Patents

Literature

30 results about "Compacted graphite iron" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

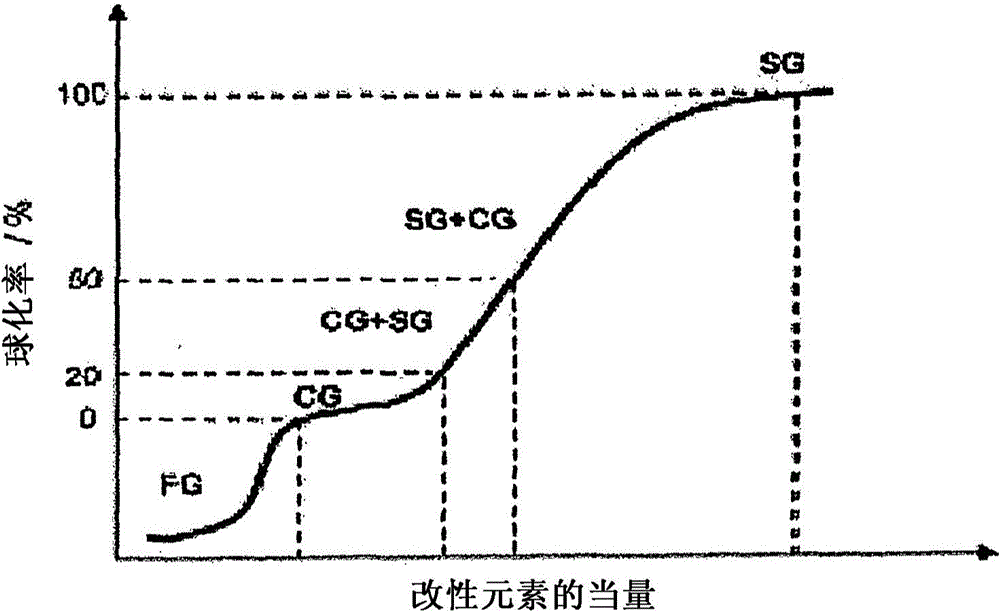

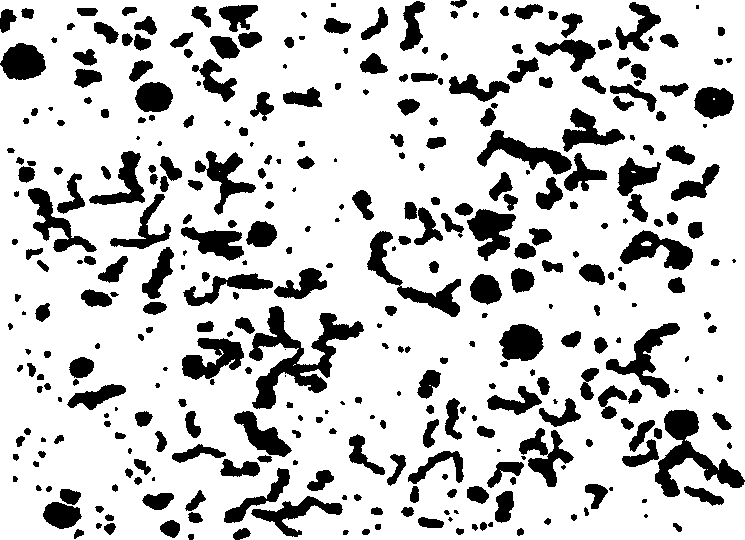

Compacted graphite iron (CGI), also known as vermicular graphite iron (GJV, VG, JV or GGV from the German: "Gusseisen mit Vermiculargraphit") especially in non-English speaking countries, is a metal which is gaining popularity in applications that require either greater strength, or lower weight than cast iron.

Insert

InactiveUS20070292671A1Improve wear resistanceExcellent heat crack resistancePigmenting treatmentMilling cuttersCompacted graphite ironAlloy

The present invention relates to a coated cemented carbide milling insert for either wet or dry machining of cast iron such as nodular cast iron (NCI), grey cast iron (GCI), austempered ductile iron (ADI) and compacted graphite iron (CGI) where a high wear resistance and an excellent resistance against thermo cracks are required comprising: a substrate comprising from about 5 to about 7 wt-% Co, from about 140 to about 250 ppm Ti+Ta and balance WC with a weight ratio Ti / Ta of from about 0.8 to about 1.3 and a PVD-layer consisting of AlxTi1-xN, with x=from about 0.50 to about 0.70 and with a thickness of from about 1 to about 10 μm. The invention also relates to a method for making cutting tool inserts and their use.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Insert

InactiveUS7767319B2Improve wear resistanceExcellent heat crack resistancePigmenting treatmentMilling cuttersHigh resistanceCompacted graphite iron

The present invention relates to a coated cemented carbide milling insert for either wet or dry machining of cast iron such as nodular cast iron (NCI), grey cast iron (GCI), austempered ductile iron (ADI) and compacted graphite iron (CGI) where a high wear resistance and an excellent resistance against thermo cracks are required comprising:a substrate comprising from about 5 to about 7 wt-% Co, from about 140 to about 250 ppm Ti+Ta and balance WC with a weight ratio Ti / Ta of from about 0.8 to about 1.3 anda PVD-layer consisting of AlxTi1−xN, with x=from about 0.50 to about 0.70 and with a thickness of from about 1 to about 10 μm. The invention also relates to a method for making cutting tool inserts and their use.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

