Patents

Literature

60 results about "Thermal bubble" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

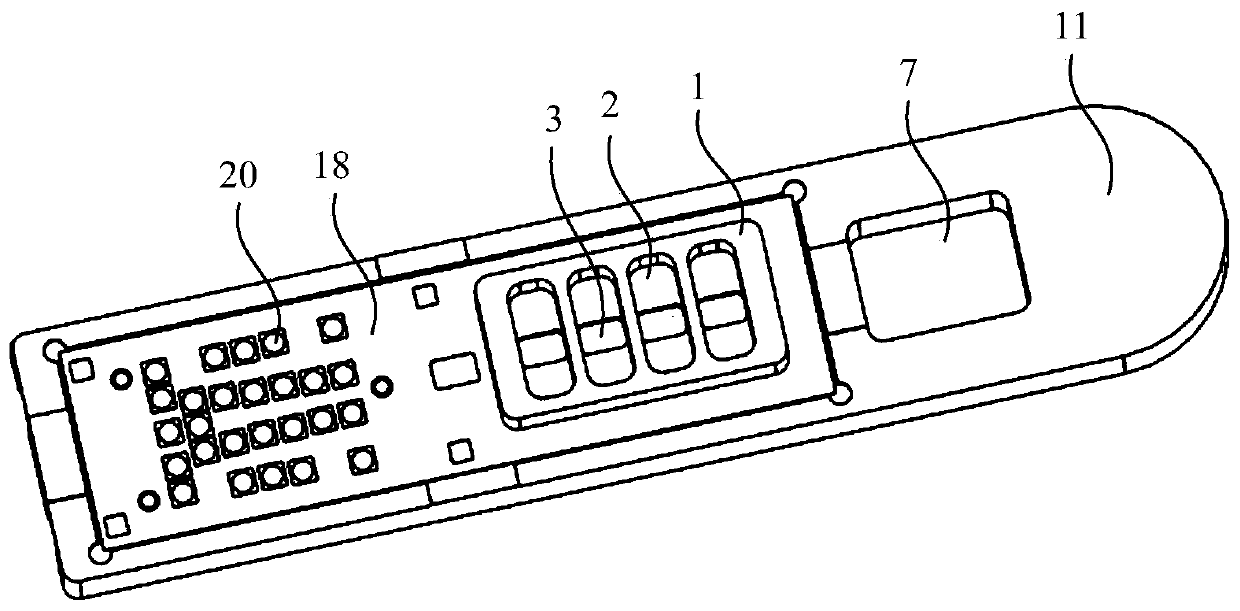

Flexible and Conformal Patch Pump

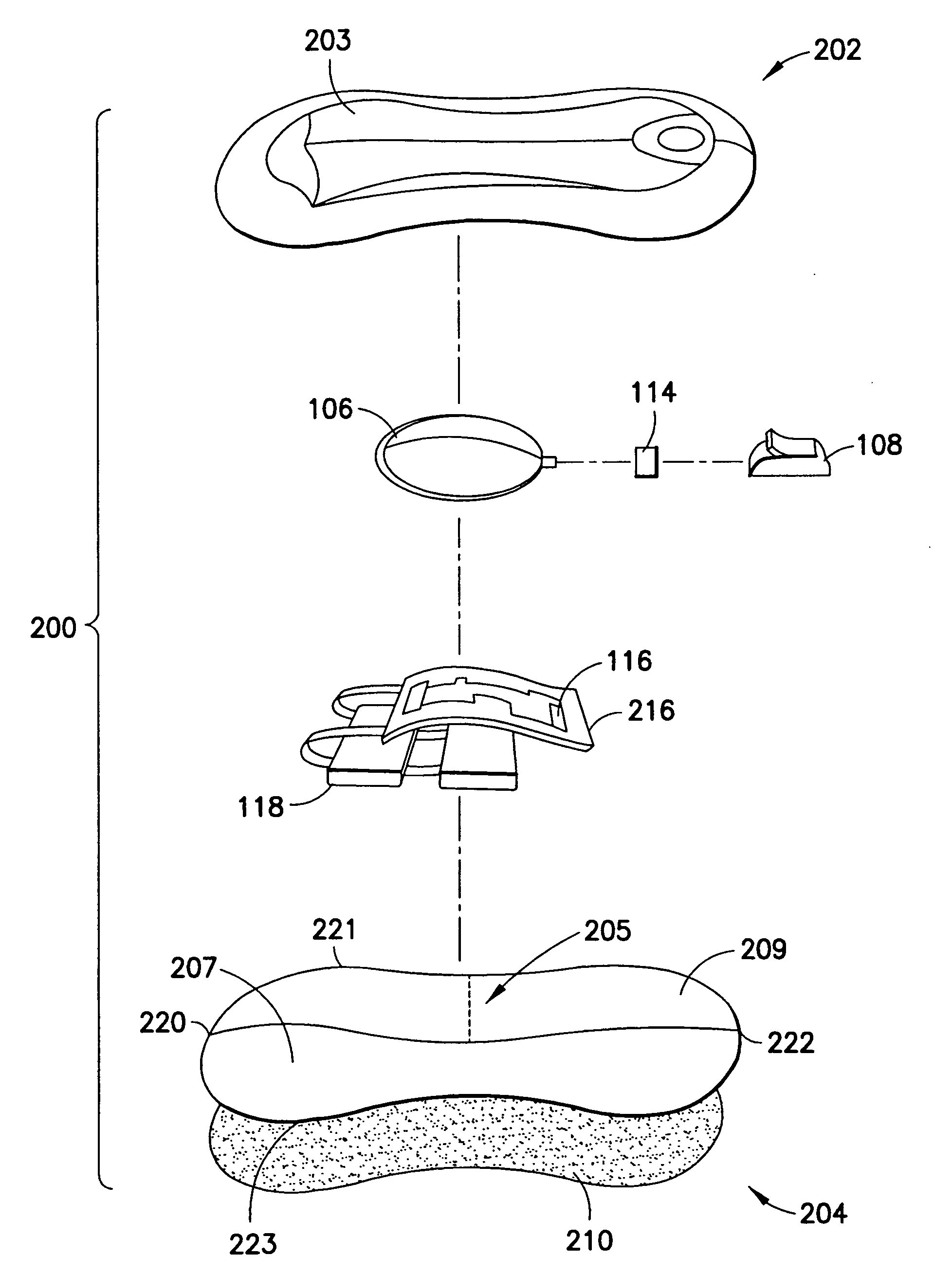

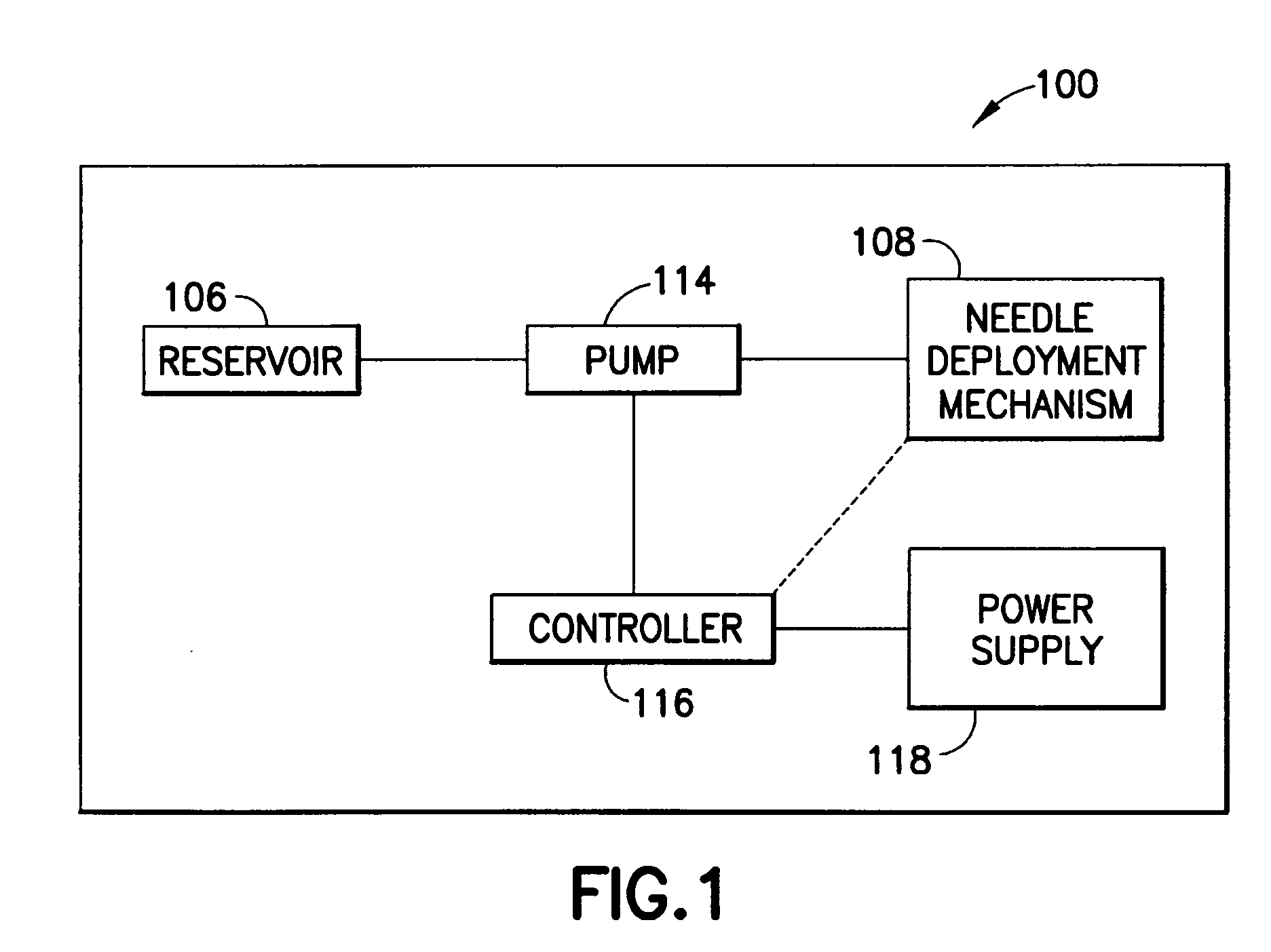

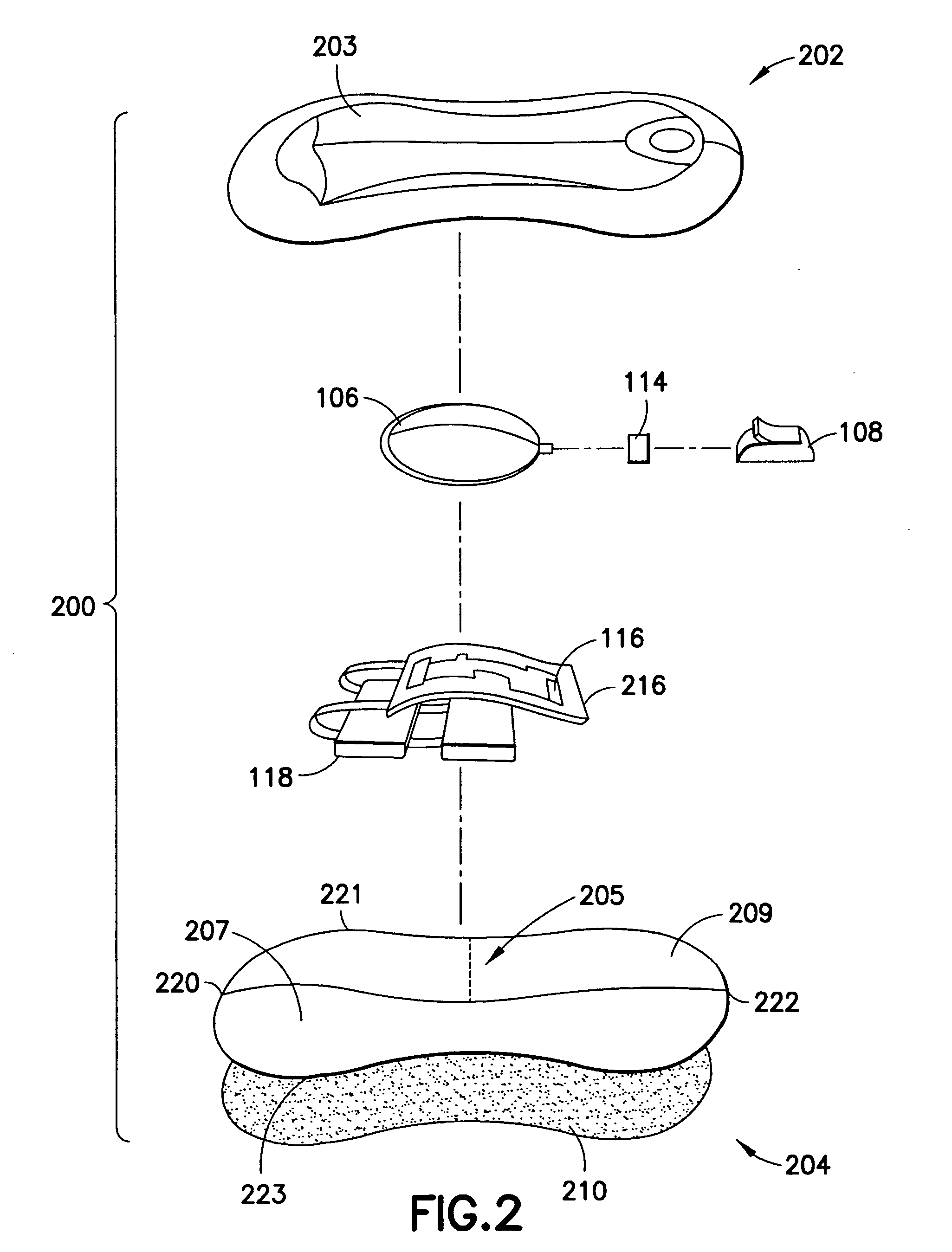

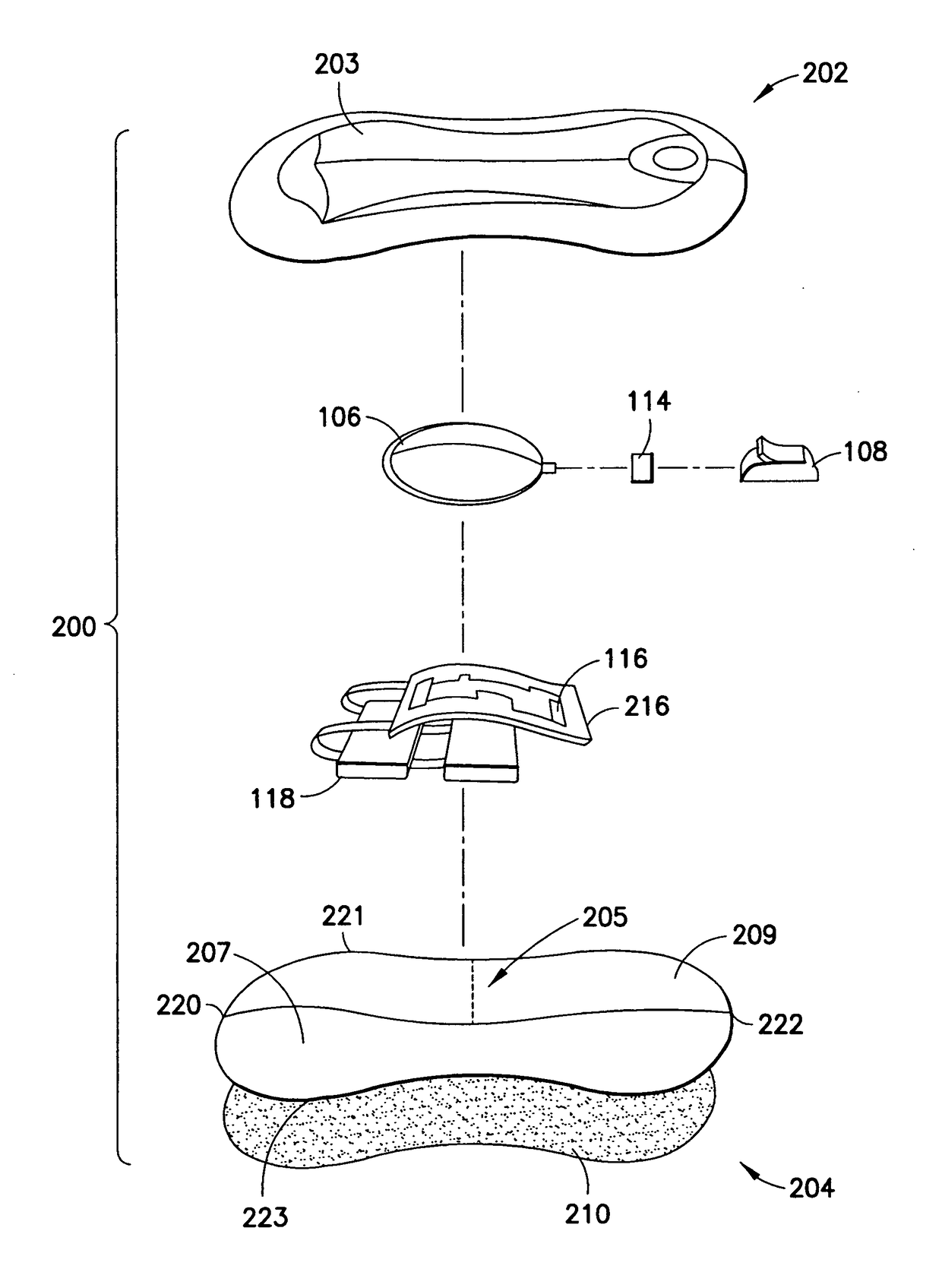

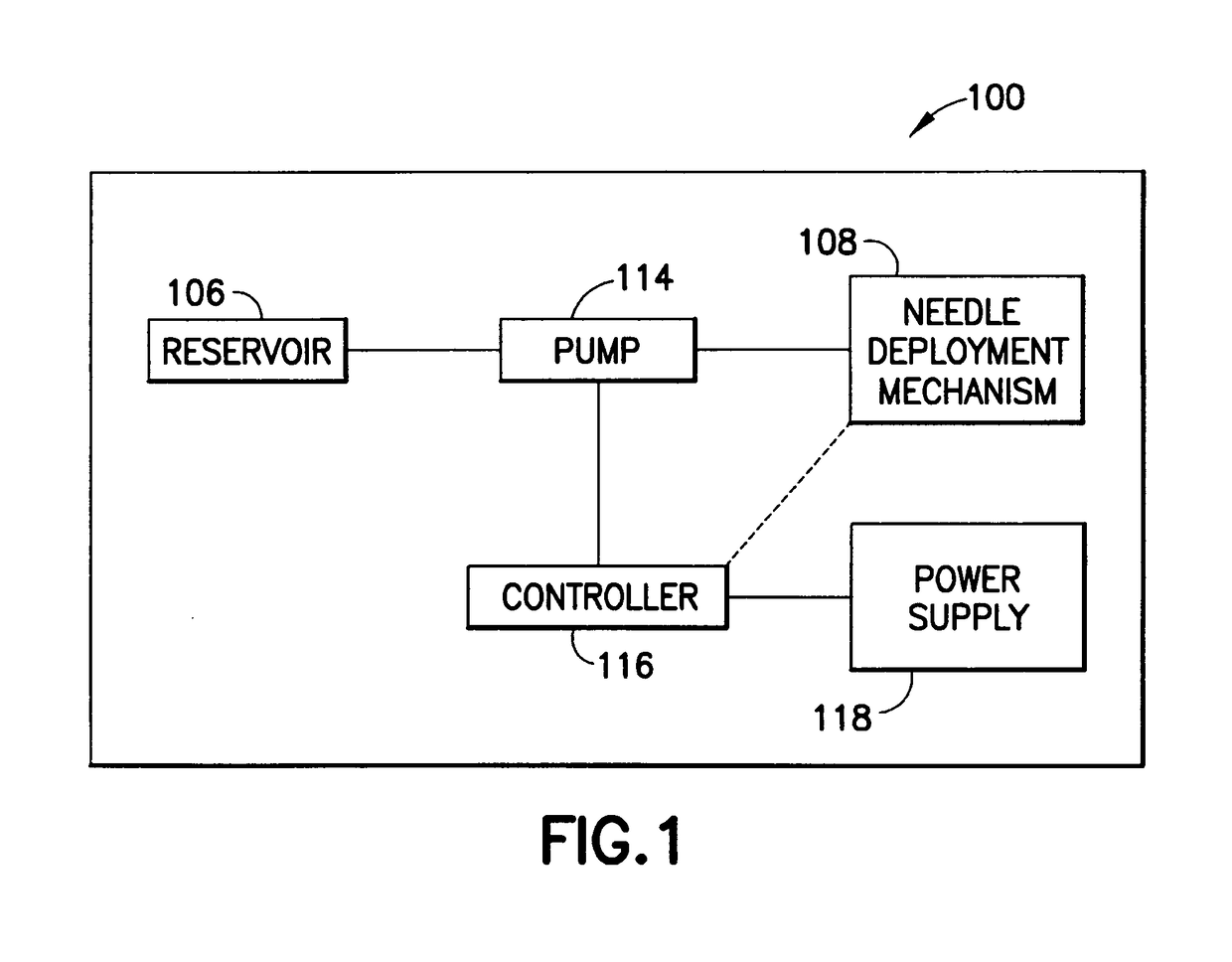

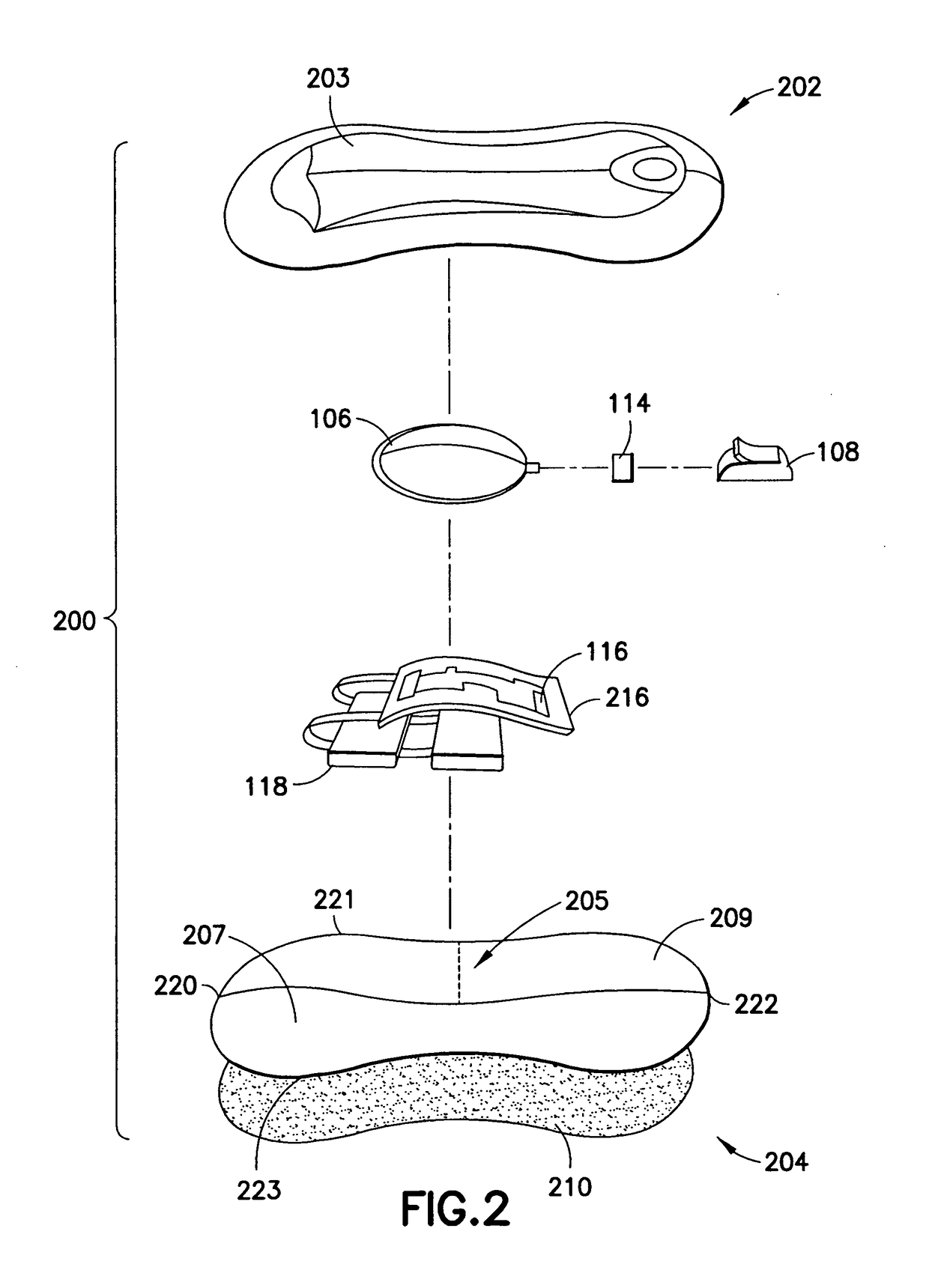

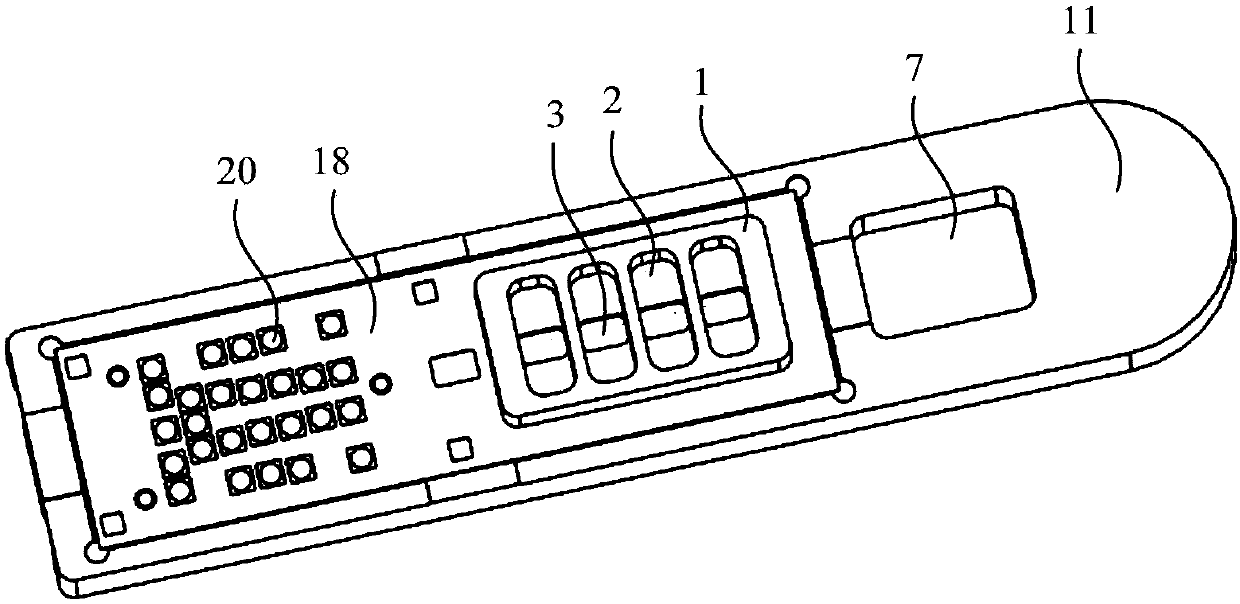

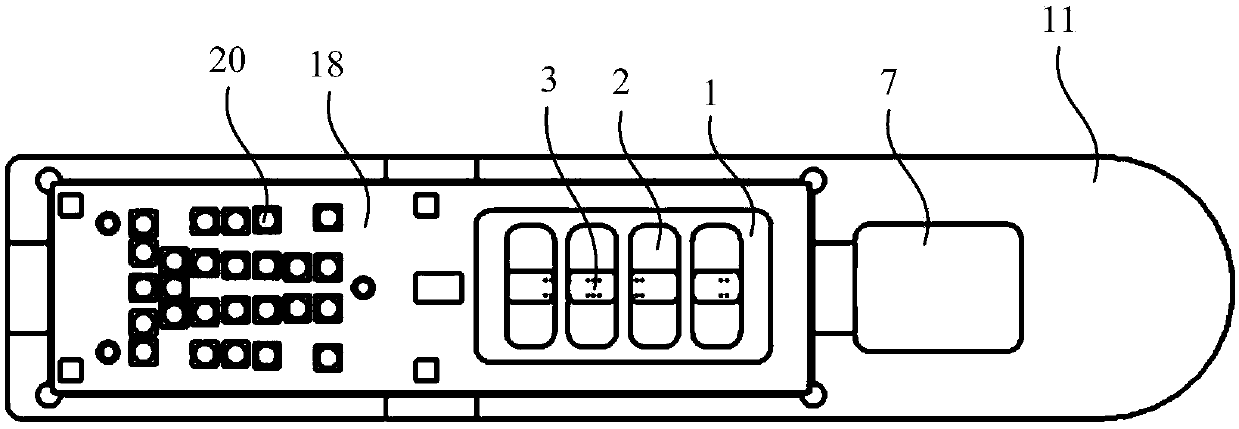

Provided is a flexible and conformal wearable, self-contained medical device. The medical device comprises an integral housing formed by a flexible upper portion and a flexible lower portion joined along their perimeters. The medical device is also provided in a plurality of shapes and configurations for increasing the flexibility and conformability of the housing. The components contained within the housing, such as a drug reservoir, printed circuit board, and power supply are preferably constructed from flexible materials and are formed, connected and positioned according to the configuration of the housing in a manner for enhancing flexibility of the housing. A thermal bubble micropump is provided for controlling flow of a drug from the flexible reservoir, that utilizes a thermal resistor provided locally to a thermal expansion fluid that causes a surrounding membrane to expand and displace a volume of drug to be provided to the user.

