A thermal bubble-driven micropump for fixed-point growth of bubbles and its preparation method

A technology of hot air bubbles and micropumps, applied in lighting and heating equipment, machine operation methods, pumps, etc., can solve problems such as low stability and reliability, blockage of microchannels, low pumping frequency, etc., and achieve improved Reliability and stability, the effect of accelerating cooling shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

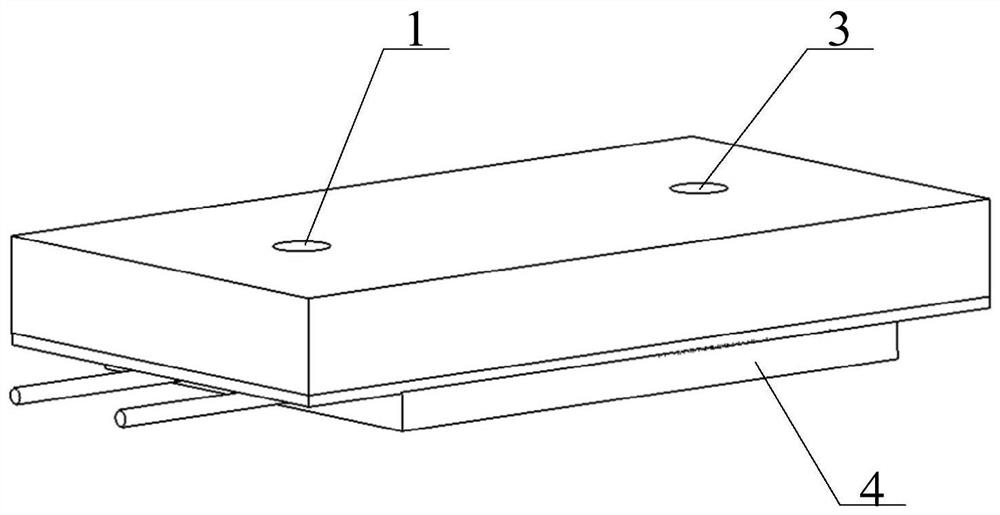

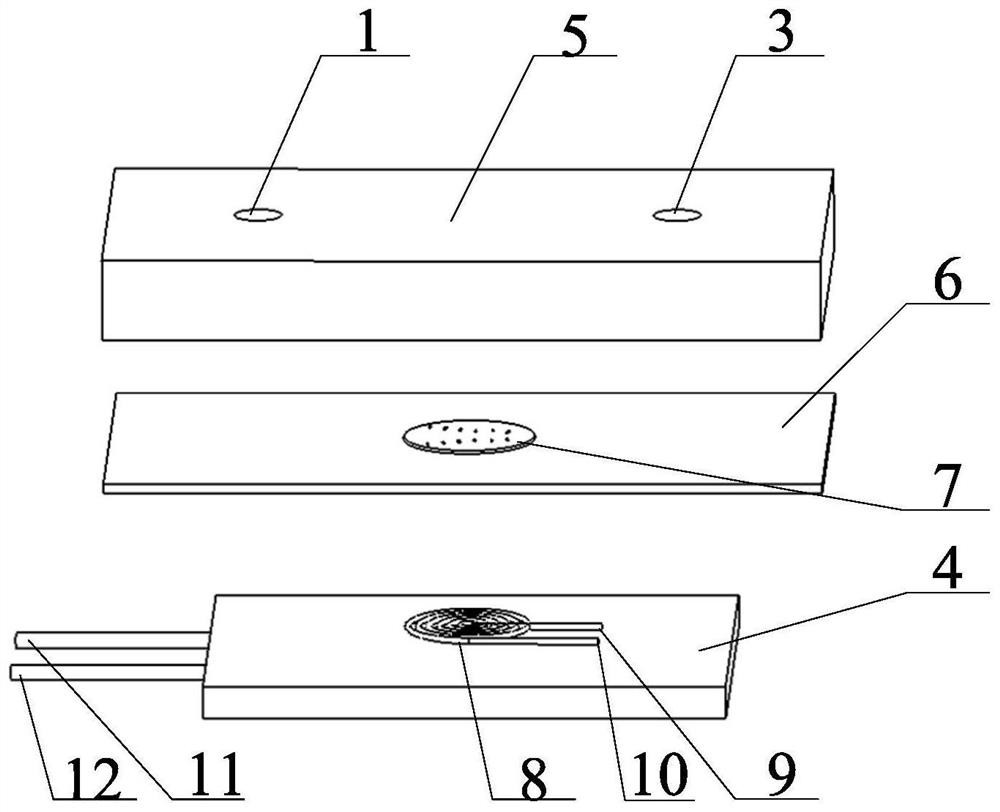

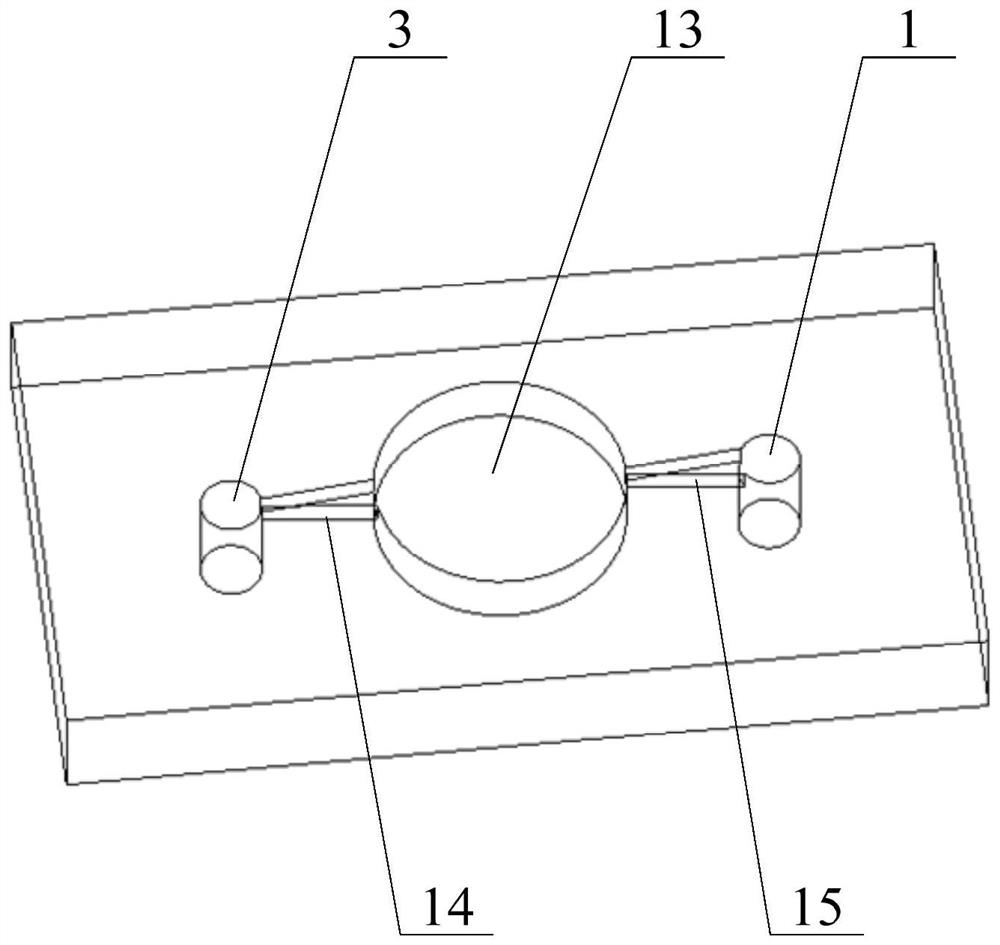

[0033] The manufacture of the thermal bubble-driven micropump consists of two parts: first, the manufacture of the heating plate 7 , and second, the manufacture of the PDMS chip 5 .

[0034] In the present invention, the heating plate 7 is manufactured by an electroplating process, and the specific process flow is as follows:

[0035] first step, Figure 8 As shown in (a), use deionized water to clean the glass substrate 6, and dry it on a glue drying table with a temperature of 110°C;

[0036] second step, Figure 8 Shown in (b), earlier sputter metal chromium 45 and metal copper 46 on glass substrate 6, then spin-coat positive photoresist 47;

[0037] third step, Figure 8 Shown in (c), adopt the heating plate mask plate 52 to expose, then develop and harden the film;

[0038] the fourth step, Figure 8 As shown in (d), an electroplating process is used to electroplate the metal heating plate 7;

[0039] the fifth step, Figure 8 As shown in (e), the positive photores...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com