Multi-cathode laminar flow plasma powder spheroidization device

A plasma and multi-cathode technology, applied in the fields of plasma, transportation and packaging, electrical components, etc., can solve problems such as restricting the ability of powder processing, and achieve the effect of reducing current density, avoiding large-scale shunting, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to better explain the present invention, a three-cathode laminar flow plasma powder spheroidization device is taken as an example, and the specific implementation of the present invention will be described in detail with reference to the accompanying drawings.

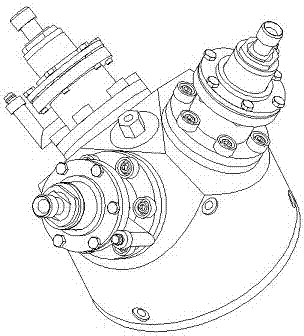

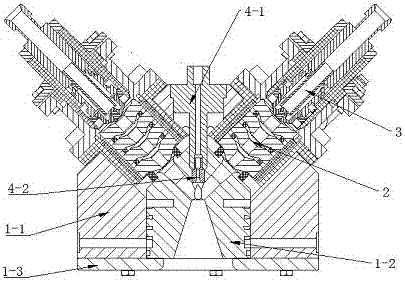

[0023] The three-cathode laminar flow plasma powder spheroidization device disclosed in the present invention is as attached figure 1 , as described in 2, consists of anode part (1), intermediate pole part (2), cathode part (3) and powder feeding part (4):

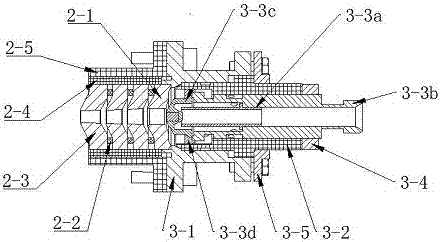

[0024] as attached figure 2 As mentioned above, the anode part (1) is composed of the anode casing (1-1), the anode (1-2), the pressing cover plate (1-3), etc., the anode casing (1-1), the anode (1- 2), the compression cover plate (1-3) is connected by bolt compression; the structure of the anode (1-2) is shown in the attached Figure 4 ;

[0025] as attached image 3 As mentioned above, the intermediate pole part (2) is composed of arc startin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com