Owner:BECTON DICKINSON & CO

Method and apparatus for depositing a biological fluid onto a substrate

ActiveUS20120050411A1Extended service lifeHigh reproducibility levelLaboratory glasswaresPrintingThermal bubbleEngineering

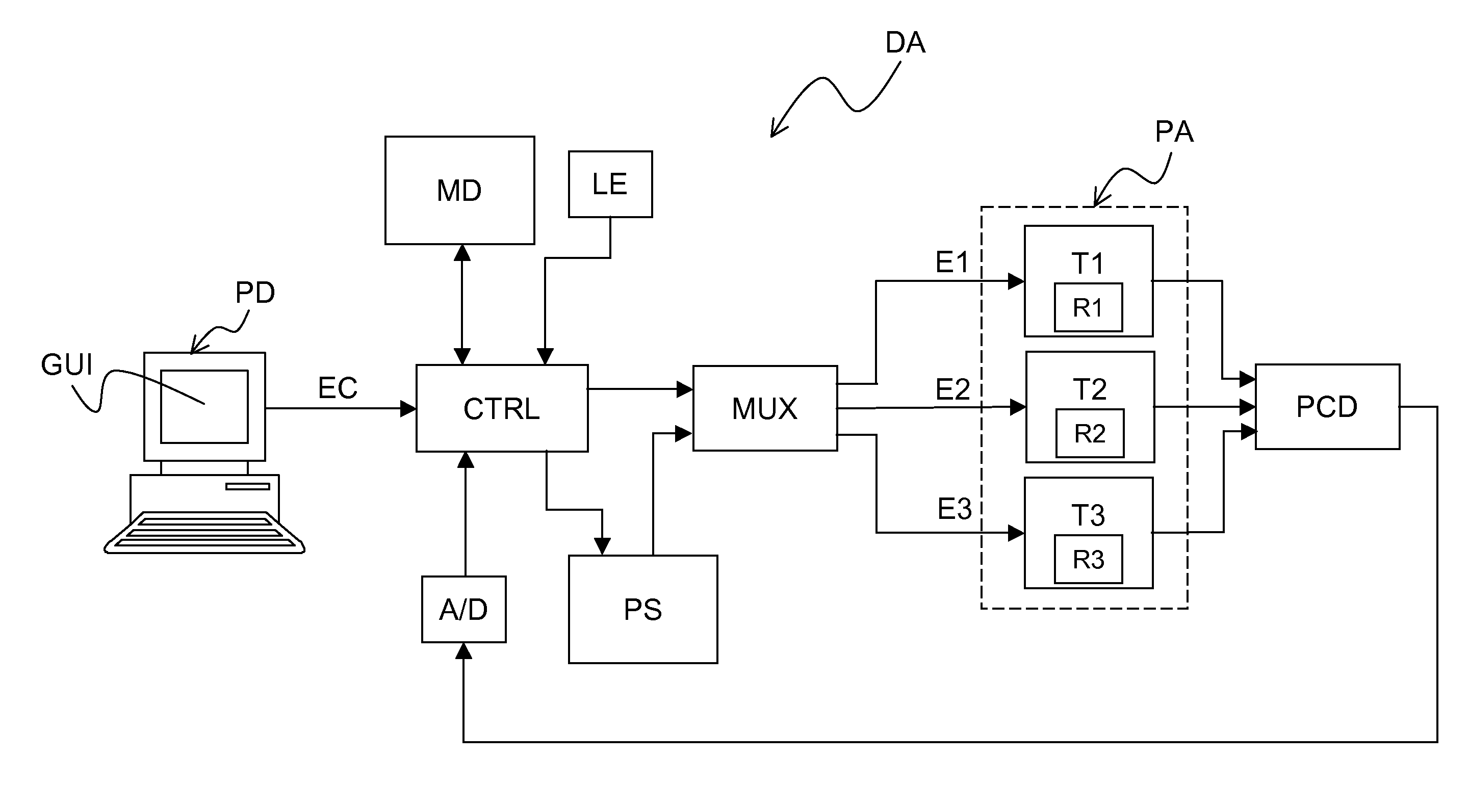

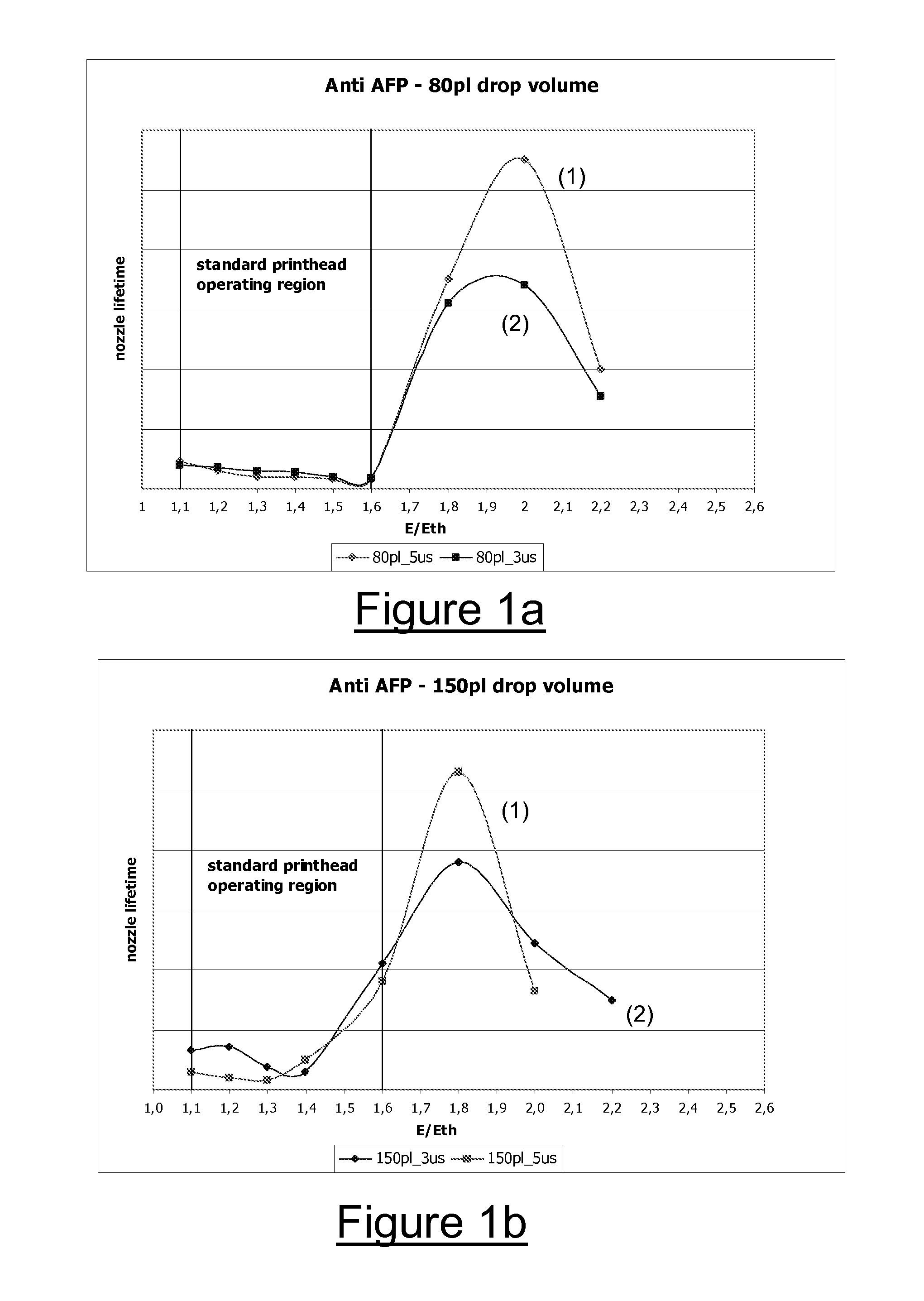

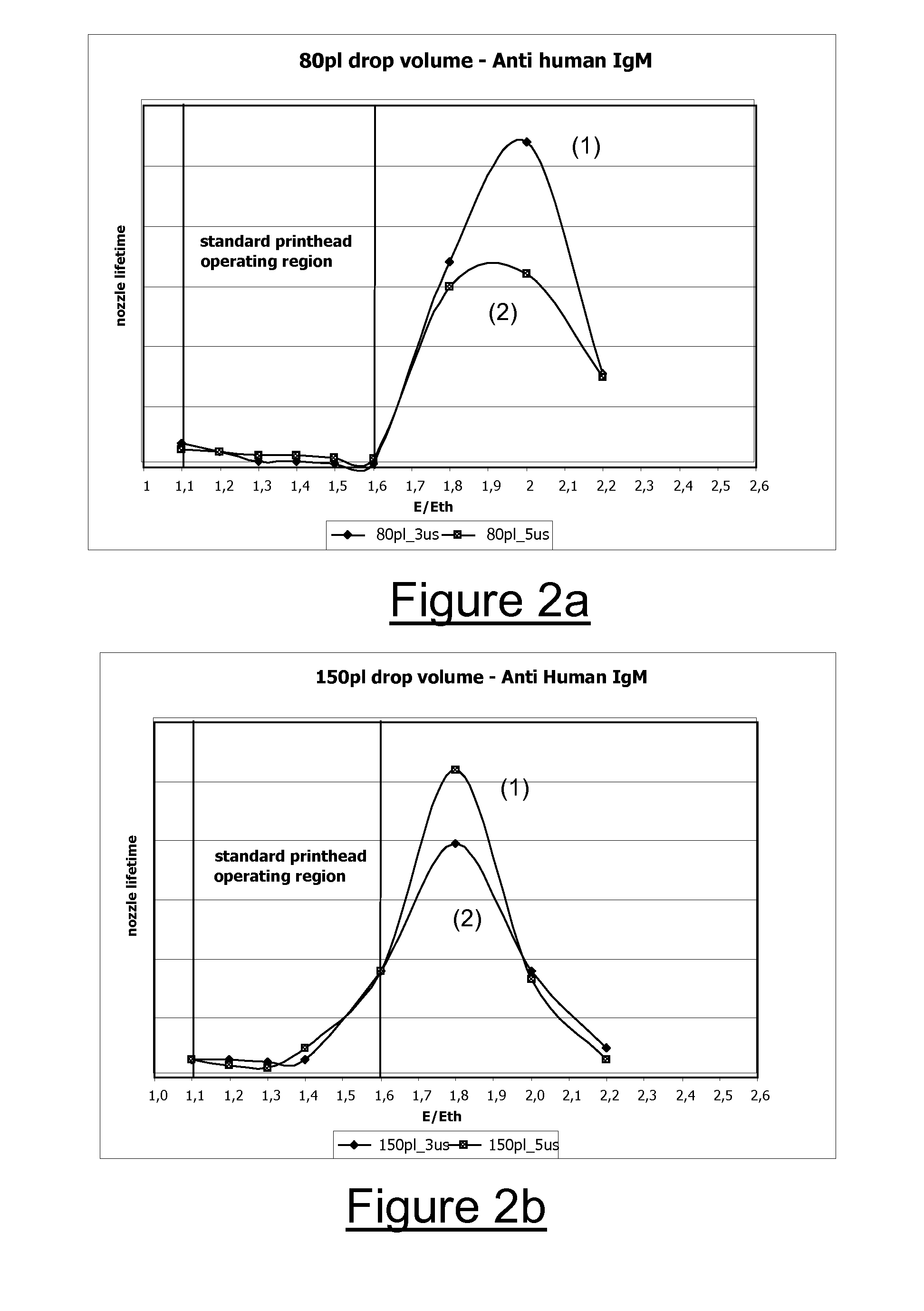

There is described a method for depositing at least one biological fluid onto a surface (12) of a substrate (10), the method comprising the steps of (i) providing at least one thermal bubble-jet printhead (T1, T2, T3) loaded with at least one biological fluid, (ii) positioning the printhead (T1, T2, T3) next to the substrate, and (iii) supplying the printhead (T1, T2, T3) with energy thereby depositing the biological fluid onto the surface (12). The printhead (T1, T2, T3) is supplied with an energy E such thatE>1.6*Eth where Eth is the threshold energy of the printhead (T1, T2, T3). There are also described an apparatus (DA) for depositing at least one biological fluid onto a surface (12) of a substrate (10) and a microarray (MA) obtained by carrying out the depositing method.

Owner:SICPA HLDG SA

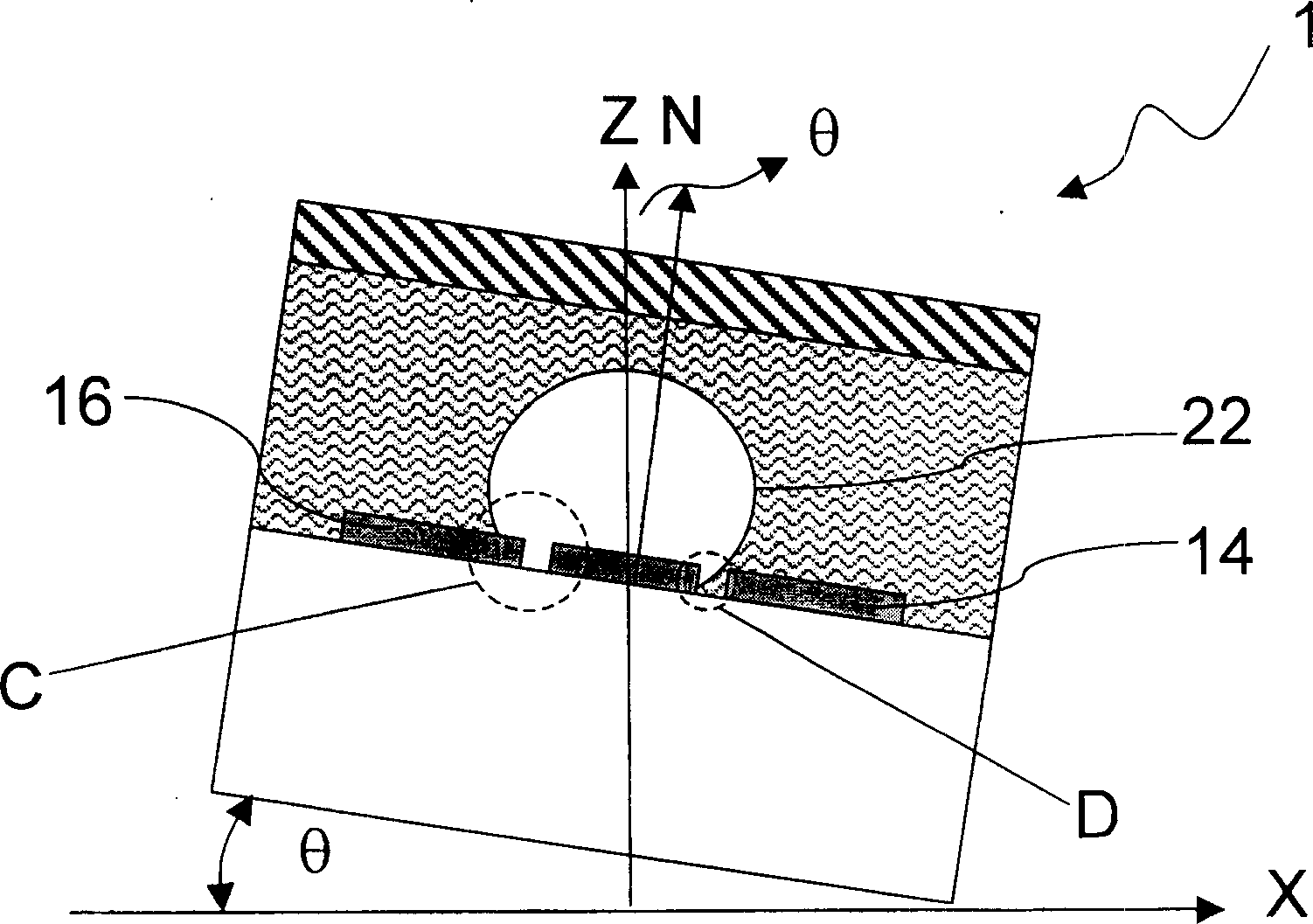

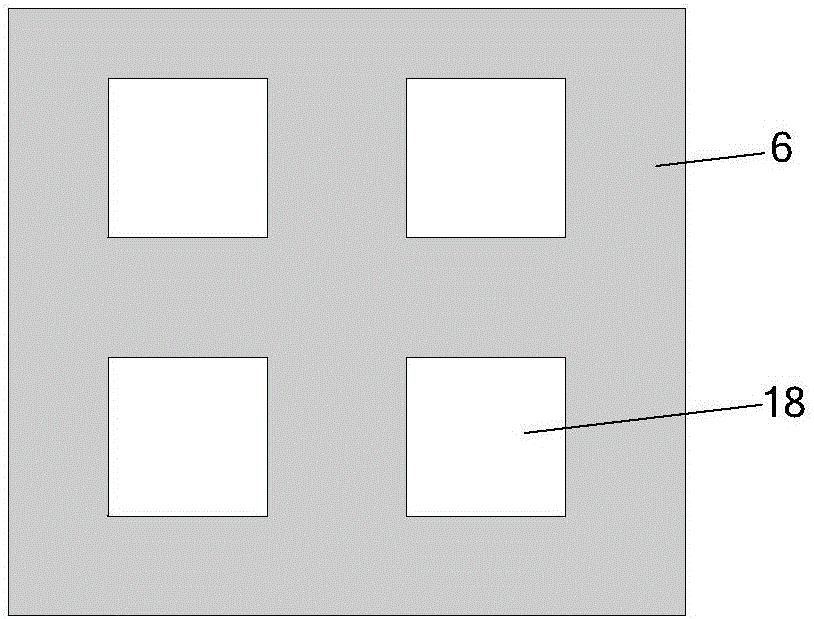

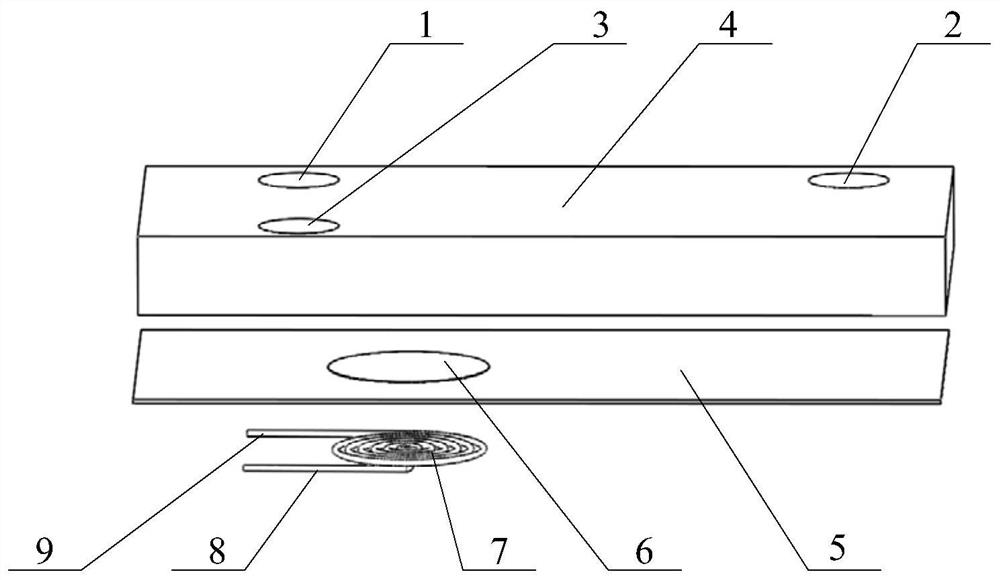

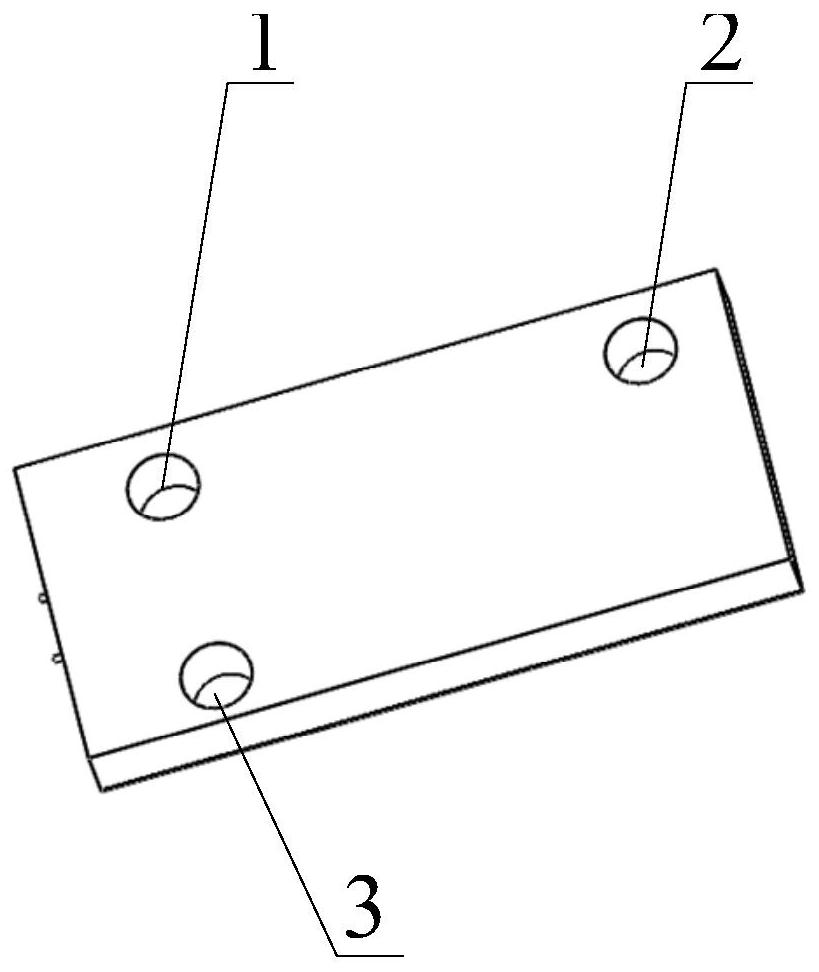

Thermal bubble type micro inertial sensor

ActiveUS7069785B2Quick responseIncrease temperatureAcceleration measurement using interia forcesIncline measurementAccelerometerThermal bubble

A thermal bubble type micro inertial sensor formed by micromachining technology includes a substrate, a heater arranged on the substrate, four temperature sensing members, a cap arranged above the substrate to cover and encapsulate the heater and the temperature sensing members, and a liquid filled into a chamber formed between the cap and the substrate. The temperature sensing members are symmetrical arranged at opposite sides of the heater and on the substrate, respectively, to sense the temperature difference beside the heater. The heater heats and partially vaporizes the liquid to form a thermal bubble in the liquid environment. Controlling the liquid characteristics and heater temperature may control the bubble size and enable the temperature sensing members to sense the temperature distribution variation. The sensor may serve as an inclinometer to sense the tilt, as well as an accelerometer to measure the acceleration.

