Automatic printer for vamp

A printing machine, automatic technology, applied in the direction of printing machine, rotary printing machine, printing, etc., can solve the problems that the printing quality is greatly affected, the position is easy to shift, and there cannot be too many through holes, so as to improve the printing effect and be practical Good performance, realize the effect of equipment integration and fully automatic operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

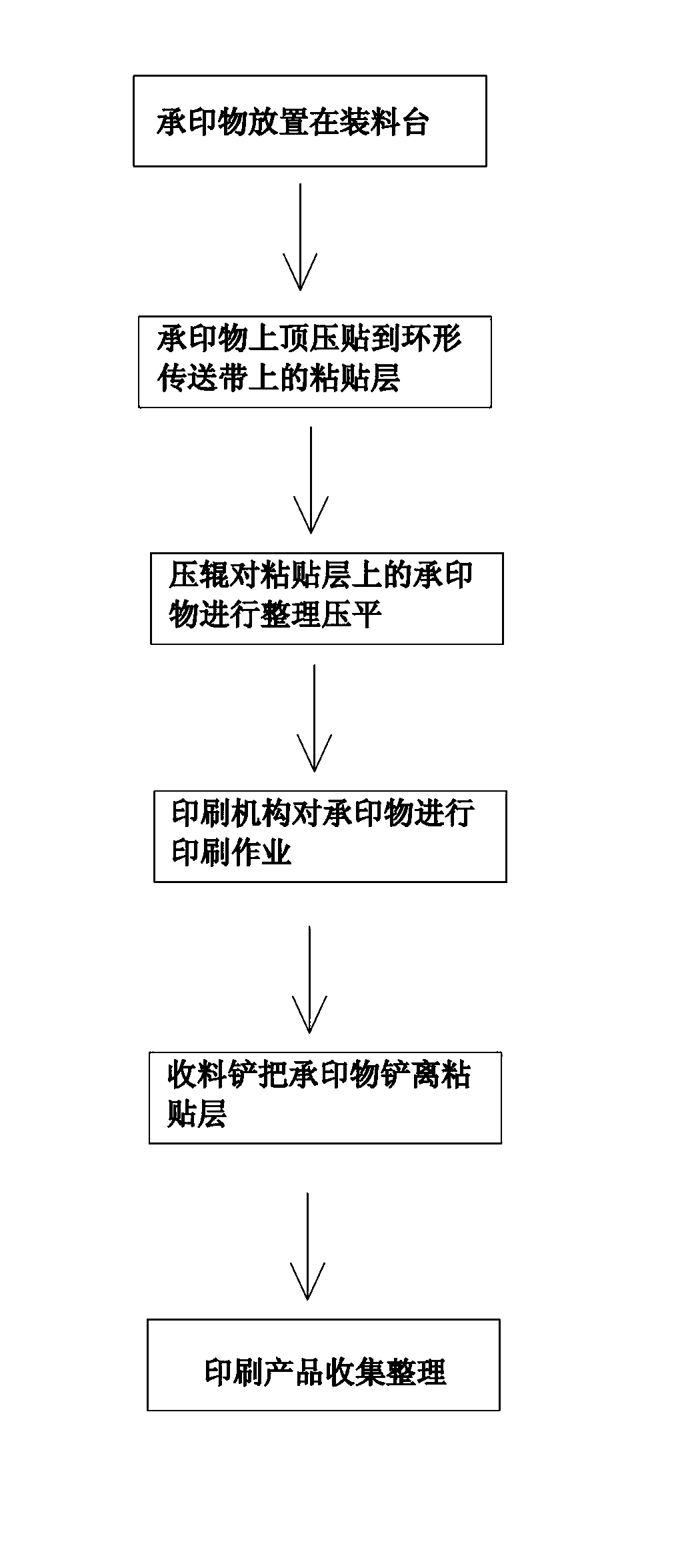

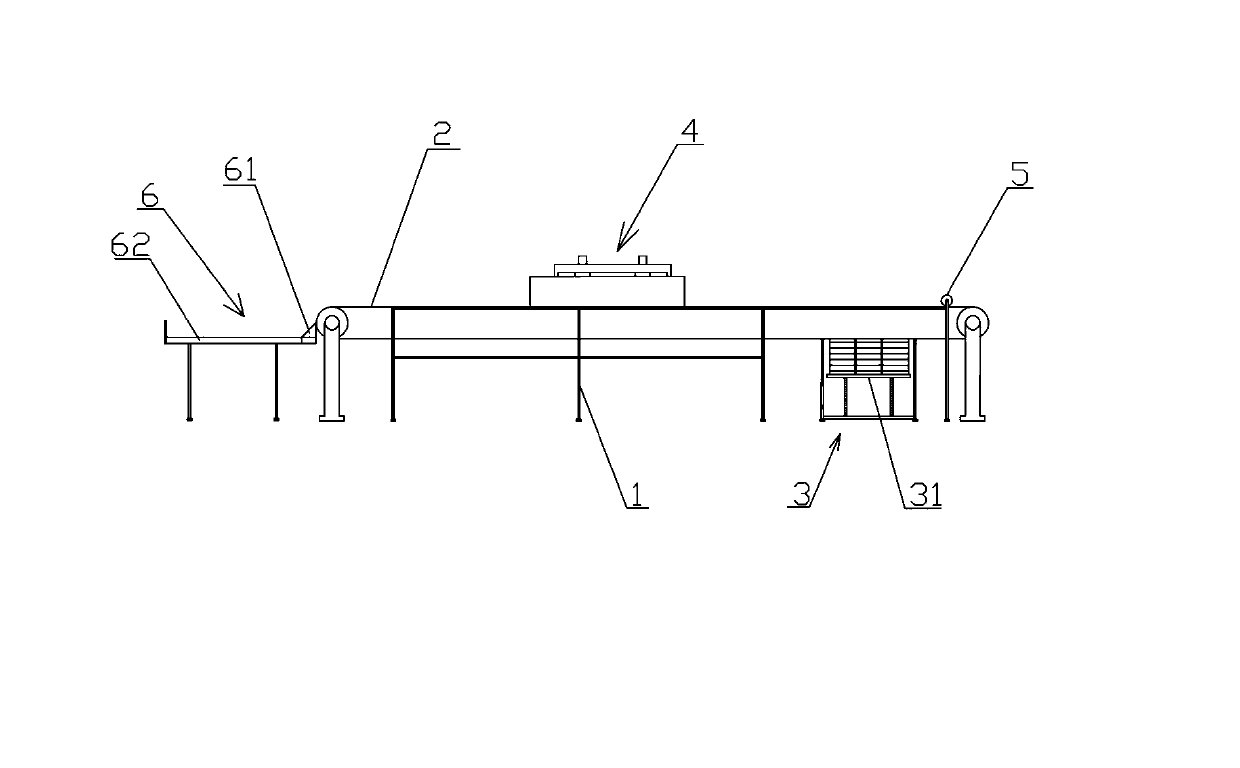

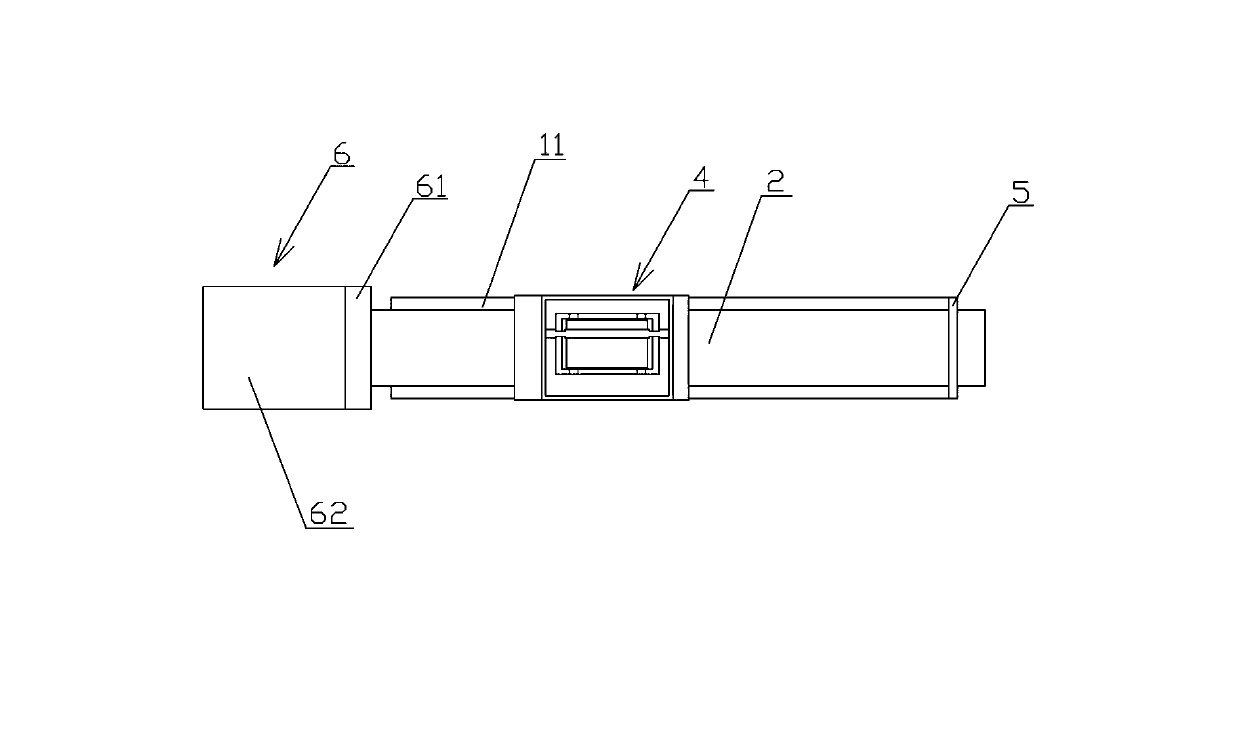

[0019] The specific implementation manner of the present invention will be further described below with reference to the accompanying drawings.

[0020] Such as figure 1 , figure 2 As shown, an automatic printing machine for shoe uppers includes a combined frame body 1 provided with a working platform 11 on which an endless conveyor belt 2 and a servo motor (figure 1) for driving are provided on the combined frame body 1 not shown in), the surface of the endless conveyor belt 2 is coated with a layer of adhesive layer that can change the adhesive strength according to the specific substrate (due to the viewing angle, it is not shown in the figure); the bottom of the combined frame body 1 is provided with a The feeding mechanism 3 for pressing the printed matter on the above-mentioned adhesive layer, the feeding mechanism 3 includes a lifting table 31 for neatly holding the printed matter and its associated lifting device (not shown in the figure) ).

[0021] Such as figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com