Thermal bubble spinning method and device for nano-fiber production

A nanofiber and electrospinning technology, which is applied in the field of air bubble electrospinning and devices used to produce nanofibers, can solve the problems of complex spinning mechanism and difficult production control, and achieve the effect of simple spinning mechanism and easy production control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

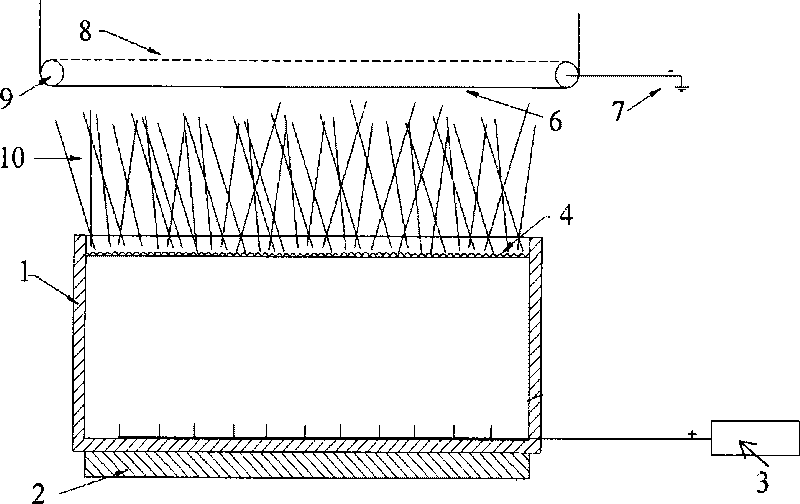

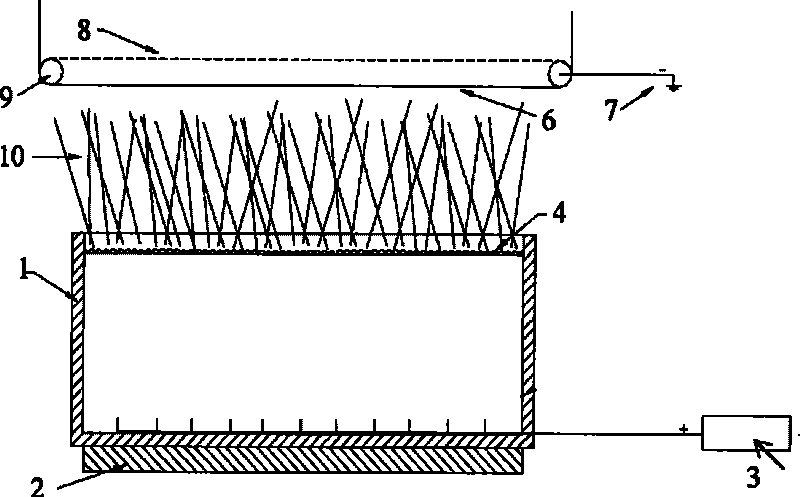

[0020] refer to figure 1 , is the structural schematic diagram of Embodiment 1 and 2 of the present invention. The described hot-bubble electrospinning device that can be used to produce nanofibers includes a liquid storage pool 1 with an open top, and a high-voltage electrostatic generator 3 connects the liquid storage tank with a metal electrode. The solution or solution 4 in the pool 1 is connected, the receiving plate 8 is grounded through the grounding electrode 7, the guide roller 9 and the receiving curtain 6 which can rotate synchronously are arranged above the liquid storage pool 1, and the receiving plate is arranged above the receiving curtain 6 8. A heating device 2 is installed at the bottom of the reservoir 1 .

[0021] First, the mass percentage is respectively 35% polyvinylpyrrolidone and 65% industrial absolute alcohol and stirs for 2.5 hours, then it is poured into the reservoir 1; open the heating device 2, and the temperature of the polyvinylpyrrolidone so...

Embodiment 2

[0023] refer to figure 1 , is the structure diagram of Embodiment 1 and 2 of the present invention, wherein the polyvinyl alcohol solution is composed of 6% polyvinyl alcohol and 94% industrial pure water in mass percentage, the stirring time is 12 hours, the temperature is 100 ° C, and the high pressure is adjusted Electrostatic generator 3 to 15 kV. Using exactly the same process steps as in Example 1, nanofibers were obtained.

Embodiment 3

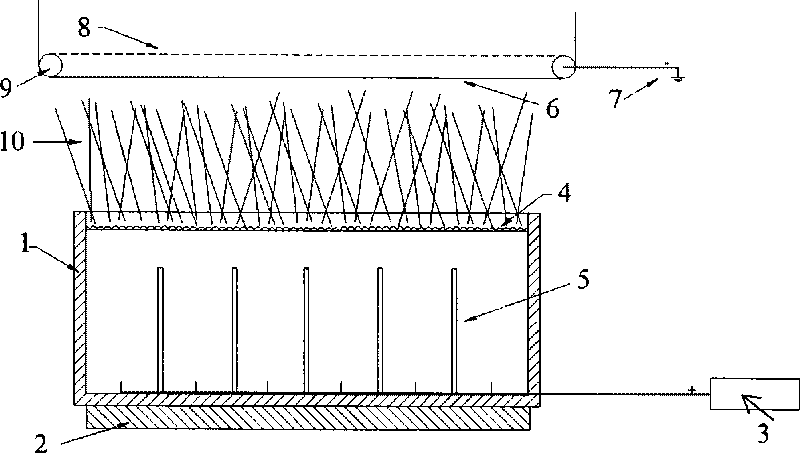

[0025] refer to figure 2 , is a schematic diagram of the structures of Embodiments 3 and 4 of the present invention. The above-mentioned hot air bubble electrospinning device that can be used to produce nanofibers is composed of the gas guide rod 5 and all the components in the structure of Embodiment 1. Except for the gas guiding rod 5, the structure of embodiment 2 is completely the same as that of embodiment 1. The bottom surface of the liquid storage tank 1 is provided with a gas guiding rod 5, the purpose of which is to concentrate the gas in the solution or solution and prevent the adhesion of several liquid bubbles.

[0026] Using exactly the same process steps as in Example 1, wherein the polyacrylonitrile solution is composed of 13% polyacrylonitrile and 87% N-dimethylformamide in mass percentage, the stirring time is 48 hours, and the temperature is 150°C , adjust the high-voltage electrostatic generator from 3 to 50 kV. Using exactly the same process steps as in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com