Thermal bubble supercharged liquid jet nozzle

A technology of liquid injection nozzles and hot bubbles, applied in fuel injection devices, engine components, machines/engines, etc., can solve the problems of difficult pressure, high production cost, complex structure, etc., and achieve simple and convenient adjustment, simplified mechanical movement, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

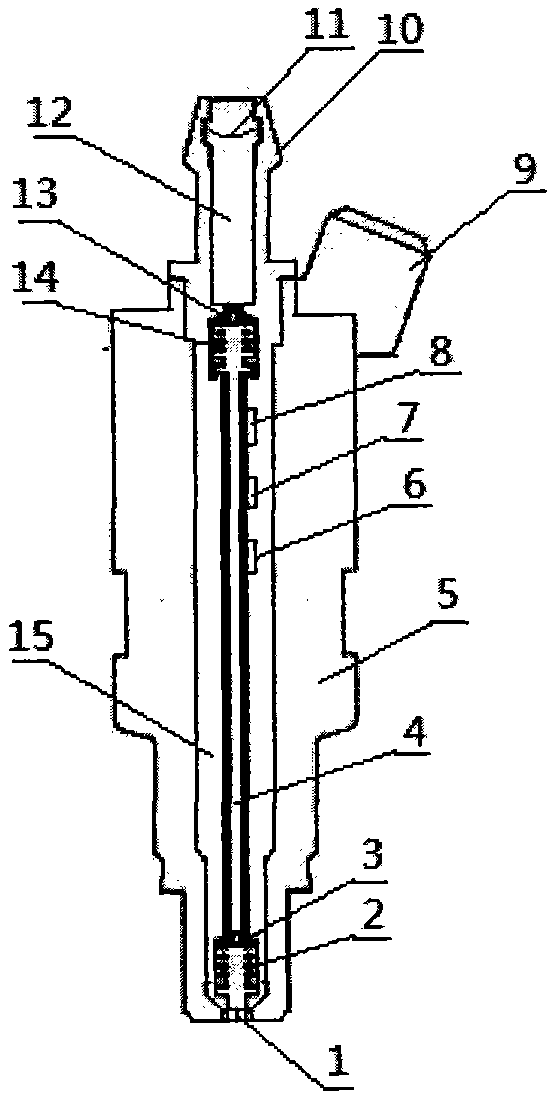

[0026] like figure 1 As shown, a hot bubble pressurized liquid spray nozzle includes a metal shell 5, a nozzle 1, an electrical connector 9, a liquid nozzle 10, a filter screen 11, a thermal insulation plastic layer 15 and a hot bubble pressurized device. The liquid channel in the liquid spray nozzle is connected with the liquid nozzle 10, the hot bubble booster device and the nozzle 1 in sequence from top to bottom, and a filter screen 11 is arranged at the entrance of the liquid nozzle, and a liquid storage area is formed between the hot bubble booster device and the liquid nozzle 12. The thermal insulation plastic layer 15 is arranged in the housing to cover the entire liquid channel.

[0027] The hot bubble pressurization device includes: a liquid spray pipe 4 , a first one-way valve, a second one-way valve, a first electric heating plate 6 , a second electric heating plate 7 , and a third electric heating plate 8 . The first one-way valve is arranged at the inlet of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com