Constant-current source driver circuit and device

A technology of driver circuit and constant current source, applied in electric lamp circuit layout, light source, electric light source, etc., can solve the problems of complex circuit structure, high comprehensive manufacturing cost, and decrease in reliability index of LED lighting fixtures, and achieve the goal of high comprehensive benefit , The effect of high reliability and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

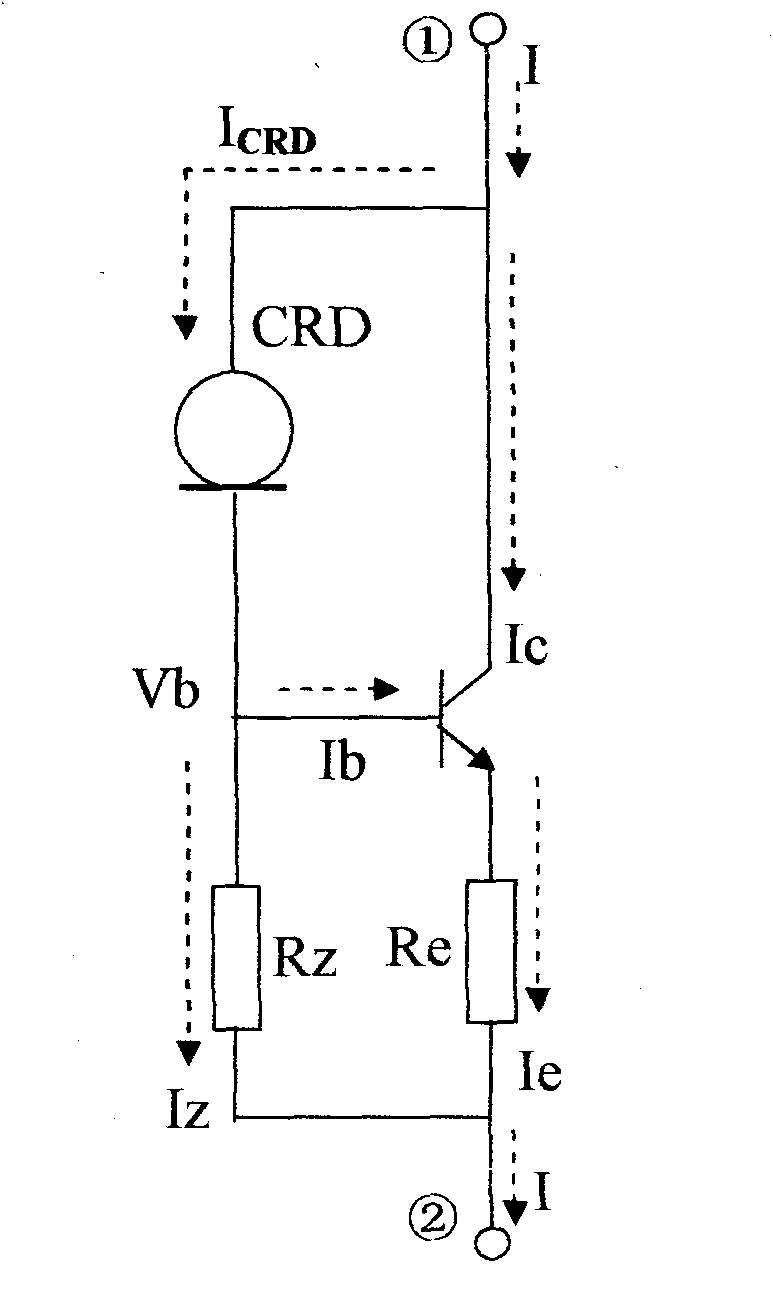

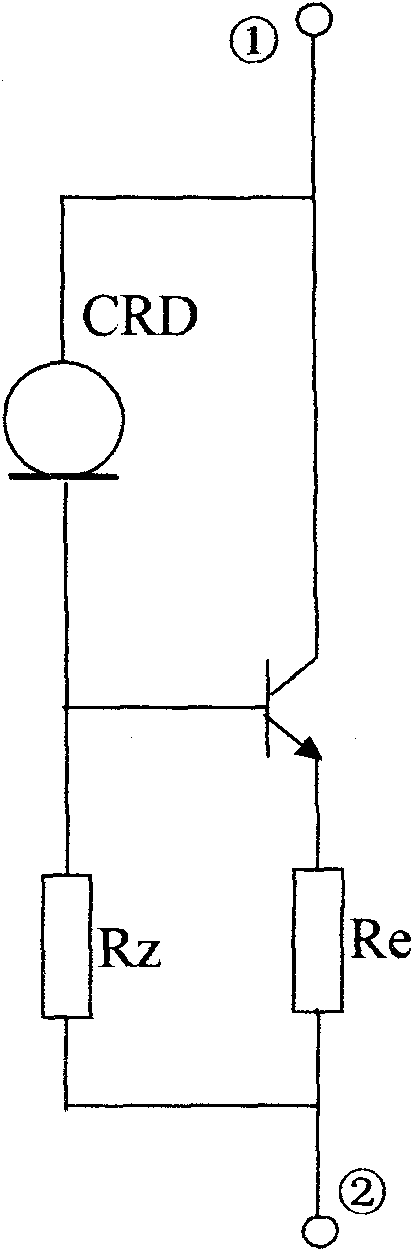

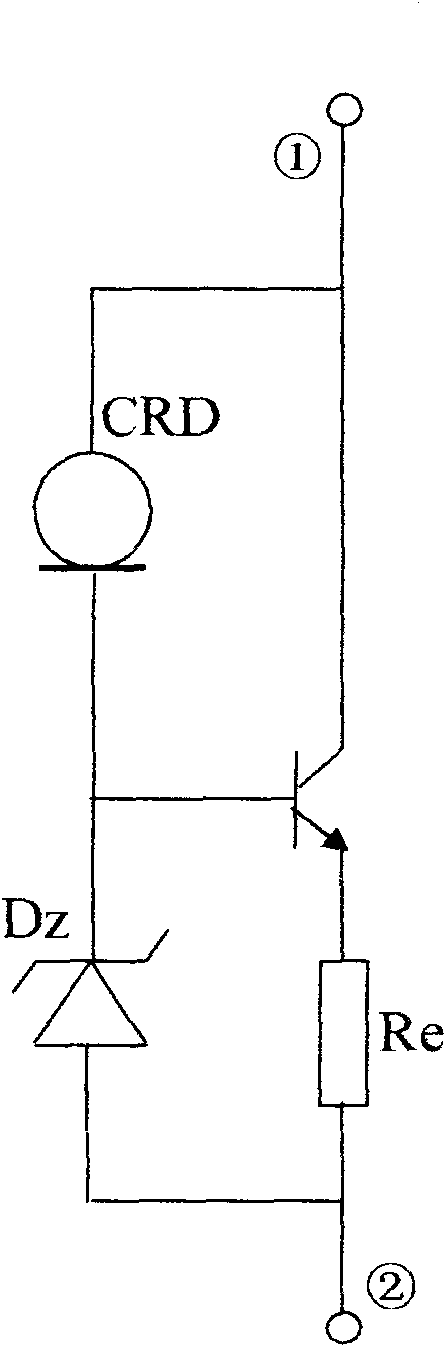

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1, AC220V / 50Hz city grid connected to 80W single-head LED street lamp

[0038] The light source of the 80W single-head LED street light in this embodiment is composed of 80 Power LEDs (power LEDs) with a rated power consumption of 1W connected in series. The circuit structure is as follows: Figure 9 shown. The bridge rectifier circuit can be a finished rectifier bridge, or it can be composed of four 1N4007 discrete diodes. The working current of the constant current source is 330mA. It is very convenient to choose the double-terminal finished device of this patent, and it can work normally without debugging.

Embodiment 2

[0039] Embodiment 2, AC220V / 50Hz city grid connected to E26 rotary 3W-LED walkway light

[0040] The circuit principle diagram of this embodiment is the same as Figure 9 , the LED light source Ds is composed of 96 ф5 straw-capped LED lamp beads in series, and the working current is 15mA. Based on this, the finished product with double-terminal packaging of this patent is selected, and it can work normally after being connected to the circuit.

Embodiment 3

[0041] Embodiment 3: AC110V / 60Hz city power grid connected to E26 rotary 8W-LED indoor lighting

[0042] The circuit principle diagram of this embodiment is the same as Figure 9 , the power grid voltage is AC110V / 60Hz, and the LED light source Ds is a light source with an LED surface package structure. The structure of the light source is densely packaged on an aluminum substrate PCB with two parallel circuits, 46 per circuit, a total of 92 14mil*14mil blue LED dies , and then cover it with a layer of yellow fluorescent powder. The two parallel LED circuit strings share a constant current source device, and the total operating current is set to 40mA. Based on this, the finished constant current source with double-terminal packaging is selected, and it can work normally after being connected to the circuit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com