Water temperature cooling circulating system in bearing part quenching water tank

A circulating system and water tank technology, applied in quenching devices, irreversible circulating compressors, refrigerators, etc., can solve the problems of unsatisfactory cooling effect, large volume of cooling equipment, and large floor space, so as to reduce waste and reduce cooling costs. Good effect, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

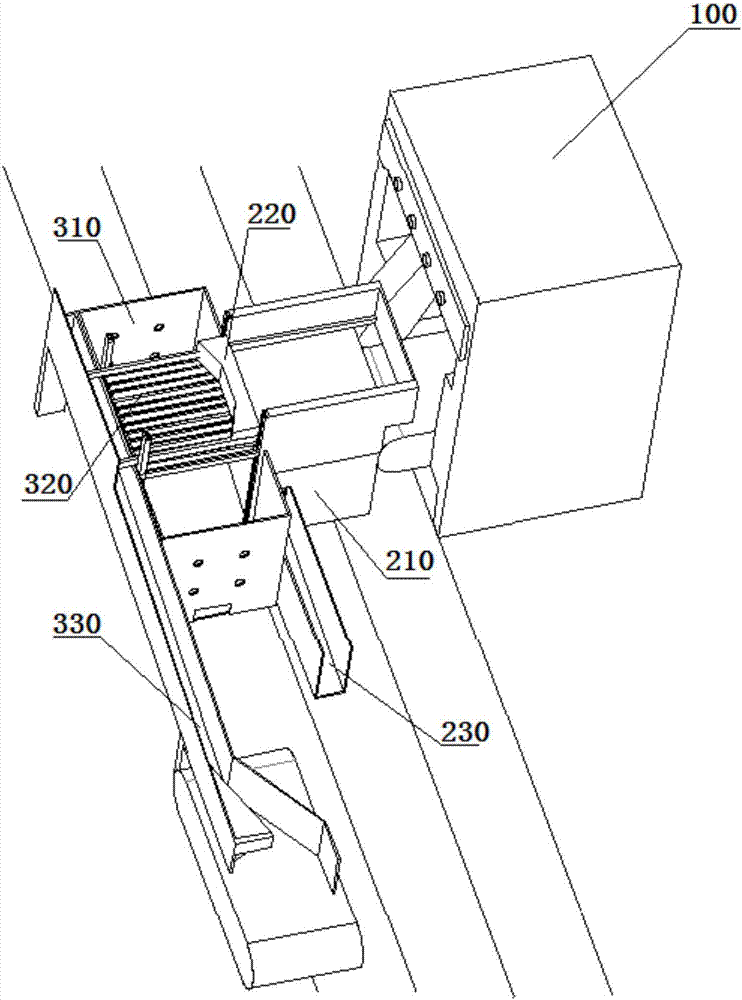

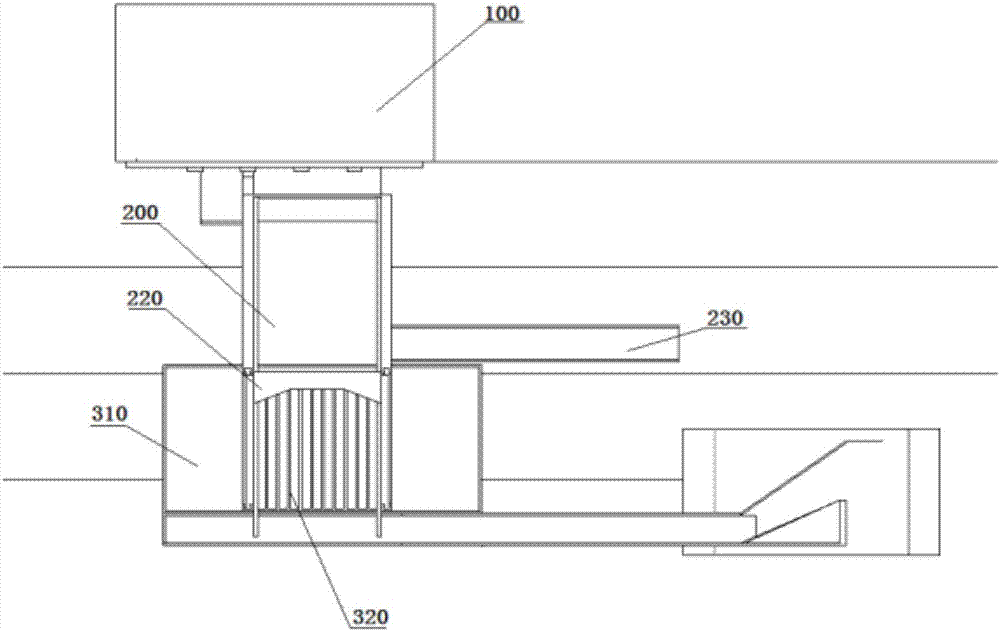

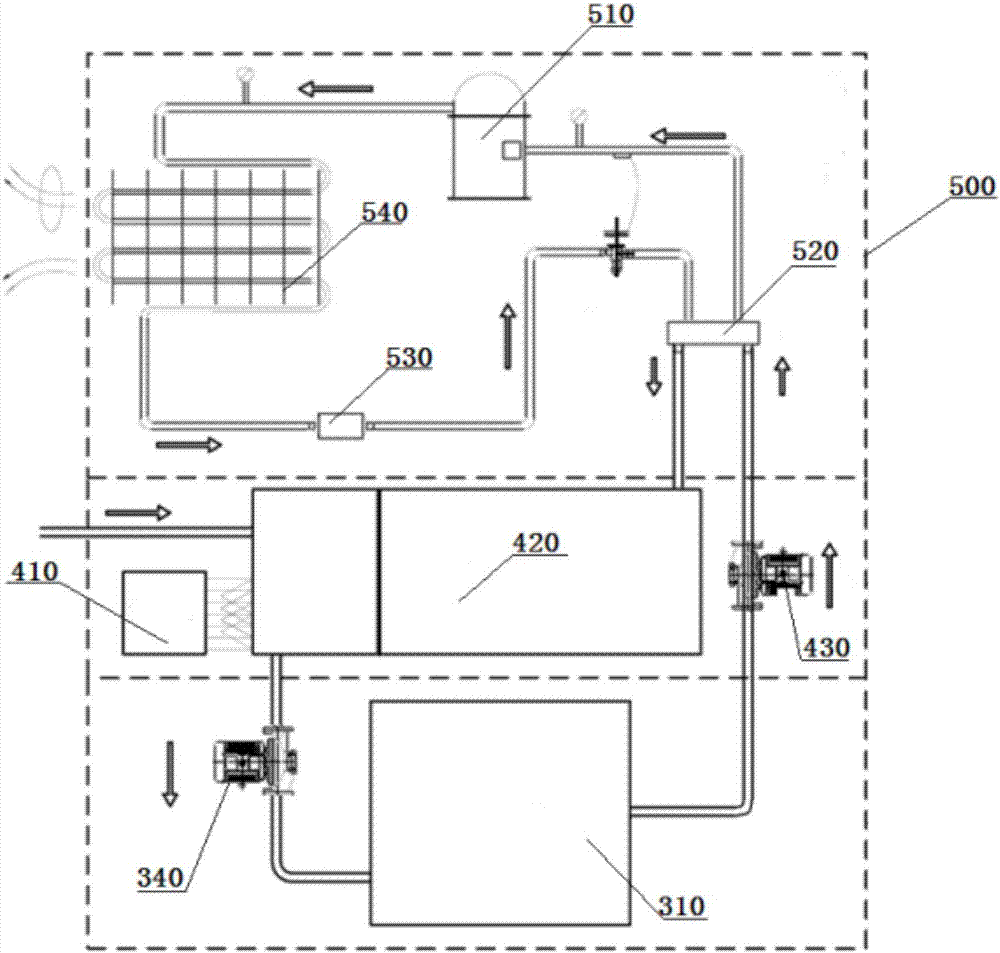

[0033] Such as figure 1 As shown, the present invention provides a water temperature cooling circulation system in a quenching water tank for bearing parts, including: a bearing processing device 100 , a bearing screening device 200 , a thinning water tank 310 , a constant temperature water tank 420 , and a cooling system 500 .

[0034] The bearing screening device 200 is provided with a pallet 210 that can be raised and lowered and folded downward; the processing outlet of the bearing processing device 100 is connected to one side of the bearing screening device 200, and the processed bearings can be transported to On the bearing screening device 200 , the supporting plate 210 of the bearing screening device 200 lifts the bearing to the height of the thinning tray 320 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com