Thermal bubble ink jet printing head chip and manufacturing method thereof

The technology of an inkjet printing head and its manufacturing method, which is applied in the field of printing, can solve the problems of performance impact, impact on printing quality, high manufacturing cost and use cost of printing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

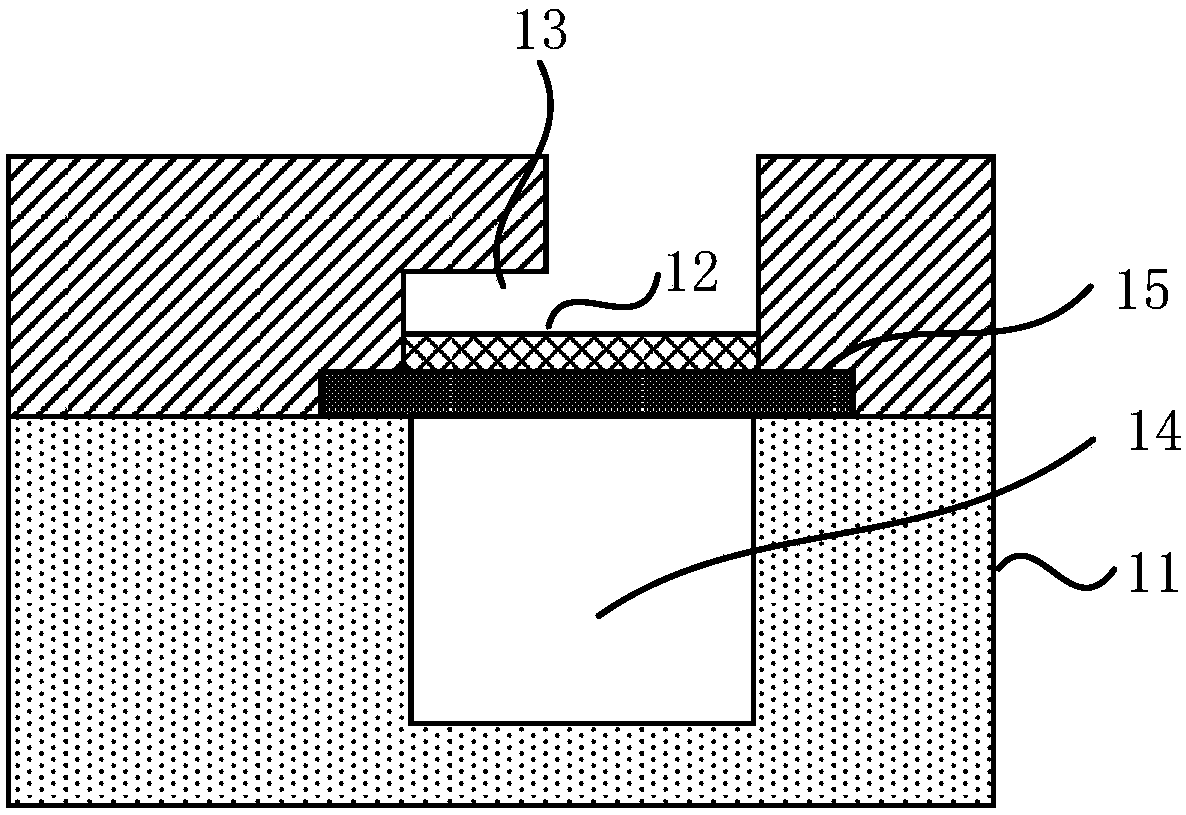

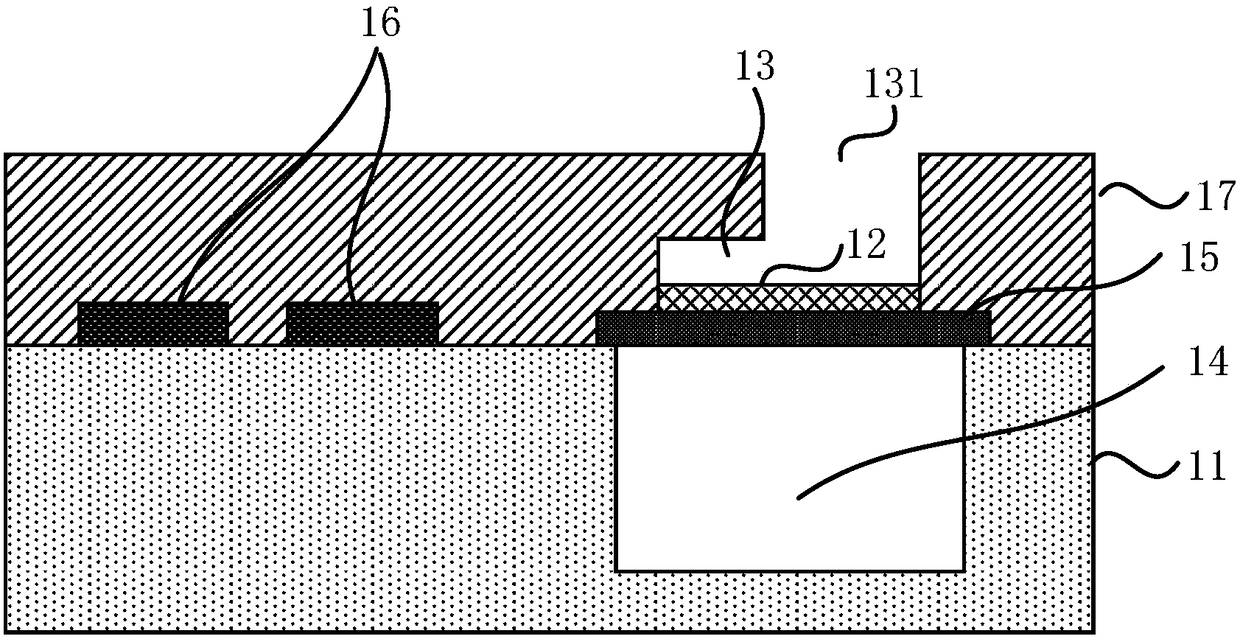

[0038] figure 1 It is a schematic structural diagram of a thermal bubble jet print head chip provided by Embodiment 1 of the present invention. refer to figure 1 , the print head chip includes a substrate 11 , a heating resistor 12 , an ink containing cavity 13 and a low thermal conductivity cavity 14 . Wherein, a heating resistor 12 is formed on the first side of the substrate 11, and an ink containing cavity 13 is formed on the side of the heating resistor 12 away from the substrate 11; wherein, a low thermal conductivity cavity 14 is formed in the substrate 11, and the low thermal conductivity cavity 14 is located on the side of the heating resistor 12 away from the ink containing cavity 13 , and the low thermal conductivity cavity 14 is filled with a material with lower thermal conductivity than the substrate. Specifically, by forming a low thermal conductivity cavity 14 in the substrate 11 and filling the low thermal conductivity cavity 14 with a material with a thermal...

Embodiment 2

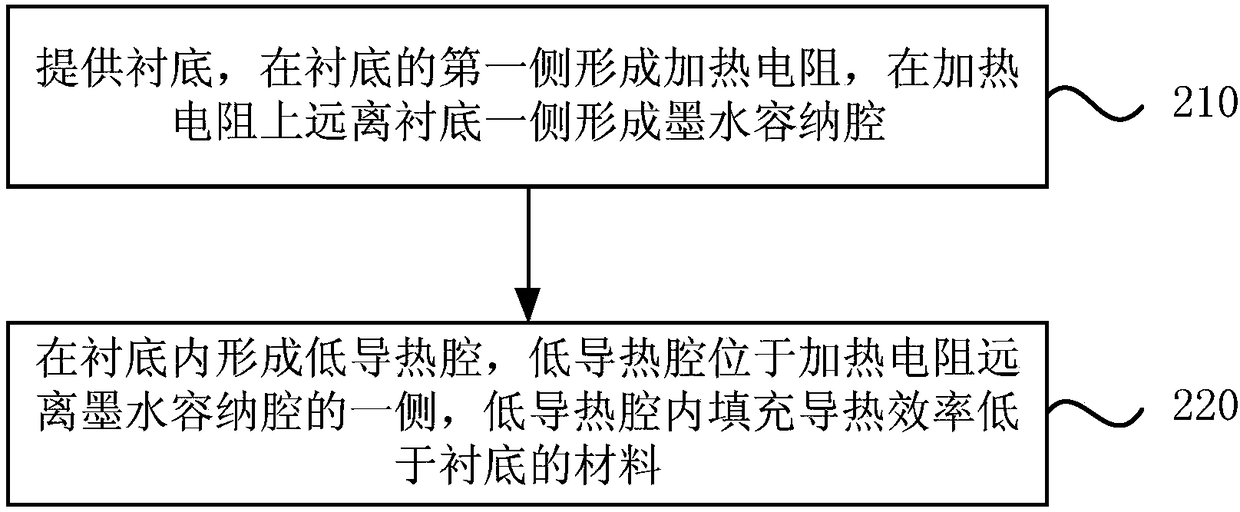

[0044] image 3It is a method for manufacturing a thermal bubble inkjet print head chip provided in Embodiment 2 of the present invention, and the method is suitable for reducing heat loss of heating resistors and improving heating efficiency. The method can be executed by a thermal bubble jet print head chip configured in the printer.

