Method and special cleaning solutions for cleaning thermal-bubble ink-jet printer jet head

An inkjet printer and a technology for cleaning nozzles, applied in chemical instruments and methods, printing, detergent compositions, etc., can solve the problems of nozzle environmental pollution and limited life of nozzles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] first cleaning solution

[0033] substance

Concentration (based on the total weight of cleaning solution)

Ethylene glycol

5

Surfactant 15-s-9

0.2

water

complete

[0034] second cleaning solution

[0035] substance

Concentration (based on the total weight of cleaning solution)

Diethylene glycol butyl ether

10

60

water

complete

[0036] third cleaning solution

[0037] substance

Concentration (based on the total weight of cleaning solution)

Diethylene glycol butyl ether

10

Colorant

1

Surfactant 15-s-7 (purchased from Dow)

0.5

0.5

water

complete

[0038] A cleaning method for cleaning nozzles of thermal bubble type inkjet printers, the steps are as follows:

[0039] (1) Use the first cleaning solution to clean the nozzle, and control the pressure at -...

Embodiment 2

[0046] first cleaning solution

[0047] substance

Concentration (based on the total weight of cleaning solution)

Ethylene glycol

30

Surfactant 15-s-7 (purchased from Dow)

2

water

complete

[0048] second cleaning solution

[0049] substance

Concentration (based on the total weight of cleaning solution)

Diethylene glycol butyl ether

60

10

water

complete

[0050] third cleaning solution

[0051] substance

Concentration (based on the total weight of cleaning solution)

2 pyrrolidone

10

Colorant

1

Surfactant 15-s-7 (purchased from Dow)

0.5

Triethanolamine

5

[0052] water

complete

2 pyrrolidone

10

Colorant

1

Surfactant 15-s-7 (purchased from Dow)

0.5

Triethanolamine

5

water

complete

[0053] A cleaning method f...

Embodiment 3

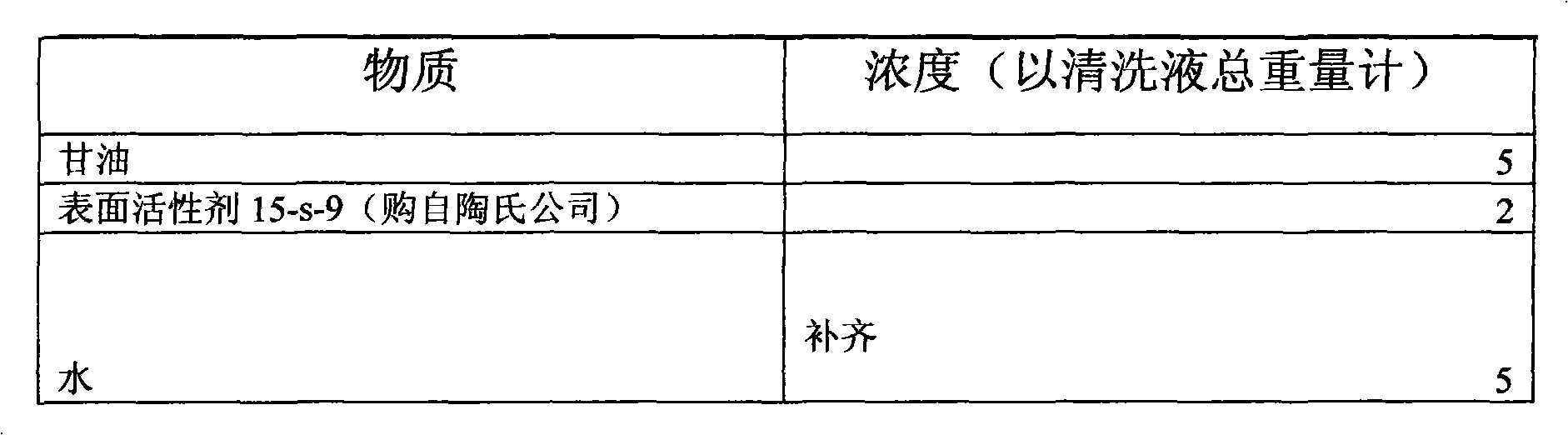

[0060] first cleaning solution

[0061]

[0062] second cleaning solution

[0063] substance

Concentration (based on the total weight of cleaning solution)

2-pyrrolidone

10

Triethanolamine

60

water

complete

[0064] third cleaning solution

[0065] substance

Concentration (based on the total weight of cleaning solution)

Diethylene glycol butyl ether

30

Colorant

5

Surfactant 15-s-7 (purchased from Dow)

0.5

Triethanolamine

0.5

water

complete

[0066] The cleaning method for cleaning the nozzle of the thermal bubble inkjet printer, the steps are as follows:

[0067] Use the first cleaning solution to clean the nozzle, and the pressure is controlled at -0.05MPa until the eluate in the nozzle has no color;

[0068] Use 350ml of the second cleaning solution to clean the nozzle, and the pressure is controlled at -0.05MPa;

[0069] Use 350ml of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com