A Thin Thermal Battery with Independent Electrode System and Heating System

An electrode system and heating system technology, which is applied in the field of thin thermal batteries, can solve the problems of high thermal battery height and cannot adapt to the development trend of thin thermal batteries, etc., to reduce the impact of thermal shock, solve high-voltage safety problems, and improve utilization. The effect of rate and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

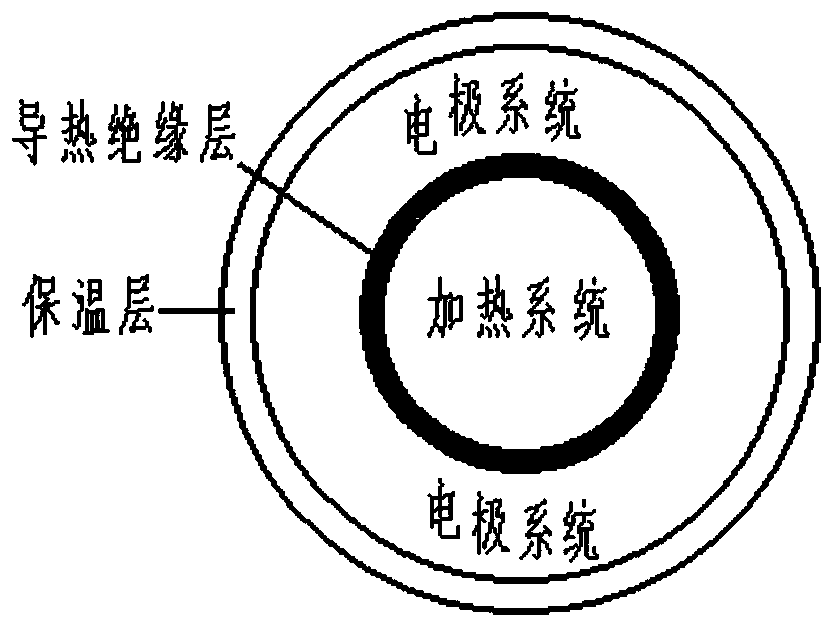

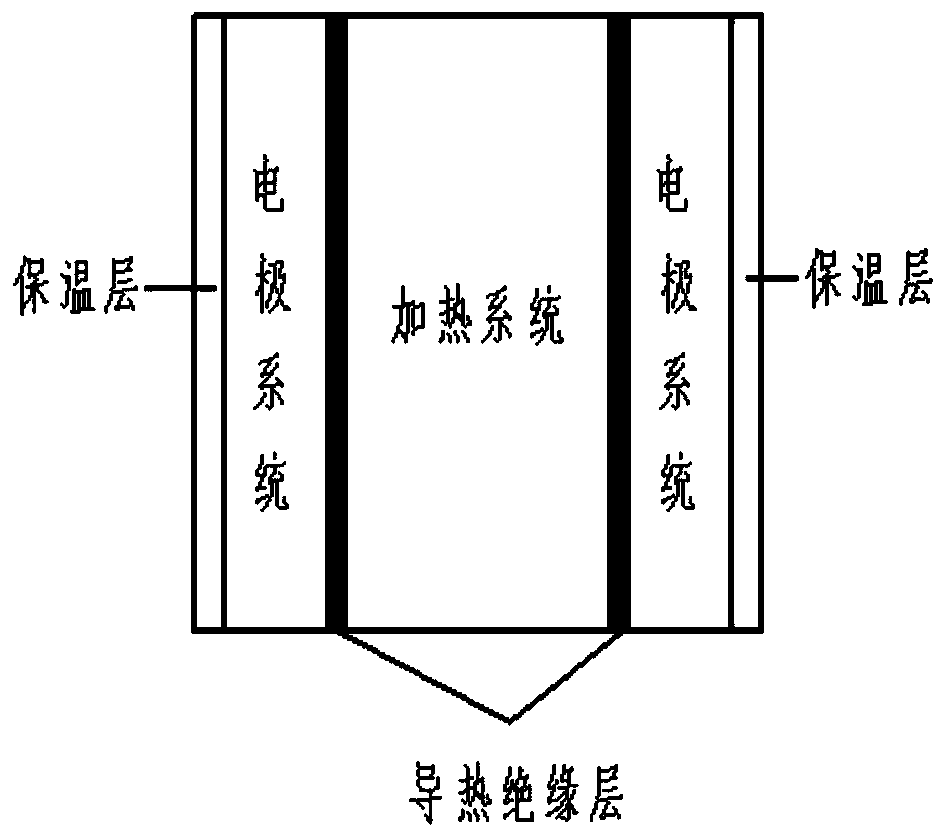

[0020] refer to Figure 1-2 , the invention is a thin thermal battery with independent electrode system and heating system. The heating system is wrapped by a heat-conducting insulating layer. The heating system supplies heat to the electrode system from around. At the same time, the combustion system is composed of a mixture of iron and potassium perchlorate, which is filled in the heat-conducting insulating layer.

