Combined strengthening method of alloy structural hole

A technology of structural holes and alloys, applied in the field of material surface strengthening, can solve the problems of fracture, stress concentration, and high alloy notch sensitivity, and achieve the effects of small damage, improved fatigue life, and uniform expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

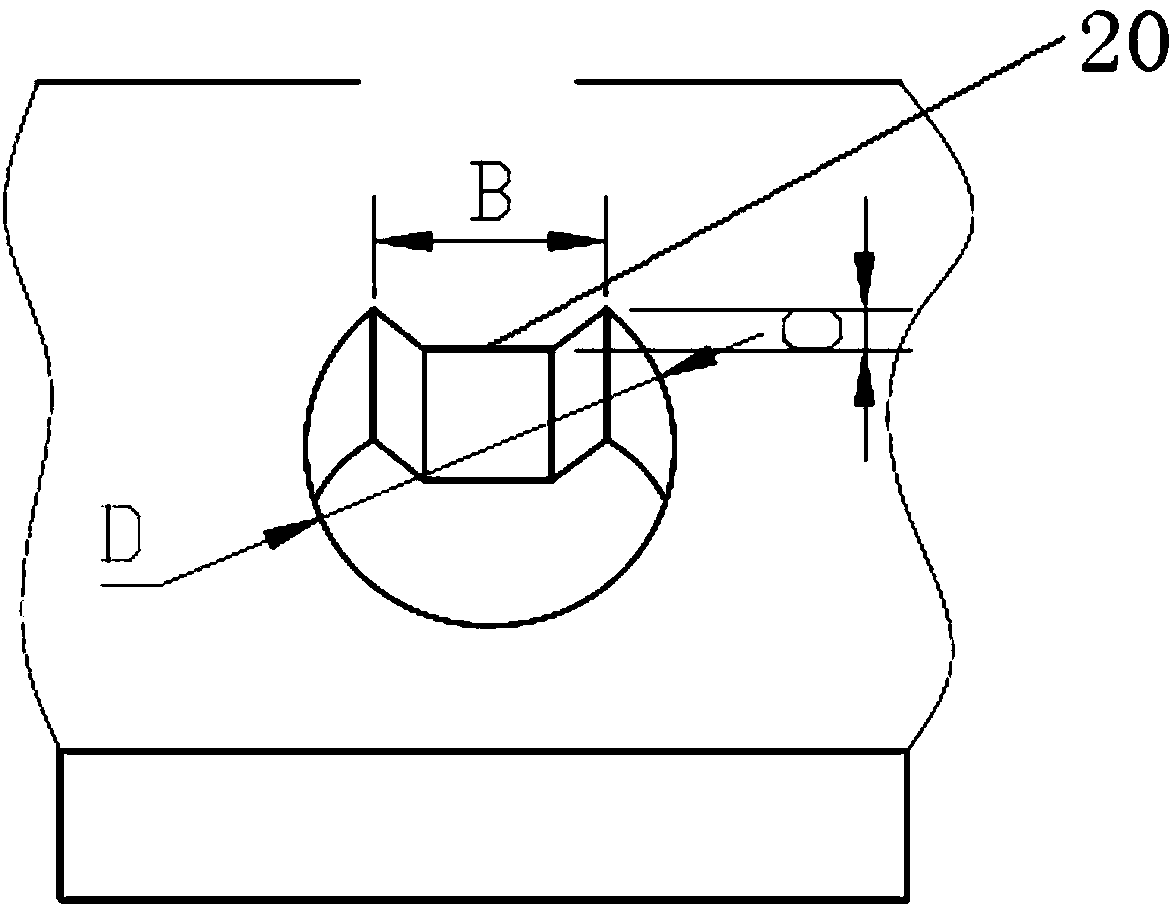

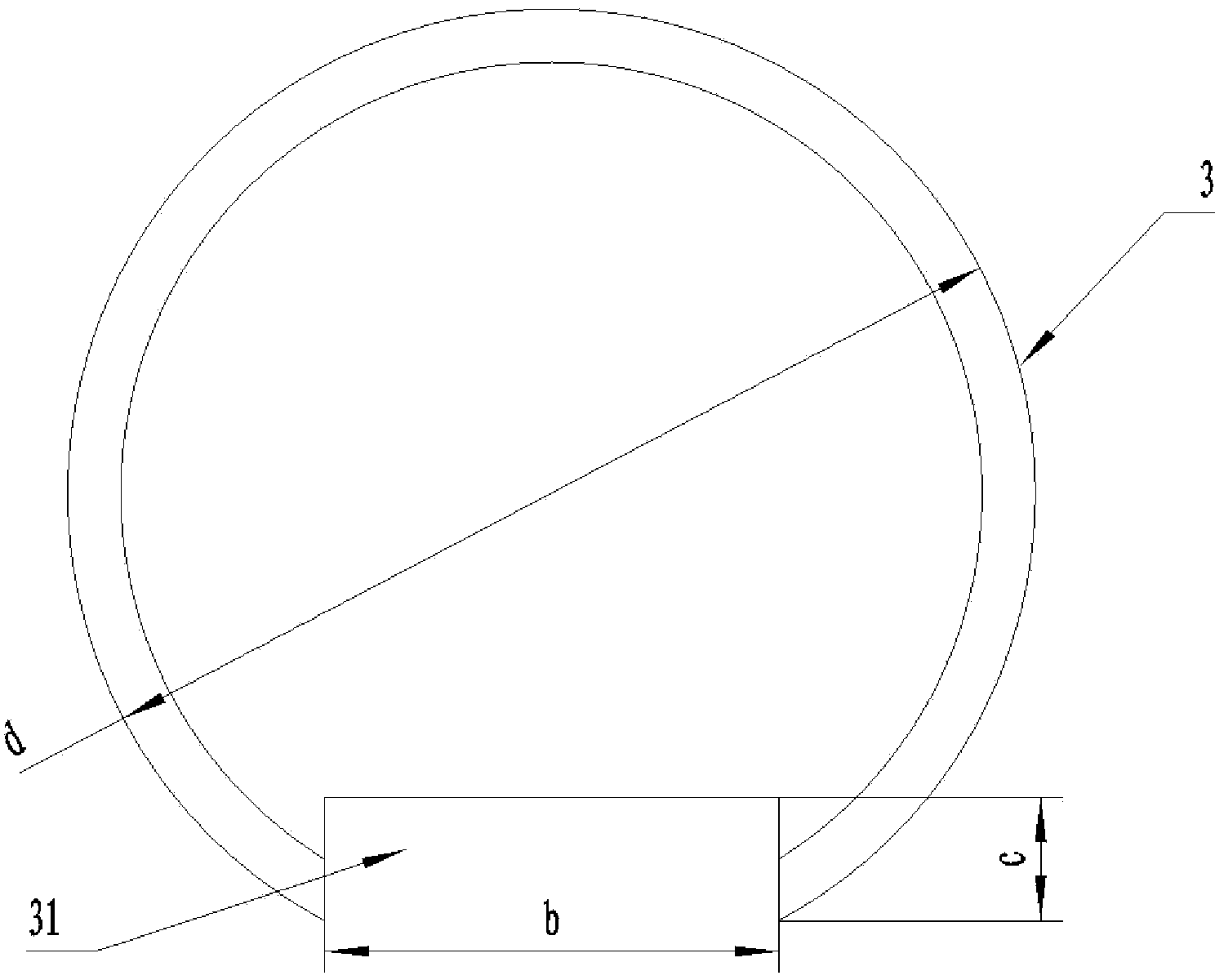

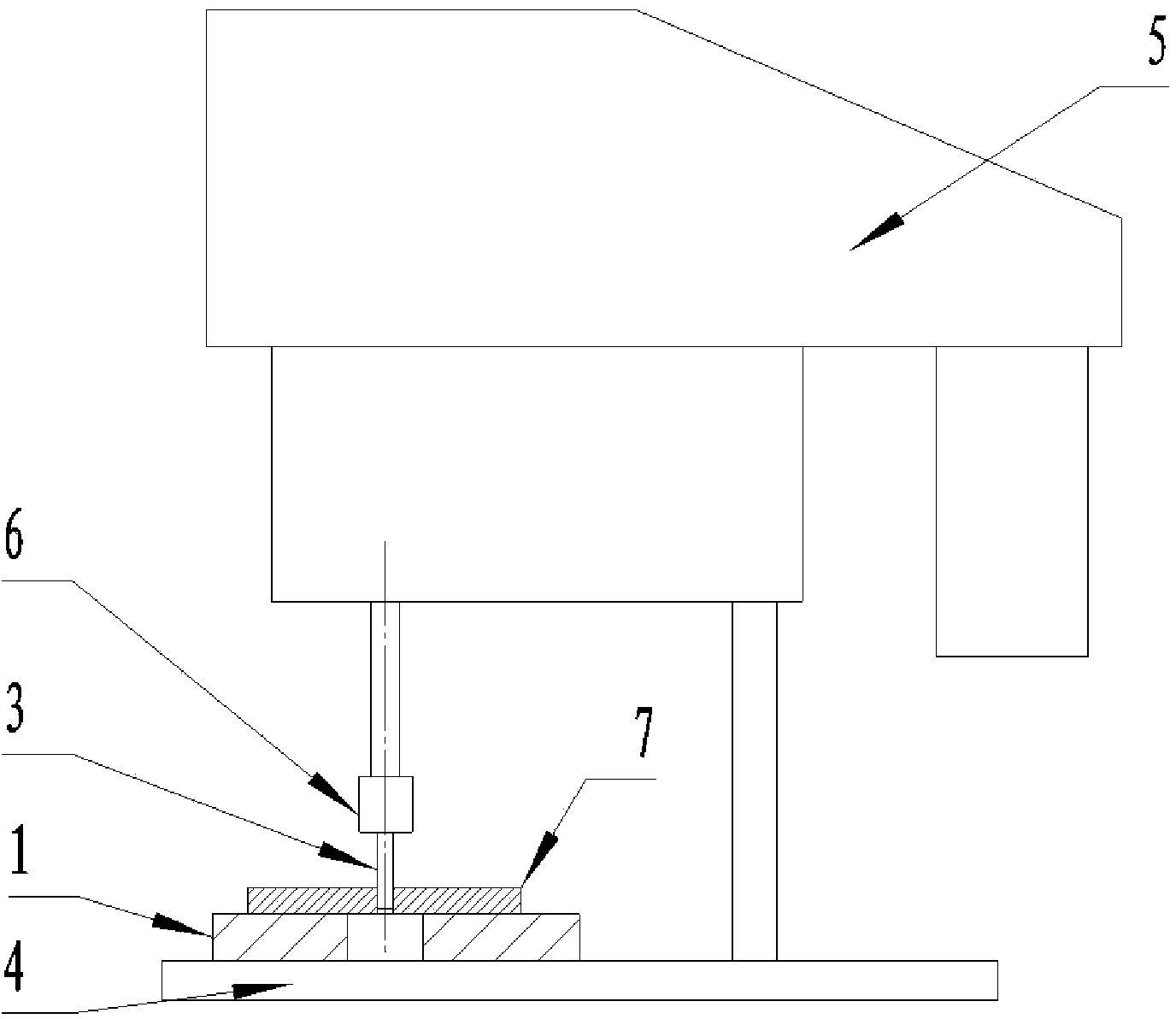

[0032] The combination strengthening method of the alloy structure hole according to the present invention will be further described in detail below in conjunction with the accompanying drawings. A combined strengthening method for alloy structure holes, characterized in that the combined strengthening method for alloy structure holes comprises the following steps:

[0033] Step 1. Design the diameter of the initial hole and the diameter of the final hole according to the amount of interference, the amount of reinforcement, and the diameter of the interference bolt;

[0034] Step 2, making an initial hole on the surface of the alloy plate according to the diameter of the initial hole in step 1;

[0035] Step 3, performing cold extrusion on the primary hole to form the final hole;

[0036] Step 4, installing interference bolts in the end holes.

[0037] Specifically, in step 1, the interference amount is 0.05mm-0.14mm, the strengthening amount is 3%-5%, and the diameter of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com