Sc cut crystal microbalance

A microbalance and quartz technology, which is applied in the direction of material analysis, measuring device, and instrument using sonic/ultrasonic/infrasonic waves, can solve the problems of detection sensitivity and accuracy deterioration, and no mention of SC-cut quartz oscillator sensor section, etc., and achieve improvement. The effect of correctness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

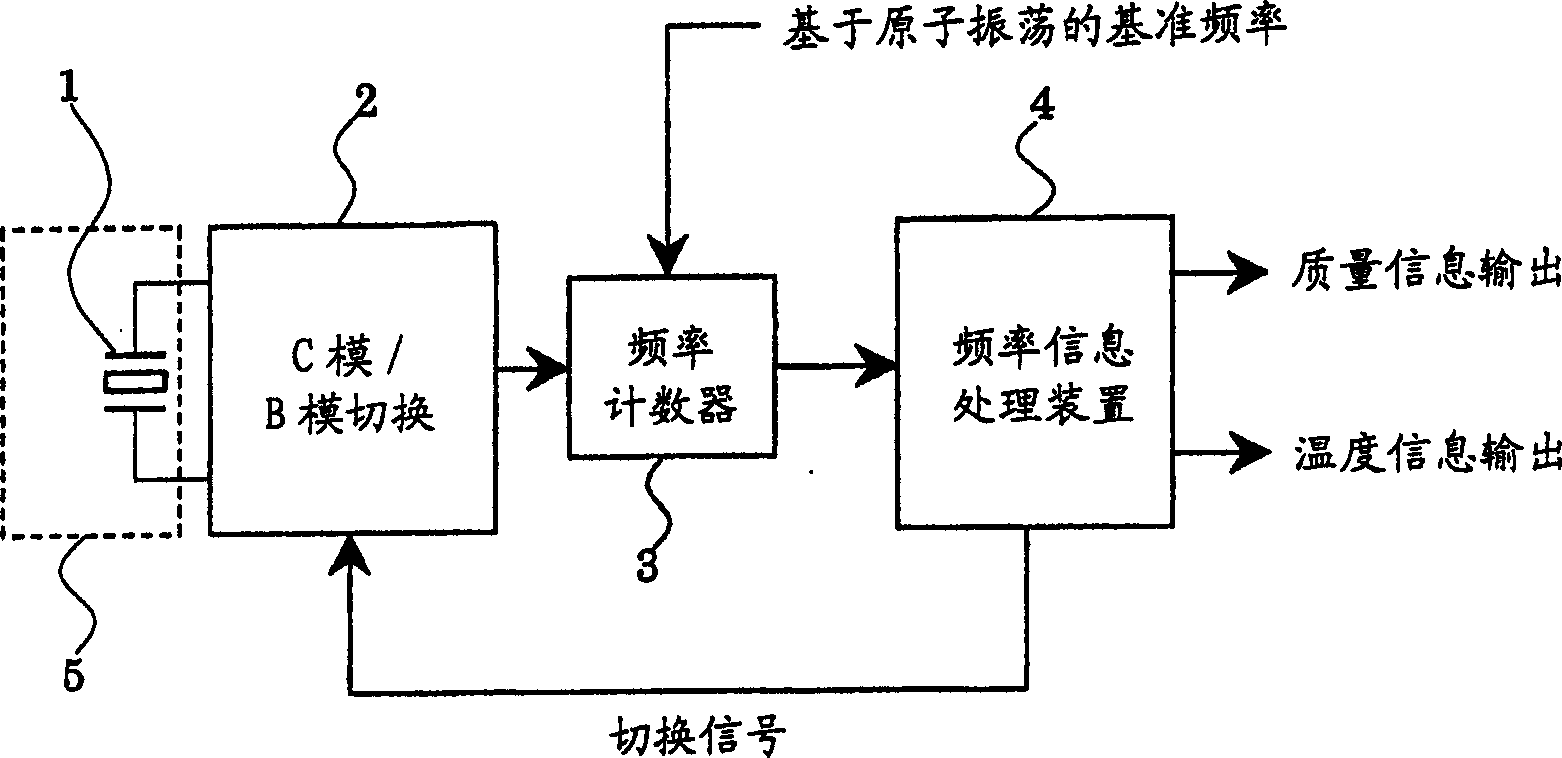

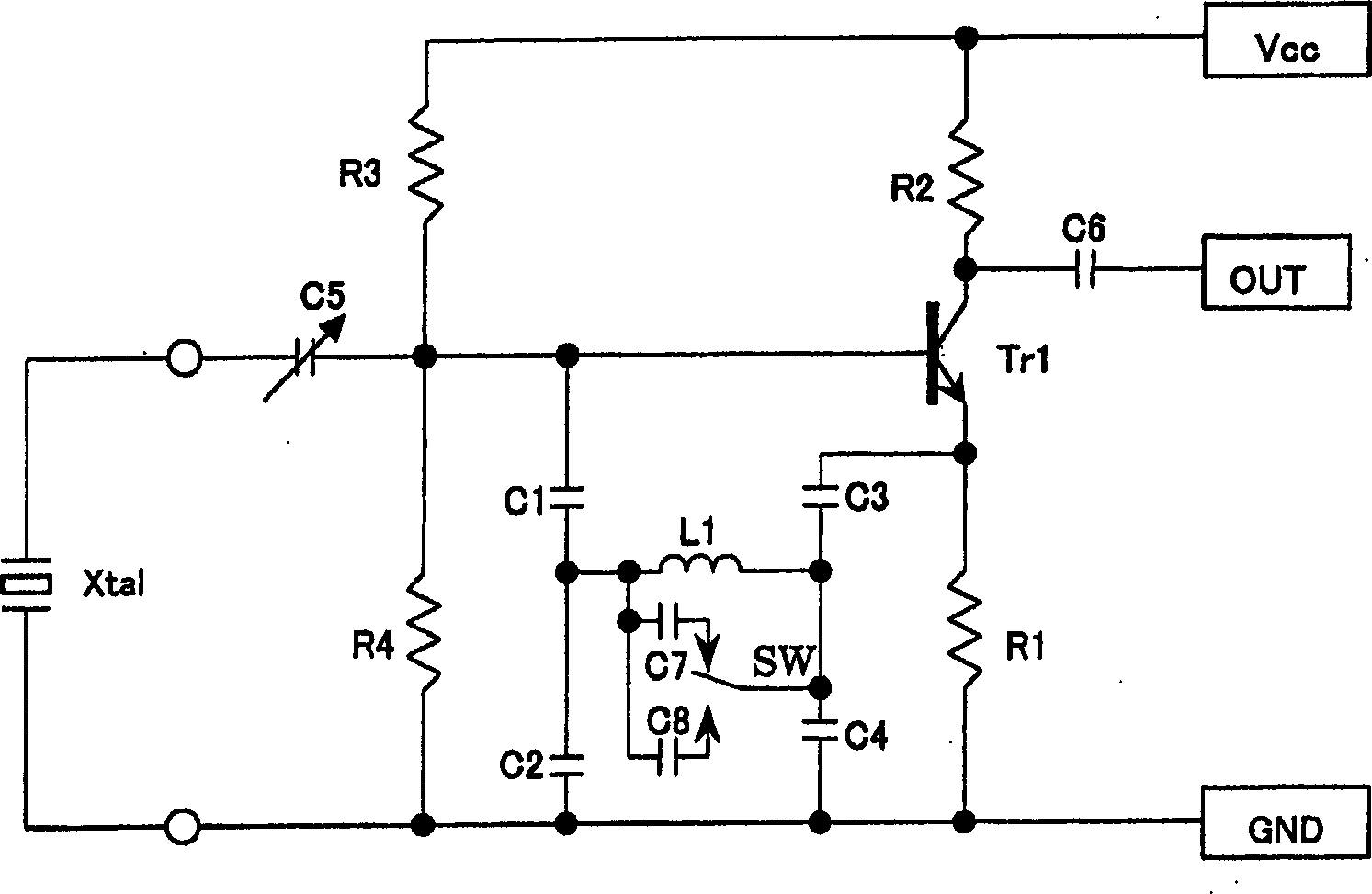