[0021] The preparation method of the electrode system is a pressing method or a thermal spraying method.

[0022] The process of the pressing method is to press the positive electrode material, diaphragm material, negative electrode material and current collector into sheets by cold pressing, and then stack the positive electrode material, diaphragm material, negative electrode material and current collector sequentially to form a monomer Battery structure, the single battery structure is stacked to form an electrode system.

[0023] The process of the thermal ...

Embodiment 2

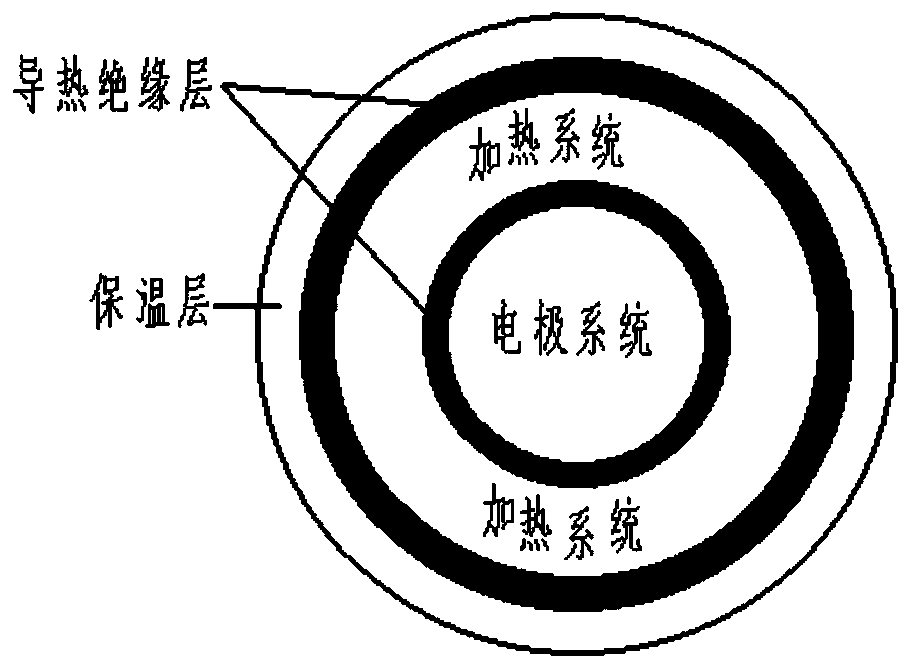

[0027] refer to Figure 3-4 , the invention is a thin thermal battery with independent electrode system and heating system. The heating system is wrapped by a heat-conducting insulating layer. The heating system supplies heat to the electrode system from around. At the same time, the combustion system is composed of a mixture of iron and potassium perchlorate, which is filled in the heat-conducting insulating layer.

[0028] The preparation method of the electrode system is a pressing method or a thermal spraying method.

[0029] The process of the pressing method is to press the positive electrode material, diaphragm material, negative electrode material and current collector into sheets by cold pressing, and then stack the positive electrode material, diaphragm material, negative electrode material and current collector sequentially to form a monomer Battery structure, the single battery structure is stacked to form an electrode system.

[0030] The process of the thermal ...

Embodiment 3

[0034] refer to Figure 3-4 , the invention is a thin thermal battery with independent electrode system and heating system. The heating system is wrapped by a heat-conducting insulating layer. The heating system supplies heat to the electrode system from around. At the same time, the combustion system is composed of a mixture of iron and potassium perchlorate, which is filled in the heat-conducting insulating layer.

[0035] The preparation method of the electrode system is a pressing method or a thermal spraying method.

[0036] The process of the pressing method is to press the positive electrode material, diaphragm material, negative electrode material and current collector into sheets by cold pressing, and then stack the positive electrode material, diaphragm material, negative electrode material and current collector sequentially to form a monomer Battery structure, the single battery structure is stacked to form an electrode system.

[0037] The process of the thermal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com