Metal three-dimensional printing method and equipment thereof

A three-dimensional printing and metal technology, applied in the field of additive manufacturing, can solve the problems of low forming precision and low bonding force between metal layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

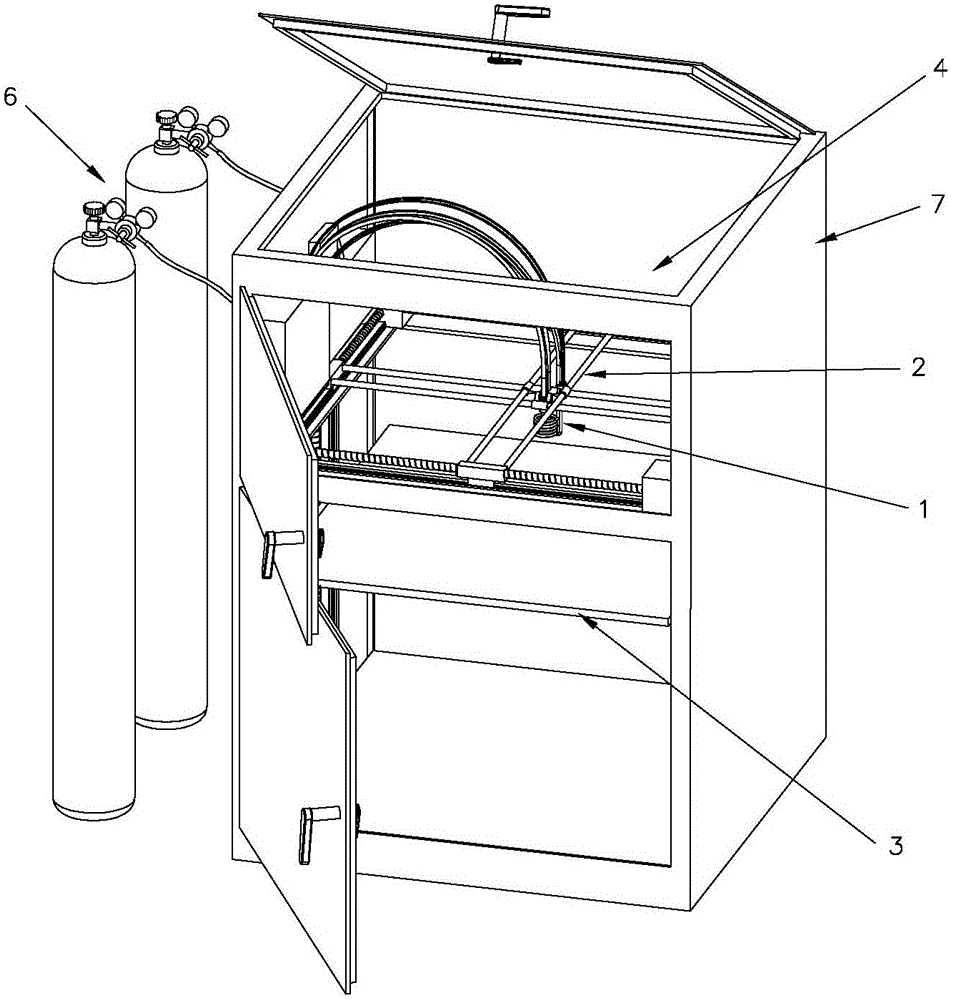

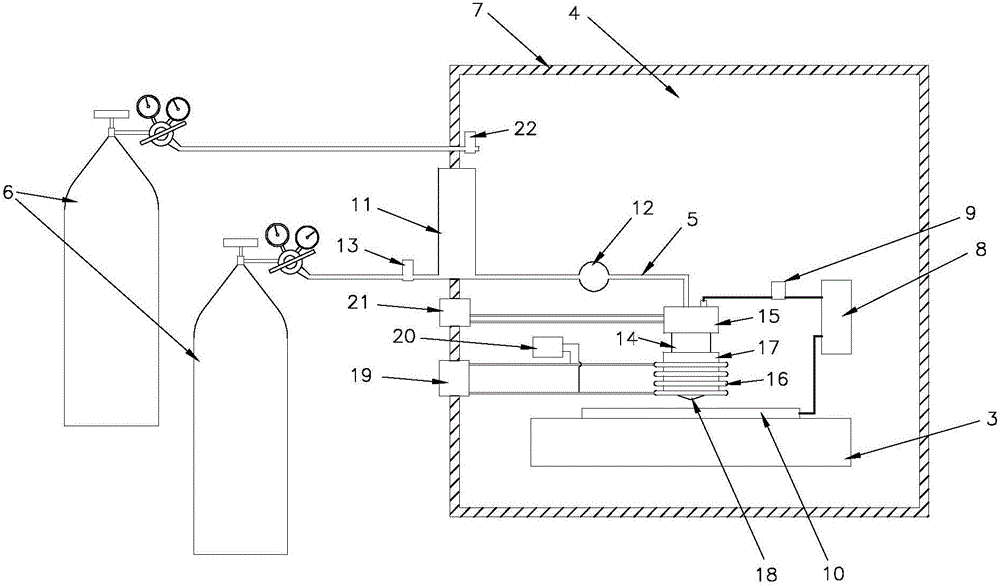

[0083] The following lists two preferred specific embodiments of a metal three-dimensional printing method of the present invention and four preferred specific embodiments of a metal three-dimensional printing device of the present invention and describes the present invention in detail in conjunction with the accompanying drawings, wherein: The