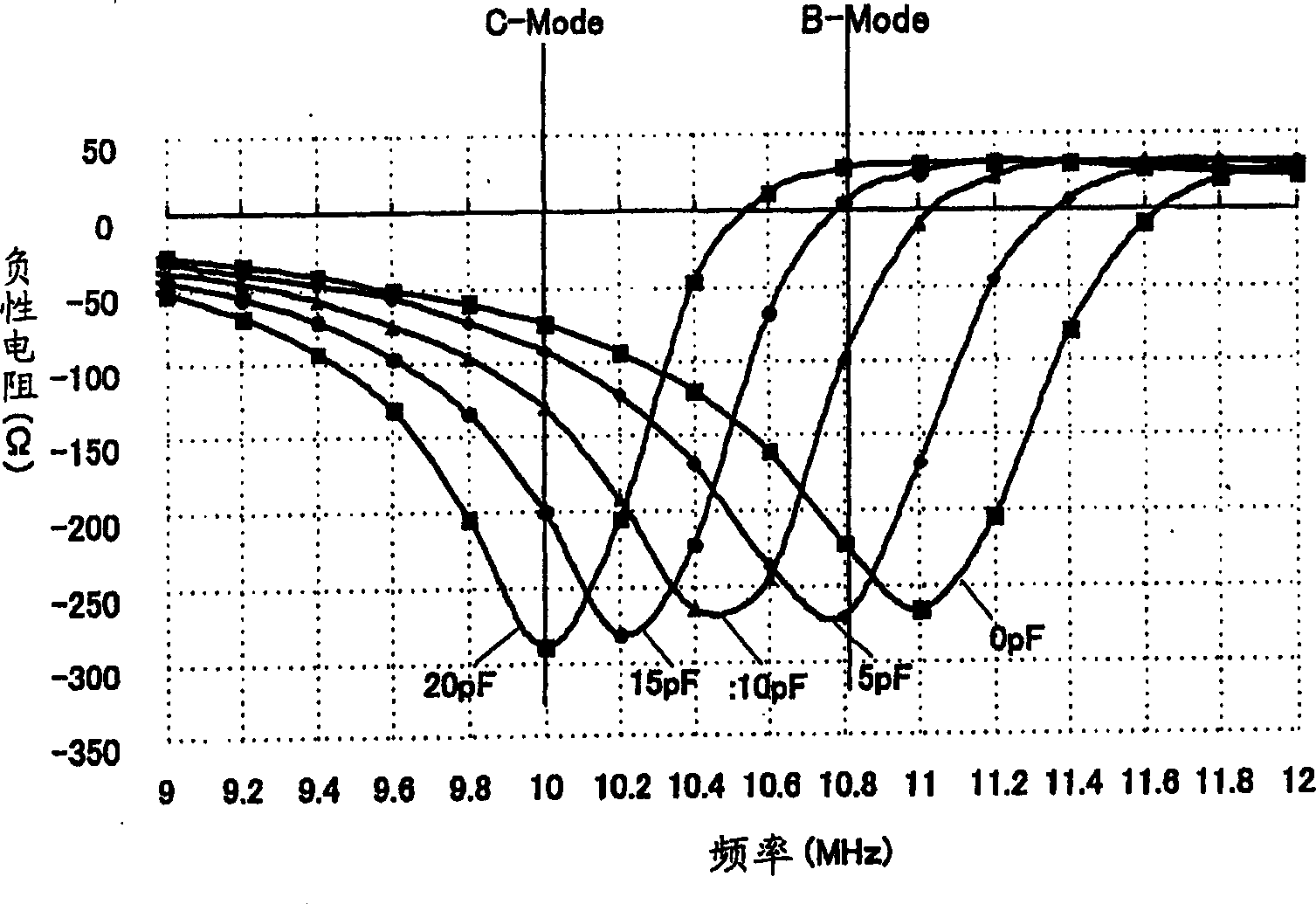

[0036] figure 1It is a circuit block diagram showing an embodiment of the SC-cut quartz microbalance of the present invention, and is composed of an SC-cut quartz vibrator 1 , a C-mode / B-mode switching oscillation circuit 2 , a frequency counter 3 , and a frequency information processing device 4 . The SC-cut quartz vibrator 1 is formed by grinding a quartz substrate cut by rotating about 22 degrees around the Z axis and then about 34 degrees around the X axis to a predetermined thickness, and attaching electrode films on both main surfaces. It is constructed by fixing to the holder with conductive adhesive or welding. The electrode portion of the SC-cut crystal vibrator 1 is placed in the atmosphere 5 to be measured, and the lead wires extending from the two electrode films are connected to the oscillation circuit 2 . The oscillation circuit 2 has a built-in switch that can be controlled by a control signal from the outside, and by switching the switch, the SC-cut crystal r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com