A toolbox for pneumatic cutting lubrication and its supply calibration and adjustment method

A tool box, box body technology, applied in the direction of manufacturing tools, metal processing equipment, maintenance and safety accessories, etc., to achieve the effects of stable supply, simple structure, and convenient supply adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

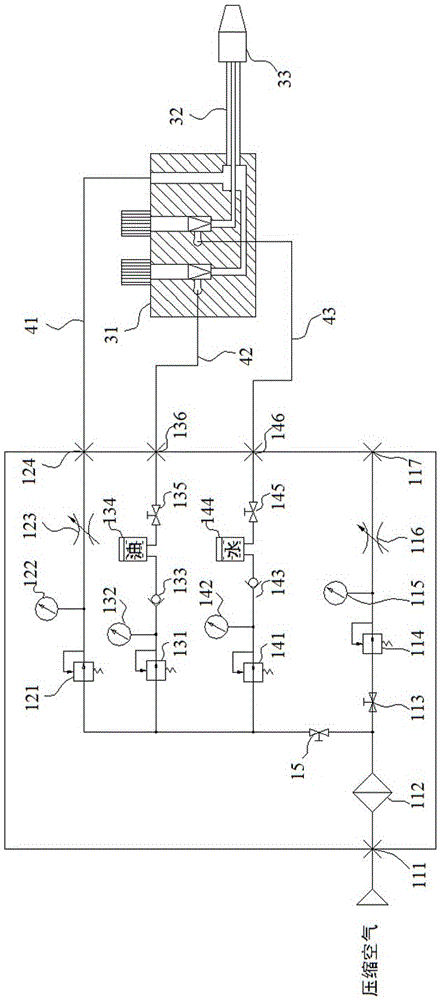

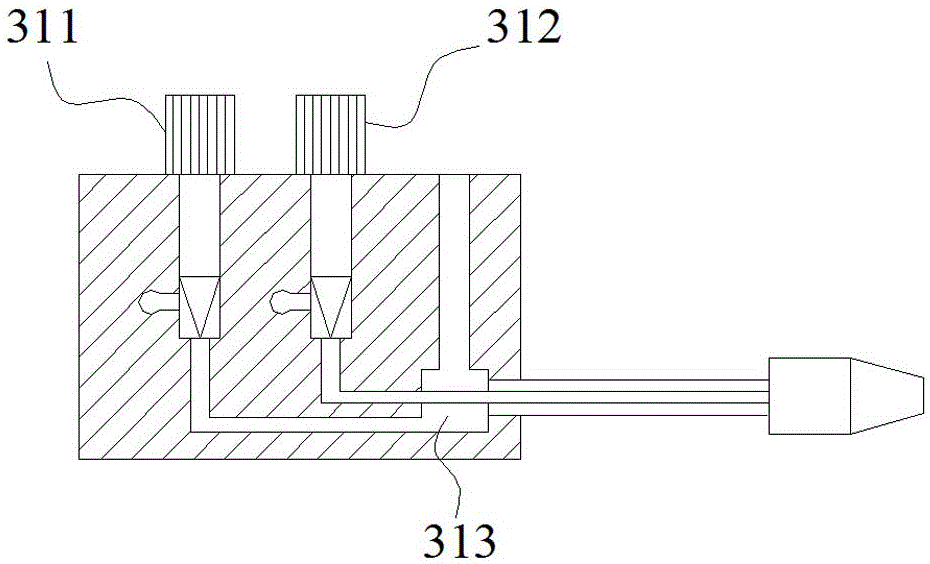

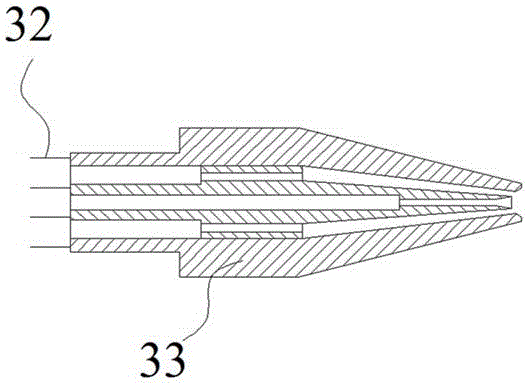

[0047] Such as Figure 1-7 As shown, the present invention proposes a toolbox for pneumatic cutting lubrication. The tool box specifically includes a box body 1, a box cover 2, an injection device and a hose bundle, and is characterized in that the box body 1 includes a cutting air source adjustment circuit and a micro compound injection circuit.

[0048] The cutting gas source adjustment circuit includes a gas source connector 111 , a gas filter device 112 , a valve 113 , a pressure reducing valve 114 , a pressure gauge 115 , a flow valve 116 and a connector 117 . The joints 117 in this embodiment are parallel double joints with dimensions of 6 mm and 8 mm respectively, so as to be suitable for connection pipelines of common pneumatic tools of different specifications.

[0049] The trace composite injection circuit includes valve 15, air injection branch, lubricating branch, and cooling branch; wherein the air injection branch includes a pressure reducing valve 121, a pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com