Environment-friendly type water-based intaglio ink used for package printing and preparation method thereof

A gravure ink, packaging printing technology, applied in the direction of ink, application, household utensils, etc., to achieve the effect of protecting health, strong color development and high gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

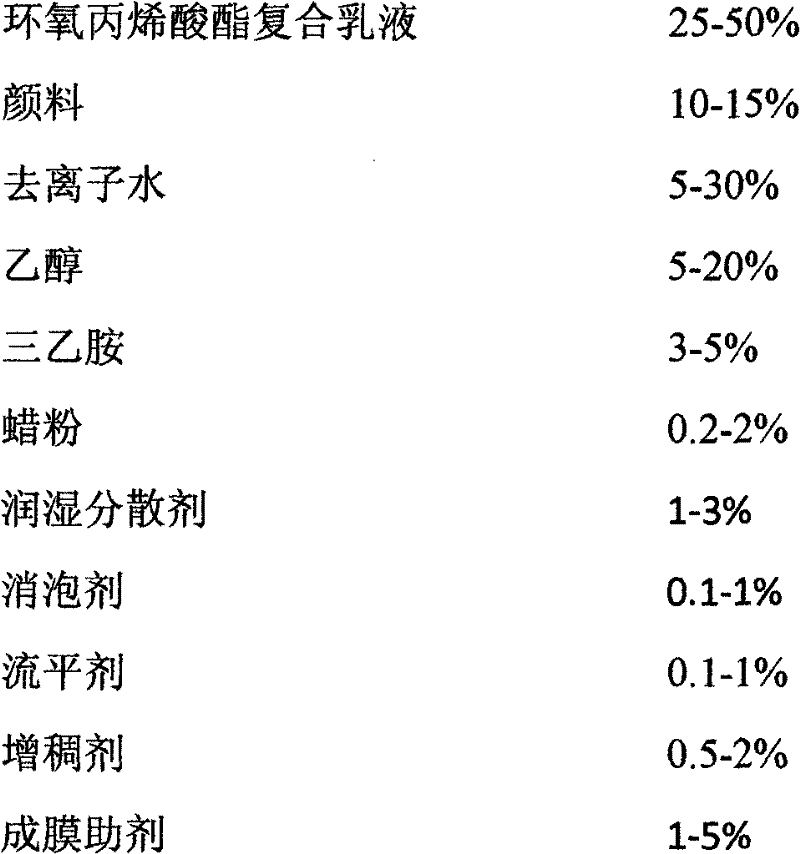

[0034] Prepare a kind of water-based gravure ink for packaging printing, the raw material composition of the present embodiment is as follows:

[0035]

[0036]

[0037]According to the above specific formula data, the water-based gravure ink for packaging and printing is prepared. The pigment in the formula refers to the light-fast pink original; the wax powder in the formula refers to oxidized polyethylene wax; the wetting and dispersing agent in the formula refers to the Disperbyk-183 is a polymer wetting and dispersing agent for water and solvent-based systems; the defoamer in the formula refers to the epoxy compound Tetronic 50RL; the leveling agent in the formula refers to silicone and acrylate water-based coating leveling agents AC-900; the thickener in the formulation refers to the polyurethane thickener used in water-soluble coatings; the coalescent in the formulation refers to alcohol ether compounds.

[0038] Epoxy acrylate composite emulsion of the present in...

Embodiment 2

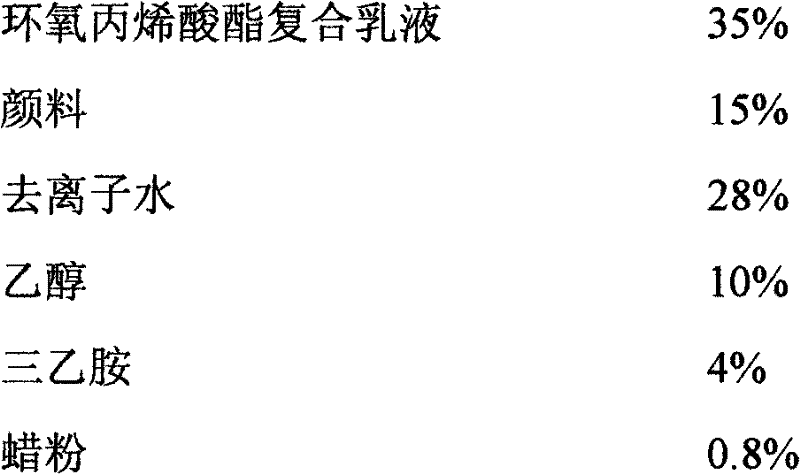

[0044] Prepare a kind of water-based gravure ink for packaging printing, the raw material composition of the present embodiment is as follows:

[0045]

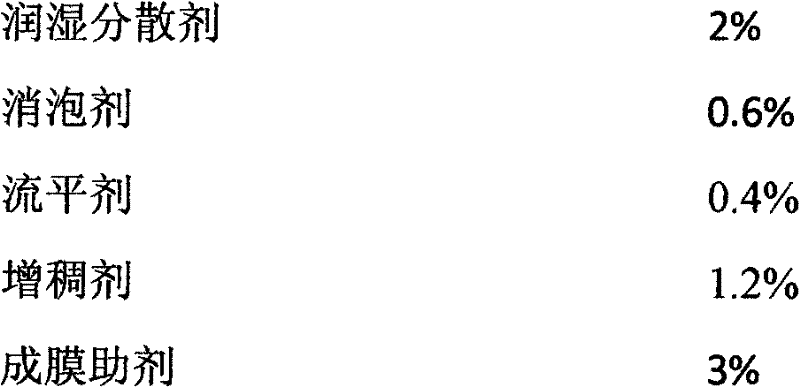

[0046]

[0047] Prepare water-based gravure ink for packaging and printing according to the above specific formula data. The pigment in the formula refers to cyanine blue BGS; the wax powder in the formula refers to microcrystalline wax; the wetting and dispersing agent in the formula refers to water-based and solvent-based polymer wetting and dispersing agent Disperbyk-185; the defoamer in the formula refers to mineral hydrocarbons and surfactant CF268; the leveling agent in the formula refers to the leveling of silicone and acrylic water-based coatings agent AC-900; the thickener in the formulation refers to the polyurethane thickener used in water-soluble coatings; the film-forming aid in the formulation refers to monoester organic compounds.

[0048] Epoxy acrylate composite emulsion of the present invention, its pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| freshness | aaaaa | aaaaa |

| freshness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com