Owner:XIANGQUN SCI & TECH

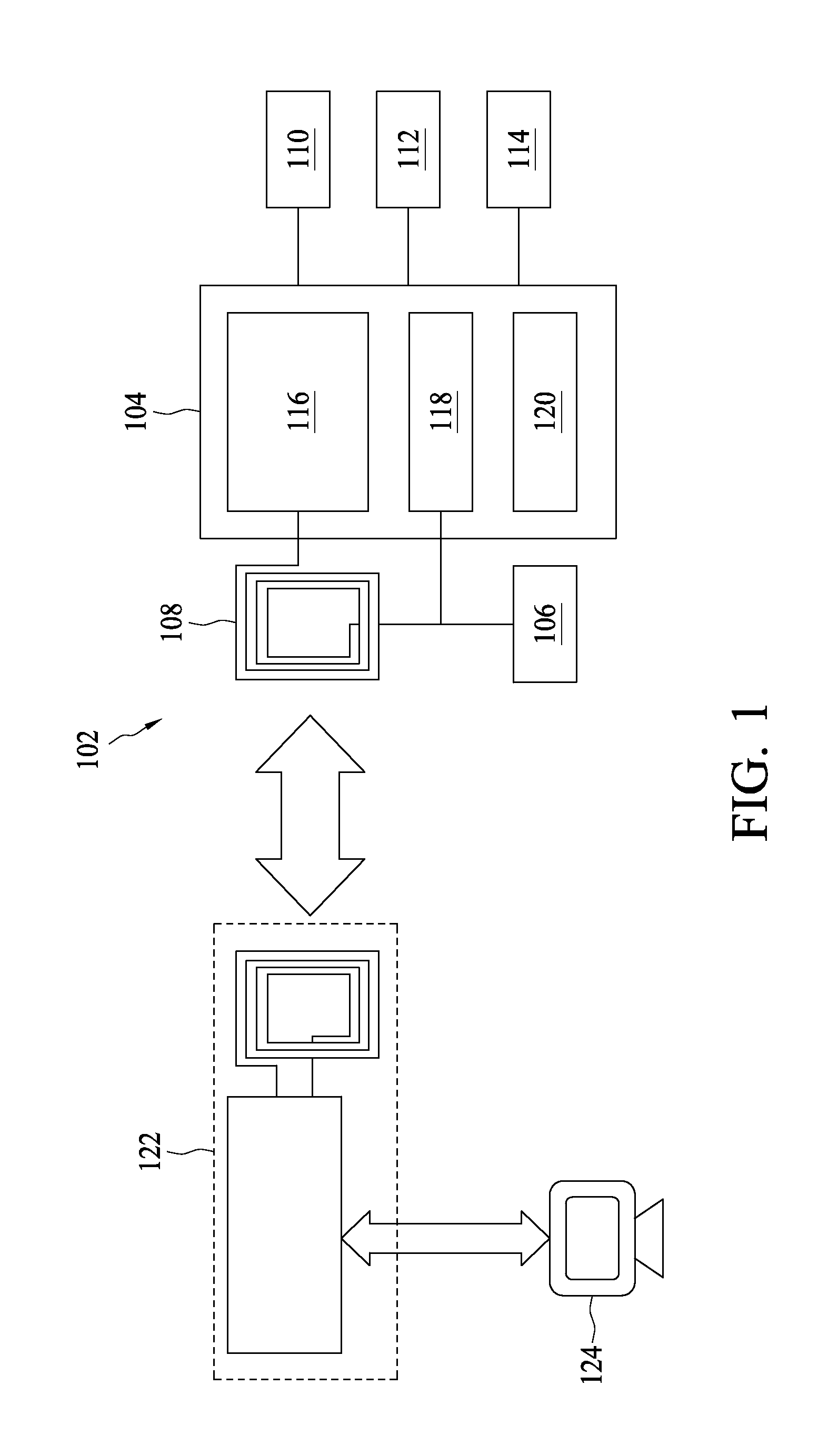

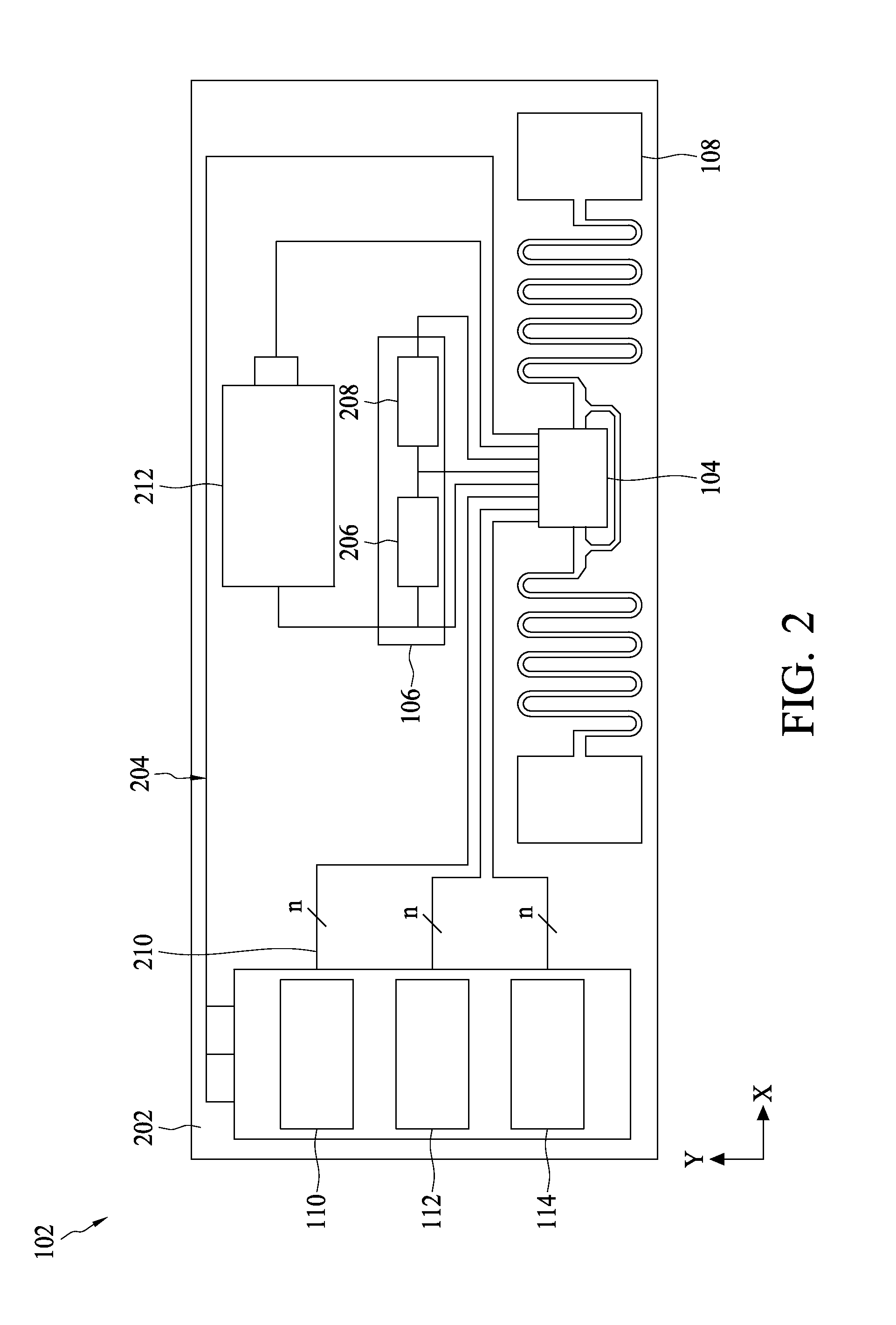

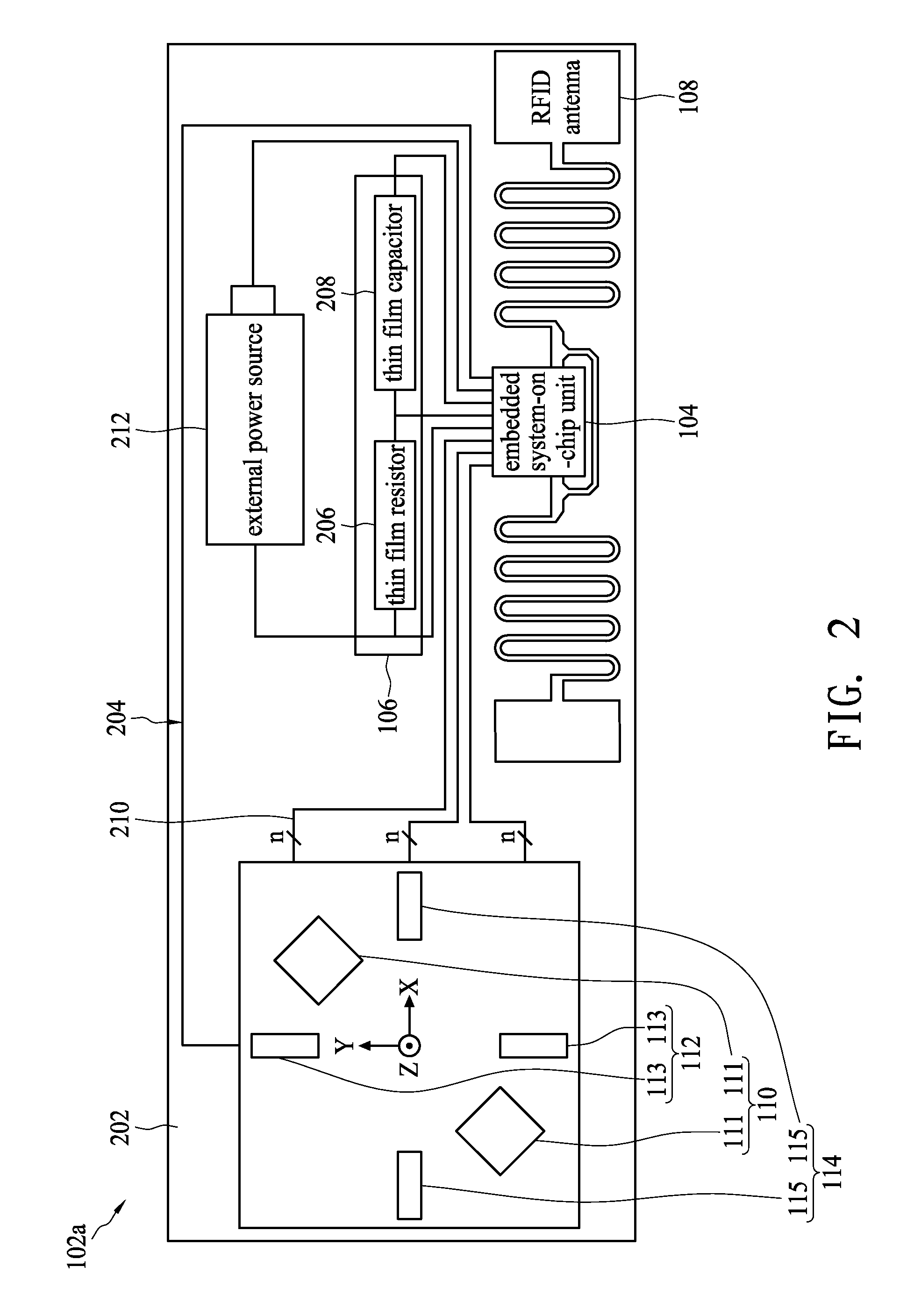

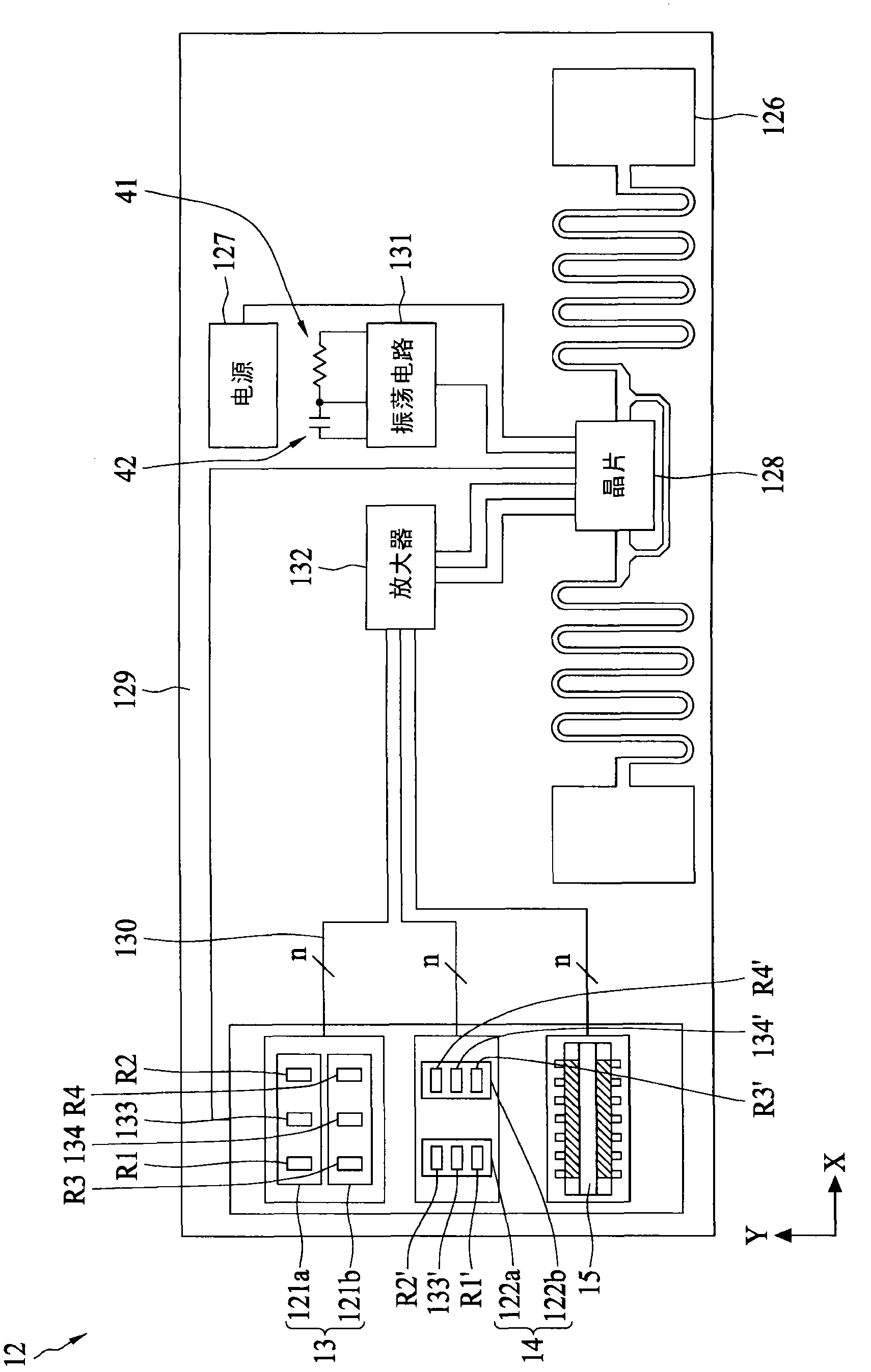

RFID Based Thermal Bubble Type Accelerometer And Method Of Manufacturing The Same

InactiveUS20110036168A1Reduce manufacturing costEasy to useAcceleration measurement using interia forcesWave amplification devicesAccelerometerThermal bubble

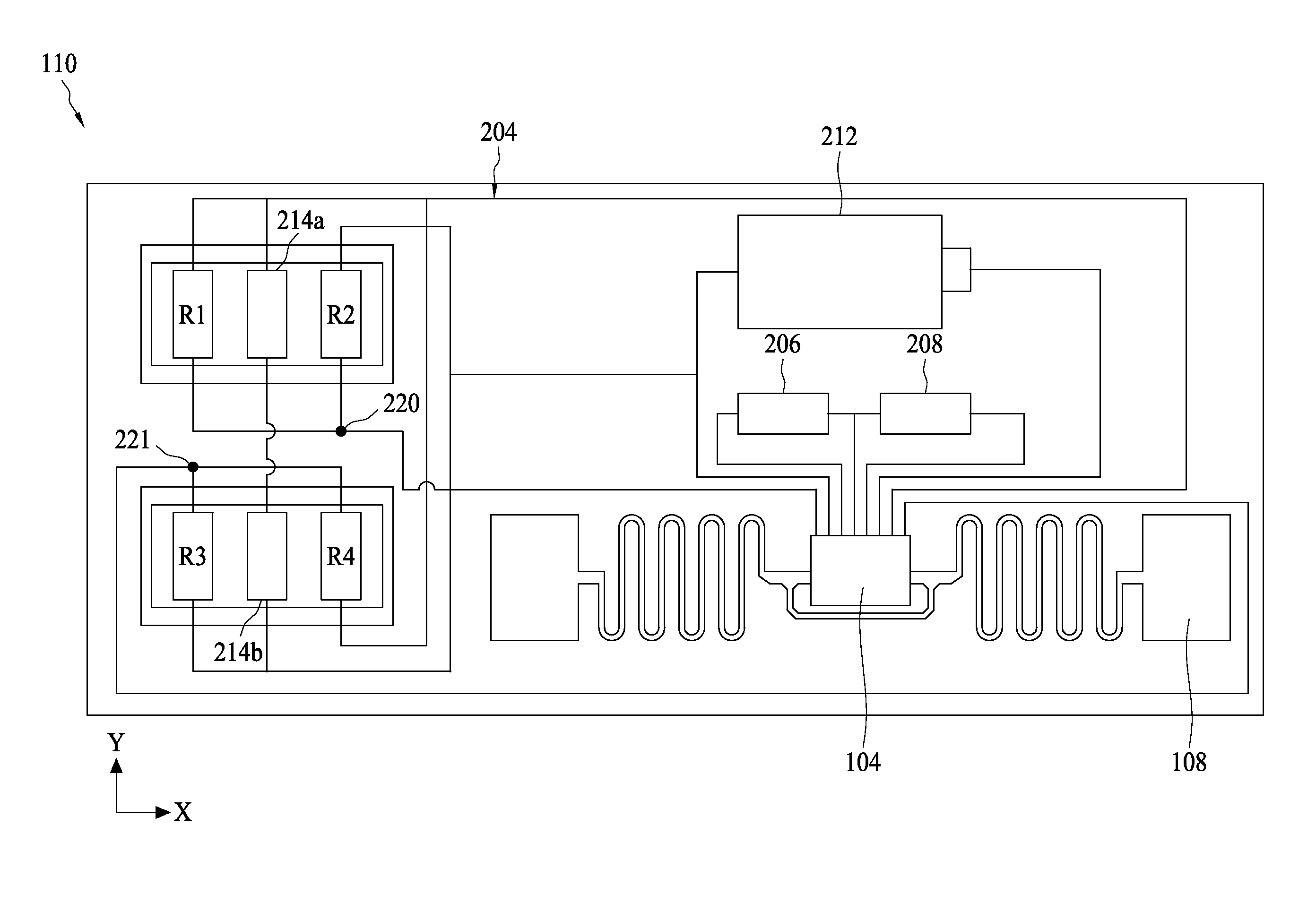

An RFID based thermal bubble type accelerometer includes a flexible substrate, an embedded system on chip (SOC) unit, an RFID antenna formed on the substrate and coupled to a modulation / demodulation module in the SOC unit, a cavity formed on the flexible substrate, and a plurality of sensing assemblies, including a heater and two temperature-sensing elements, disposed along the x-axis direction and suspended over the cavity. The two temperature-sensing elements, serially connected, are separately disposed at two opposite sides and at substantially equal distances from the heater. Two sets of sensing assemblies can be connected in differential Wheatstone bridge. The series-connecting points of the sensing assemblies are coupled to the SOC unit such that an x-axis acceleration can be obtained by a voltage difference between the connecting points. The x-axis acceleration can be sent by the RFID antenna to a reader after it is modulated and encoded by the modulation / demodulation module.

Owner:CHUNG HUA UNIVERSITY

Low voltage and low power thermal bubble film type microfluid driving device

InactiveCN1521500AControl flow directionEasy to combine controlMicrobiological testing/measurementMaterial electrochemical variablesBoiling pointLow voltage

The invention relates to a low voltage low power heat bubble thin film type micro-fluid drive apparatus, wherein the fluid arrangement includes a fluid channel, in which fluid fills and flow from and out from the opening of the fluid channel, a heat bubble thin film type actuator comprising heating plates arranged on the bottom of the confined fluid chamber, which is insulated from the fluid channel through elastic membrane and is filled with low-boiling point liquid.

Owner:IND TECH RES INST

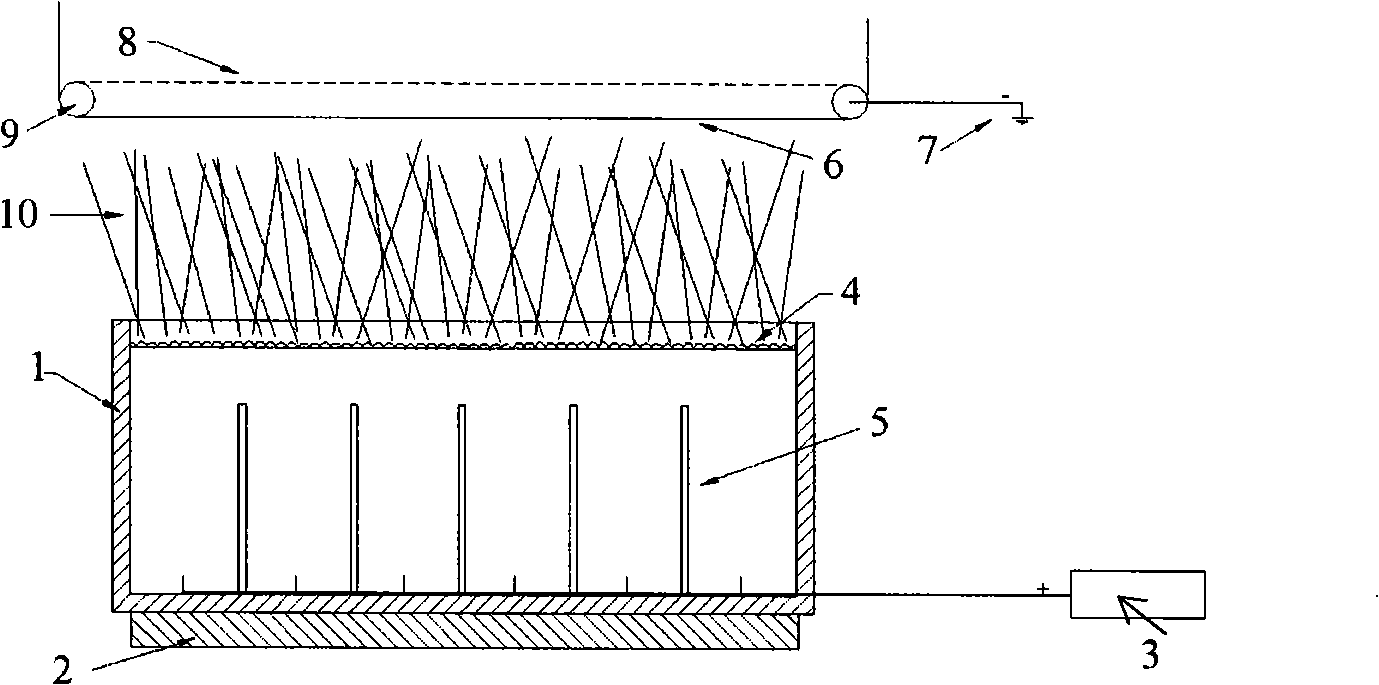

Thermal bubble spinning method and device for nano-fiber production

InactiveCN101275299ASimple spinning mechanismEasy production controlArtificial thread manufacturing machinesFilament/thread formingFiberMetallic electrode

Owner:DONGHUA UNIV

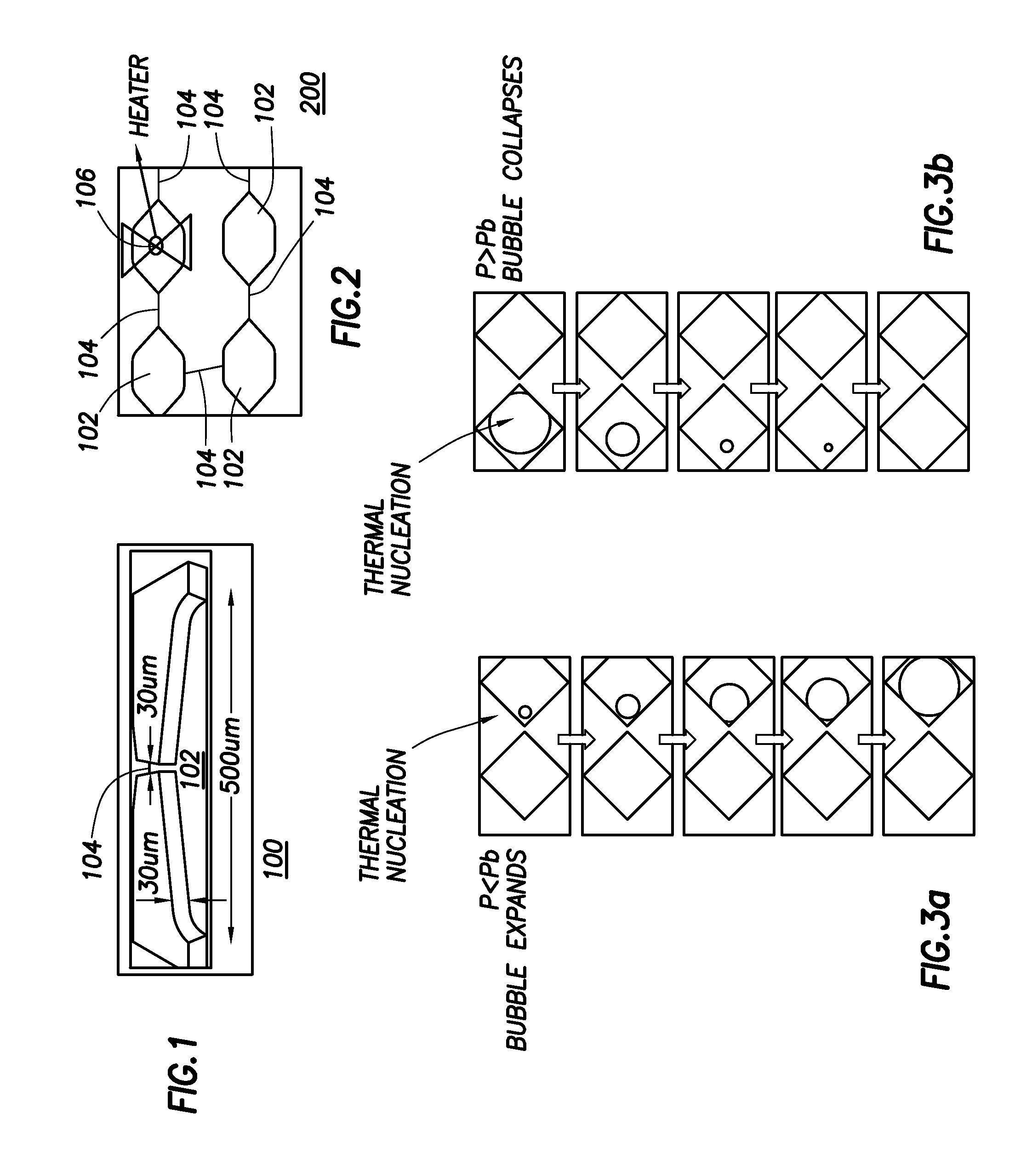

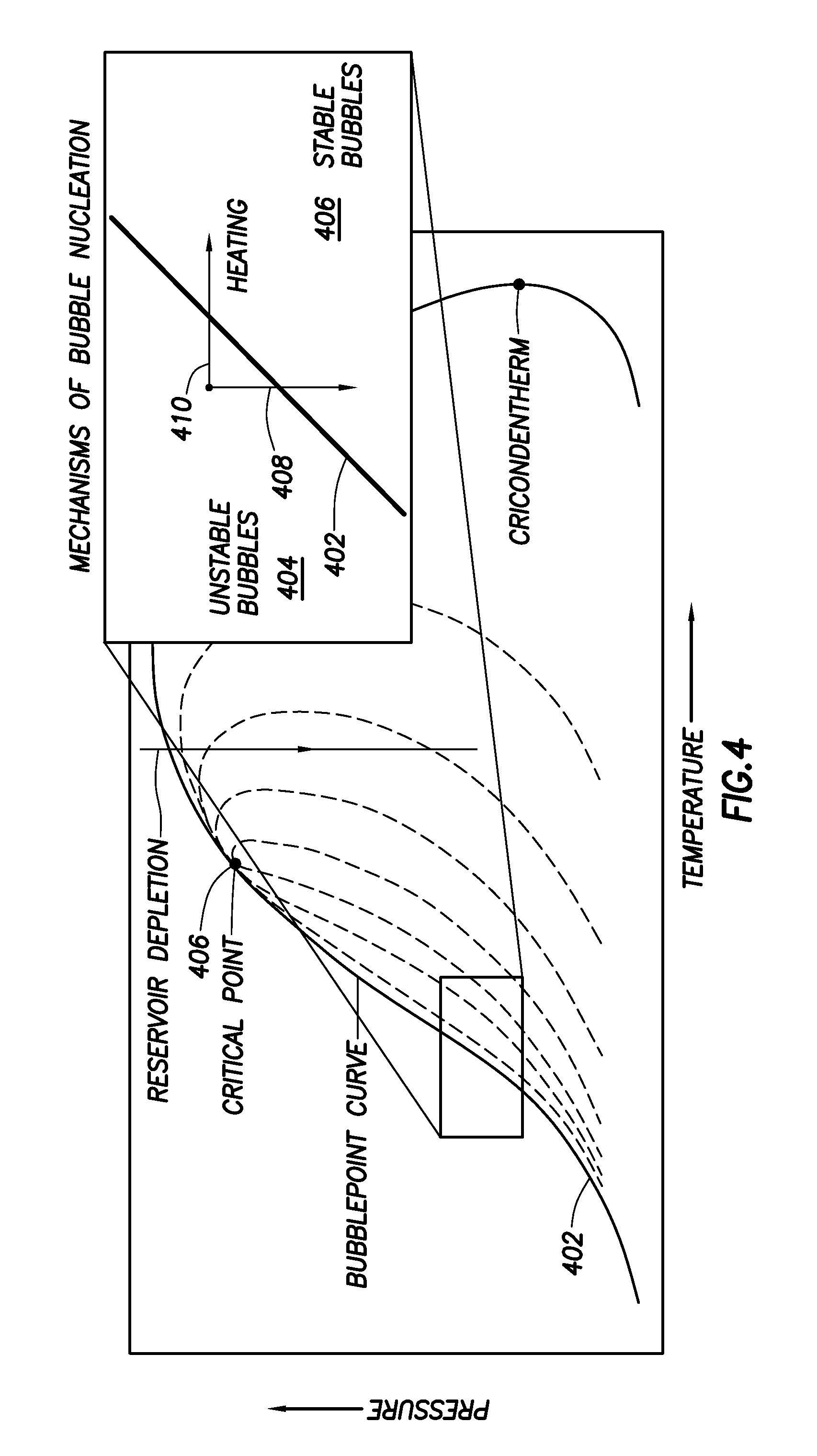

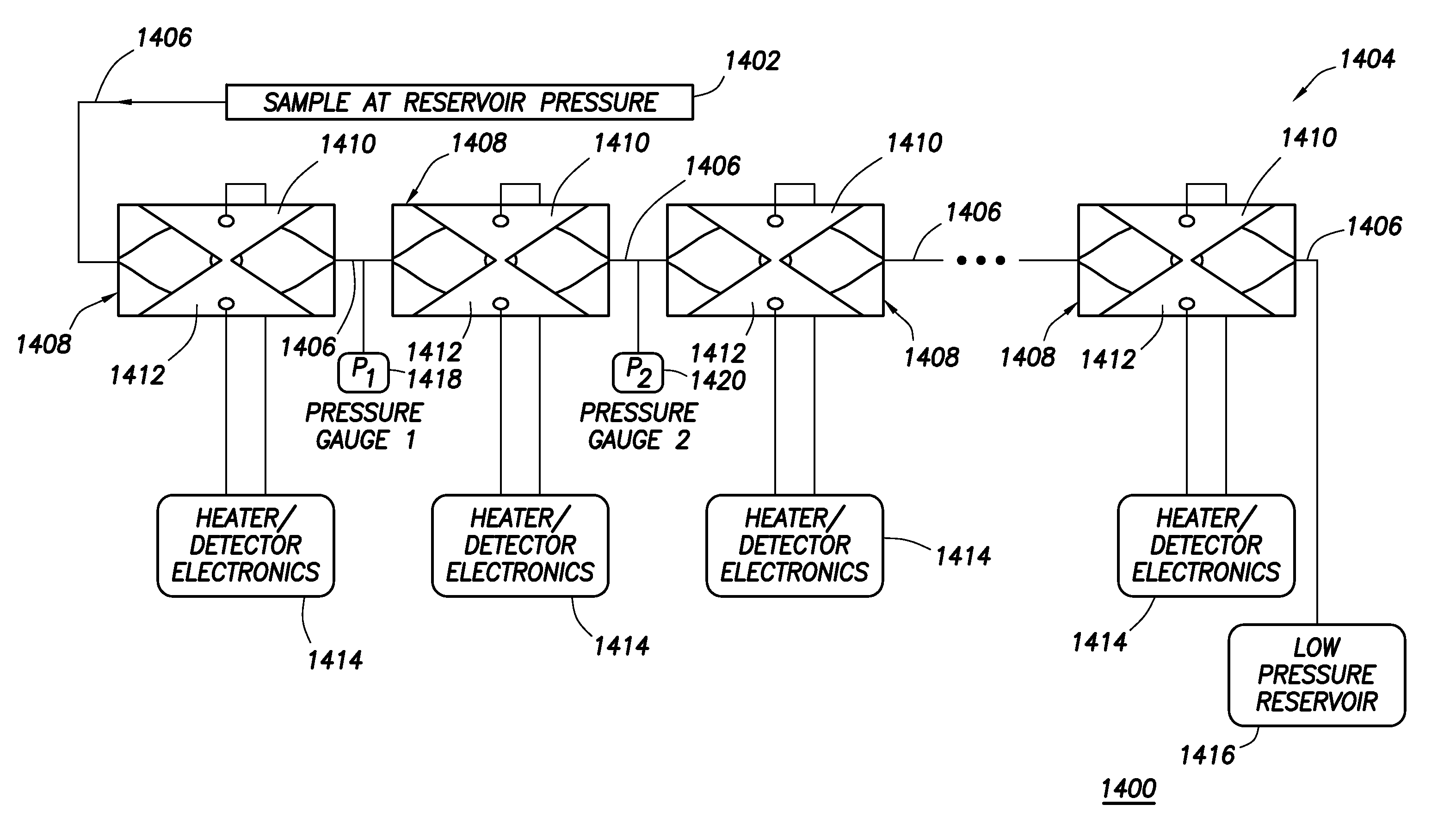

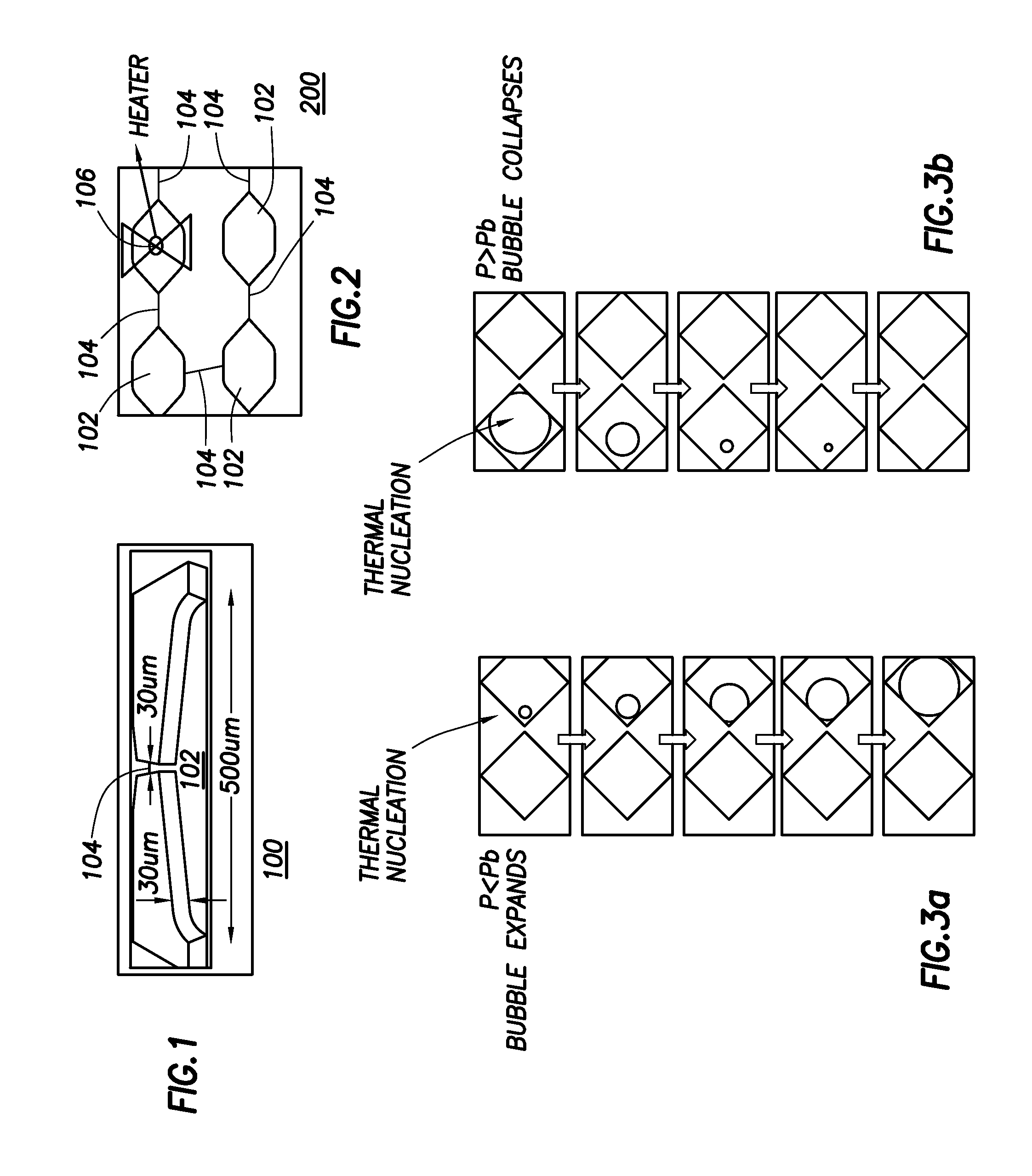

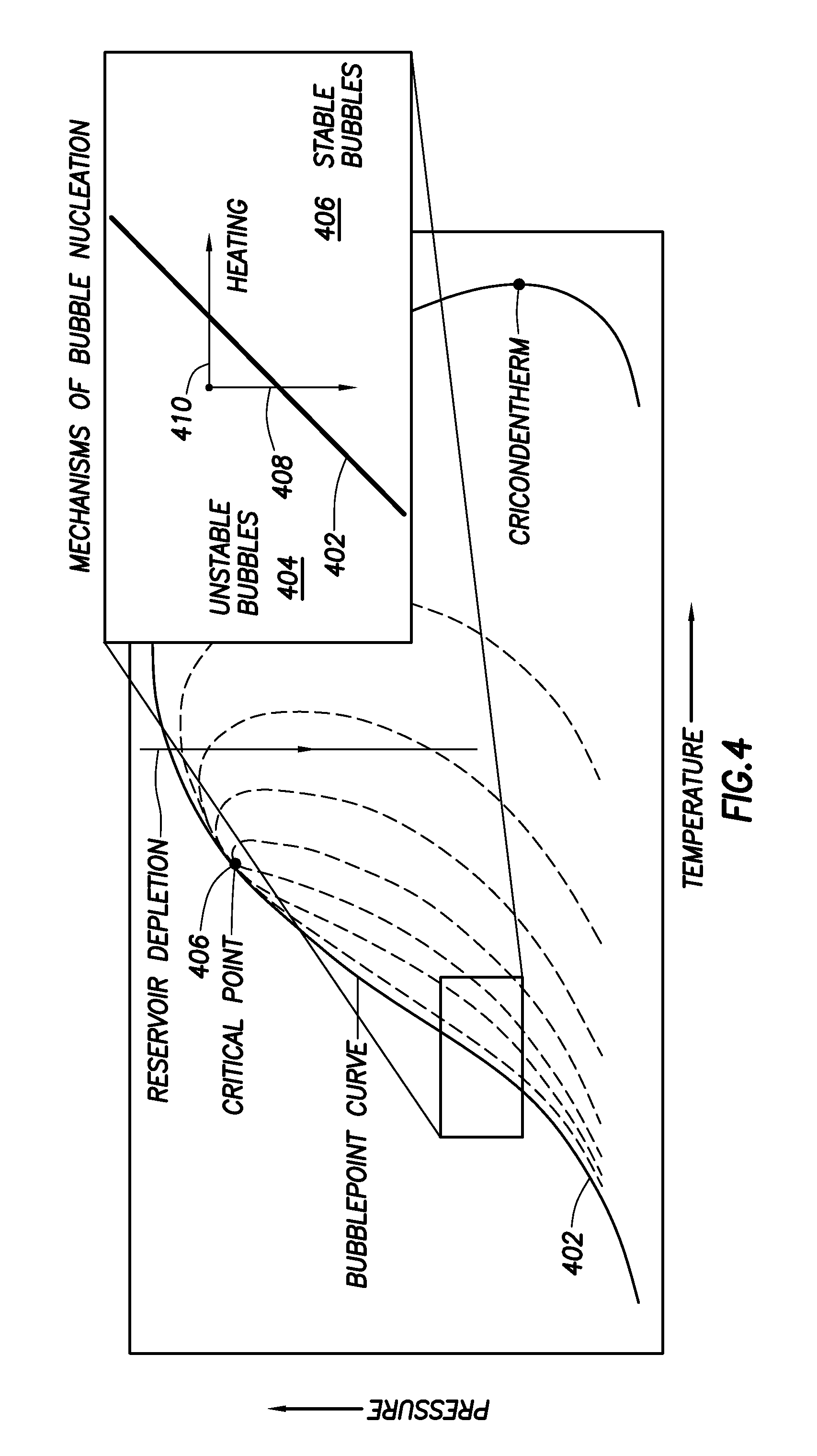

Thermal bubble point measurement system and method

ActiveUS20110259090A1Accurate measurementImproved bubble point measurementConstructionsWithdrawing sample devicesThermal bubbleBubble point

A method and an apparatus for nucleating bubbles in an oil-gas mixture, including introducing a sample comprising an oil-gas mixture into a chamber; and heating the sample with a heater until at least one bubble is thermally nucleated in the chamber. The bubble point (BP) pressure of the sample can be determined by detecting pressure at two points in a system, which includes the chamber and the heater, and by determining the behavior of the nucleated bubble as the pressure on the bubble is varied.

