Laser ink-jetting head

An inkjet head and laser technology, applied in printing and other directions, can solve the problems of restricting the type and quality of media, high manufacturing cost of inkjet head, and the distance cannot be too large, and achieve the effects of low cost, fast injection speed and simple circuit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

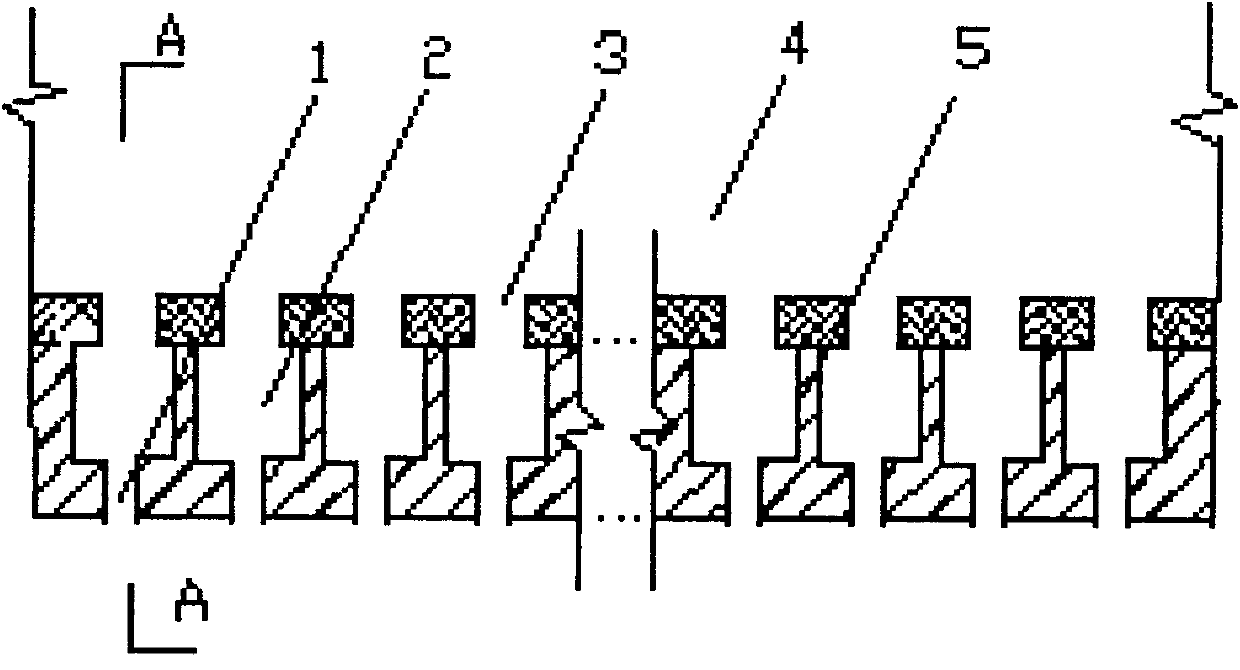

[0021] figure 1 According to the internal structure diagram of the inkjet part of the present invention, the ink chamber (4) is full of ink, and the ink enters from the ink inlet passage (3) in the small ink chamber (2) separated by the substrate (5), and the ink is pressurized from Jet out from the ink jet hole (1).

