Diaphragm structure and leak valve

A technology of diaphragm structure and air leakage valve, which is applied in the direction of valve device, engine components, mechanical equipment, etc., can solve the problems of poor flow capacity and poor reverse cut-off ability of air leakage valve, and achieve strong flow capacity and reverse Strong cut-off ability and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

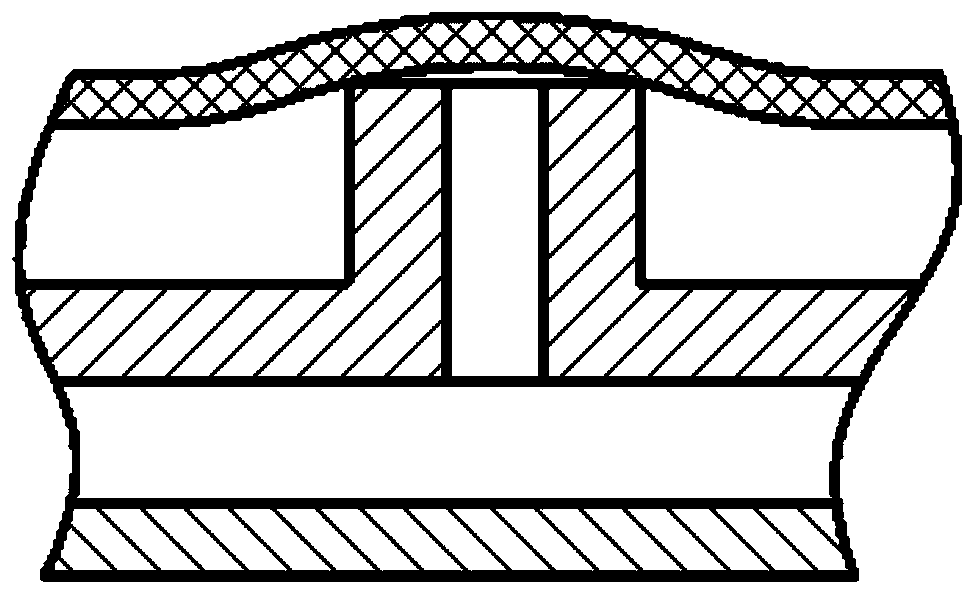

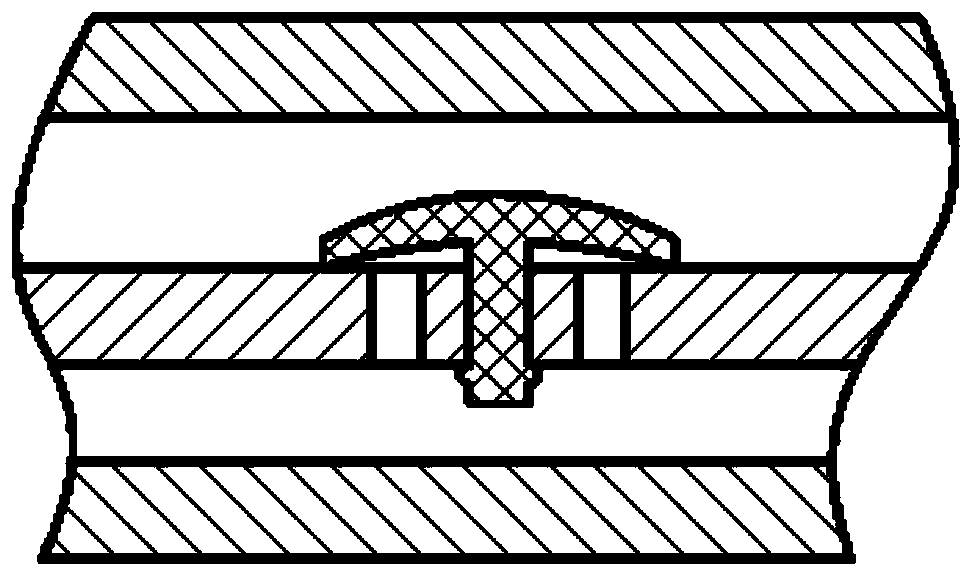

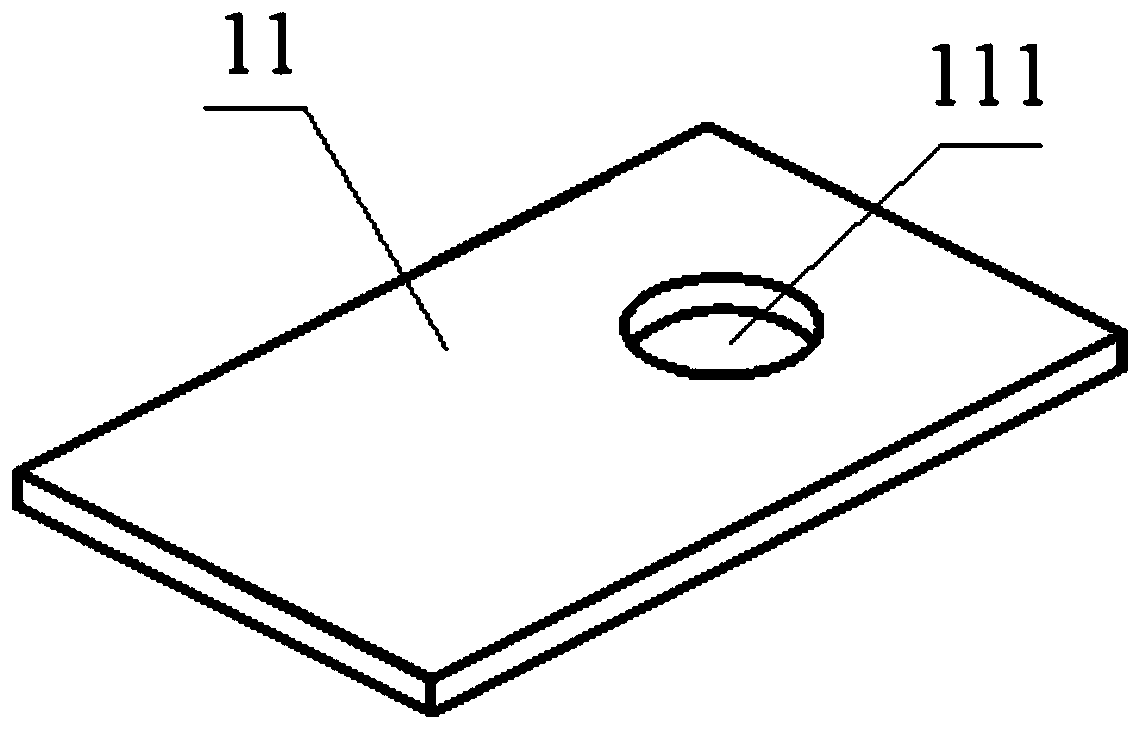

[0036] Such as Figure 3-10 As shown, the present embodiment provides a diaphragm structure 1 , including a diaphragm body 11 on which a cantilever beam valve plate 12 is arranged. Specifically, the diaphragm body 11 is provided with an installation hole 111 , and the cantilever beam valve plate 12 is disposed in the installation hole 111 . Preferably, the diaphragm body 11 can produce a certain elastic deformation, and the installation hole 111 is a round hole.

[0037] The cantilever beam valve plate 12 includes a valve plate body 121 and a cantilever 122 , there are at least two cantilevers 122 , and the valve plate body 121 is arranged in the installation hole 111 through the cantilever 122 . Specifically, the valve body 121 can be circular, square, triangular, polygonal, etc., as long as it can cover the third air hole 31. At least two cantilevers 122 are evenly distributed along the edge of the valve body 121, and one end of the cantilever 122 is connected to the valve ...