Owner:SCHLUMBERGER TECH CORP

Thermal foaming or thermal bubble type printer digital printing process using reactive dye ink

InactiveCN104213443AImprove ergonomicsHigh color reproductionDyeing processEnvironmental resistanceCellulose

The invention discloses a thermal foaming or thermal bubble type printer digital printing process using a reactive dye ink; the digital printing process uses the reactive dye ink with high temperature resistance and long survivability; digital inkjet printing of cotton, silk, wool, linen and cotton fabrics can be realized on a thermal foaming or thermal bubble type printer, wherein the cotton, silk, wool, linen and cotton fabrics are not sized by use of a synthetic sizing agent prepared from urea, sodium alginate, nutmeg, cellulose or any paste material as a main raw material; the process is simple in step, less in water consumption, low in energy consumption, economic and environmentally-friendly, and solves the problems, in the prior art, of hydrolysis and alcoholysis of the reactive dye ink when the reactive dye ink passes through a thermal foaming or thermal bubble type printer head and crust formation and ink path blocking for the reason that high temperature of the printer head cause part of the reactive dye ink to be dried and pulverized into powder, and application of the reactive dye ink in the thermal foaming or thermal bubble type printer can be realized.

Owner:GUANGZHOU LIANYIN DIGITAL TECH +1

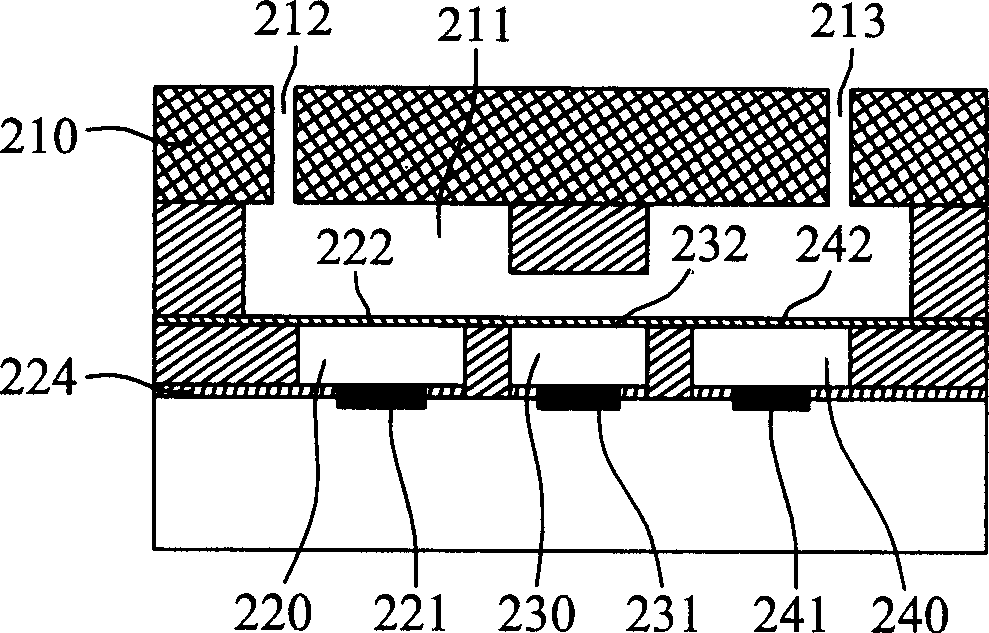

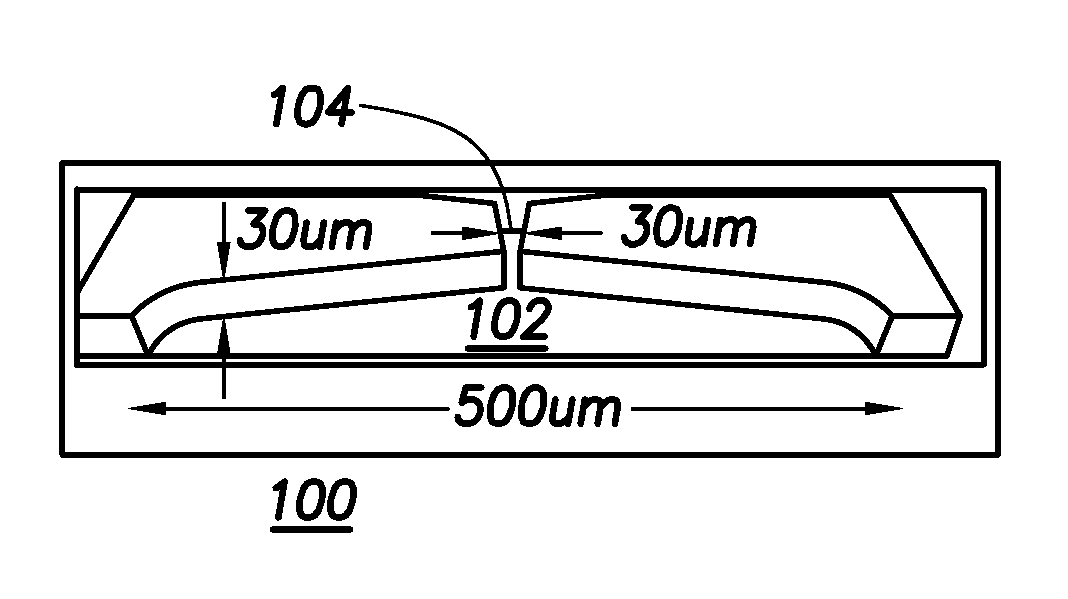

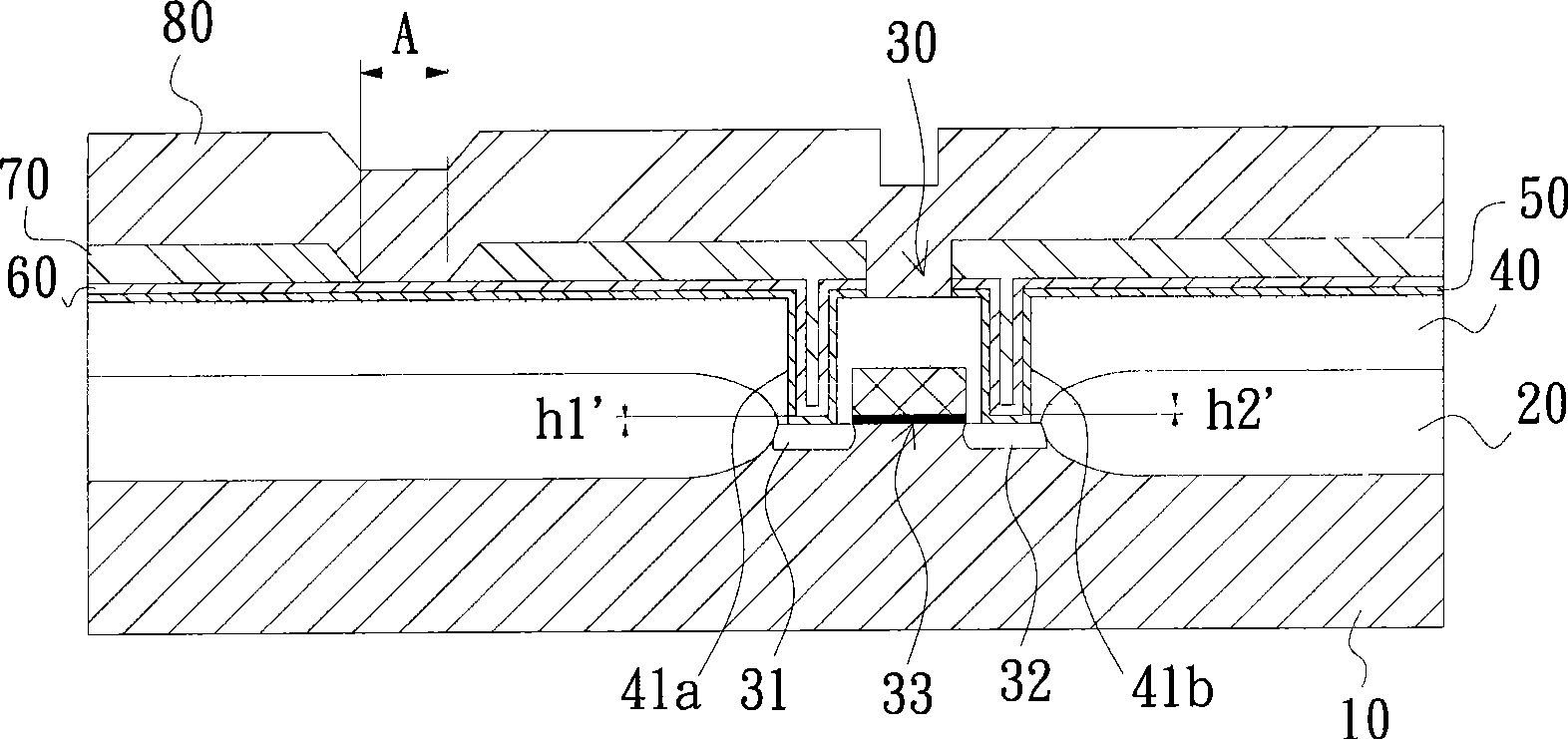

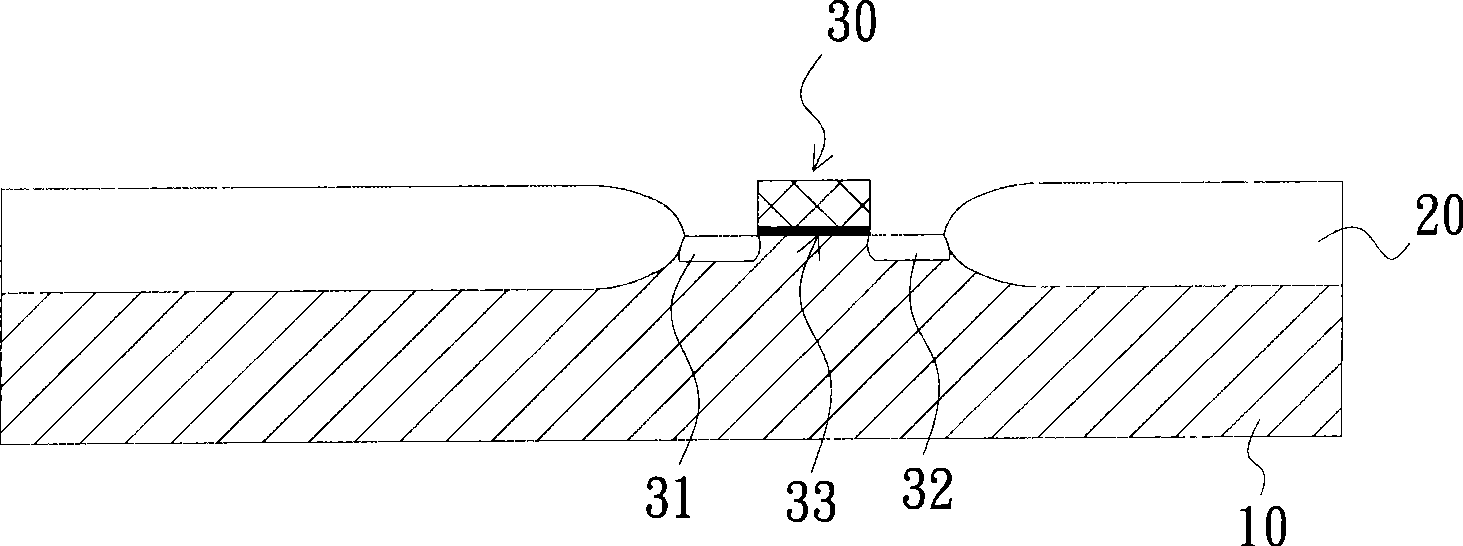

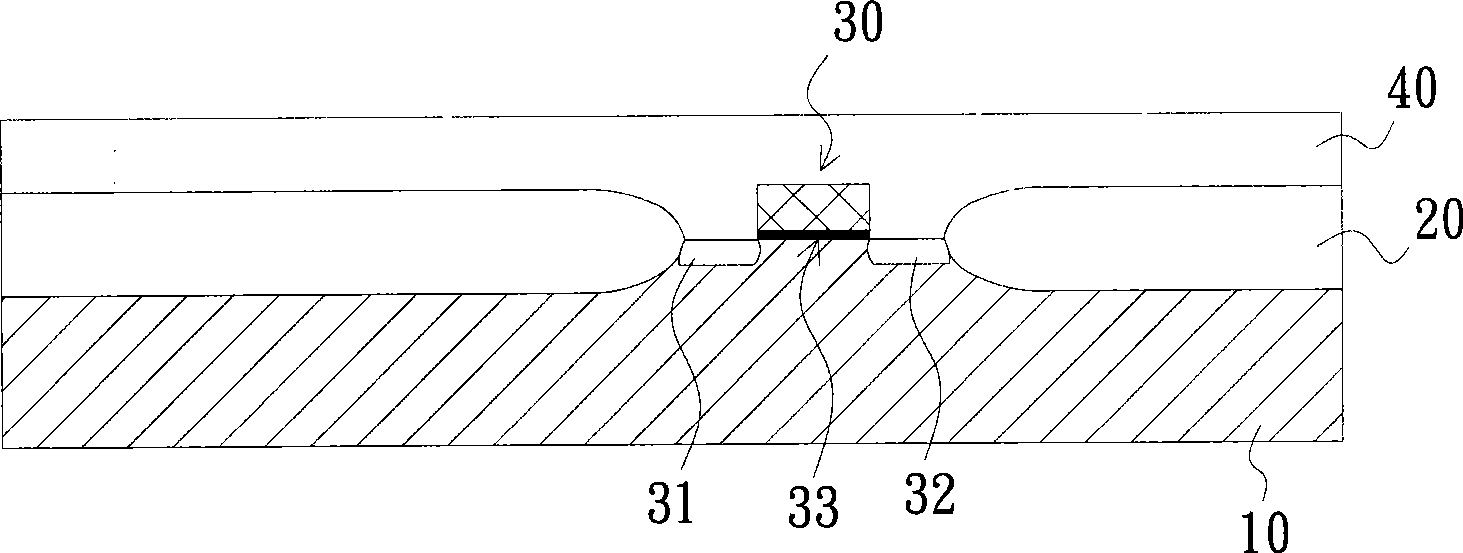

Micro fluidic module

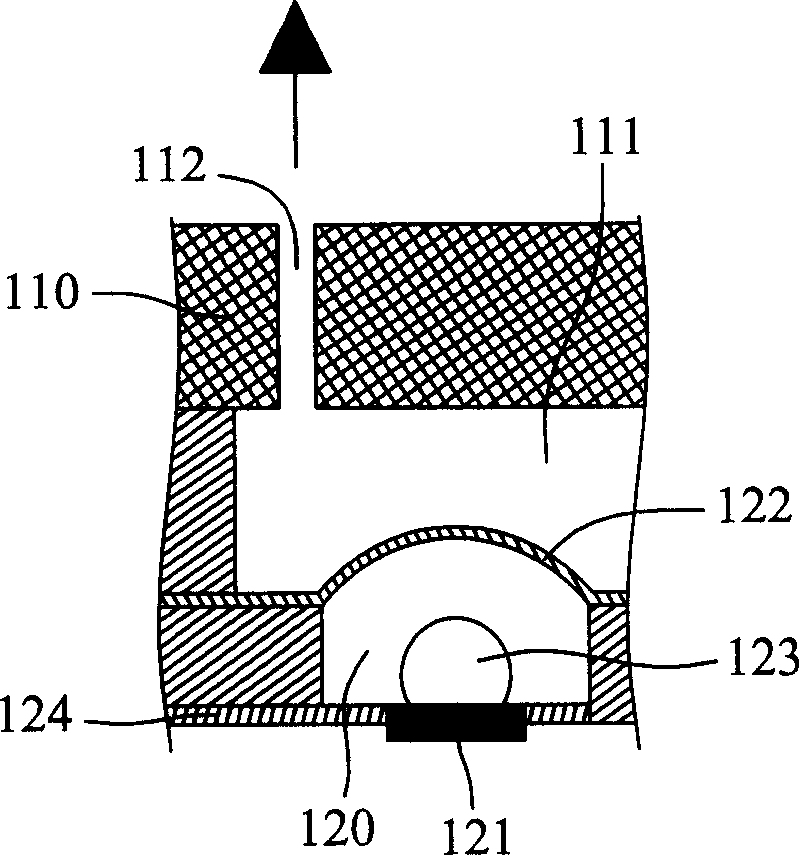

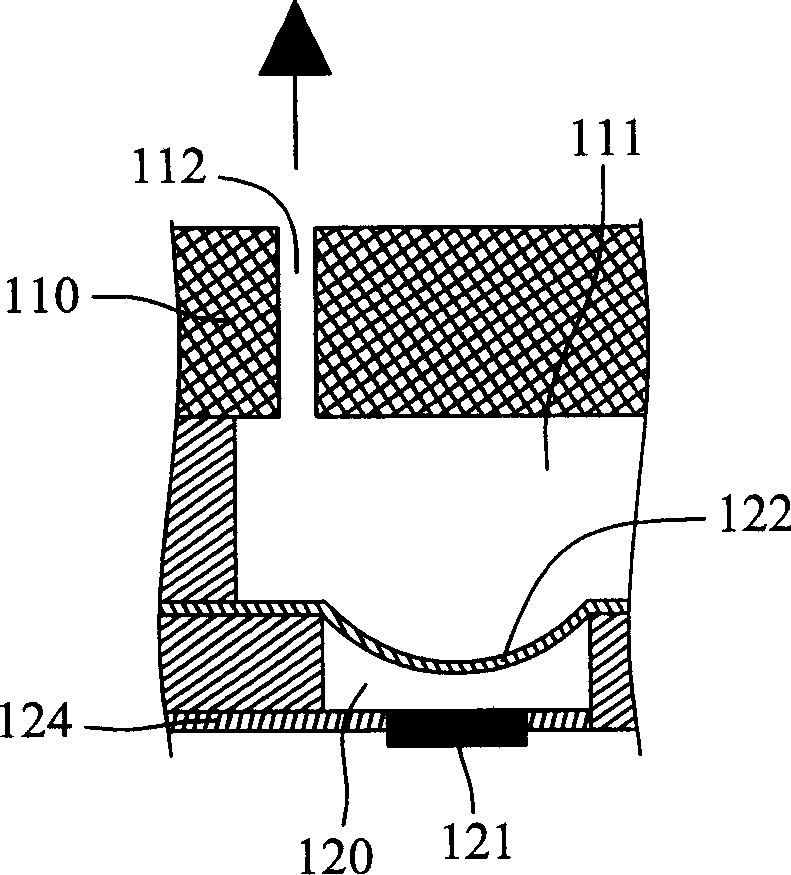

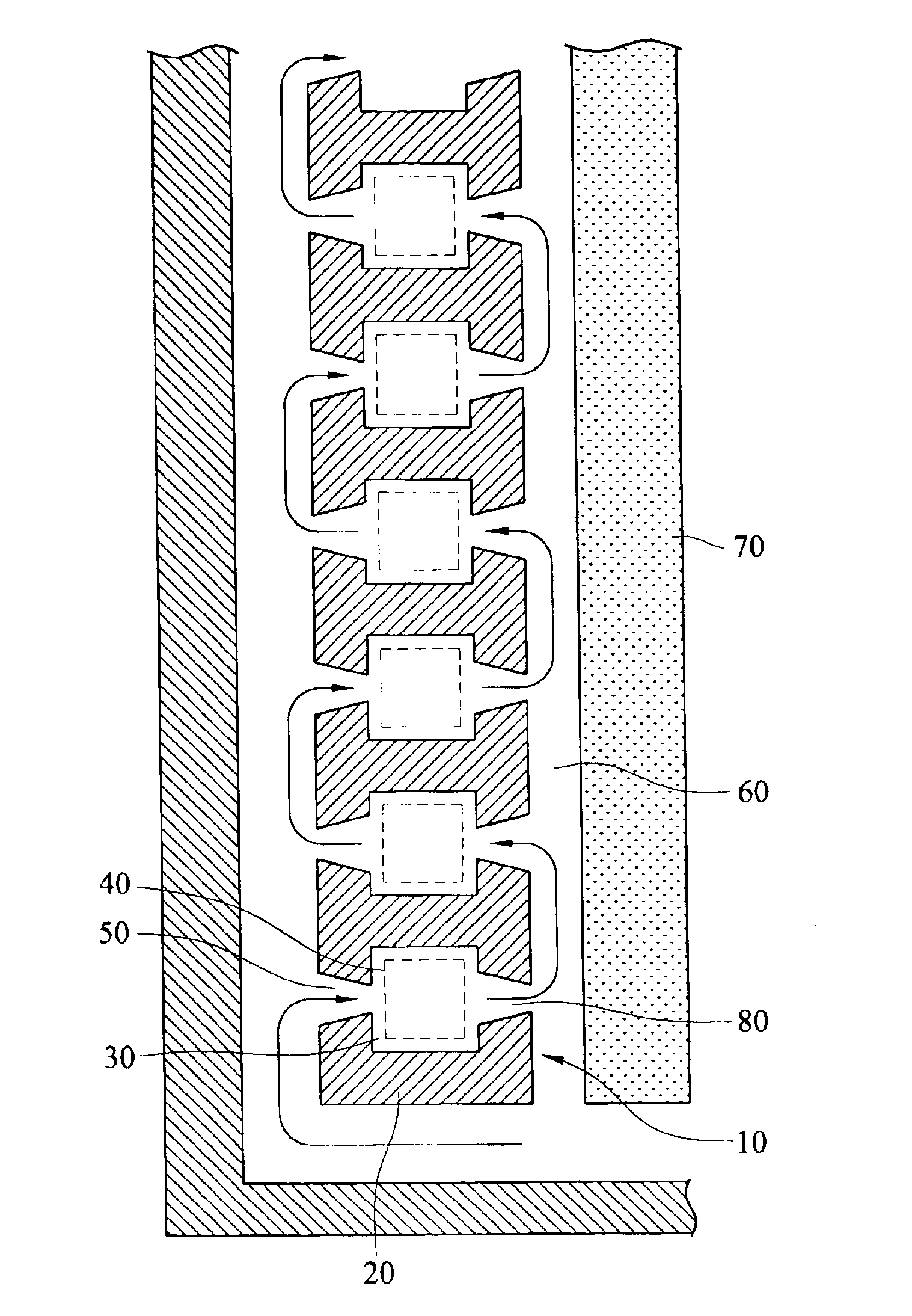

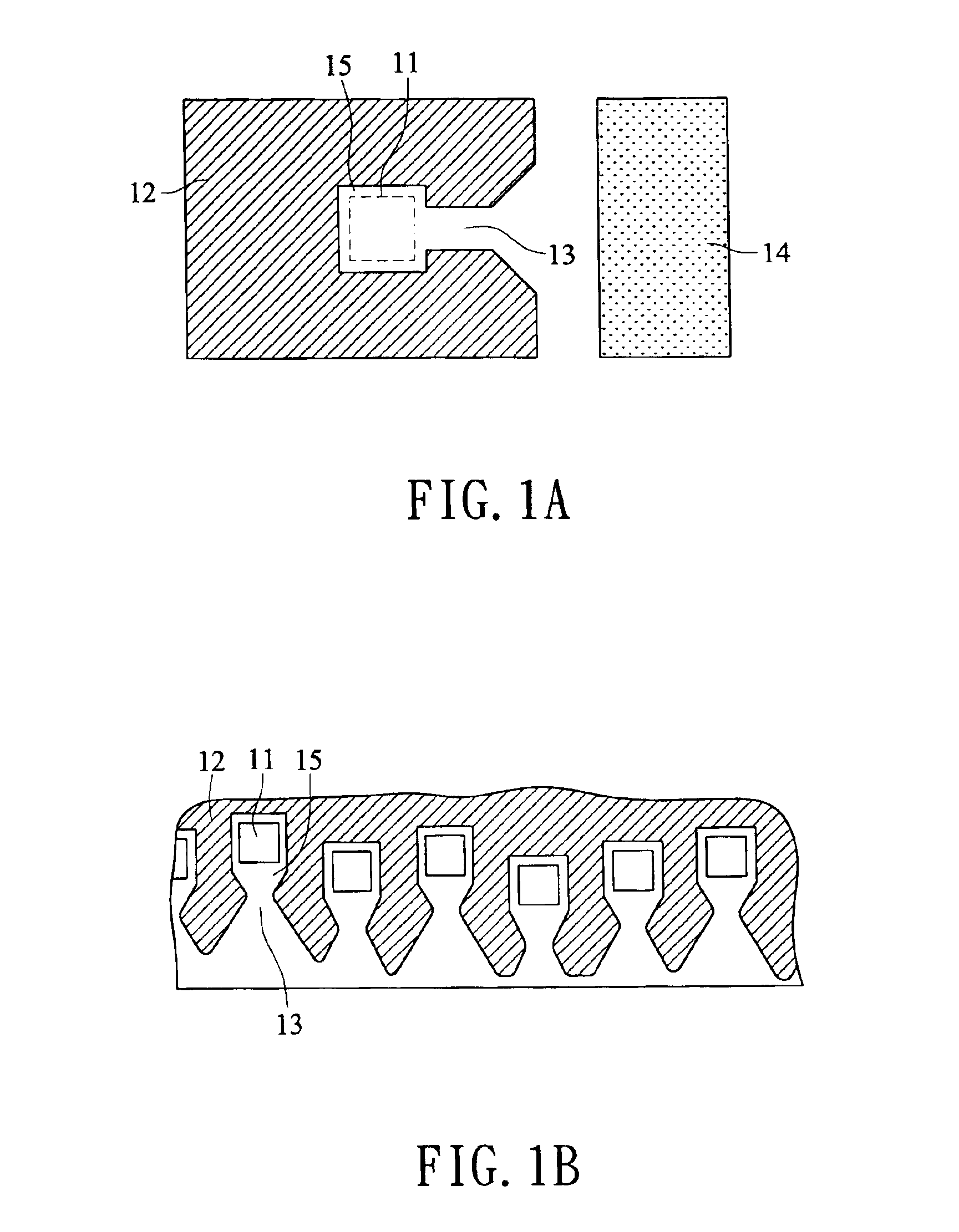

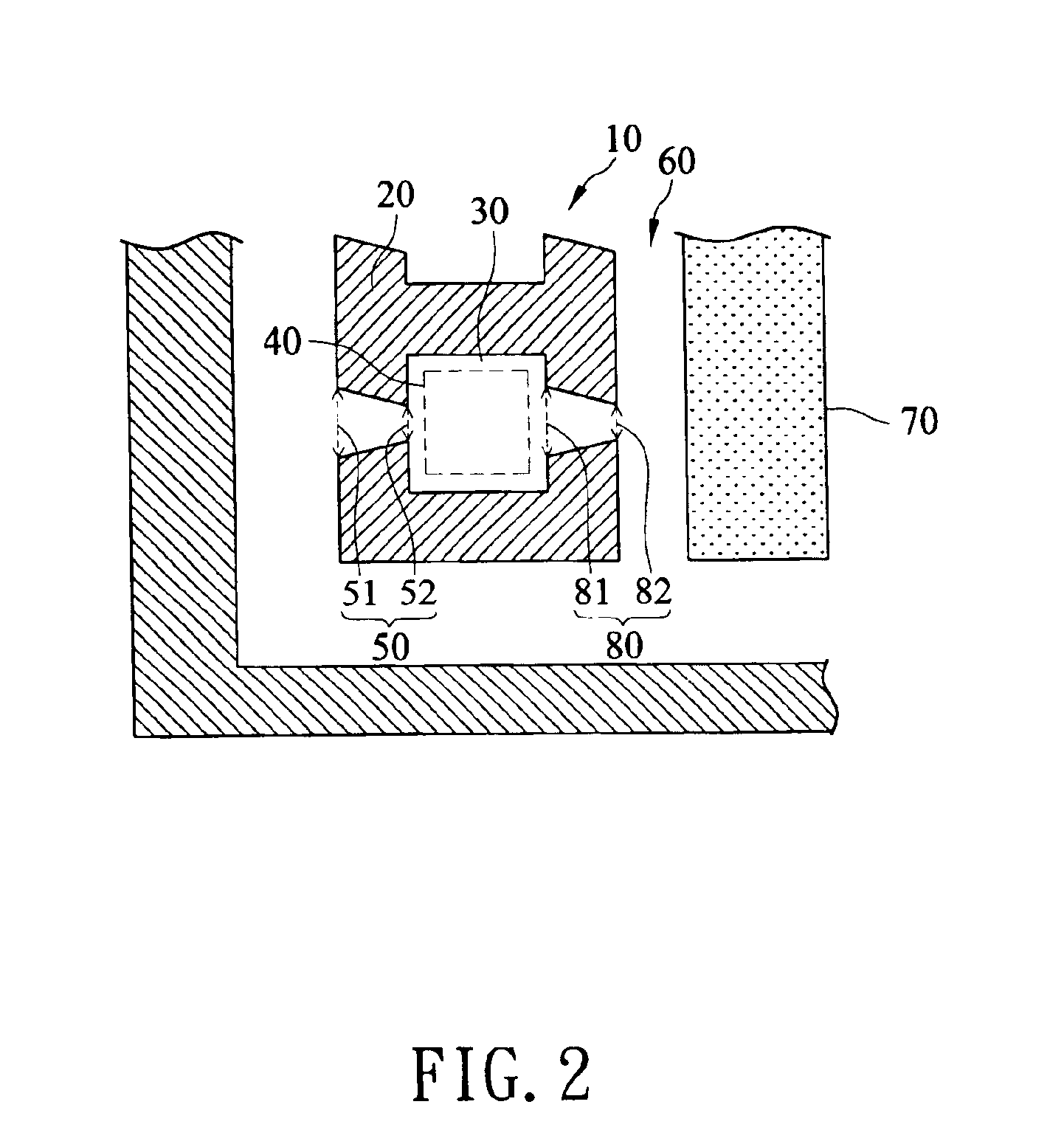

A micro fluidic module having at least a micro fluid channel barrier comprises at least an actuator, a firing chamber, a plurality of convergent fluid outlet channel and a plurality of convergent fluid inlet channel. The actuator (e.g. a heater) boils the working fluid and generates thermal bubble and instant high pressure to eject the working fluid outside and expel the working fluid through the fluid outlet channel. Then, the working fluid refills from the fluid inlet channel. Therefore, the working fluid flows consistently through the firing chamber. The working fluid flowing through adjacent firing chambers are arranged in different or consistent directions. Therefore, the refilling speed of the working fluid is increased, and the operating frequency of the module is improved.

