Laser ink-jet printing technology

A technology of inkjet printing and technology, applied in the field of inkjet printing technology, can solve the problems of expensive machine and consumables, difficult storage of consumables, troublesome cleaning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

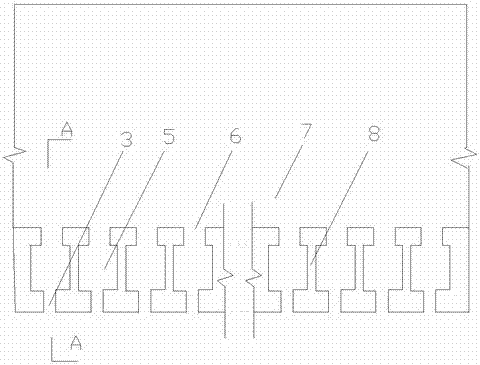

[0026] Laser inkjet printing includes printing control system, laser scanning system, inkjet head and paper feeding mechanism and other components. Only the specific implementation of the inkjet part is introduced here, and the rest of the components are all existing mature technologies. The inkjet part mainly includes laser scanning system and inkjet head.

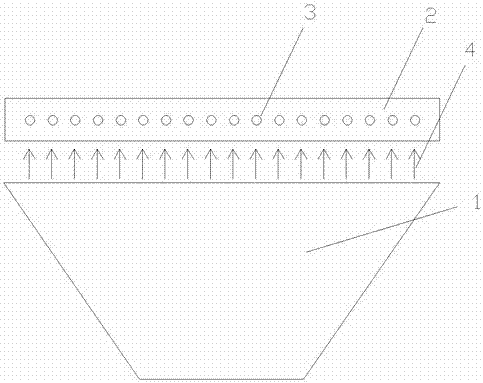

[0027] figure 1 It is a structural diagram of the inkjet part according to the first embodiment of the present invention, the inkjet head (2) has ink inside or is supplied by an external ink cartridge. The laser scanning system (1) modulates, deflects and focuses the laser (4) and scans and irradiates the inkjet head (2) in sequence, and ejects ink droplets from the nozzles (3) in the inkjet head (2) as required.

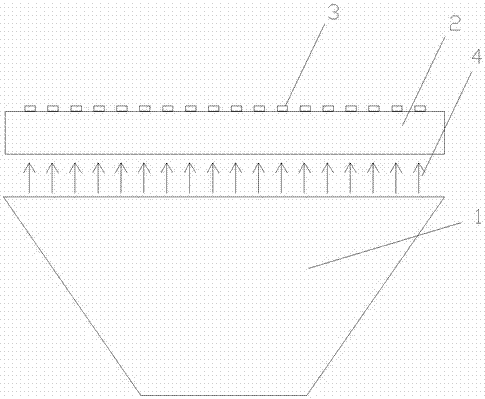

[0028] figure 2 It is a structural diagram of the inkjet part according to the second embodiment of the present invention, the structure is basically the same as that of the first embodiment, except that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com