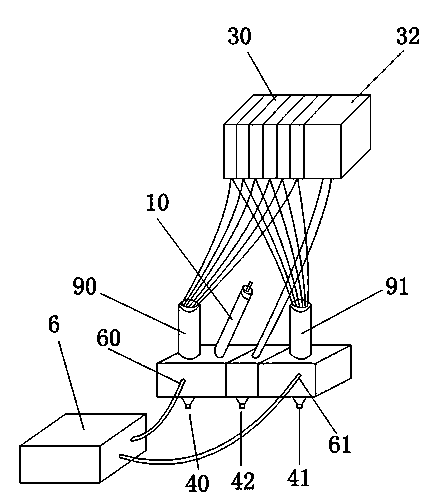

[0064] Embodiment 1: A DLP color three-dimensional printing device based on down-illuminated molding performs a color printing process:

[0065] First establish a computer model of a three-dimensional object, slice and layer it after generating the support, and obtain the shape information and surface color information of each layer; associate the obtained information data with the automatic control system; the forming plate 1 rises to the highest (or suitable ) position, the nozzle group 4 slides into the forming working pool 2, and the automatic control system controls the moving mechanism 5 to drive the nozzle group 4 to move in three displacement directions of freedom, front and rear, left and right, and up and down, and spray out the base layer of the three-dimensional model at the same time. After the base layer is sprayed, the nozzle group 4 returns to its position, and the forming plate 1 is lowered to connect with the forming working pool 2, and then the DLP projection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com