Owner:IND TECH RES INST

RFID based thermal bubble type accelerometer and method of manufacturing the same

InactiveUS8307708B2Reduce manufacturing costSolid-state devicesSemiconductor devicesAccelerometerThermal bubble

Owner:CHUNG HUA UNIVERSITY

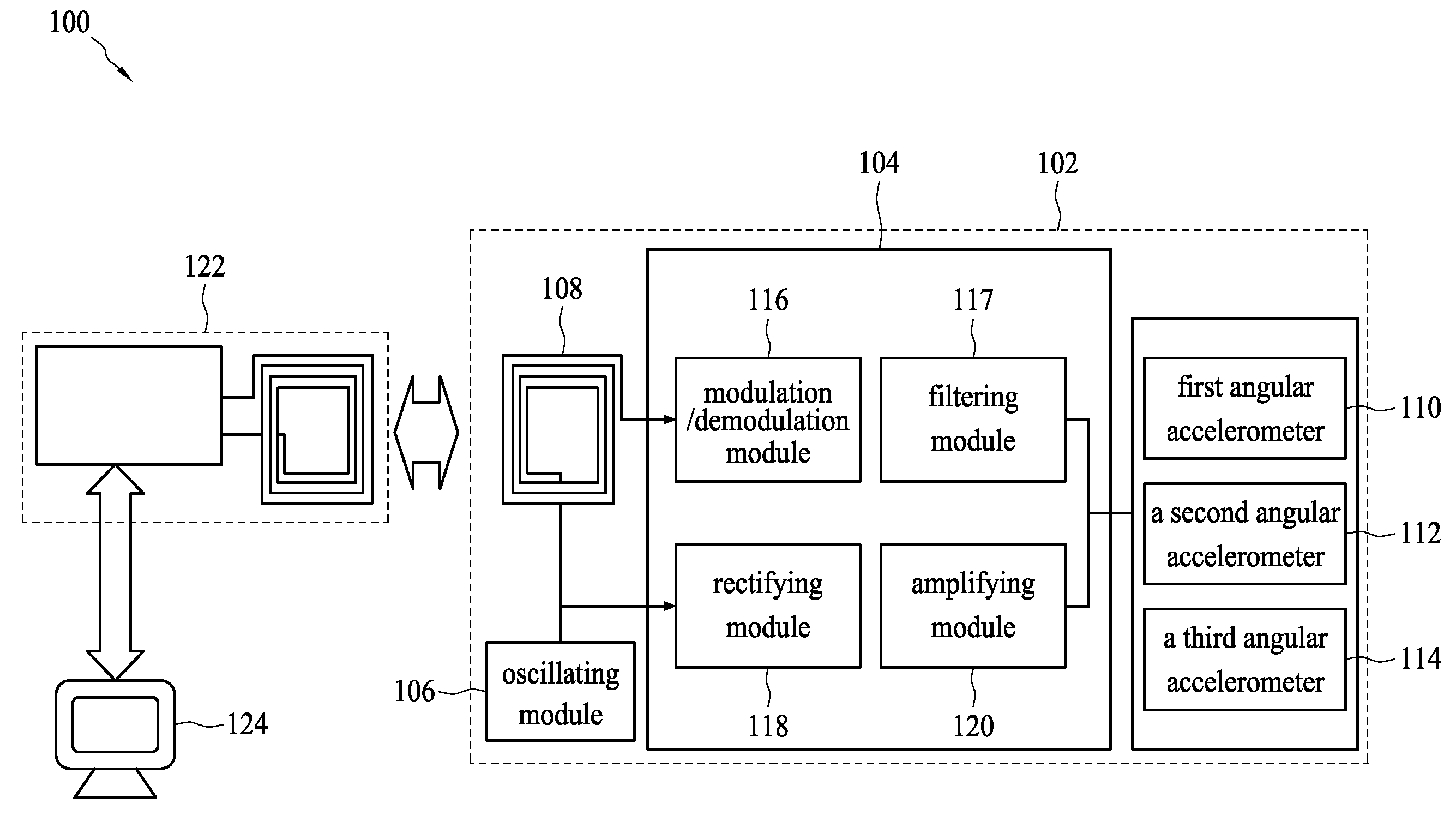

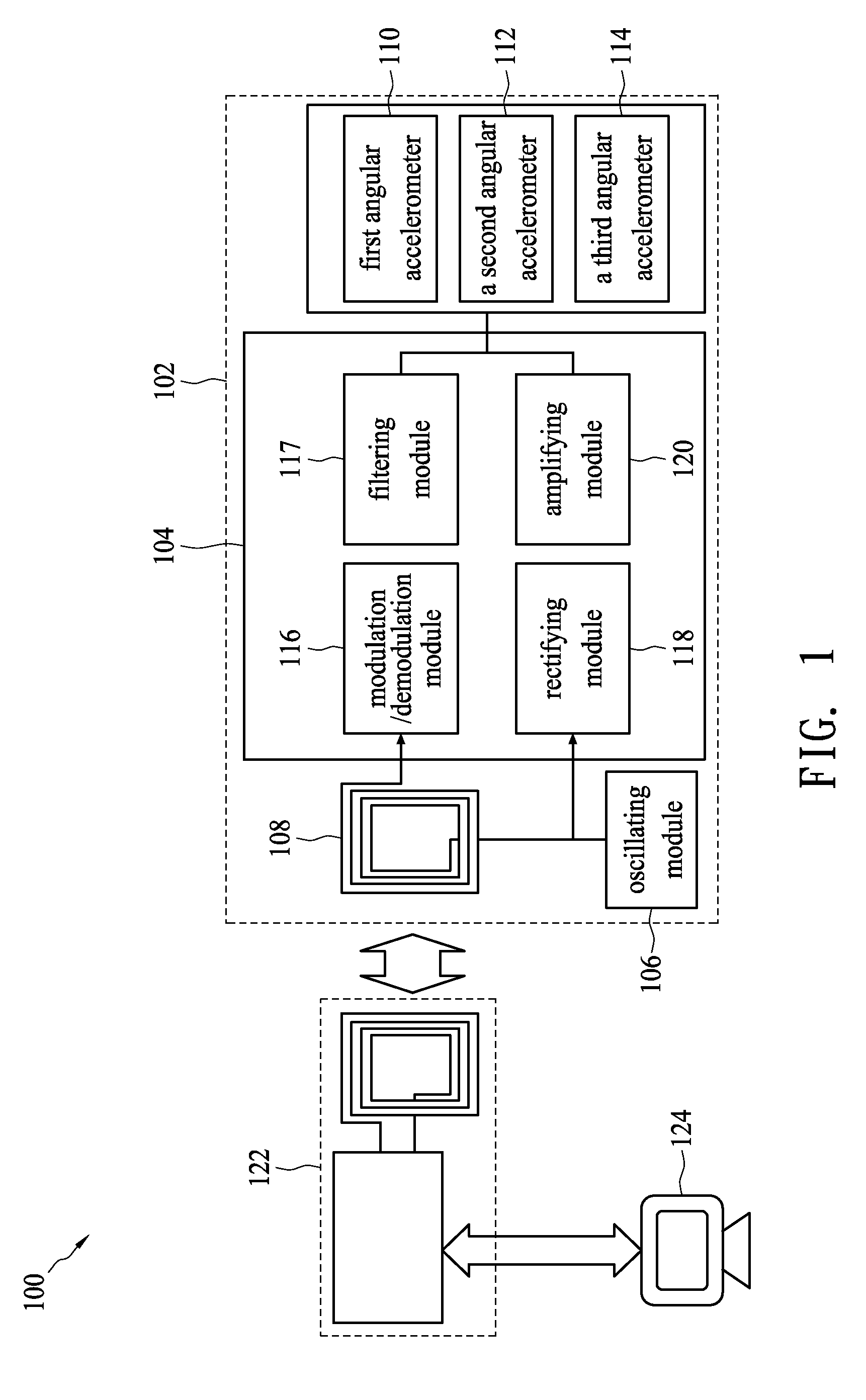

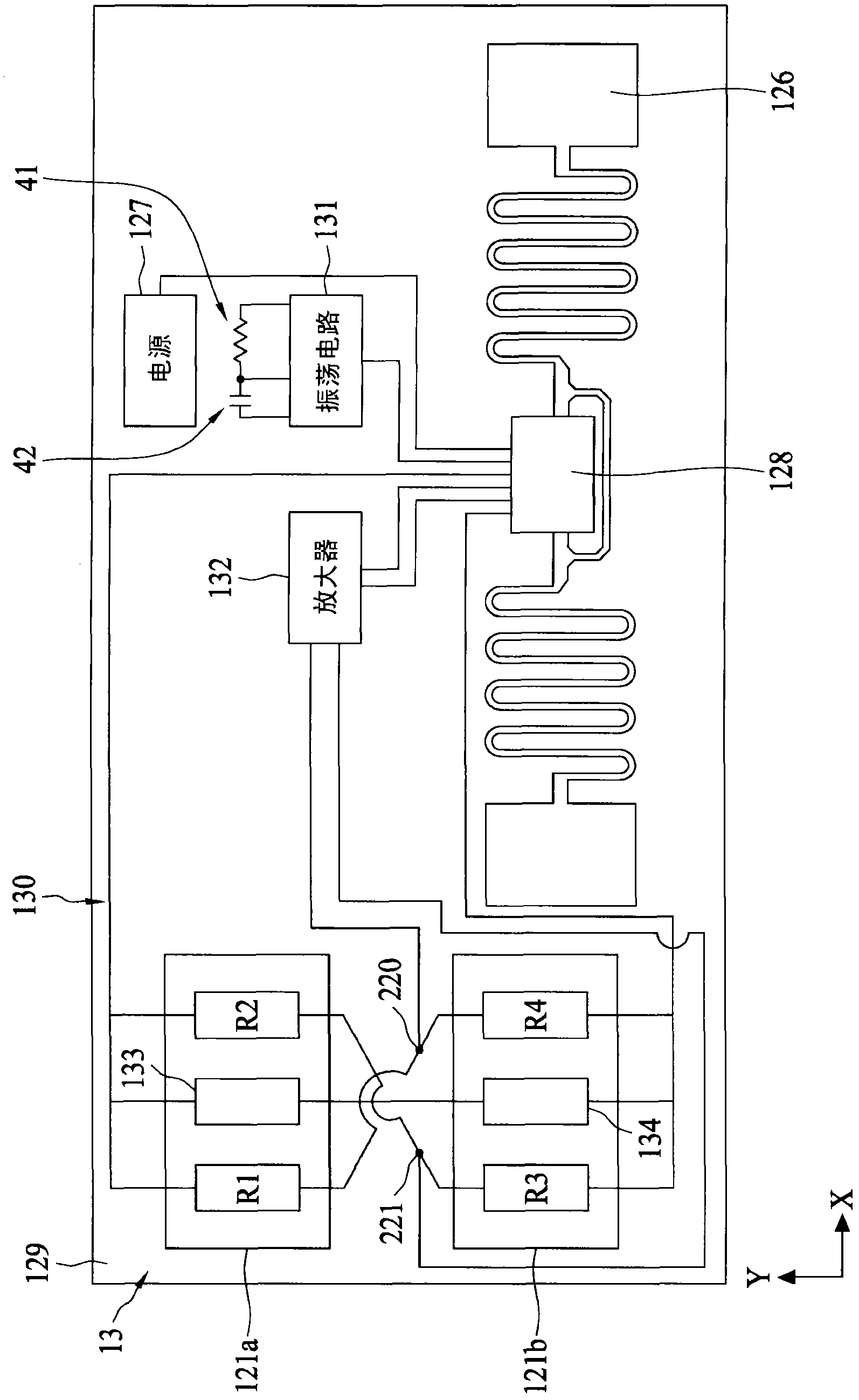

Thermal Bubble Type Angular Accelerometer

InactiveUS20110100123A1Reduce manufacturing costEasy to useAcceleration measurement using interia forcesSolid-state devicesThermal bubbleEngineering

An RFID, Bluetooth as well as zigbee based thermal bubble type angular accelerometer includes a flexible substrate, a base layer, at least one cavity, and at least one sensing assembly. The base layer is formed on the flexible substrate. The at least one cavity is formed on the base layer. The at least one sensing assembly is suspended over the at least one cavity. The sensing assembly comprises a heater and two temperature sensing elements, wherein the two temperature sensing elements are substantially symmetrically disposed on opposite sides of the heater, and the heaters and the two temperature sensing elements extend in a radial direction.

Owner:CHUNG HUA UNIVERSITY

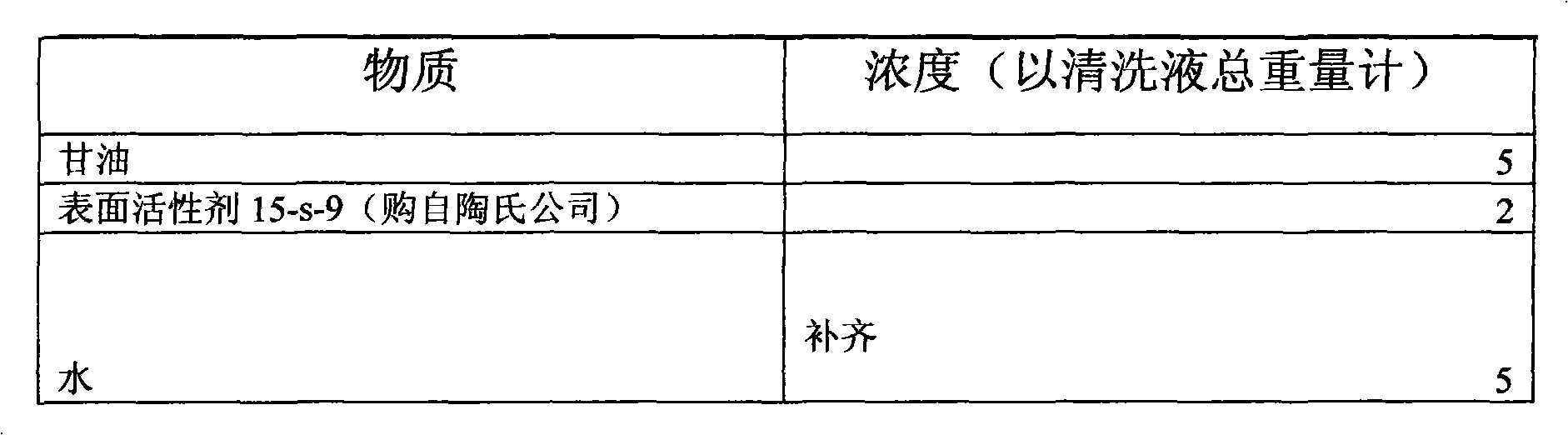

Method and special cleaning solutions for cleaning thermal-bubble ink-jet printer jet head

InactiveCN101982316AExtended use timeReduce printing costsSurface-active non-soap compounds and soap mixture detergentsPrintingThermal bubbleEngineering

The invention relates to a method and special cleaning solutions for cleaning a thermal-bubble ink-jet printer jet head. The method comprises the following steps: (1) cleaning the jet head by using a first cleaning solution under the cleaning pressure of minus 0.05 MPa until the eluate from the jet head is colorless; (2) cleaning the jet head by using 250-350 ml of a second cleaning solution under the cleaning pressure of minus 0.05 MPa; (3) cleaning the jet head by using 250-350 ml of the first cleaning solution under the cleaning pressure of minus 0.05 MPa; (4) cleaning the jet head by using 250-350 ml of a third cleaning solution under the cleaning pressure of minus 0.05 MPa; and (5) filling the third cleaning solution into the ink box of the ink-jet printer, and after installing the jet head which is cleaned by the third cleaning solution on the printer, printing the color area with the corresponding color. The experimental result indicates that the three cleaning solutions and the cleaning method have the advantage of obvious improvement action on the jet head, thereby effectively prolonging the service life of the thermal-bubble ink-jet printer jet head and lowering the printing cost for per unit printing area.

Owner:北京联创佳艺影像新材料技术有限公司

Thermal bubble type minitype inertia sensing element

InactiveCN1525145AQuick responseImprove heating efficiencyConverting sensor output electrically/magneticallyTemperature controlDevice form

The invention provides a hot bubble micro inertial sensing cell, a micro device formed by micro-manufacturing technique, setting a heater on a basal plate and four groups of temperature sensing cells around the heater symmetrically, to sense the temperature change, setting a sealed cover on the basal plate, which is sealed to coat the heater and temperature sensors to make a liquid phase filled in a space formed by the sealed cover and basal plate; using the heater to heat the liquid phase fluid to form a hot bubble in the liquid phase fluid, controlling the size of bubble by water surface tension and temperature control to make the temperature sensing cells able to sense the change of temperature distribution, the inclined direction and magnitude as an incline meter, and the direction and magnitude of acceleration as an acceleration gauge.

Owner:XIANGQUN SCI & TECH

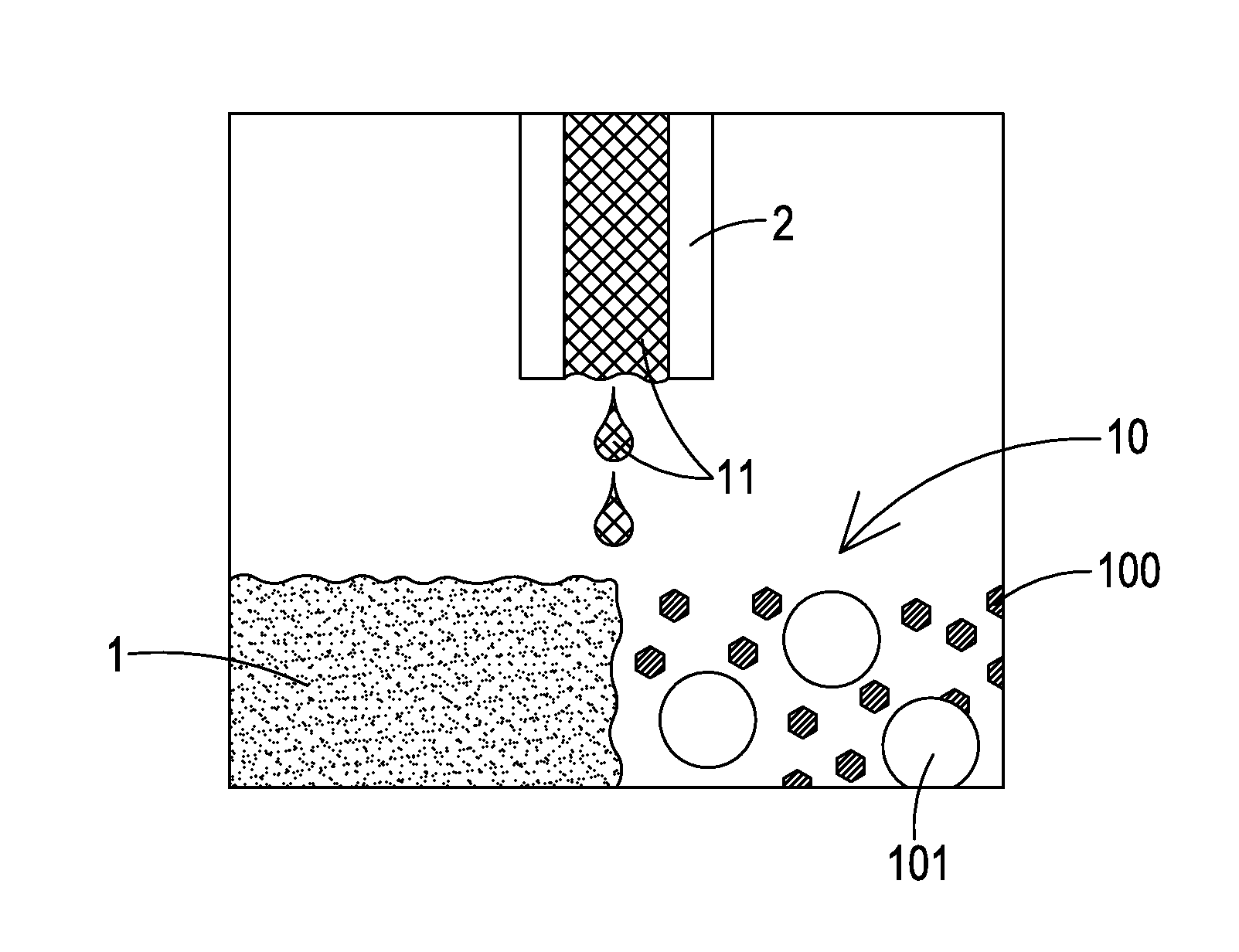

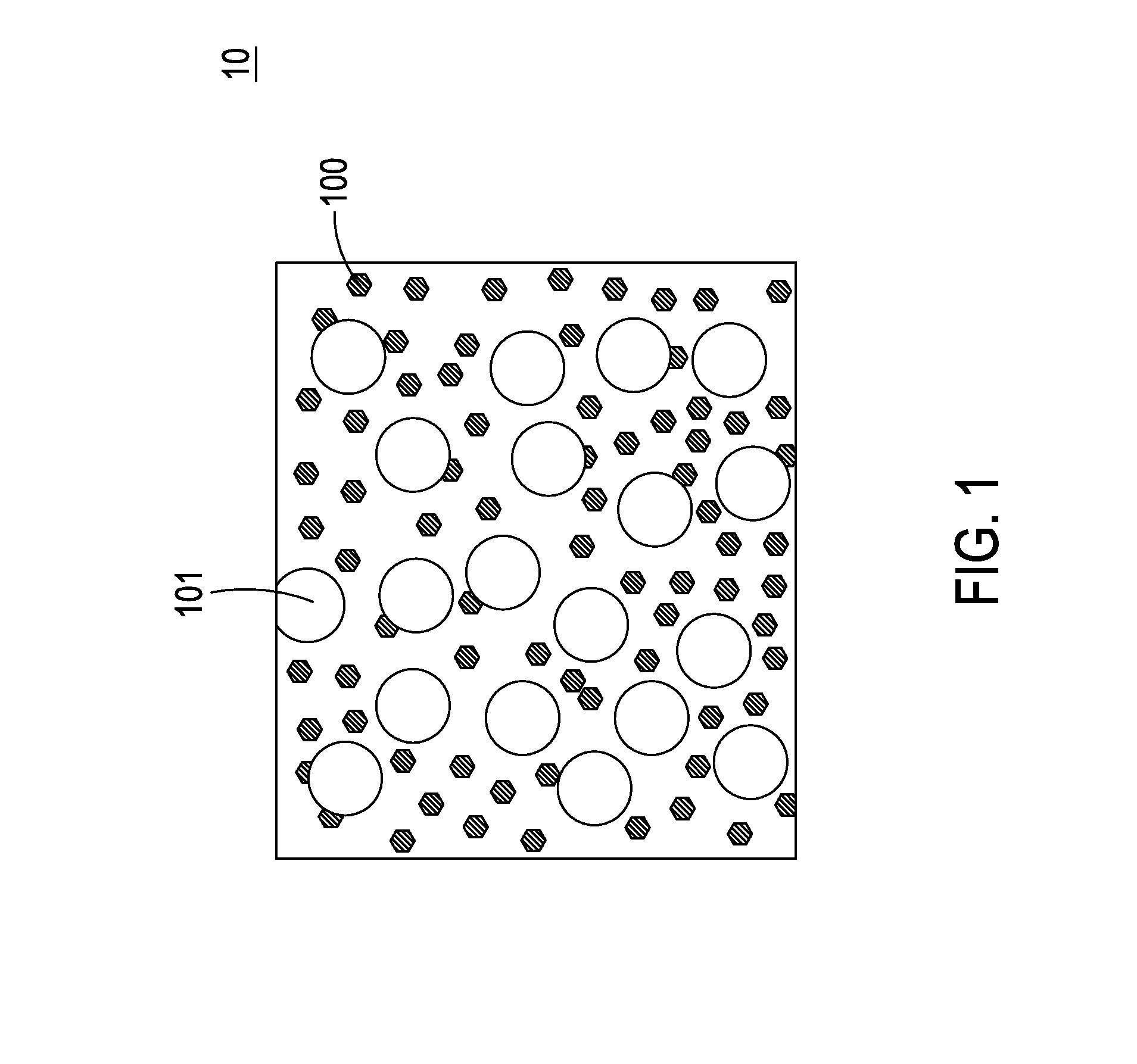

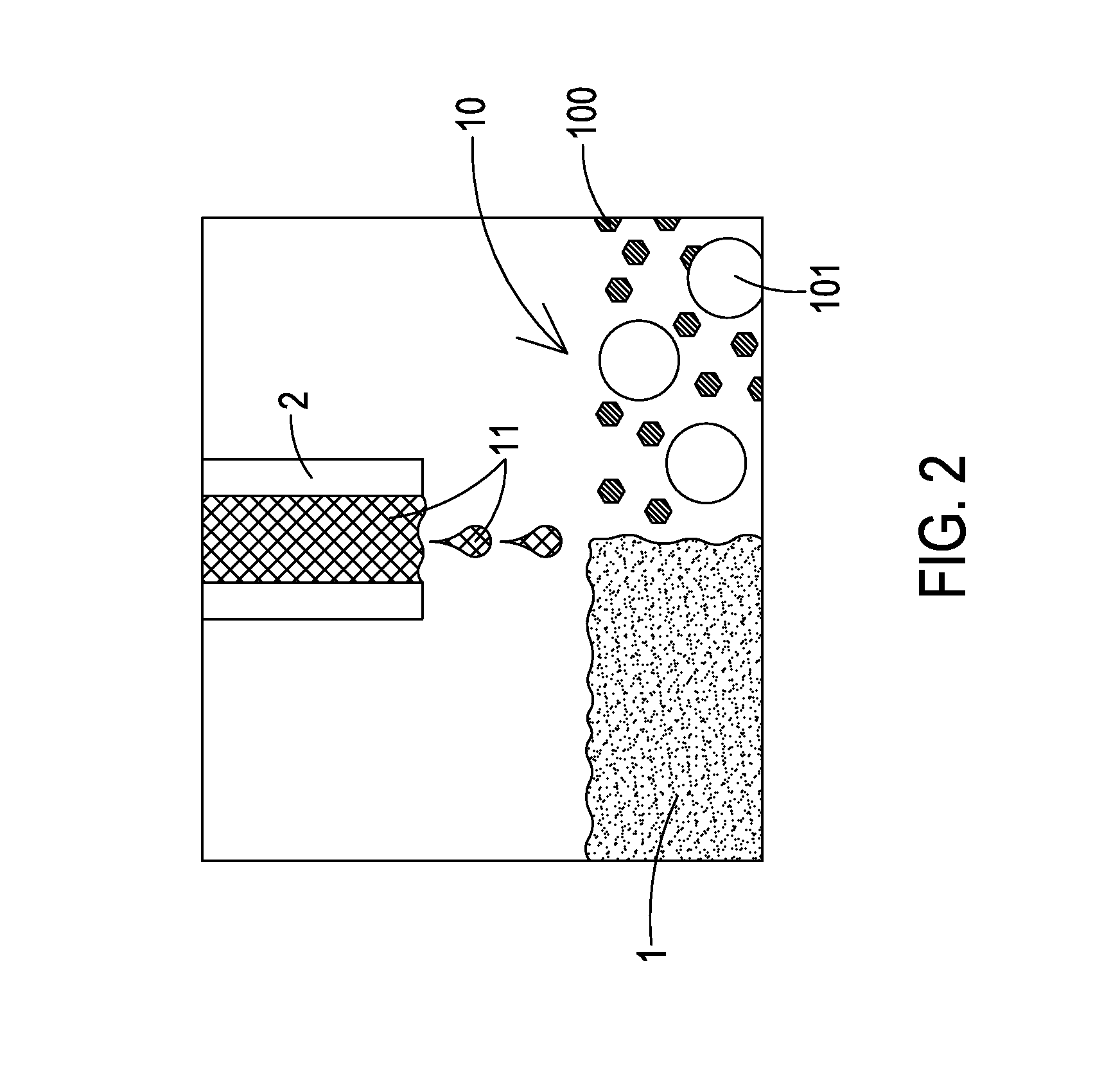

Three-dimensional prototyping composition

InactiveUS20150232648A1Good curative effectImprove efficacyFireproof paintsAdditive manufacturing apparatusAlcoholPowder mixture

A three-dimensional prototyping composition includes a construction powder mixture and an inkjet liquid. The construction powder mixture includes a powdery molding material and a powdery binding agent. The inkjet liquid includes a nonionic surfactant, at least one polyalcohol compound, an alcohol ether compound, an antimicrobial agent and deionized water. While the inkjet liquid and the construction powder mixture are in contact with each other, the physical binding function of the powdery binding agent of the construction powder mixture is activated. Consequently, the powdery molding material and the powdery binding agent stick together to form a molded construction layer of a three-dimensional object. Moreover, the construction powder mixture can be recycled. Moreover, since the inkjet liquid may be ejected through the thermal bubble printhead, the fabricating cost of the three-dimensional physical model is reduced.

