Thermal bubble type ink-jet printing head and manufacturing method thereof

An inkjet print head and a manufacturing method are used in inkjet printing. It can solve problems such as difficult to process ink chambers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

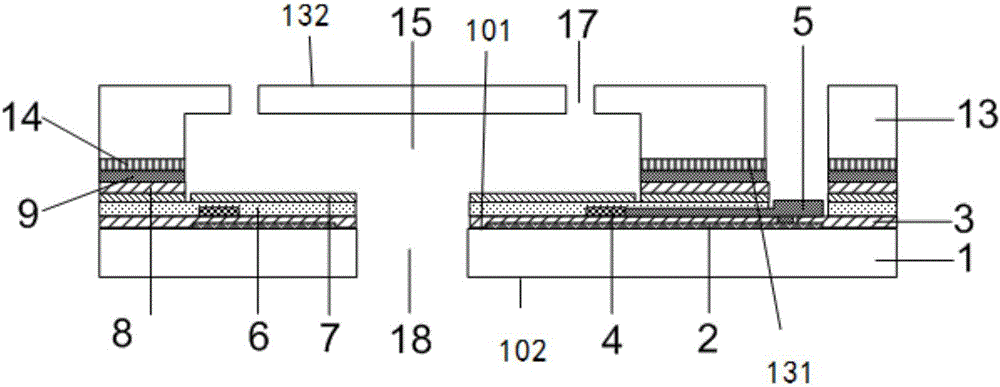

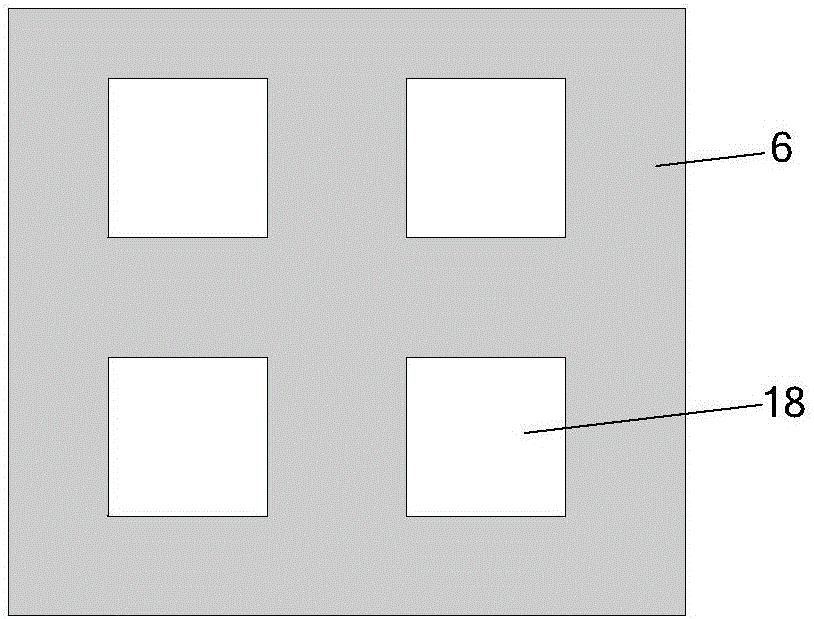

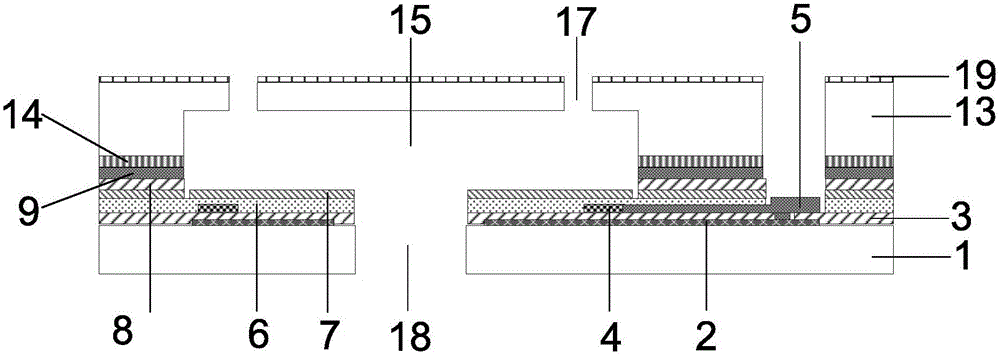

[0043] See figure 1A thermal bubble type inkjet printing head shown in a preferred embodiment of the present invention includes a substrate 1, a cover sheet 13 bonded on the substrate 1 and a heating element 4 arranged on the substrate 1, CMOS driving circuit 2 and metal electrodes 5 . The substrate 1 is made of insulating material, including but not limited to silicon; the cover sheet 13 is made of insulating material, including but not limited to silicon. The substrate 1 and the cover sheet 13 are bonded through a bonding process. The bonding process used in this embodiment is preferably aluminum-germanium bonding or gold-tin bonding. A bonding layer is formed between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com