[0045] refer to image 3 , the manufacturing method of the thermal bubble inkjet printing head chip that the present embodiment provides, specifically comprises the following steps:

[0046] Step 210 , providing a substrate, forming a heating resistor on a first side of the substrate, and forming an ink containing chamber on a side of the heating resistor away from the substrate.

[0047] After the substrate is provided, a heating resistor is formed on the first side of the substrate for generating heat, and an ink containing chamber is formed on the side of the heating resistor away from the substrate for storing ink. When the heat generat...

Embodiment 3

[0052] Figure 4 It is a method for manufacturing a thermal bubble jet print head chip provided in Embodiment 3 of the present invention, refer to Figure 4 , on the basis of the above embodiment, the forming the low thermal conductivity cavity in the substrate includes: forming at least two micro cavities on the second side surface of the substrate; forming a low thermal conductivity cavity in the substrate through at least two micro cavities Thermal cavity. That is, step 220 in the second embodiment includes the following steps 320 and 330 .

[0053] refer to Figure 4 , the manufacturing method of the thermal bubble inkjet print head chip of the present embodiment specifically includes:

[0054] Step 310 , providing a substrate, forming a heating resistor on a first side of the substrate, and forming an ink containing cavity on a side of the heating resistor away from the substrate. For details, please refer to the description in step 210 in the second embodiment.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com