Owner:MICROJET TECH

Laser ink-jet printing technology

The present invention relates to the laser ink-jet printing technology. In the prior art, a laser printer is fast in printing speed, high in printing quality, high in printer cost and expensive in consumables, while an ink-jet printer is low in printer cost, cheap in consumables and slow in printing speed. The above laser ink-jet printing technology integrates the laser printer and the ink-jet printer, wherein the laser is modulated by utilizing a laser scanning system. Meanwhile, the laser deflection is controlled, so that the laser is enabled to shoot into each small ink chamber of an ink-jet head. The photoinduced deformation of components occurs inside the small ink chamber, and the size of the interior of the small ink chamber changes. Each small ink chamber inside the ink-jet head injects ink drops, so that the on-demand ink-jet printing is realized. Meanwhile, based on the ultrasonic focusing generated due to the acoustic effect of the periodic intensity-modulated laser, the ink-jet is realized. Since one part of the ink-jet head is free of any circuit, the requirement on the manufacturing process of the ink-jet head is relatively low compared with the thermal bubble technology and the piezoelectric inkjet technology. The structure is much simpler compared with the laser printer, and the printing speed is faster. Meanwhile, page amplitudes can be conveniently manufactured, and the high-precision printing is realized more easily. The use cost is low.

Owner:韦翔

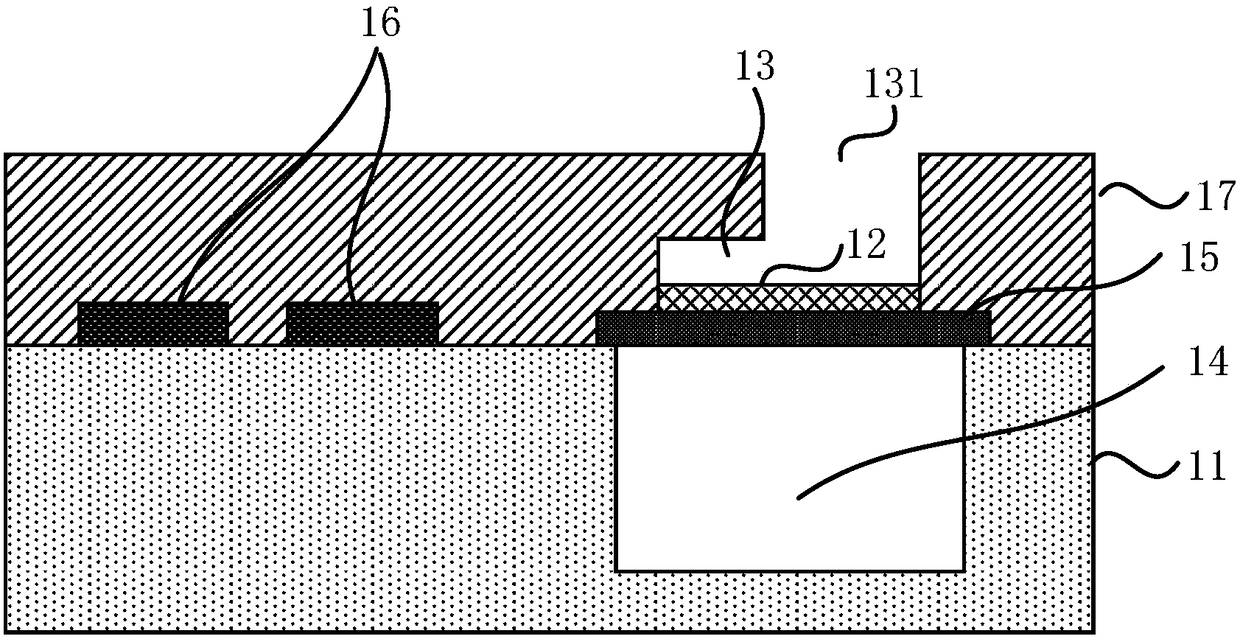

Thermal bubble ink jet printing head chip and manufacturing method thereof

InactiveCN108248219ASmall working currentImprove heating efficiencyPrintingElectrical resistance and conductanceThermal bubble

Owner:SHANGHAI AUREFLUIDICS TECH CO LTD

Laser ink-jetting head

InactiveCN102019753AReduce production processLow technical requirementsPrintingThermal bubbleEngineering

The invention relates to a laser ink-jetting printing head. The main parts of the laser ink-jetting printing head comprise a laser generator, a laser deflecting part, an ink-jetting part, and the like. Laser is sequentially projected in all small ink chambers of the ink-jetting part after being deflected by the laser deflecting part and generates thermal pressure or dynamic pressure, and ink is jetted out by pressure. Compared with a thermal bubble type and piezoelectric type ink-jetting head, laser ink-jetting printing head has low technical requirement for the manufacture process, simple circuit, high jetting speed and lower cost, can be easily manufactured into the ink-jetting head with page width and is easy to realize high-precision printing.

Owner:韦翔

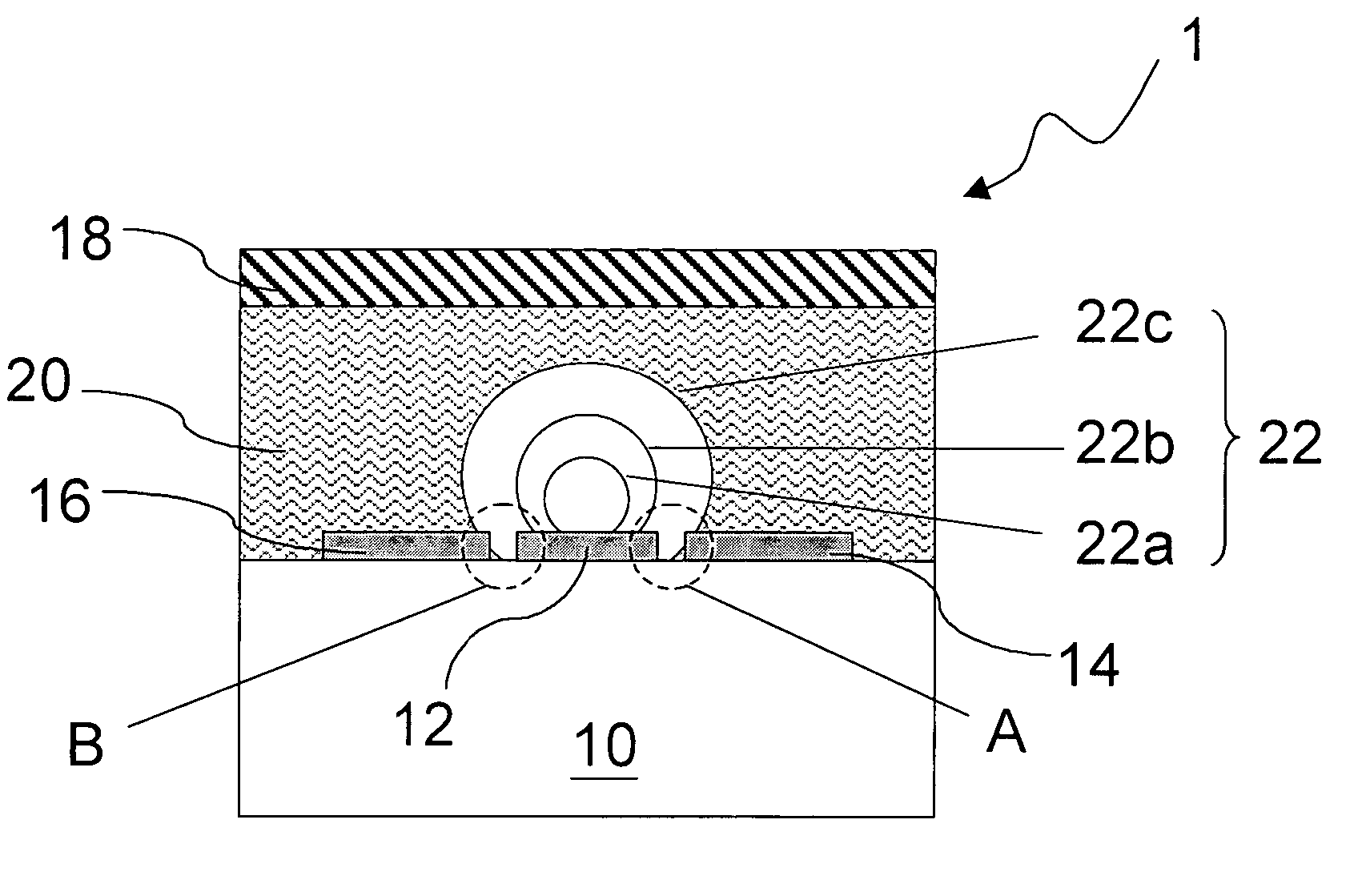

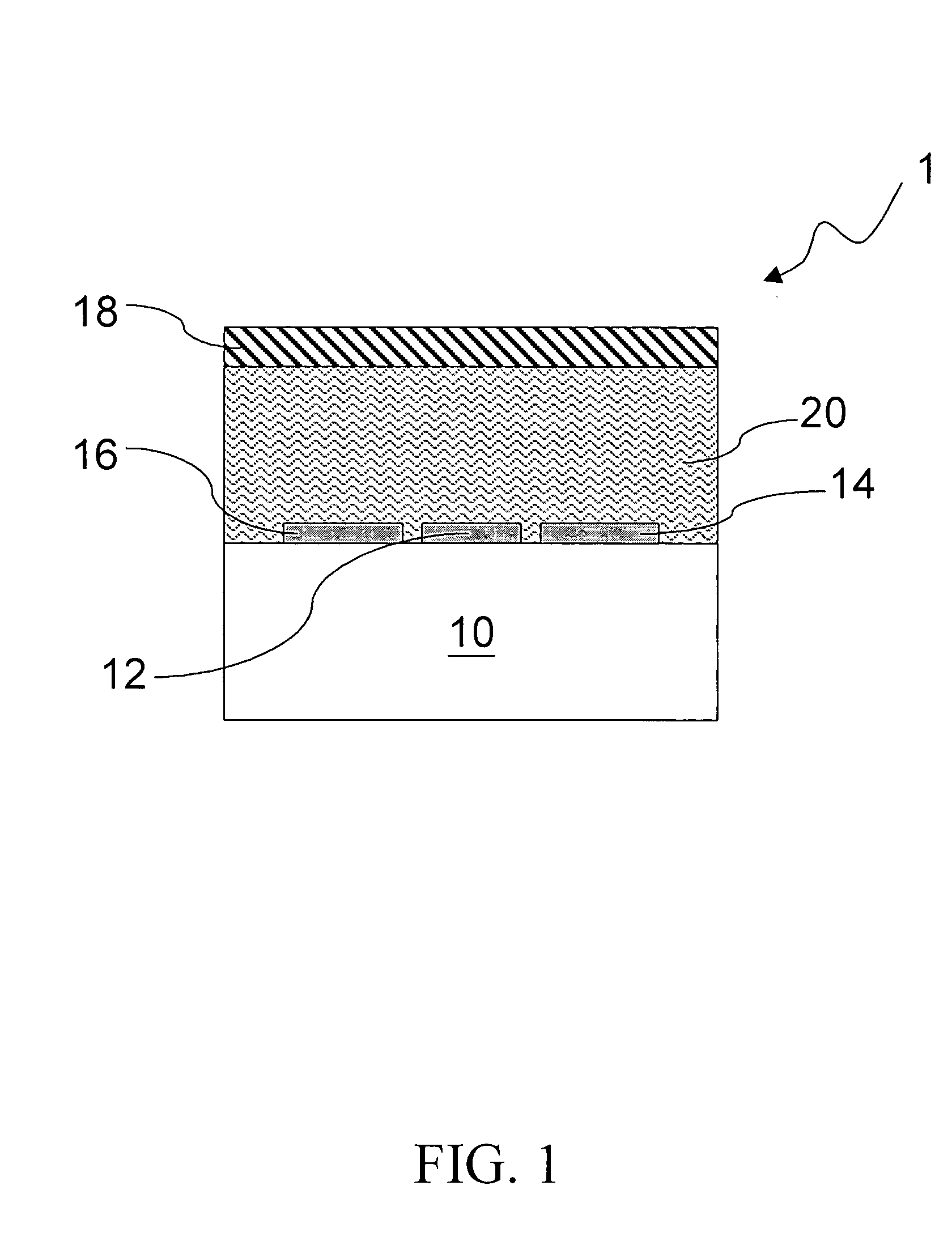

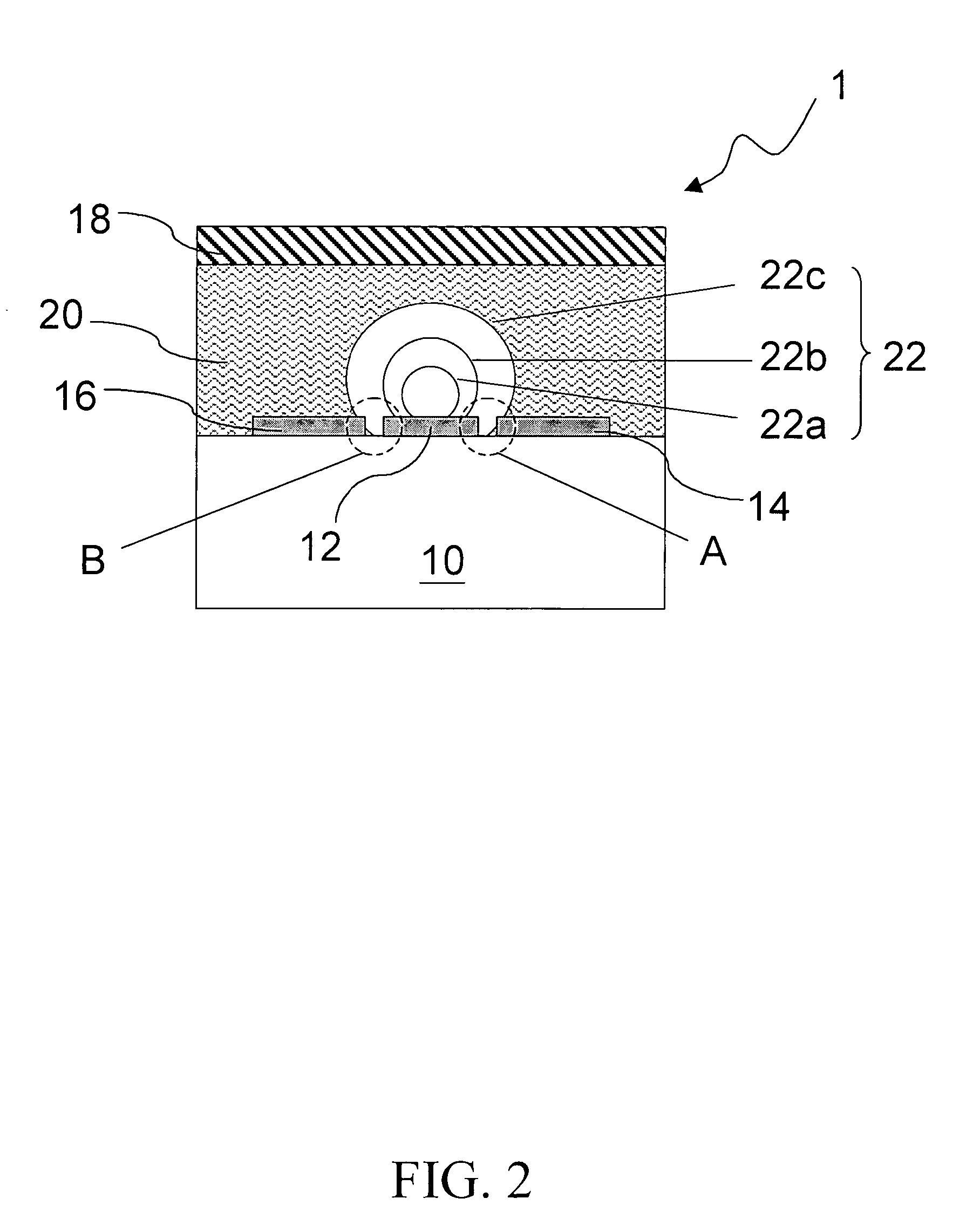

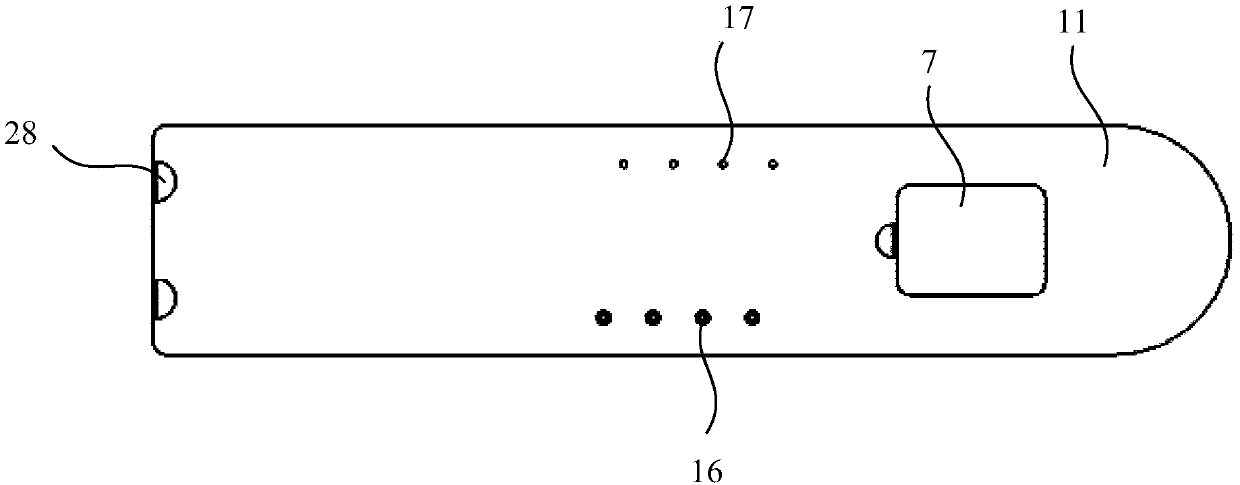

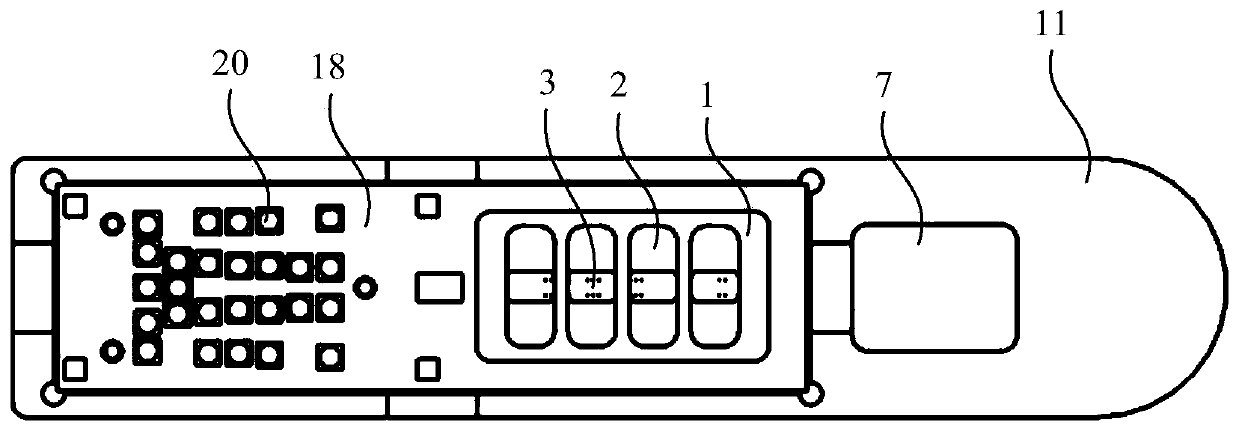

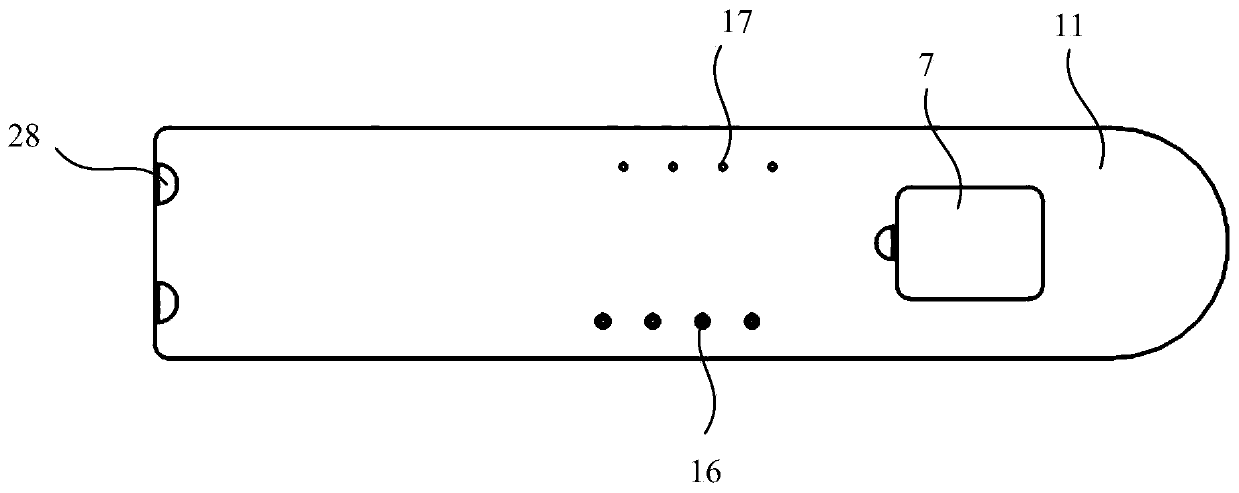

Flexible and conformal patch pump

Provided is a flexible and conformal wearable, self-contained medical device. The medical device comprises an integral housing formed by a flexible upper portion and a flexible lower portion joined along their perimeters. The medical device is also provided in a plurality of shapes and configurations for increasing the flexibility and conformability of the housing. The components contained within the housing, such as a drug reservoir, printed circuit board, and power supply are preferably constructed from flexible materials and are formed, connected and positioned according to the configuration of the housing in a manner for enhancing flexibility of the housing. A thermal bubble micropump is provided for controlling flow of a drug from the flexible reservoir, that utilizes a thermal resistor provided locally to a thermal expansion fluid that causes a surrounding membrane to expand and displace a volume of drug to be provided to the user.

Owner:BECTON DICKINSON & CO

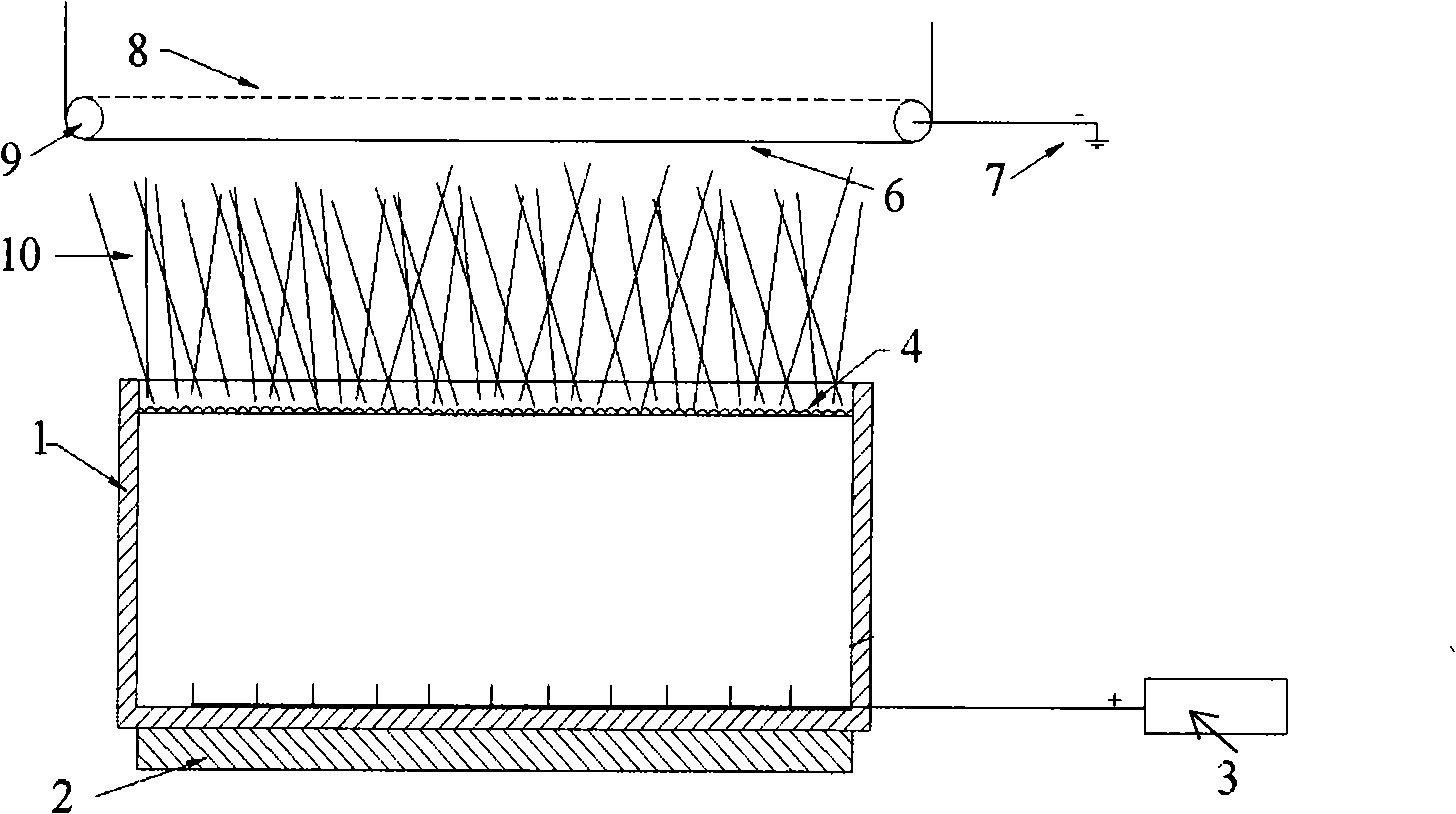

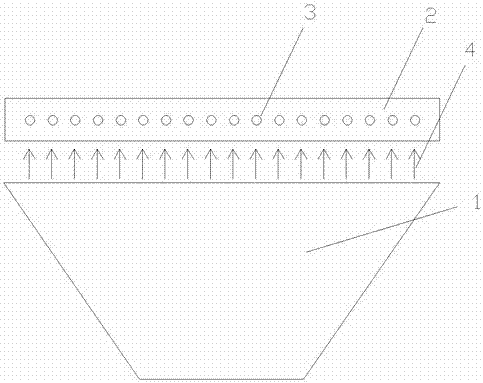

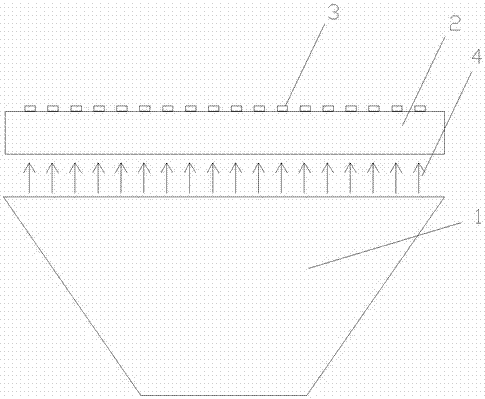

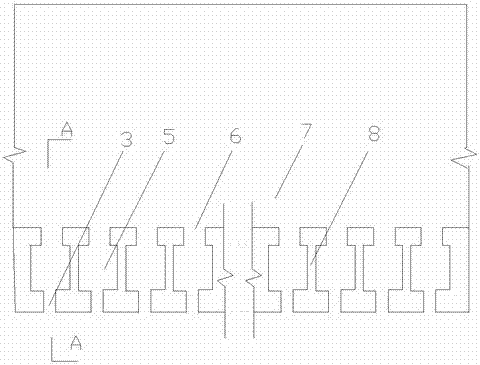

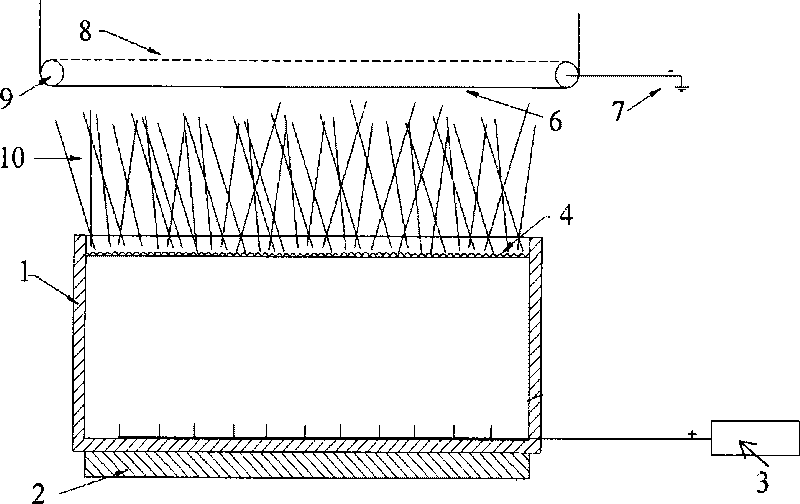

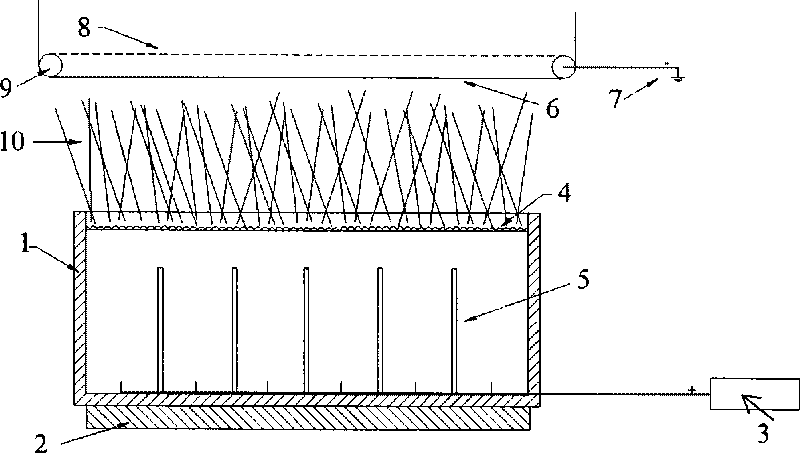

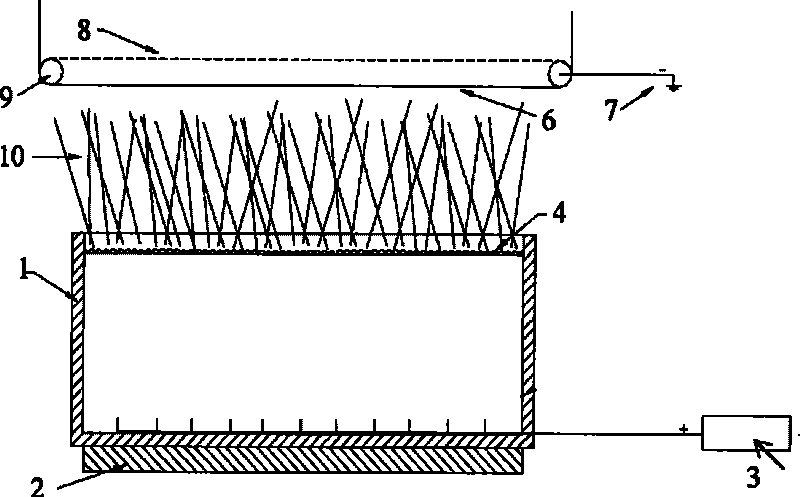

Thermal bubble spinning method and device for nano-fiber production

InactiveCN101275299BSimple spinning mechanismEasy production controlArtificial thread manufacturing machinesFilament/thread formingFiberSpinning

A hubble-bubble spin method and apparatus for producing nano fibre is disclosed. The method includes the following steps: a spinning solution or dissolving body is poured in a liquid storage pool after stirring; a large amount of rule vacuole appear on the liquid level after heating, the high-pressure electrostatic generator polarization vacuole is switched on, a jet current spurts out at the topof the vacuole to shoot toward the receiving polar plate, and deposits at a receiving curtain between the solution liquid level and the receiving polar plate. The apparatus is composed of a liquid storage pool, a heating mechanism, a high-pressure electrostatic generator, the receiving polar plate, an orienting roll, an earth electrode and the receiving curtain, wherein, the heating mechanism is at the bottom of the liquid storage pool, the high-pressure electrostatic generator is connected to the solution or dissolving body in the liquid storage pool the metallic electrode, thereby forming apositive pole, the receiving polar plate is earthed through the earth electrode to form a negative pole, and the receiving polar plate, the orienting roll and the receiving curtain are provided abovethe liquid storage pool. The invention possesses the advantages of simple spinning mechanism, and being easy to carry out actual production control.

