Wireless thermal bubble type accelerometer and preparation method thereof

A thermal bubble, accelerometer technology, applied in multi-dimensional acceleration measurement, acceleration measurement using inertial force, etc., can solve problems affecting performance and life, consumption, large energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

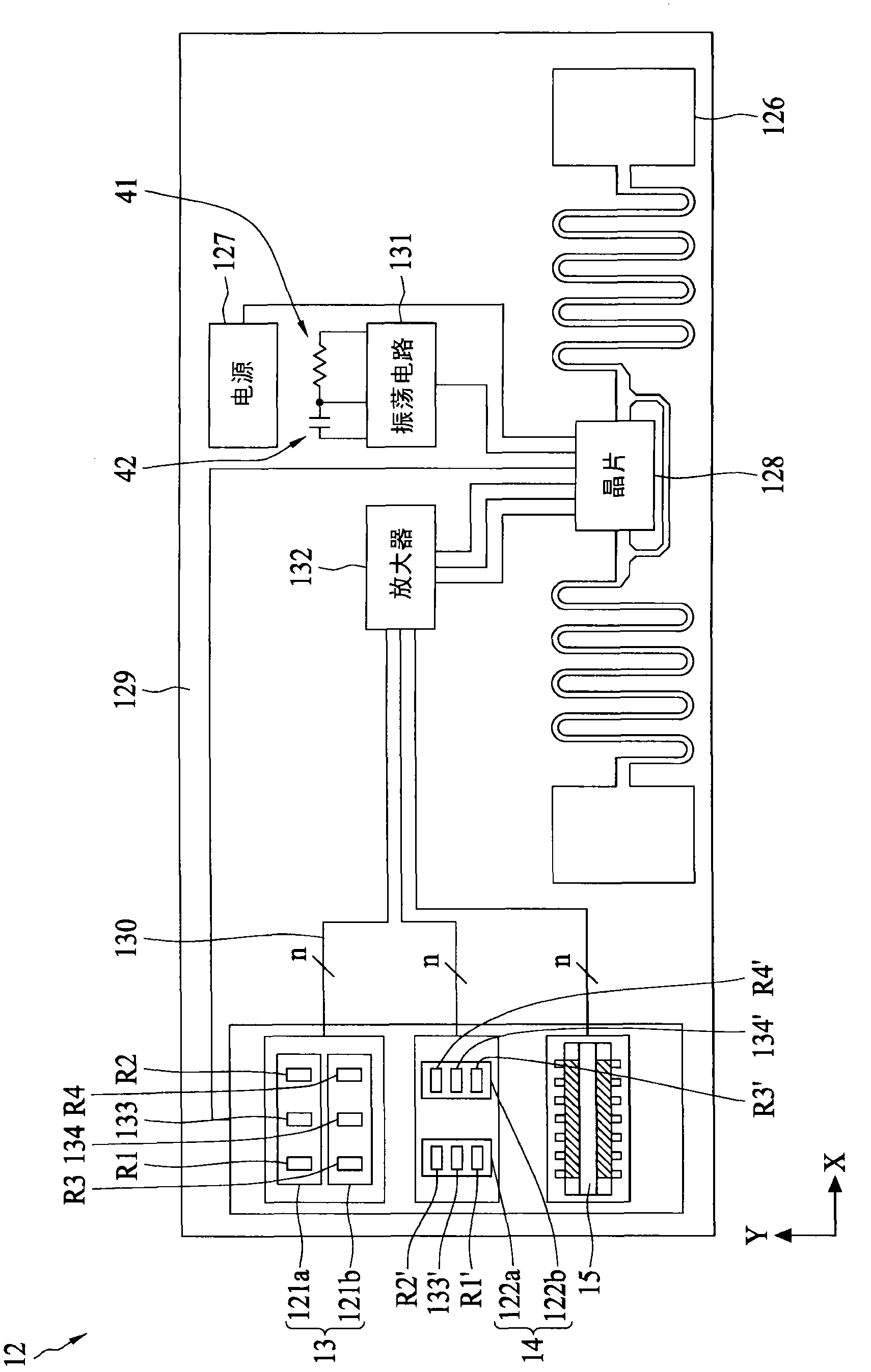

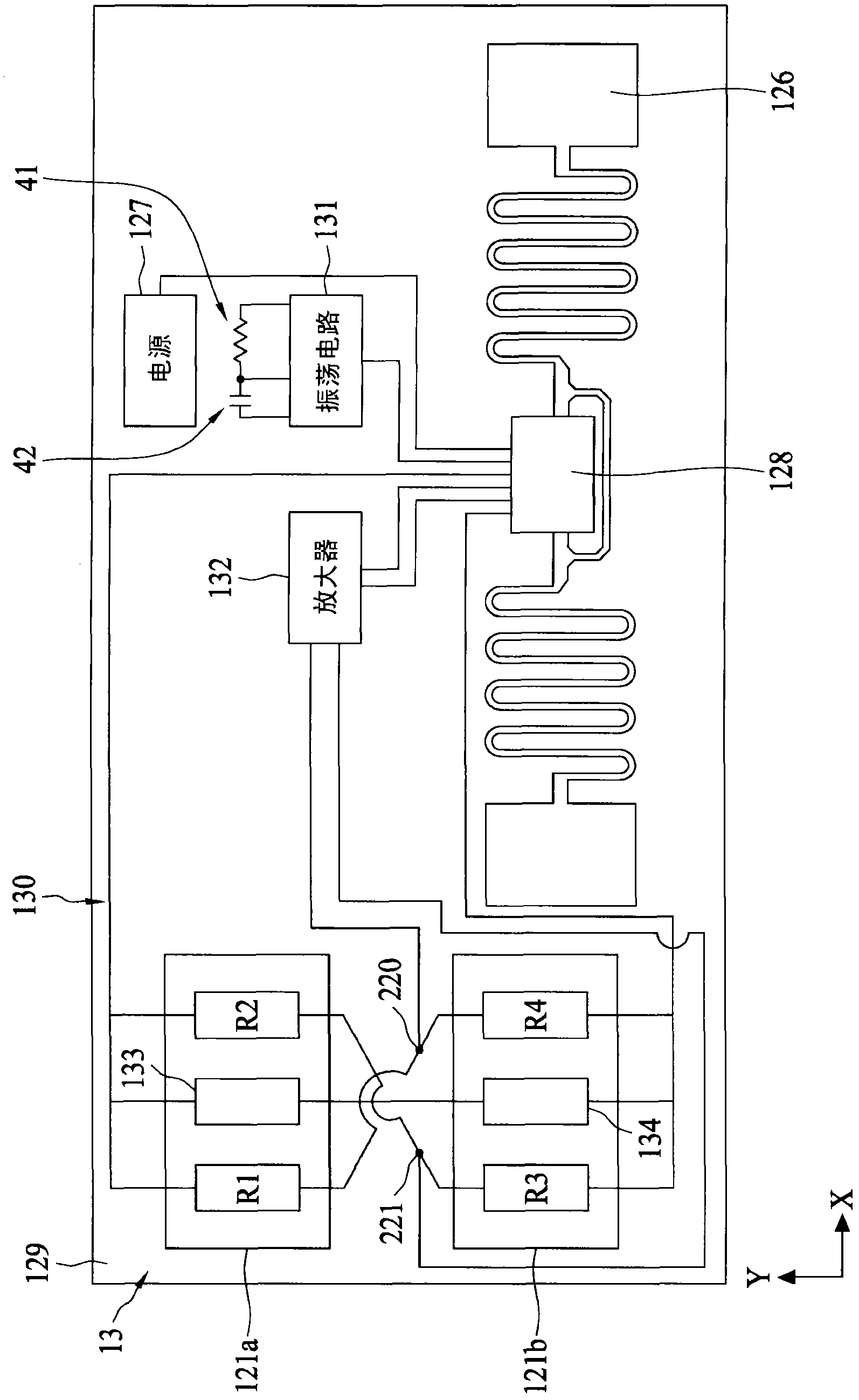

[0105] On the one hand, the heater and temperature sensing element of the thermal bubble accelerometer disclosed in the present invention are directly attached to the supporting heat-insulating substrate layer instead of being suspended on the groove, so the thermal bubble accelerometer disclosed in the present invention The accelerometer has the advantages of easy fabrication, high yield, more durability, and low manufacturing cost.

