Waterfast dye fixative compositions for ink jet recording sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

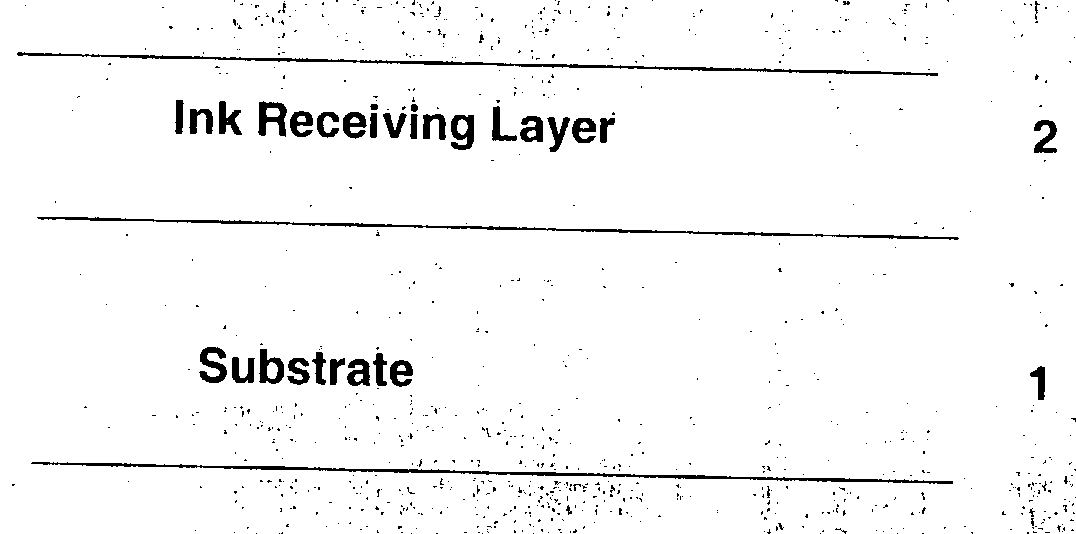

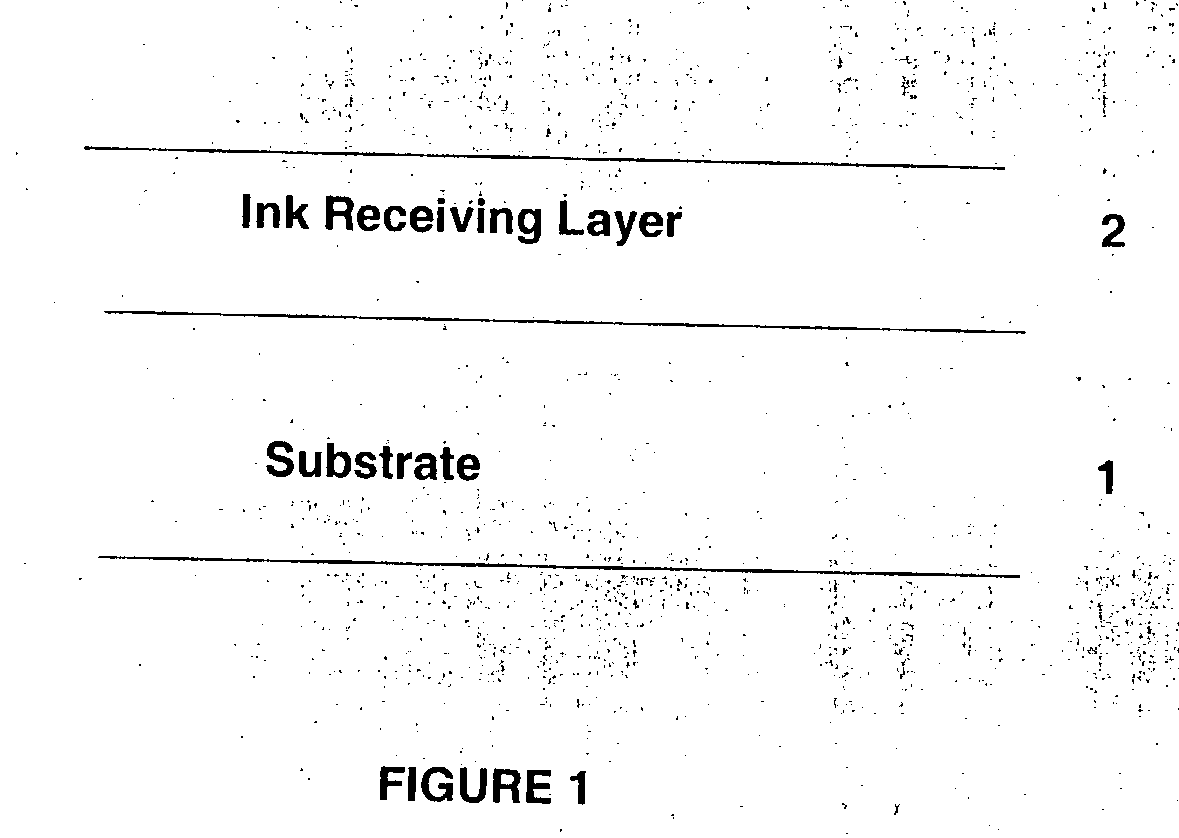

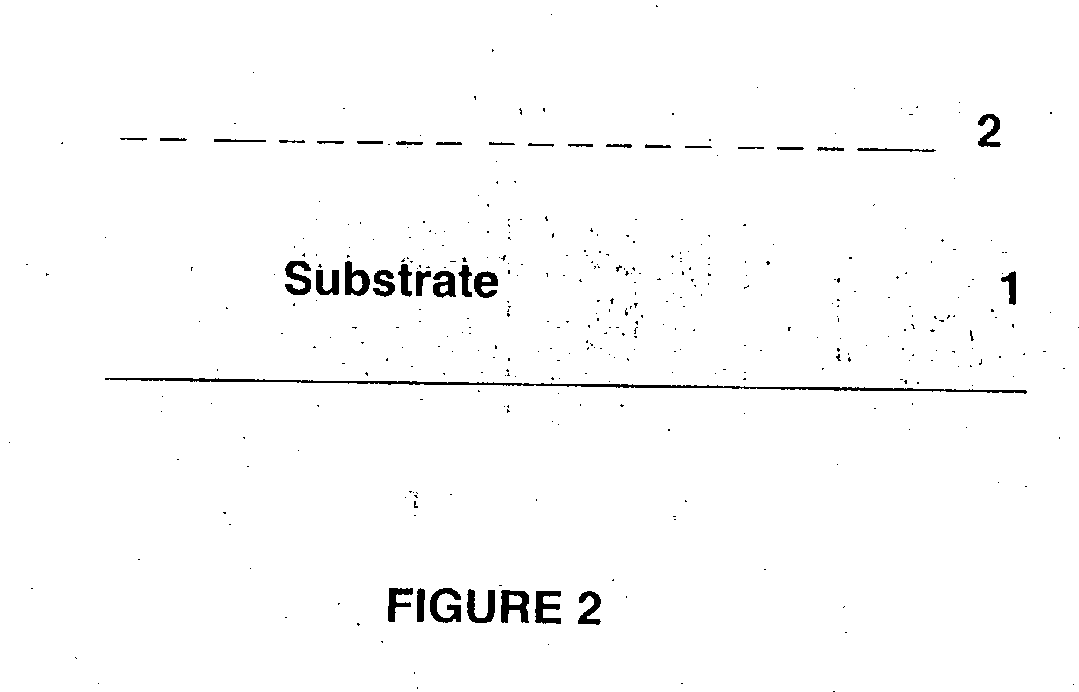

Image

Examples

example i

[0061] The print density and waterfastness of an ink jet recording sheet according to the present invention was tested. The specific formulation tested is set forth below in Table I. This example is of a size press formulation containing a blend of two dye fixatives and starch.

1TABLE I Formulation of Dye Fixative Composition Used in Size Press Quantity Concentration Dry Weight Ratio Ingredient (g) (%) (%) Starch 25.2 10 25 Fissatore L 11.3 44 50 Sumachlor 5.0 50 25 Water 58.5 0 0 Totals 100 10 100 Fissatore L is dicyandiamide-formaldehy-de resin, CAS #26591-12-8 (Lamberti, SPA, Italy). Sumachlor is aluminum chlorohydrate, CAS # 12359-72-7 (Summit Research Labs, Flemington, NJ).

[0062] The starch used in this example was a Penford hydroxyethyl starch, designated PG-290, CAS#9005-27-0 (Penford Products, Cedar Rapids, Iowa). This starch was cooked in a starch cooker following the heating schedule recommended by the manufacturer at a concentration of 10% solids. The two dye fixatives, Fi...

example ii

[0066]

2TABLE II Formulation of Dye Fixative Composition Used in Size Press Quantity Concentration Dry Weight Ratio Ingredient (g) (%) (%) Starch 20.2 10 20 Arquad DMCB-80 6.3 80 50 Sumachlor 6.0 50 30 Water 67.5 0 0 Totals 100 10 100 Sumachlor is aluminum chlorohydrate, CAS # 12359-72-7 (Summit Research Labs, Flemington, NJ). Arquad DMCB-80 is benzyl cocoalkyl dimethyl quaternary ammonium chloride, CAS# 61789-71-7 (Akzo Nobel Chicago, IL).