Owner:DONGHUA UNIV

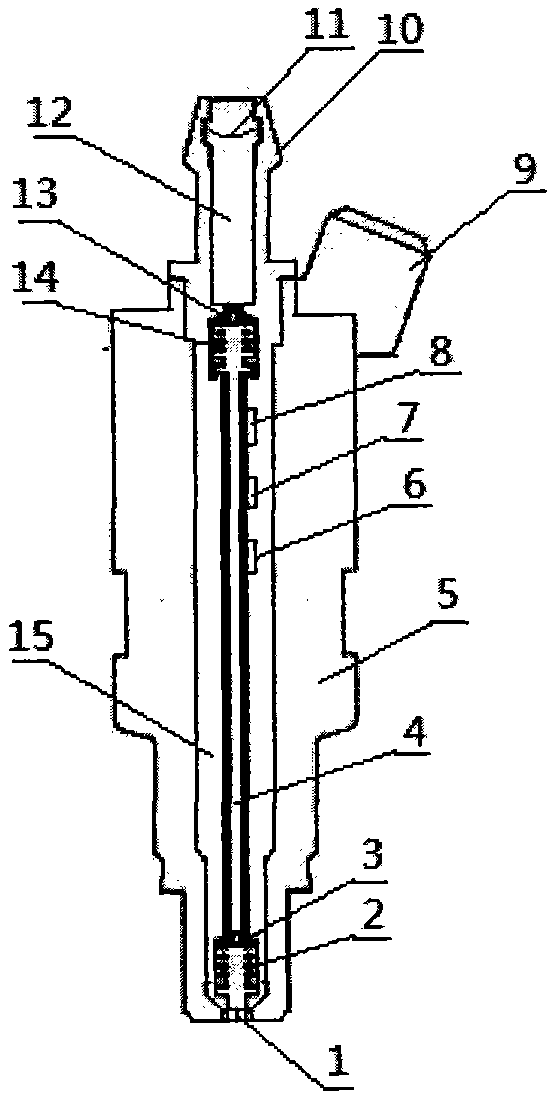

Thermal bubble supercharged liquid jet nozzle

InactiveCN103742324ASimple structureImprove compatibilityFuel injection apparatusMachines/enginesLiquid jetElectricity

The invention belongs to the field of liquid jet technologies, and particularly relates to a thermal bubble supercharged liquid jet nozzle which comprises a shell (5), a jet nozzle (1), an electric connector (9), a liquid nozzle (10) and a thermal bubble supercharging device. A liquid channel in the liquid jet nozzle is sequentially connected with the liquid nozzle (10), the thermal bubble supercharging device and the jet nozzle (1) from top to bottom, and a liquid storage zone (12) is formed between the thermal bubble supercharging device and the liquid nozzle; the thermal bubble supercharging device comprises a liquid jet tube (4), a first check valve, a second check valve and heating devices, the first check valve is arranged at an inlet of the liquid jet tube, the second check valve is arranged at an outlet of the liquid jet tube, and the heating devices are arranged on the liquid jet tube. The thermal bubble supercharged liquid jet nozzle has the advantages that the thermal bubble supercharged liquid jet nozzle is simple in structure, low in energy consumption, high in reliability and wide in temperature application range, and low-pressure liquid can be quickly jetted at a high pressure.

Owner:苟仲武

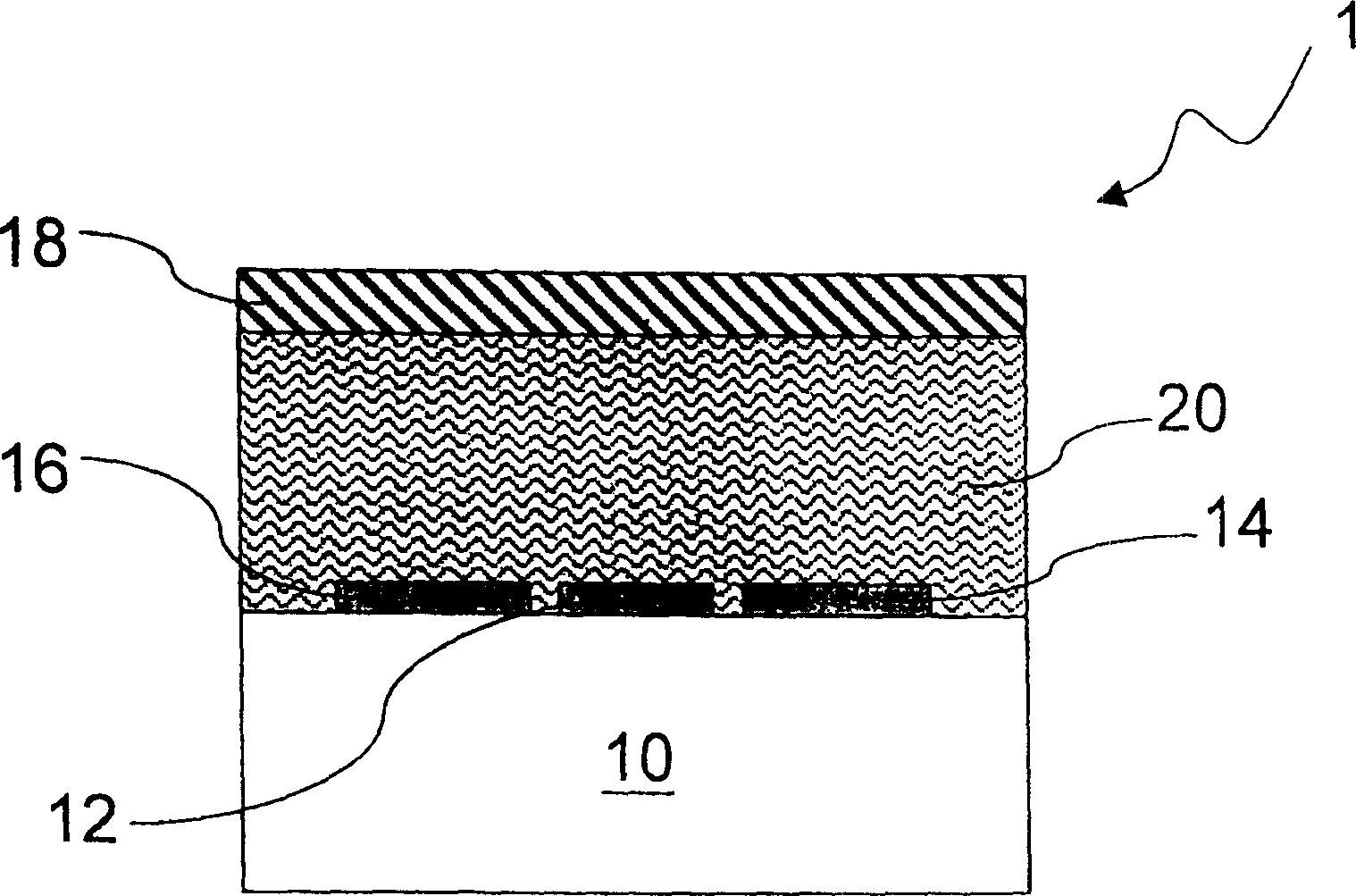

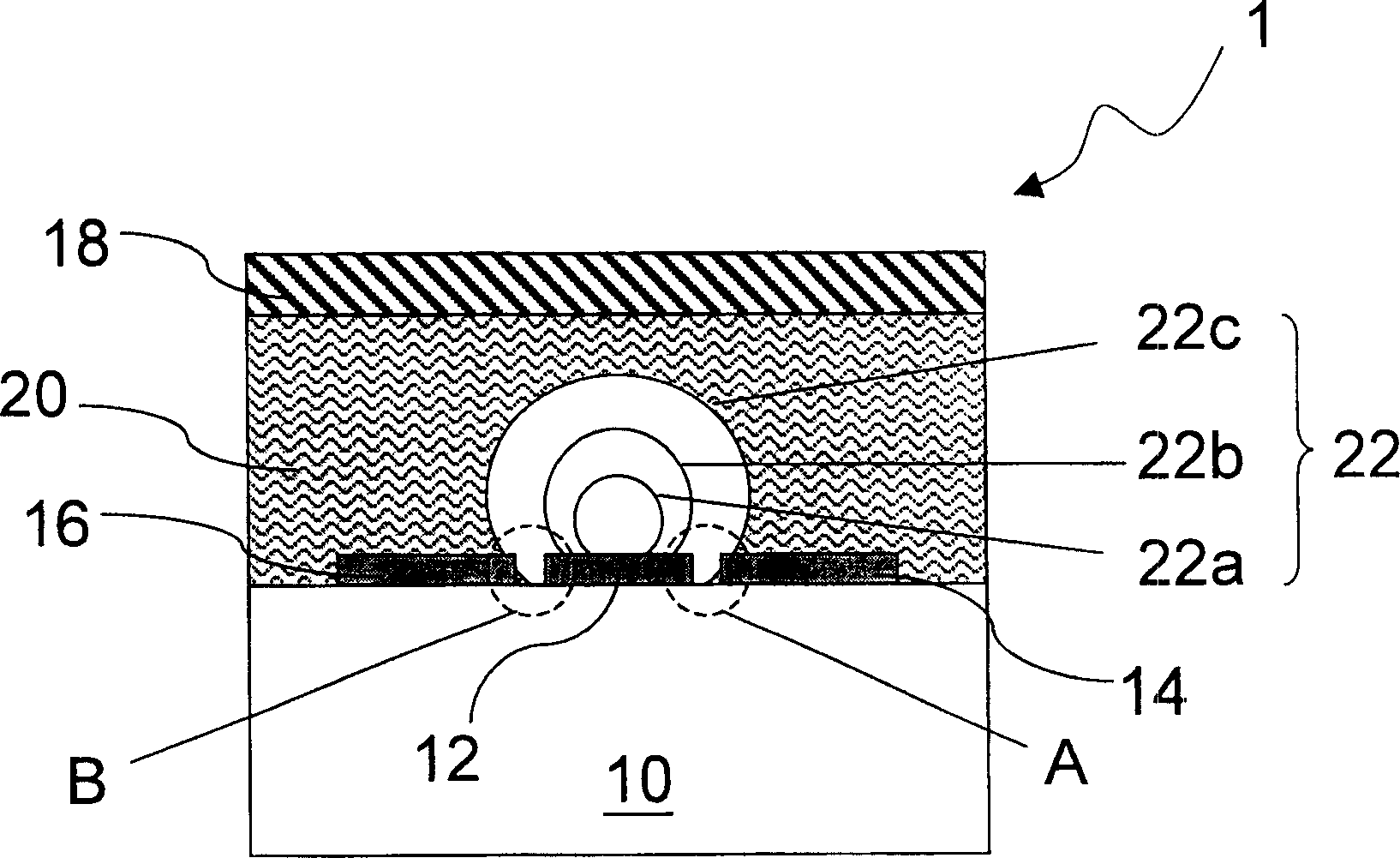

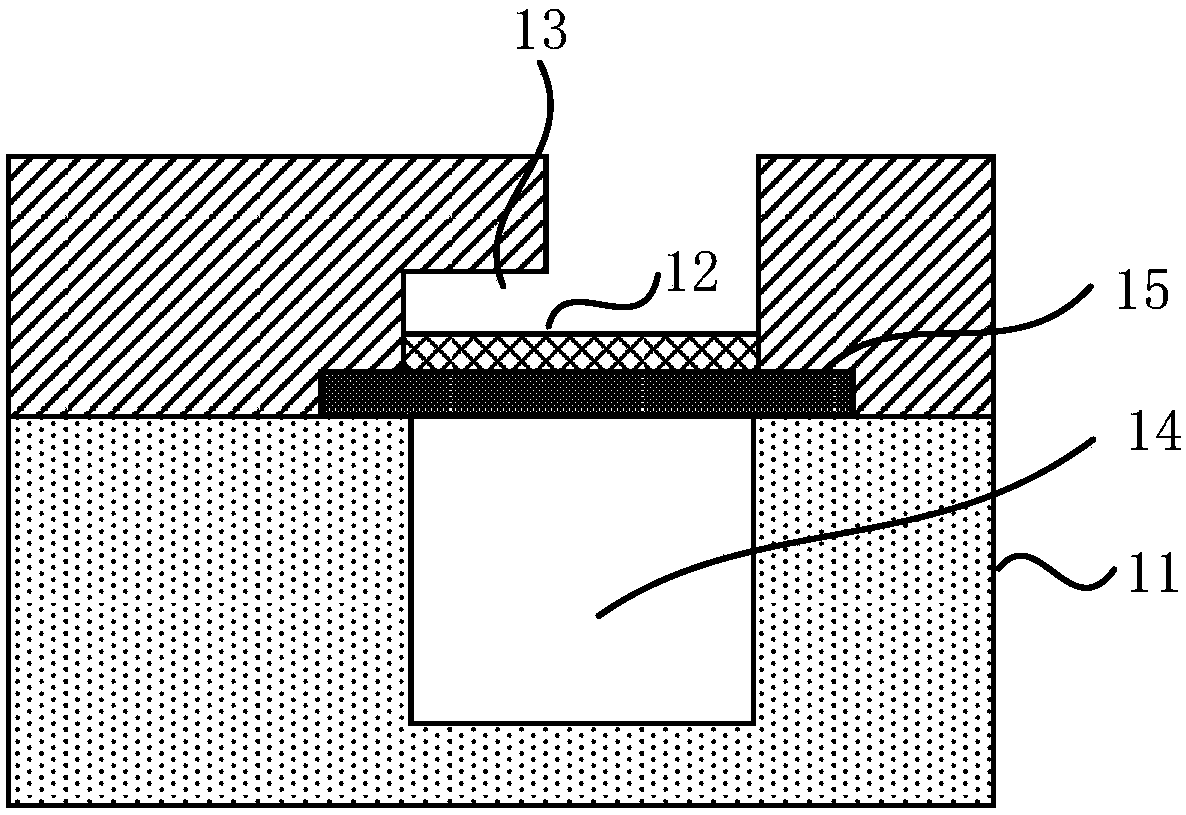

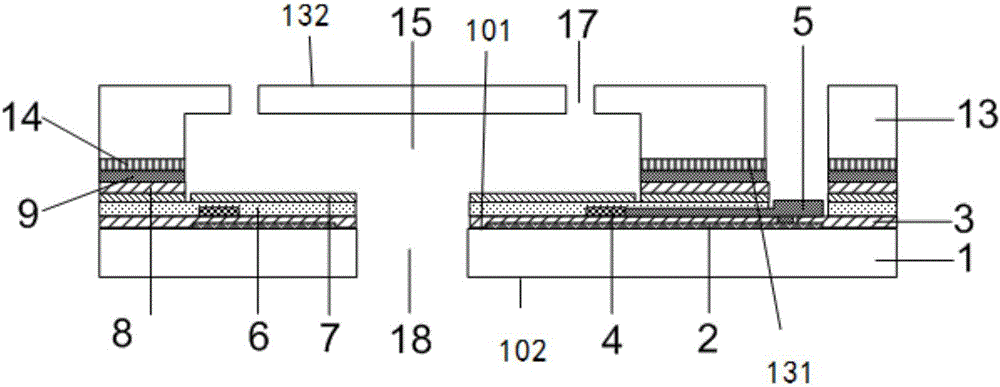

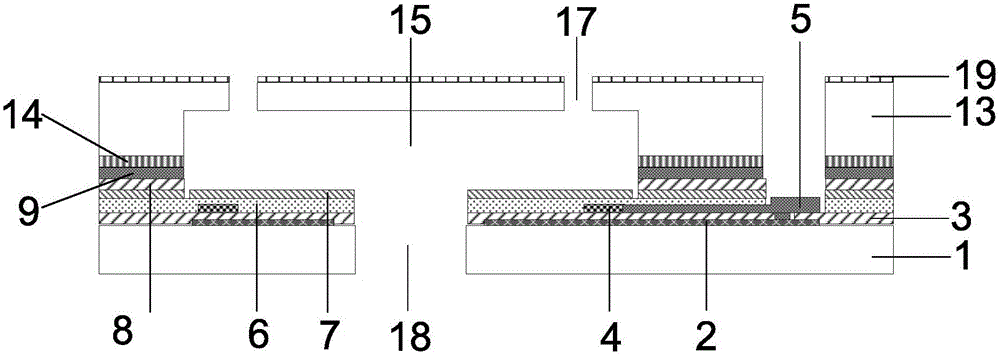

Thermal vapor bubble type ink jet head chip structure and method for producing the same

InactiveCN101456282AReduce thermal shock effectsExtended service lifePrintingElectrical resistance and conductanceVapor bubble

The invention relates to a thermal bubble inkjet head chip structure and a method for manufacturing the same. The thermal bubble inkjet heat chip structure comprises a basal layer, an oxidation layer and a driving circuit, a dielectric layer, a source electrode and a drain electrode, a cushion layer, a resistance layer, a conductive layer and a protective layer, wherein the oxidation layer and the driving circuit are formed above the basal layer, the driving circuit is enclosed by the oxidization layer, the dielectric layer is formed above the driving circuit, the source electrode and the drain electrode are exposed in the driving circuit, the cushion layer is formed above the dielectric layer and covers the driving circuit and the drain electrode, the resistance layer is formed above the cushion layer and is provided with a heating area, the conductive layer is covered on the resistance layer partially and the protective layer is formed above the conductive layer and above the heating area. The cushion layer added between the dielectric layer and the resistance layer can cushion instant high temperature generated in the resistance layer, reduce the heat impact effect withstood by the dielectric layer below the heating layer and consequently improve the service life of the inkjet heat chip.

Owner:INT UNITED TECH

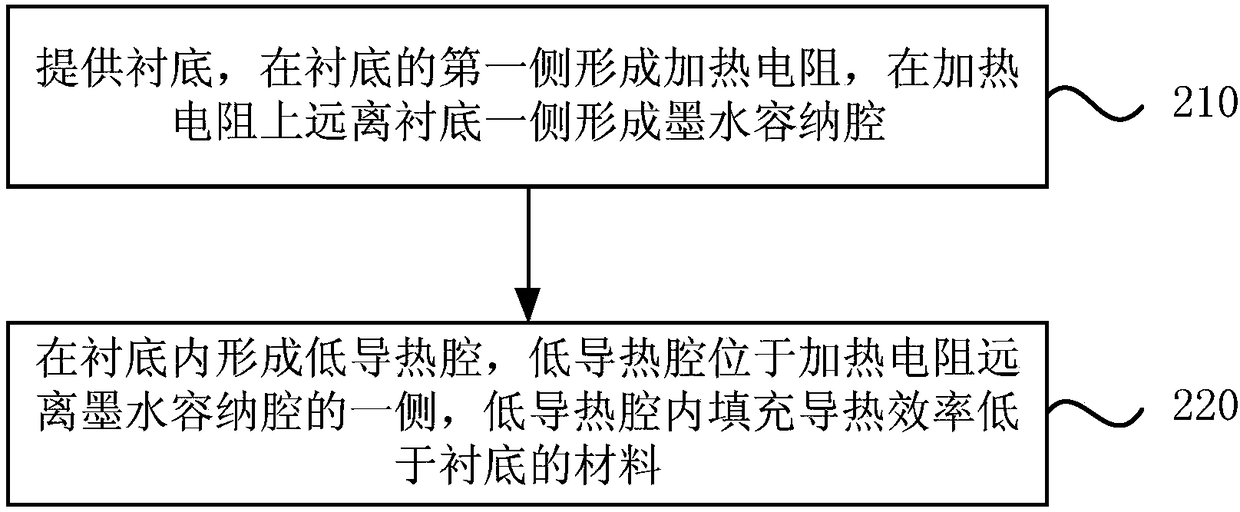

Thermal bubble type ink-jet printing head and manufacturing method thereof

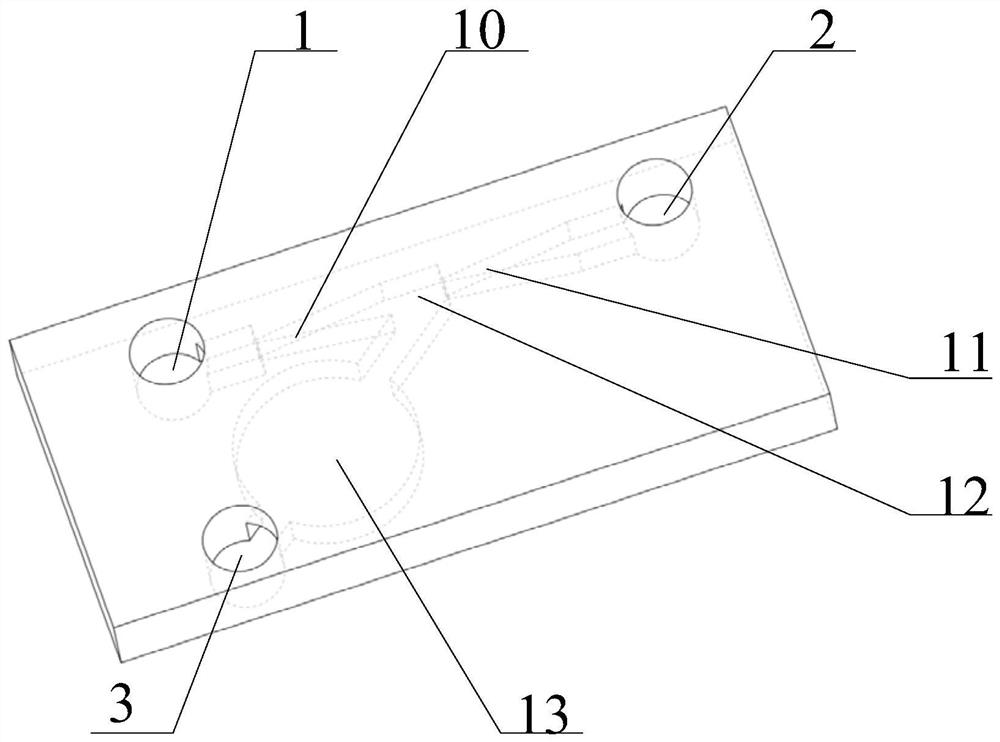

The invention relates to a thermal bubble type ink-jet printing head and a manufacturing method thereof, and is applied to ink-jet printing. The thermal bubble type ink-jet printing head comprises a substrate and a cover plate bonded on the substrate, an ink chamber for storing ink is formed between the substrate and the cover plate in a surrounding manner, an ink supply channel communicating with the ink chamber is formed on the substrate in a penetrating manner, nozzles communicating with the ink chamber are formed on the cover plate in a penetrating manner, the substrate is provided with a heating element for heating the ink in the ink chamber, and the thermal bubble type ink-jet printing head also comprises a driving circuit electrically connected with the heating element and a metal electrode electrically connected with the heating element and the driving circuit.

Owner:苏州工业园区纳米产业技术研究院有限公司

Digital PCR (dPCR) system and dPCR droplet forming method

ActiveCN110819522AReduce consumptionReduce dosageBioreactor/fermenter combinationsHeating or cooling apparatusLiquid layerChemical physics

The invention provides a digital PCR (dPCR) system and a dPCR droplet forming method. The dPCR system comprises at least one droplet forming assembly and a droplet spray hole assembly, wherein each droplet forming assembly comprises at least one droplet collection groove, the droplet spray hole assembly is connected to the lower side of the at least one droplet forming assembly and comprises multiple droplet spray holes, the droplet spray holes communicate with the at last one droplet collection groove, and vaporization components are arranged in the droplet spray holes and used for vaporizingdPCR solution liquid layers in the droplet spray holes and quickly pushing the vaporized liquid layers into droplet forming oil in the at least one droplet collection groove to form dPCR droplets. The dPCR droplet forming method forms dPCR droplets at high speed by a thermal bubble technology, can realize the droplet forming speed larger than 1,000 per second and has the efficient dPCR oil utilization rate.

Owner:SHANGHAI IND U TECH RES INST

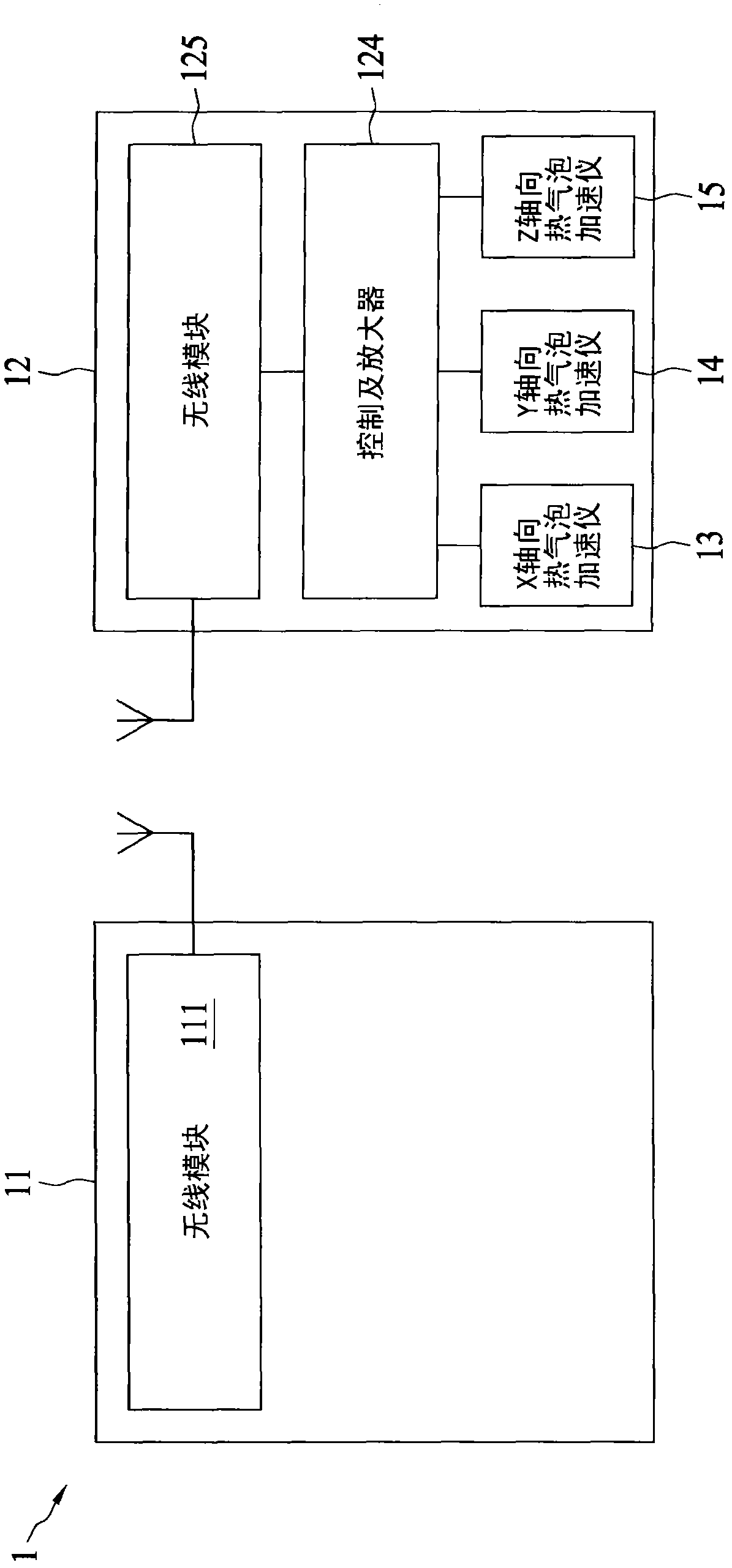

Wireless thermal bubble type accelerometer and preparation method thereof

InactiveCN103185810AAcceleration measurement using interia forcesAcceleration measurement in multiple dimensionsAccelerometerThermal bubble

The invention discloses a wireless thermal bubble type accelerometer and preparation method thereof. The wireless thermal bubble type accelerometer comprises a first insulating substrate, a circuit, a first acceleration sensing device and a first support layer. The circuit is formed on the first insulating substrate. The first acceleration sensing device is coupled with the circuit and comprises two first temperature sensing elements and a first heater between the two first temperature sensing elements. The first support layer is attached to the first insulating substrate and supports the two first temperature sensing elements and the first heater.