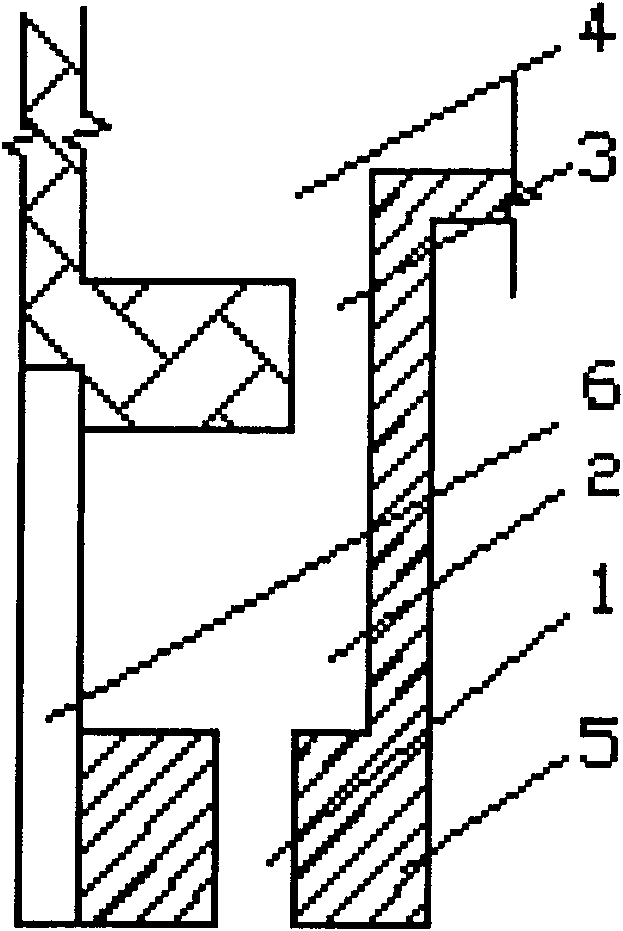

[0022] figure 2 It is a schematic structural view of the A--A cross-section of the ink-jet unit according to the present invention. The laser passes through the transparent body (6) and directly heats the ink in the small ink chamber (2) to generate thermal pressure, and the ink flows from the ink-ejection hole ( 1) directly sprayed out.

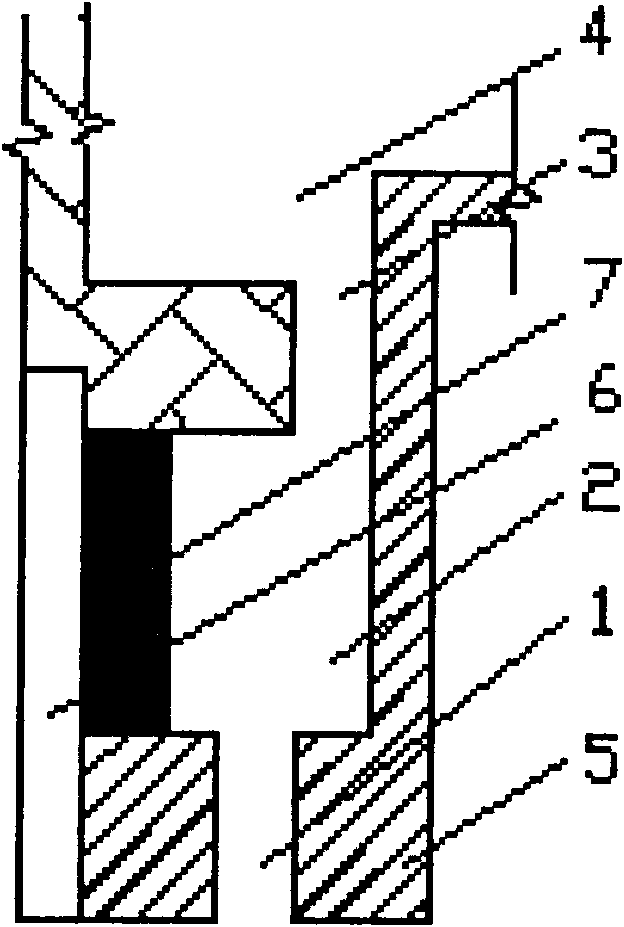

[0023] image 3 It is another structural diagram of the A--A section of the inkjet component of the present invention. The laser passes through the transparent body (6), does not directly heat the ink, but irradiates on the active component (7), and the active component (7) Absorb heat and heat up or produce deformation, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com