A jet tube membrane bioreactor

The technology of a biological reaction device and a membrane bioreactor is applied in the field of a jet-tube membrane biological reaction device, which can solve the problems of easy membrane fouling, high membrane cost, and high operating energy consumption, so as to save pipeline costs and reduce shearing effect. power, improve the effect of treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with embodiment the present invention will be further described.

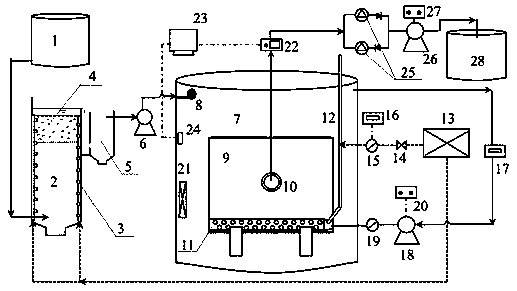

[0037] Such as Figure 1-3 Shown, a jet tube type membrane bioreactor, comprising:

[0038] Raw solution supply tank 1, used to accommodate waste water to be treated;

[0039] An upflow biological fluidized bed reactor 2, the upper part of the upflow biological fluidized bed reactor 2 is filled with a granular activated carbon interlayer 4;

[0040] Overflow settling tank 5, described overflow settling tank 5 is connected on the outer wall of upflow type biological fluidized bed reactor 2 top;

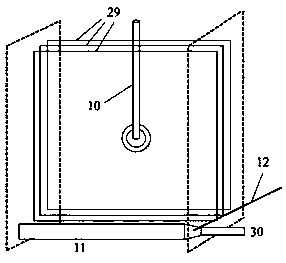

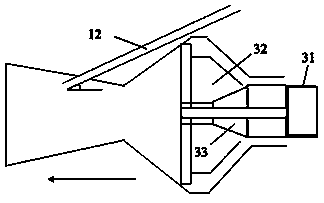

[0041] The membrane bioreactor 7 is equipped with a membrane module 9 and an injector 11 inside. The membrane module 9 includes several flat membranes 29 and injectors 11 arranged in sequence, and the two flat membranes 29 on the outside are equipped with permeated water Pipeline 10, permeate water outlet pipe 10 protrudes from membrane bioreactor 7, membrane module 9 is formed by three fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com