Owner:CHUNG HUA UNIVERSITY

Plaster for eliminating tumor

InactiveCN101485691ACured rheumatic tumorSimple recipeHeavy metal active ingredientsUnknown materialsDiseaseOyster

The invention discloses an external tumor-reducing ointment for tumor therapy, which belongs to a pasty patent medicine of external application of traditional Chinese medicines. Ingredients of the external tumor-reducing ointment according to the mixture ratio are characterized by comprising 10 percent of calamine, 10 percent of yellow lead, 30 percent of overburnt oyster shell, 15 percent of water powder, and 45 percent of rice vinegar. Firstly, the ingredients are separated and crushed into 200-mesh fine powder for standby, 10 percent of calamine and 10 percent of yellow lead are placed into an iron pot, then 45 percent of rice vinegar is added and heated, the constant stirring is performed during the heating, then 30 percent of overburnt oyster shell is added into the mixture when being heated until thermal bubble appears in the iron pot, the constant stirring is still performed after 30 percent of overburnt oyster shell is added into the mixture, then 15 percent of water powder is added into the mixture after the stirring for 5 to 10 minutes, and finally the constant heating and stirring are performed to prepare a finished ointment. The finished ointment is placed on gauze or craft paper, then is pasted at an afflicted part, and is replaced once a day, and diseases such as anemogenous sclerosis, blood tumor, nodular varicosity, bone tumor, sarcoma, fatty tumor, hemorrhoid tumor, moles and rotten wound can be cured in a week or so. The external tumor-reducing ointment has the advantages of simple prescription and process, convenient use, and quick therapeutic effect, and is an ideal tumor-reducing product.

Owner:冯武夷

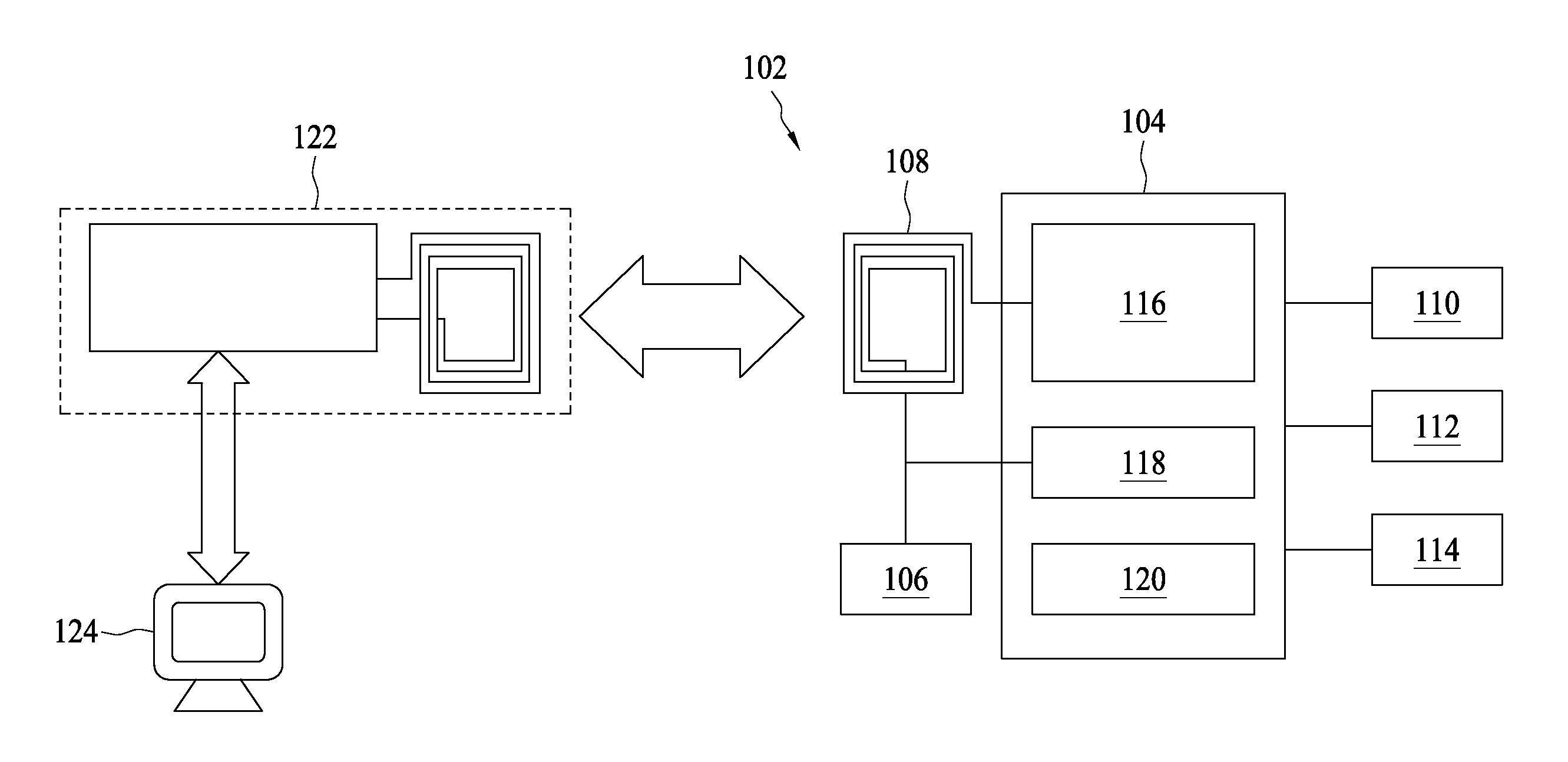

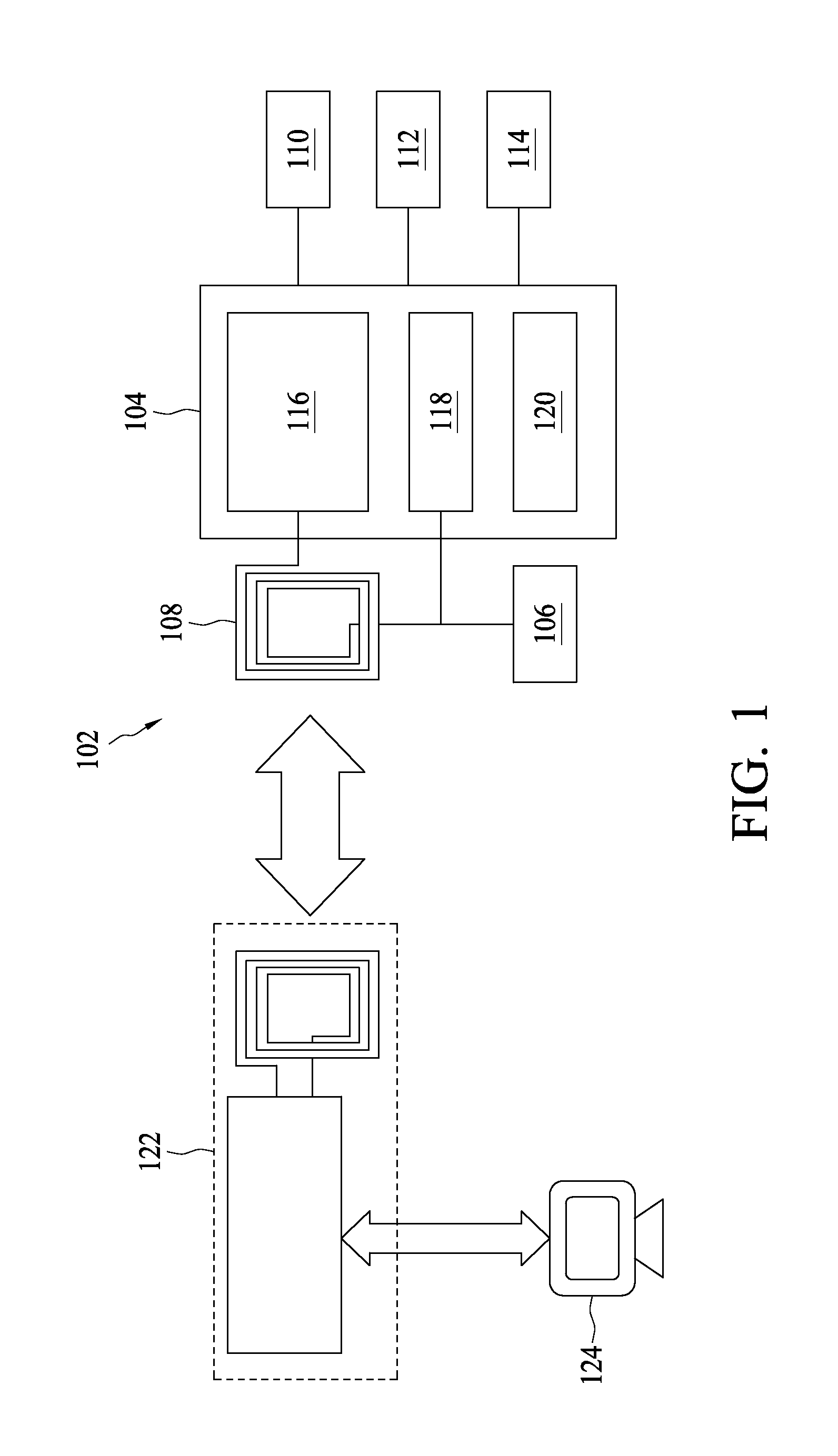

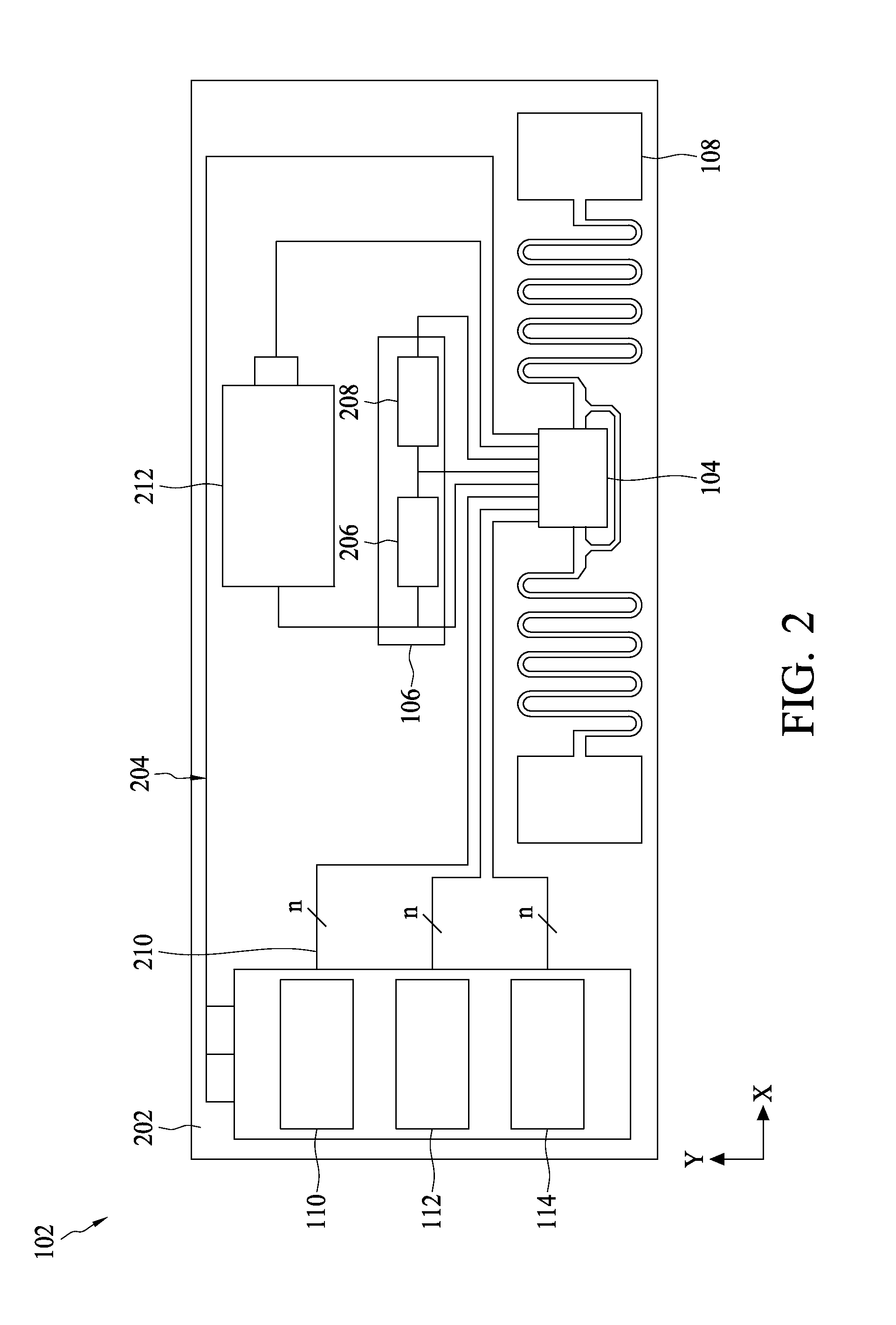

Thermal bubble point measurement system and method

ActiveUS8950246B2Accurate measurementEasy to measureConstructionsWithdrawing sample devicesThermal bubbleBubble point

A method and an apparatus for nucleating bubbles in an oil-gas mixture, including introducing a sample comprising an oil-gas mixture into a chamber; and heating the sample with a heater until at least one bubble is thermally nucleated in the chamber. The bubble point (BP) pressure of the sample can be determined by detecting pressure at two points in a system, which includes the chamber and the heater, and by determining the behavior of the nucleated bubble as the pressure on the bubble is varied.

Owner:SCHLUMBERGER TECH CORP

Digital polymerase chain reaction (PCR) system

PendingCN110628610AIncrease the speed of formationReduce consumptionBioreactor/fermenter combinationsHeating or cooling apparatusThermal bubbleFormation rate

The invention provides a digital polymerase chain reaction (PCR) system. The digital PCR system comprises a droplet formation assembly and a droplet nozzle assembly; the droplet formation assembly comprises a droplet collection tank; the droplet nozzle assembly is connected under the droplet formation assembly, and comprises a plurality of droplet nozzles; the droplet nozzles communicate with thedroplet collection tank; vaporizing components are arranged inside the droplet nozzles so as to be used for vaporizing part of the liquid of a digital PCR solution in the droplet nozzles, as well as quickly pushing the remaining liquid of the digital PCR solution into droplet forming oil in the droplet collection tank so as to form digital PCR droplets. By adopting a thermal bubble technology to form high-speed digital PCR droplets, the digital PCR system is capable of achieving a droplet formation rate of more than 1000 droplets per second; and moreover, the digital PCR system has highly efficient digital PCR oil utilization rate.

Owner:SHANGHAI IND U TECH RES INST

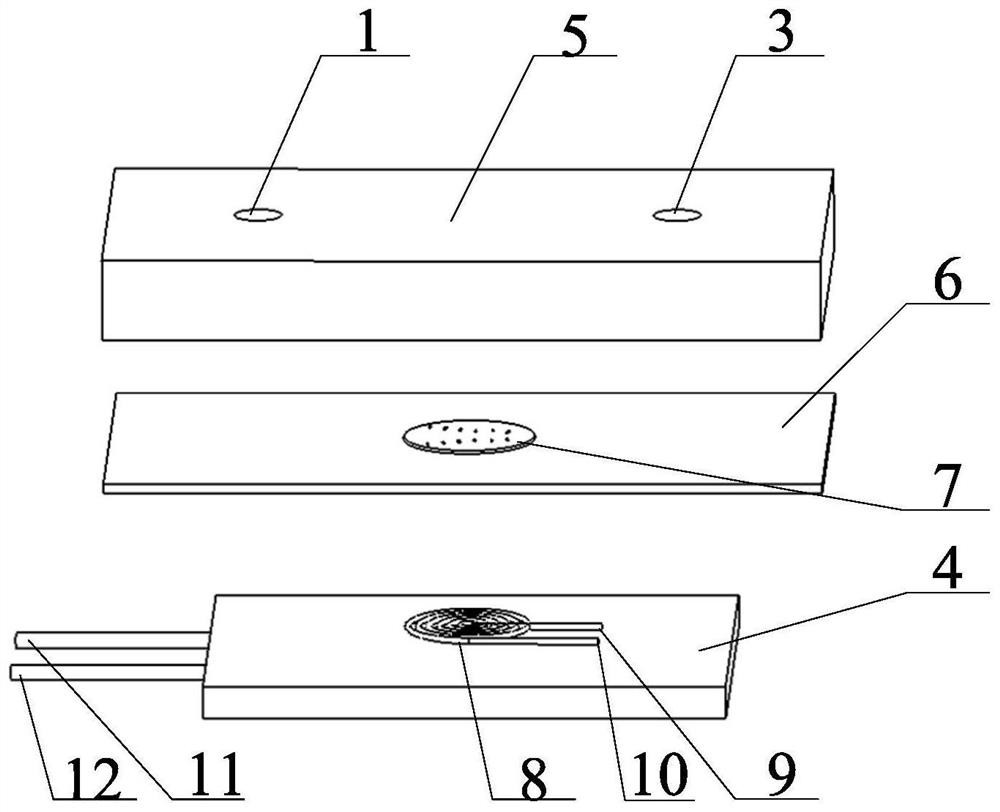

Heat-insulated micropump driven by induction heating thermal bubbles and preparation method thereof

ActiveCN113175423BReduce the impactReduce the temperatureCoil arrangementsPumpsThermal insulationThermal bubble

Heat-insulated micropump driven by induction heating and preparation method Thermal bubble drive for microfluid delivery, specifically a heat-bubble-driven micropump with heat source isolation function, using high-frequency alternating current wireless induction heating to generate heat bubbles , to drive the micropump. The liquid is used to isolate the heat source from the pumped liquid in the microchannel, reducing the influence of high temperature on the properties of the solution. This heat-insulated hot-bubble-driven micropump not only has the advantages of simple and easy-to-integrate structure, low working voltage, and long service life of ordinary hot-bubble micropumps, but also can reduce the temperature of the pumped liquid and reduce the impact of high temperature on some organisms in the solution. Or the damage of chemical substances, so the heat-bubble-driven heat-insulated micropump has a better application prospect.

Owner:BEIJING UNIV OF TECH

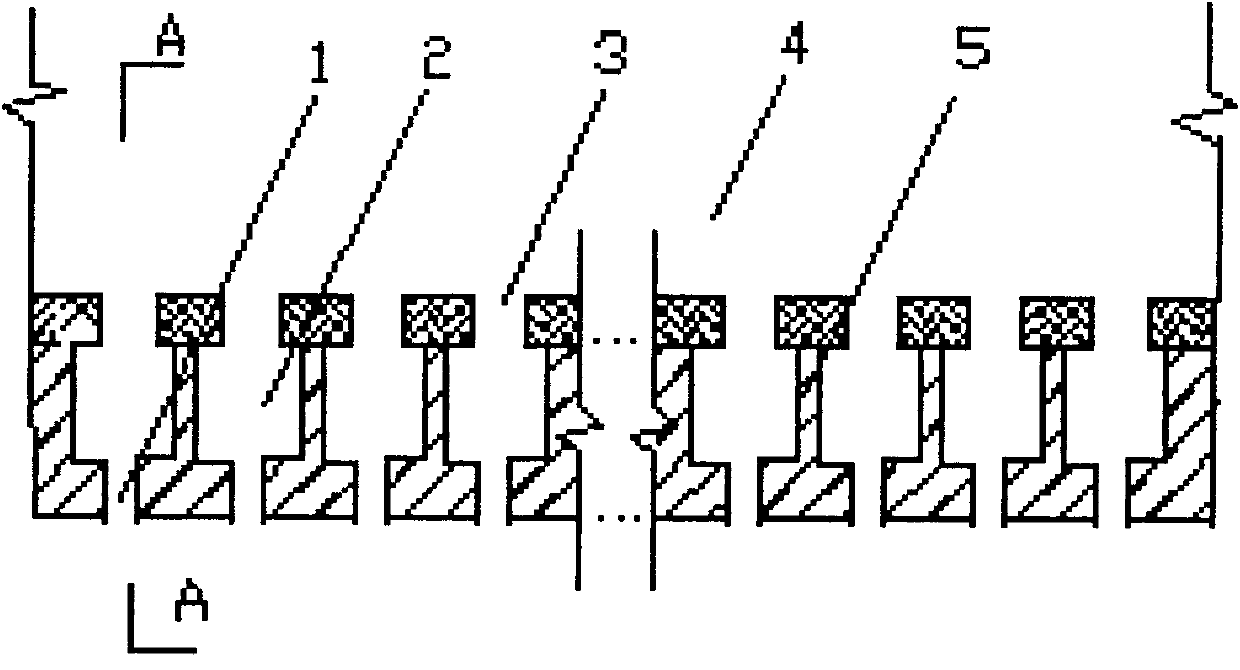

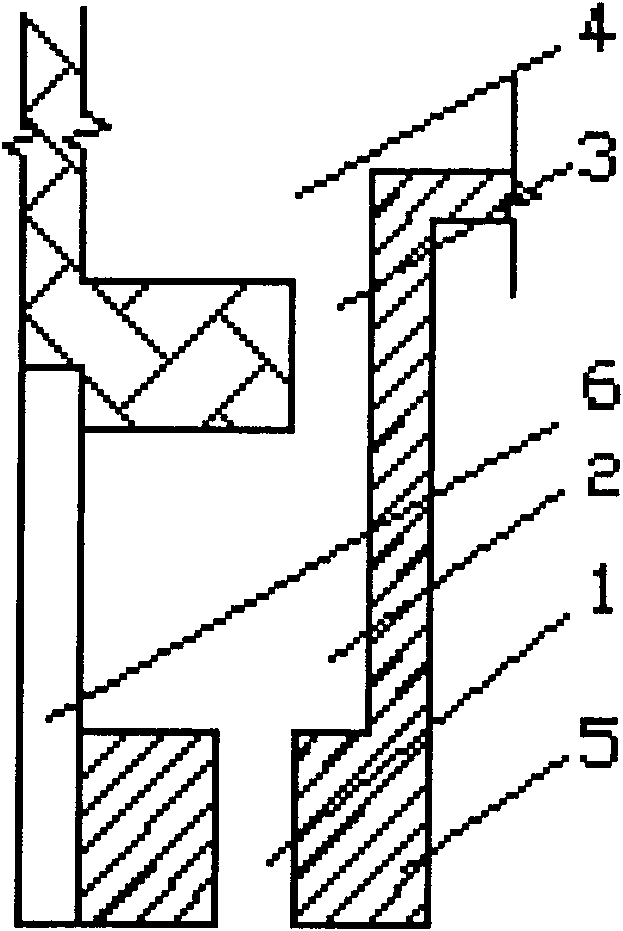

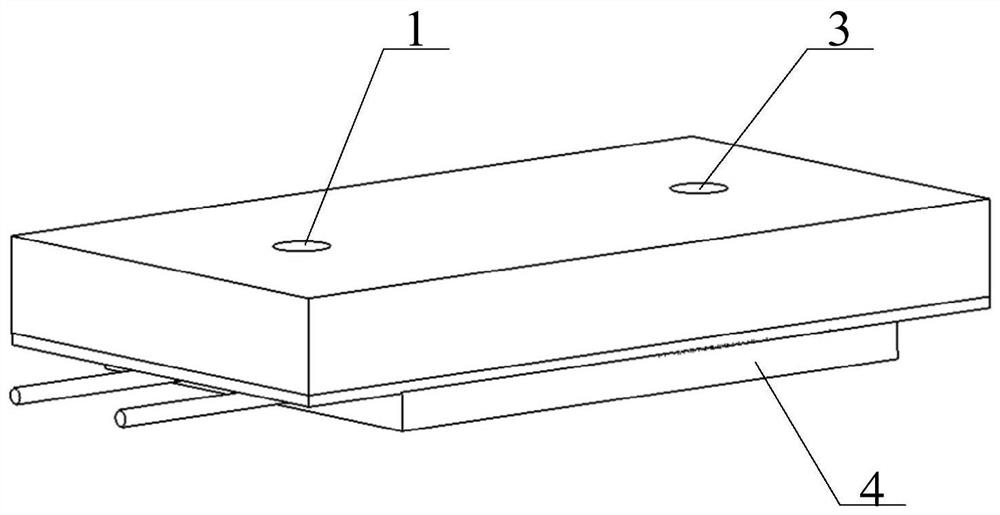

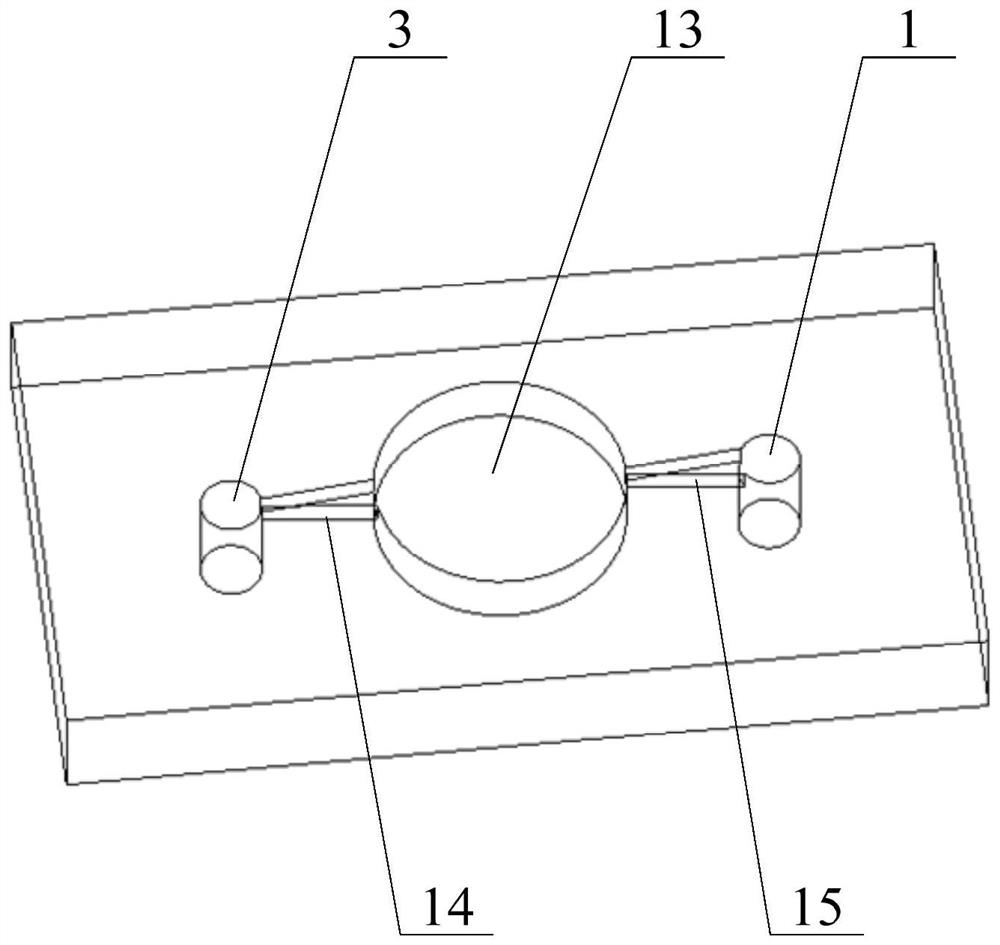

A thermal bubble-driven micropump for fixed-point growth of bubbles and its preparation method

ActiveCN111472956BAvoid cloggingSpeed up cooling shrinkageFluid heatersCoil arrangementsMicrofluidicsThermal bubble

A thermal bubble-driven micropump and a preparation method for fixed-point growth of bubbles belong to the field of microfluidic technology. The present invention is a heat-bubble-driven micro-pump used for micro-fluid delivery, specifically a heat-bubble-driven micropump using high-frequency current wireless induction heating manufactured by MEMS micromachining technology. Heating plate, the micro-heating plate is designed with recesses arranged in a certain regular shape, so that the recesses can adjust the growth position of the hot bubbles, by controlling the periodic expansion and contraction of the hot bubbles, combined with the different resistances of the micro-channels on both sides of the pump chamber , and finally the micropump achieves directional pumping. In order to improve the reliability and operating frequency of the micropump, a cooling device is added to the micropump to enhance the heat dissipation capability of the micropump in the shrinking stage of the thermal bubble. The micropump proposed by the invention can be widely used in the fields of aerospace, biomedicine, chemistry and the like.

Owner:BEIJING UNIV OF TECH

Lacquer for paper base lacquer painting and preparation method thereof

PendingCN109627825AGood flexibilityReduce harmDrying oil coatingsArtist's paintsUltrasonic cavitationLacquer

The invention discloses lacquer for paper base lacquer painting and a preparation method thereof, and belongs to the technical field of lacquer painting. Natural lacquer and boiled pure tung oil are adopted as raw materials, by coordinating the ratio of the lacquer and the tung oil, on the basis of ultrasonic treatment mixing, the ultrasonic mechanical action is used for performing mechanical shearing on tung oil, the fusion degree and the fineness of the tung oil and the natural lacquer are improved, soaking on a paper base is facilitated, due to the ultrasonic cavitation effect, cavitation thermal bubbles are formed in the tung oil and natural lacquer mixing solution, the reaction of the tung oil and the natural lacquer is facilitated, the reaction efficiency is improved, the preparationtechnology is simple, lacquer applicable to paper base lacquer painting creation is prepared, development of the paper base lacquer painting is facilitated, and meanwhile the new research direction is put forward for follow-up lacquer painting research.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com