Thermal vapor bubble type ink jet head chip structure and method for producing the same

A chip structure and manufacturing method technology, applied in printing and other directions, can solve problems such as inconvenience, borophosphosilicate glass brittleness, and general products and methods without suitable structures and methods, so as to reduce costs, increase service life, and reduce heat. The effect of the shock effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

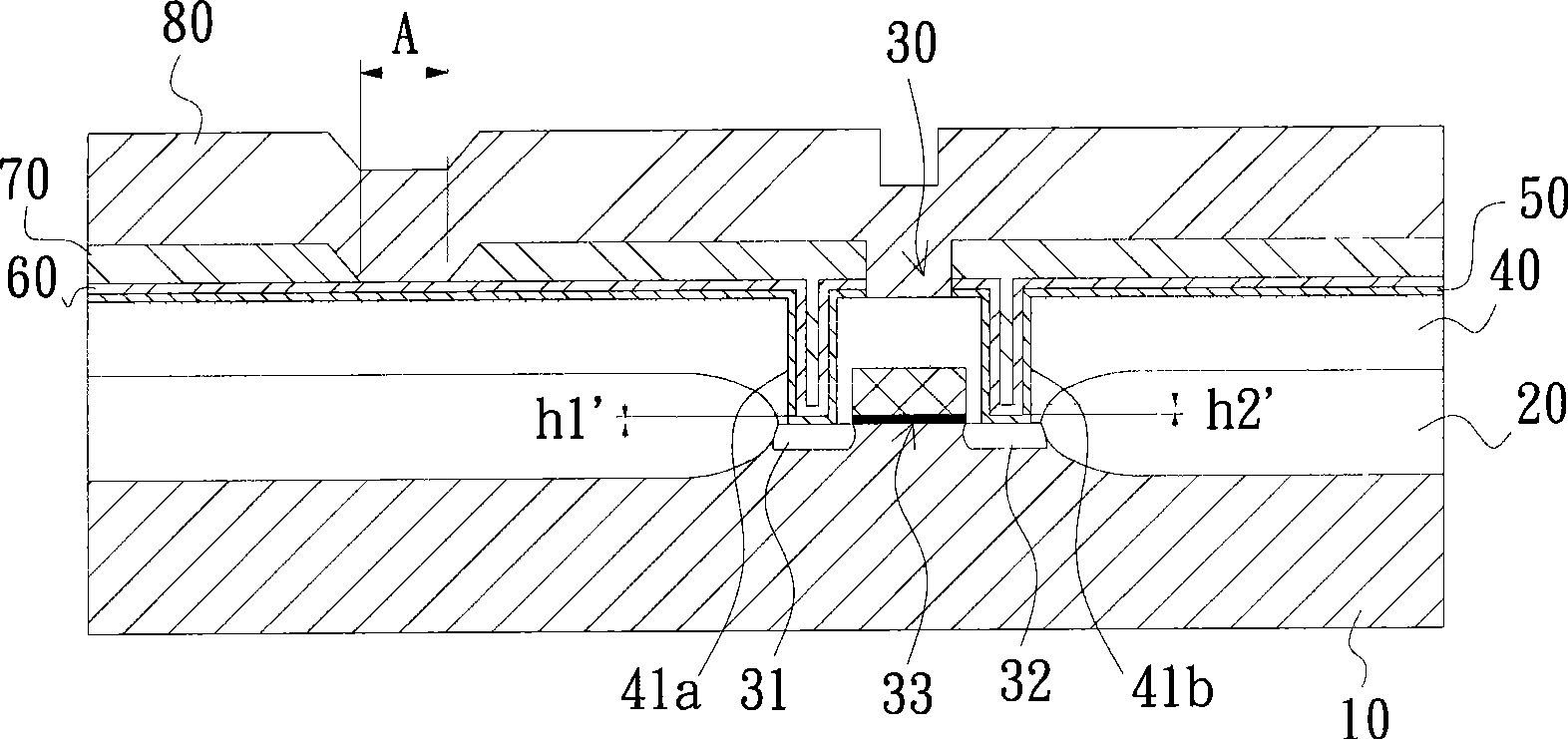

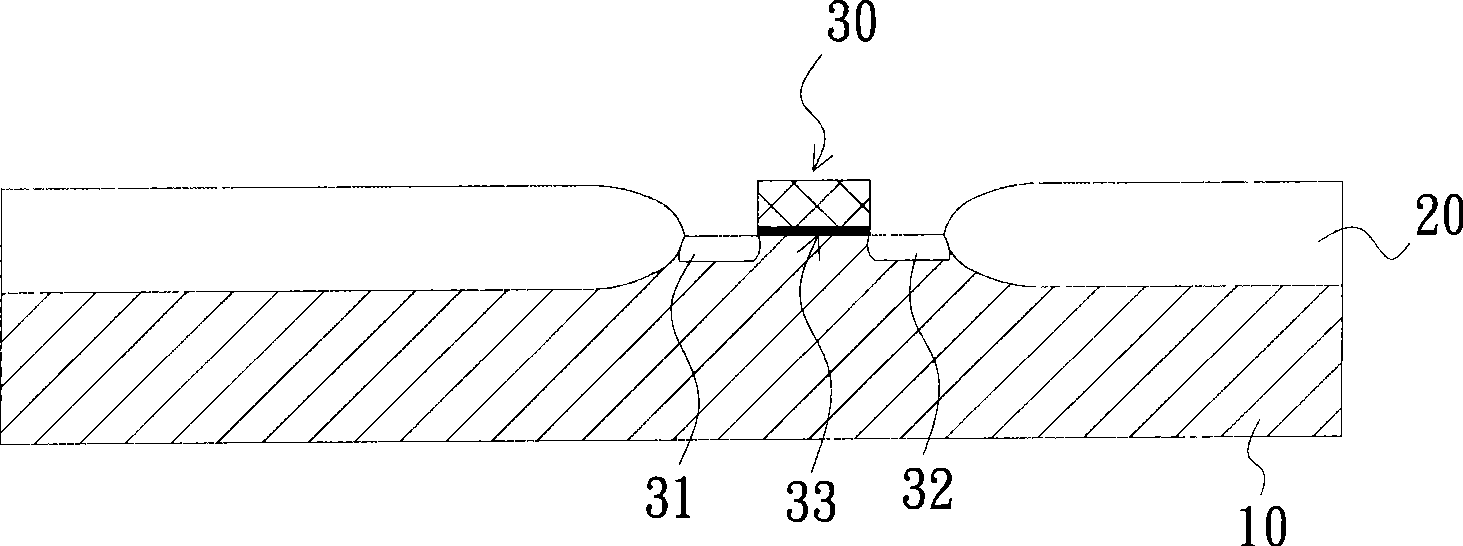

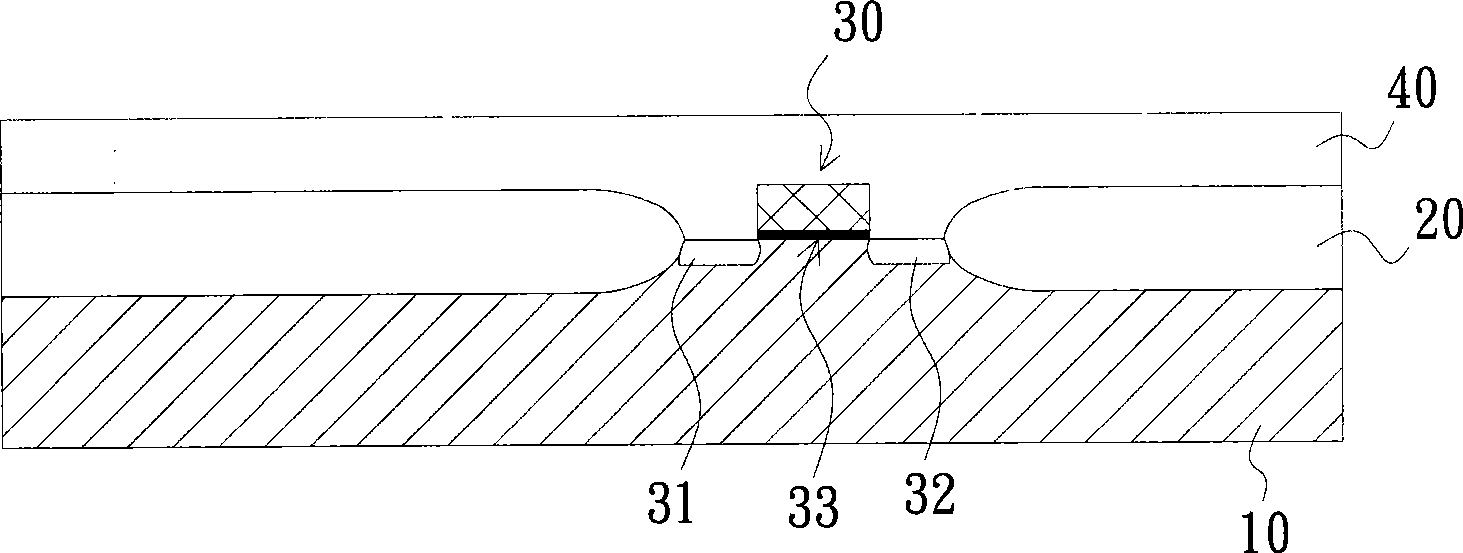

[0059] For further elaborating the technical means and effect that the present invention takes for reaching the intended invention purpose, below in conjunction with accompanying drawing and preferred embodiment, to the thermal bubble type ink-jet head chip structure that proposes according to the present invention and its manufacturing method its specific Embodiments, structures, methods, steps, features and effects thereof are described in detail below.

[0060] Other purposes and advantages of the present invention can be further understood from the technical features disclosed in the present invention. The aforementioned and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of preferred embodiments with reference to the drawings. Through the description of the specific implementation mode, when the technical means and functions adopted by the present invention to achieve the predetermined...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com