[0067] The two dye fixatives, Arquad DMCB-80 and Sumachlor, were received from the manufacturers as solutions in water, with concentrations shown in Table I. These dye fixatives were added to tap water in the quantities shown in Table I. The percent solids of the solution was 10% in total solids, and the viscosity was less than 20 cps. Concentrated sodium hydroxide solution was then added to this solution while stirring to raise the pH to 7. This dye fixative mixture was then added to an equal quantity of cooked starch solution, also at 10% solids....

example iii

[0069]

3TABLE III Formulation of Dye Fixative Composition Used in Size Press Quantity Concentration Dry Weight Ratio Ingredient (g) (%) (%) Starch 20.8 10 21 Nalco CP261 9.4 40 37 Sumachlor 8.3 50 42 Water 61.5 0 0 Totals 100 10 100

[0070] The two dye fixatives, Nalco CP261 and Sumachlor, were received from the manufacturers as solutions in water, with concentrations shown in Table I. These dye fixatives were added to tap water in the quantities shown in Table I. The percent solids of the solution was 10% in total solids, and the viscosity was less than 20 cps. Concentrated sodium hydroxide solution was then added to this solution while stirring to raise the pH to 7. This dye fixative mixture was then added to an equal quantity of cooked starch solution, also at 10% solids.

[0071] Sizing of paper with no existing surface sizing was performed in the lab using the same conditions as described above in Example I. The paper was then printed and tested using the same conditions as described...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com