[0106] In one aspect, the present invention discloses a method for measuring a thermal bubble accelerometer signal in the vertical axis (Z-axis) using a socket connector to connect the signal to signal processing and wireless circuitry. This connection design is easy to manufacture, install and low cost.

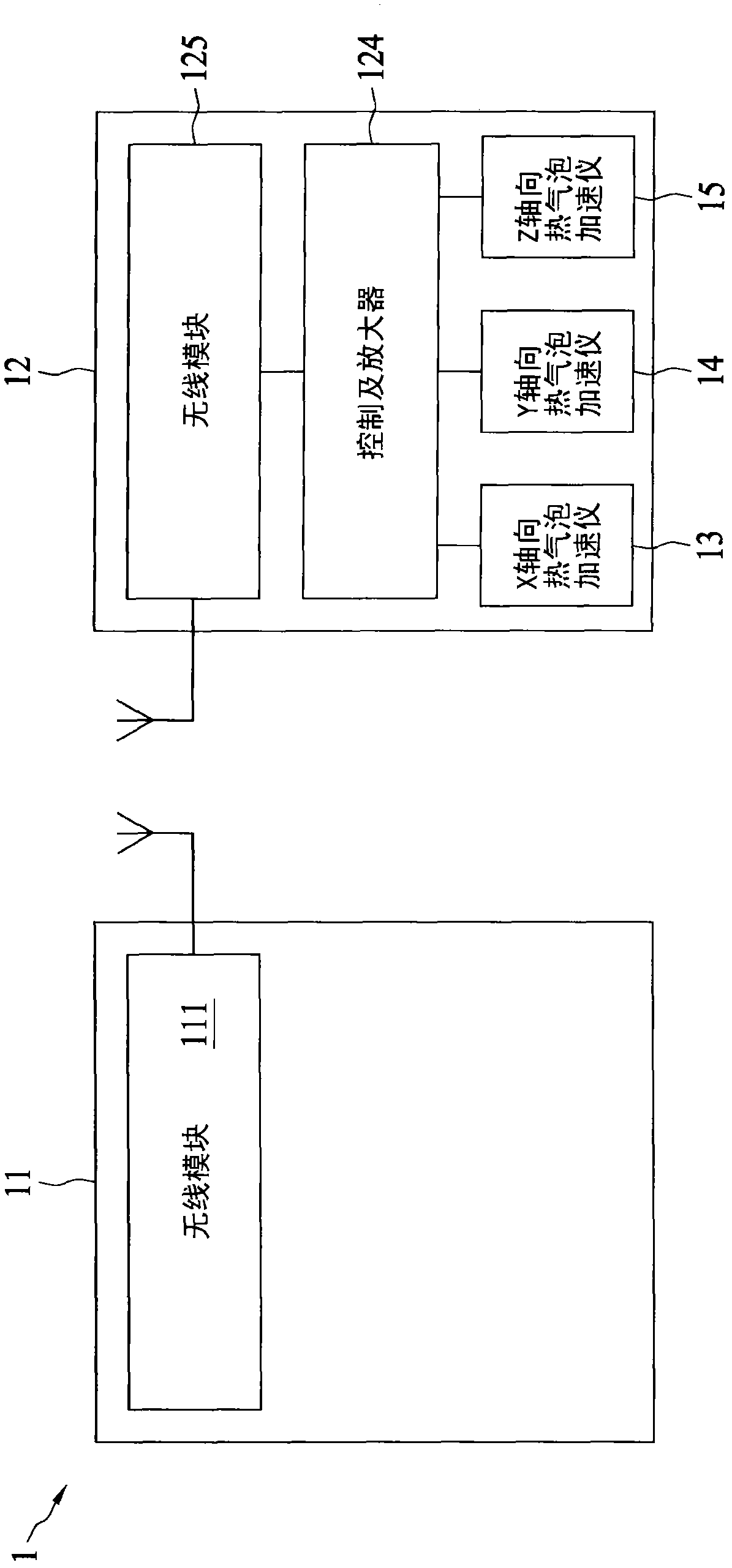

[0107] figure 1 A schematic diagram showing a multi-axial acceleration wireless measurement system 1 according to an embodiment of the present invention is shown. refer to figure 1 As shown, the multi-axial acceleration wireless measuring s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com