Electrofluid ink jet printing spray in array and logic control method

A logic control and electrofluidic technology, applied in printing, printing devices, etc., can solve the problems of low printing accuracy, low efficiency, and inability to realize nano-sized printing, and achieve the effect of improving precision, high precision and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

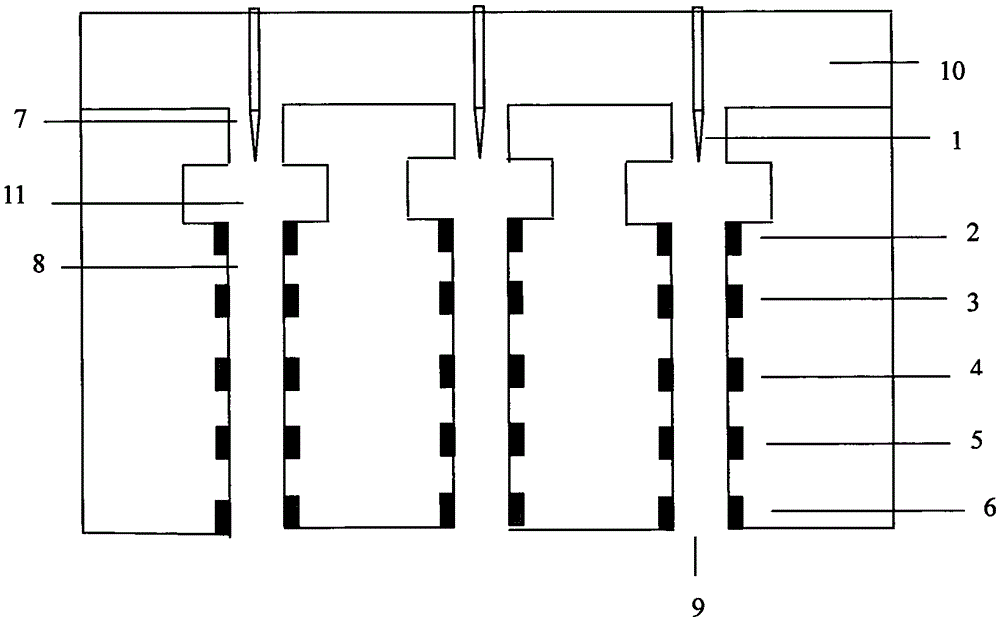

[0033] see figure 1 , the arrayed electrofluid jet printing nozzle is provided with an ink cartridge 10 and three independent orifice systems 11 arranged in an array corresponding to the ink cartridge 10, each independent orifice system 11 includes a feed hole 7, an ejection orifice 9, and the channel 8 between the feed hole 7 and the ejection hole 9, the channel 8 is provided with 6 electrodes, A electrode 1, B electrode 2, C electrode 3, D electrode 4, E electrode 5, F electrode 6. The feed hole 7 of each independent nozzle hole system 11, the nozzle hole 9, the channel 8, the A electrode 1, the B electrode 2, the C electrode 3, the D electrode 4, the E electrode 5, and the F electrode set on the channel 8 The electrodes 6 are distributed on the same axis. The spacing between the electrodes is fixed. Wherein, the A electrode 1 is a needle-shaped electrode, and the B electrode 2 , the C electrode 3 , the D electrode 4 , the E electrode 5 , and the F electrode 6 are ring ele...

Embodiment 2

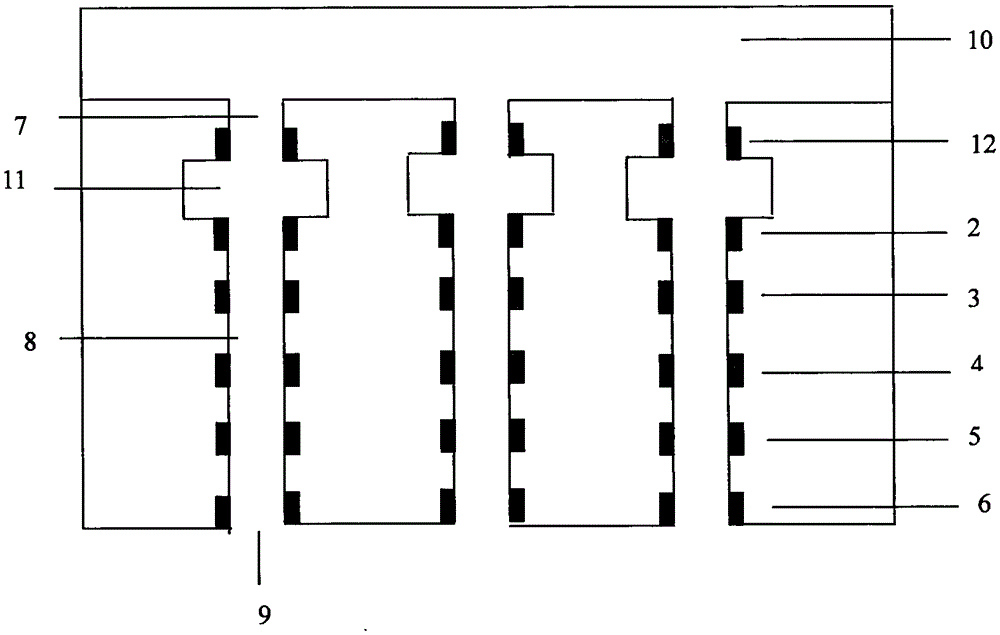

[0040] see figure 2 , the arrayed electrofluid jet printing nozzle is provided with an ink cartridge 10 and three independent orifice systems 11 arranged in an array corresponding to the ink cartridge 10, and each independent orifice system 11 includes a feed hole 7 and an ejection hole 9 , and the channel 8 between the feed hole 7 and the ejection hole 9, the channel 8 is provided with 6 electrodes, G electrode 12, B electrode 2, C electrode 3, D electrode 4, E electrode 5, F electrode 6 , the feed hole 7 of each independent orifice system 11, the ejection hole 9, the channel 8, the G electrode 12, the B electrode 2, the C electrode 3, the D electrode 4, the E electrode 5, and the F electrode arranged on the channel 8 6, for the same axis distribution. The spacing between the electrodes is fixed. Wherein, the G electrode 12, the B electrode 2, the C electrode 3, the D electrode 4, the E electrode 5, and the F electrode 6 are ring electrodes.

[0041] The power supply supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com