Low voltage and low power thermal bubble film type microfluid driving device

A technology of driving device and hot bubble, which is applied in measurement devices, electrochemical variables of materials, determination/inspection of microorganisms, etc., can solve the problems of loss of mobility, difficulty in integration, and inability to effectively control the direction of fluid flow, and achieve high speed. , the effect of reducing the power consumption of voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

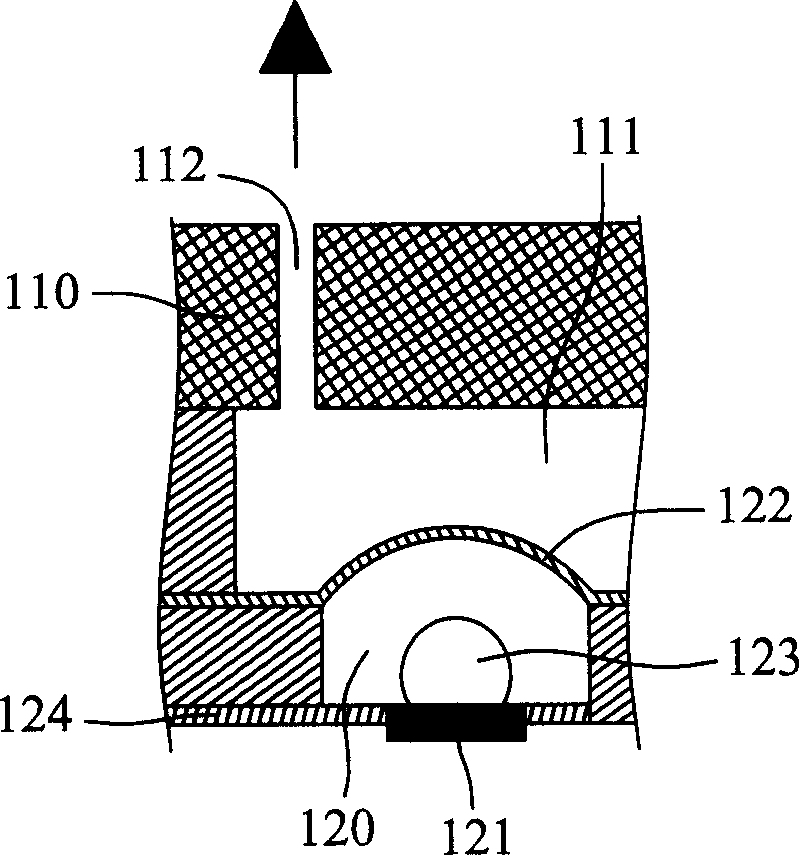

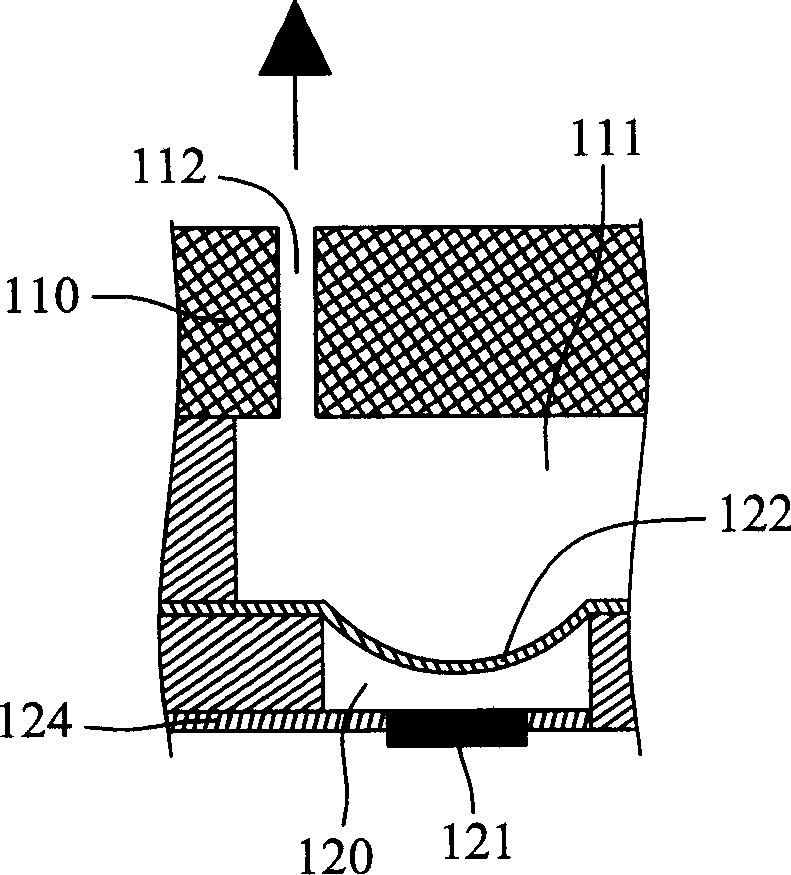

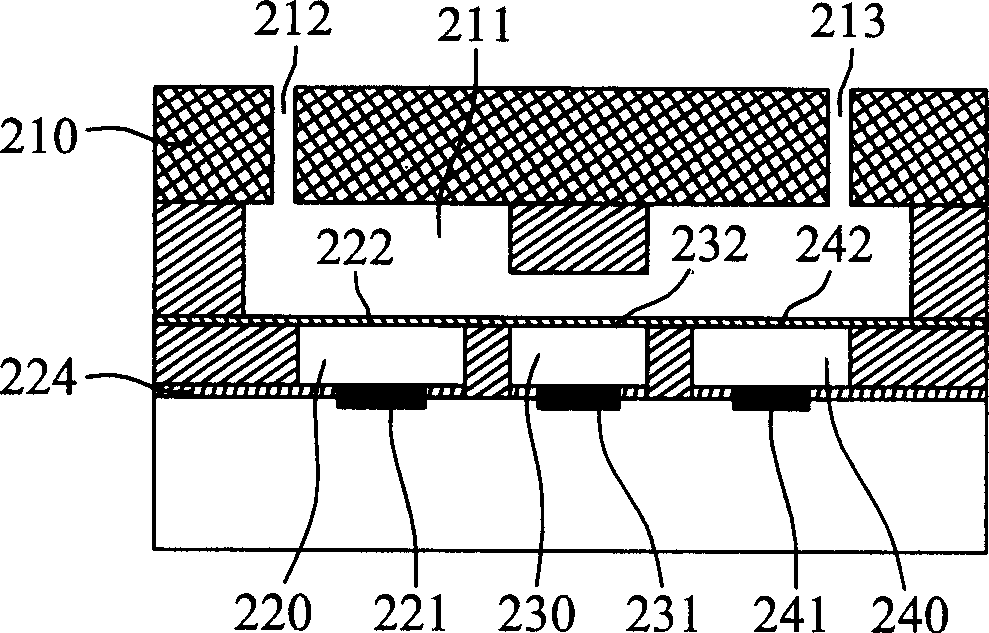

[0027] Please refer to figure 1 with figure 2 , is a schematic diagram of the operation of the first embodiment of the present invention, its fluid structure 110 includes a fluid channel 111 for fluid passage and a fluid inlet and outlet 112 for fluid in and out; adjacent to its fluid channel 111 is provided with a hot air bubble film actuator, is It is composed of a heating sheet 121 arranged at the bottom of a sealed liquid chamber 120, and an elastic film 122 separating the fluid channel at the top of the sealed liquid chamber 120. Then make the heating plate 121 provide enough energy to make the liquid in the liquid chamber 120 reach a specific temperature to generate the bubble 123 through the electrode 124, and simultaneously, as figure 1 As shown, since the bubble 123 rises and pushes the elastic membrane 122 to expand the liquid chamber 120, while the volume of the fluid channel 111 is compressed to push the liquid outward; and, as figure 2 As shown, after the bubb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com