first to second preferred specific embodiments of a metal 3D printing device of the invention respectively apply the first to second preferred specific embodiments of a metal 3D printing method of the present invention.

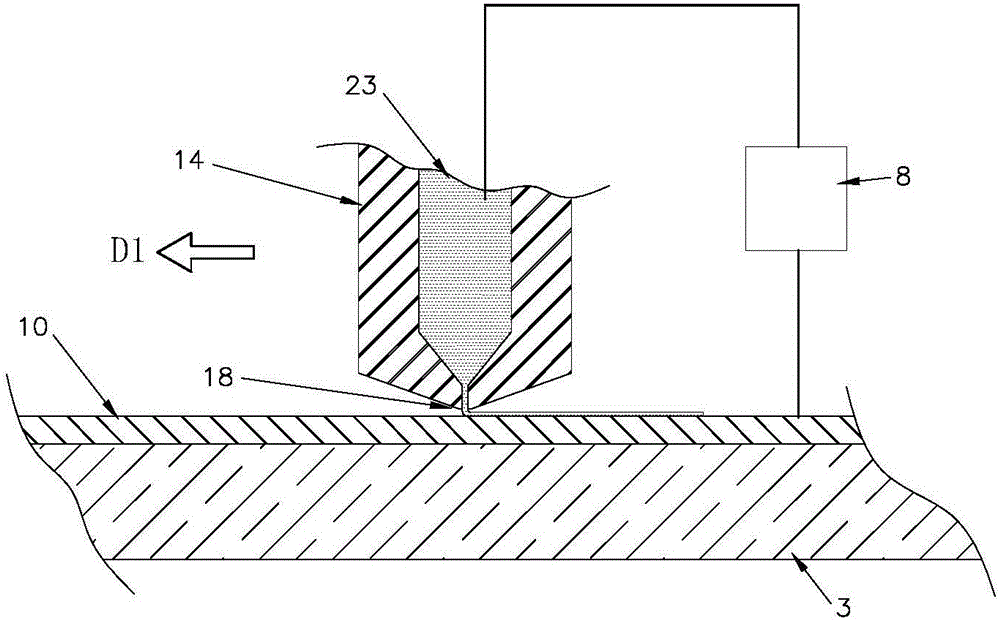

[0084] as attached image 3 to attach Figure 10 The first preferred specific embodiment of a metal 3D printing method of the present invention is shown: a metal 3D printing method, the main process of which is: placing molten or softened and flowable metal into a 3D printing device The molding area (corresponding to the attached figure 1 And attached figure 2 As shown in the molding cavity 4), the melted or softe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com