Embodiment 2

[0048] Such as Figure 11 As shown, the leakage valve in this embodiment is basically the same in structure as the leakage valve in Embodiment 1, the only difference is that the second air hole 22 is not in contact with the diaphragm structure 1 , and there is a gap between them. Through the above setting, in the initial state, the second air hole 22 communicates with the first cavity 4; when inhaling air, a large pressure difference is required to cause the diaphragm body 11 of the diaphragm structure 1 to elastically deform and then close the second air hole 22, but in During the air outlet process, the second air hole 22 is easy to open.

Embodiment 3

[0050] Such as Figure 12 As shown, the leakage valve in this embodiment is basically the same structure as the leakage valve in Embodiment 1, the only difference is that the diaphragm structure 1 is set separately, and the diaphragm structure 1 includes a left diaphragm 13 and a right diaphragm 14, and the left diaphragm 13 is located between the second air hole 22 and the fourth air hole 32, separating the first cavity 4 and the second cavity 5; the right diaphragm 14 is provided with a mounting hole 111, and a cantilever beam valve plate 12 is installed on the mounting hole 111, and the right The diaphragm 14 is located between the first cavity 4 and the third air hole 31 , and the connection between the third air hole 31 and the first cavity 4 is controlled by the cantilever valve plate 12 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com