Method and device for preparing high alloy materials by solid and liquid mixing and continuous extrusion

A technology for solid-liquid mixing and alloying materials, which is applied in the field of solid-liquid mixing continuous extrusion to prepare high-alloy materials, can solve the problems of low yield, low density, and reduce the number and size of equilibrium precipitation phases, so as to improve the density and yield, reduce intermediate steps, increase the effect of nucleation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

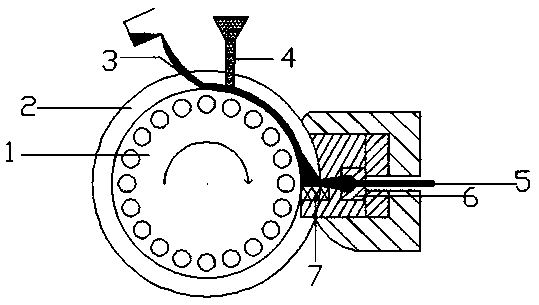

[0027] A device for preparing high-alloy materials by solid-liquid mixing and continuous extrusion, such as figure 1 As shown, it includes extrusion wheel 1, extrusion wheel groove 2, deflector 3, feeding device 4, mold 6, plug 7; said extrusion wheel 1 is provided with extrusion wheel groove 2, deflector 3 Located above the extrusion wheel groove 2, inserted into the extrusion wheel groove 2 at an angle of 40°, the feeding device 4 is set above the wheel groove and inserted vertically into the extrusion wheel groove 2 and located on the side of the deflector 3, extrusion The wheel groove 2 is provided with a plug 7, the plug 7 is tangent to the extrusion wheel groove 2, the line formed by the upper surface of the plug 7 and the center of the extrusion wheel 1 and the insertion point of the deflector 3 are in line with the center of the extrusion wheel 1 The straight line that forms is vertical, and plug 7 is connected with mold 6, and mold 6 is an extrusion die, and the upper...

Embodiment 2

[0035] A device for preparing high-alloy materials by solid-liquid mixing and continuous extrusion. The difference from Example 1 is that the inclination angle of the guide plate 3 inserted into the extrusion wheel groove 2 is 70°, and other components are the same as the device in Example 1. .

[0036] The method for preparing Al-20Si-2Fe by solid-liquid mixing and continuous extrusion using the device of this embodiment, the specific steps are as follows:

[0037] (1) Ingredients: mix and mix the raw materials according to the mass percentage of 78% Al, 2% Fe and 20% Si;

[0038] (2) Melting: put the aluminum-iron-silicon mixed powder prepared in step (1) into the crucible, put the crucible into the metal melting furnace, and set the temperature to 1500°C for melting;

[0039](3) Forming: Slowly pour the molten metal obtained in step (2) into the extrusion wheel groove 2 on the extrusion wheel 1 along the guide plate 3, start the motor, and drive the extrusion wheel 1 to ro...

Embodiment 3

[0043] A device for preparing high-alloy materials by solid-liquid mixing and continuous extrusion. The difference from Example 1 is that the deflector 3 is inserted into the extrusion wheel groove 2 with an inclination angle of 60°, and other components are the same as the device in Example 1. .

[0044] The method for preparing Al-5Cu by solid-liquid mixing and continuous extrusion using the device of this embodiment, the specific steps are as follows:

[0045] (1) Ingredients: Mix and mix the raw materials according to the mass percentage of 95% Al and 5% Cu;

[0046] (2) Melting: Put the aluminum-copper mixed powder prepared in step (1) into the crucible, put the crucible into the metal melting furnace, and set the temperature to 1100°C for melting;

[0047] (3) Forming: Slowly pour the molten metal obtained in step (2) into the extrusion wheel groove 2 on the extrusion wheel 1 along the guide plate 3, start the motor, and drive the extrusion wheel 1 to rotate, and the ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com