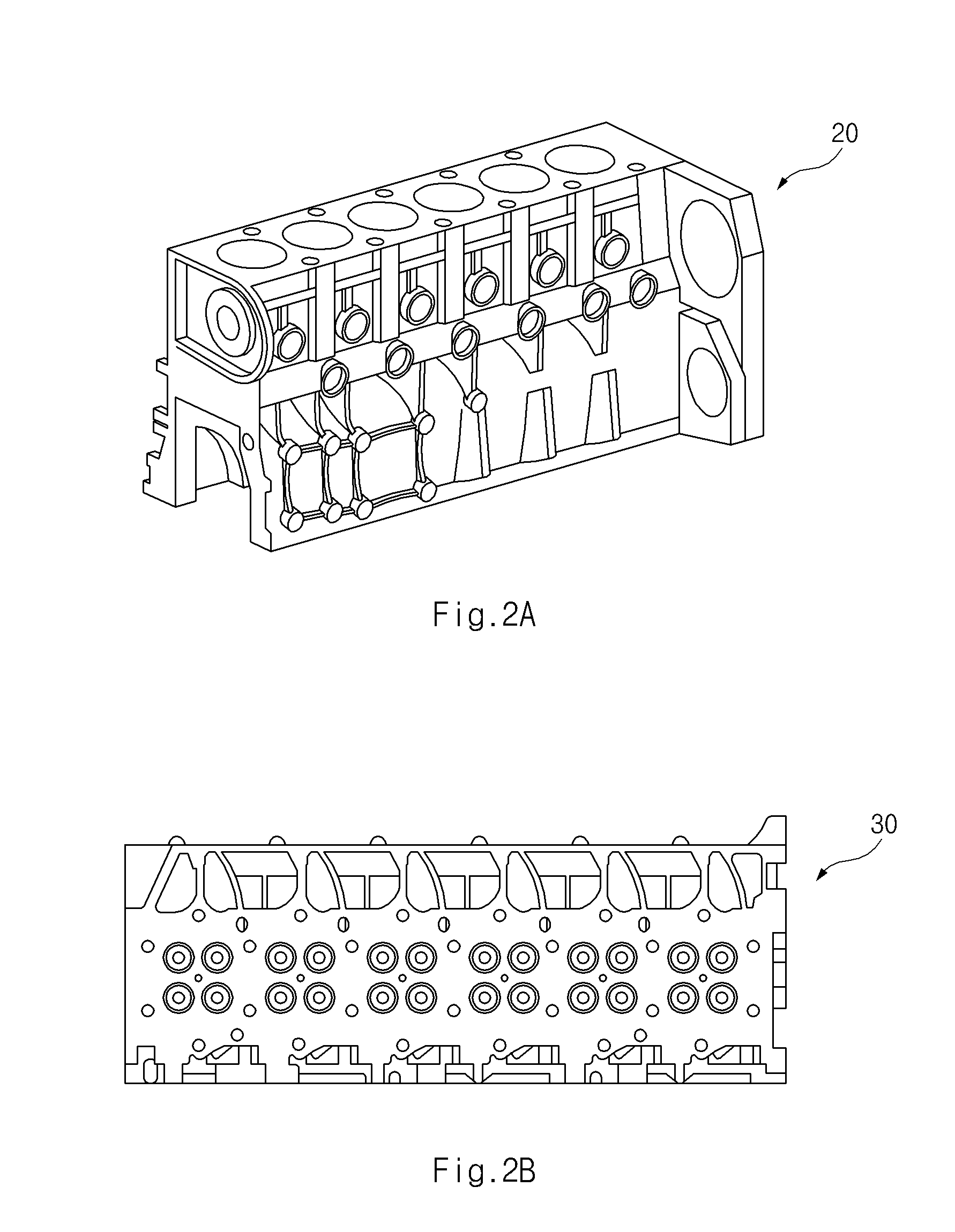

Compacted graphite iron, engine cylinder head and vehicle

A compacted graphite iron having composition comprising: Fe as a major ingredient, C: of about 3.4˜4.2 wt %, Si: of about 1.5˜2.5 wt %, P: 0.10 wt % or less (not including 0), S: of about 0.10 wt % or less (not including 0), Cr: of about 0.10 wt % or less (not including 0), Mn: of about 0.1˜0.6 wt %, Cu: of about 0.2˜1.6 wt %, Sn: of about 0.1 wt % or less (not including 0), Mg: of about 0.05 wt % or less (not including 0), Mo: of about 0.05˜0.5 wt %, at least one ingredient of V: of about 0.05˜0.5 wt % and Ti: of about 0.05˜0.5 wt %, and other inevitable impurities; an engine cylinder head; and a vehicle.

Owner:HYUNDAI MOTOR CO LTD

Coated inserts for milling

The present invention discloses coated cemented carbide milling inserts, particularly useful for rough and semifinishing milling of grey cast iron, highly alloyed grey cast iron, compacted graphite iron (CGI) with or without cast skin under dry conditions. The inserts are characterised by a WC-Co cemented carbide with a low content of cubic carbides and a W-alloyed binder phase and a coating including an inner layer of TIC x N y with columnar grains followed by a wet blasted layer of ±-Al 2 O 3 . on the rake face and coloured top layer on the clearance side. The invention also relates to a method of making cutting tool inserts according to the above.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Cgi cast iron and a production method for the same

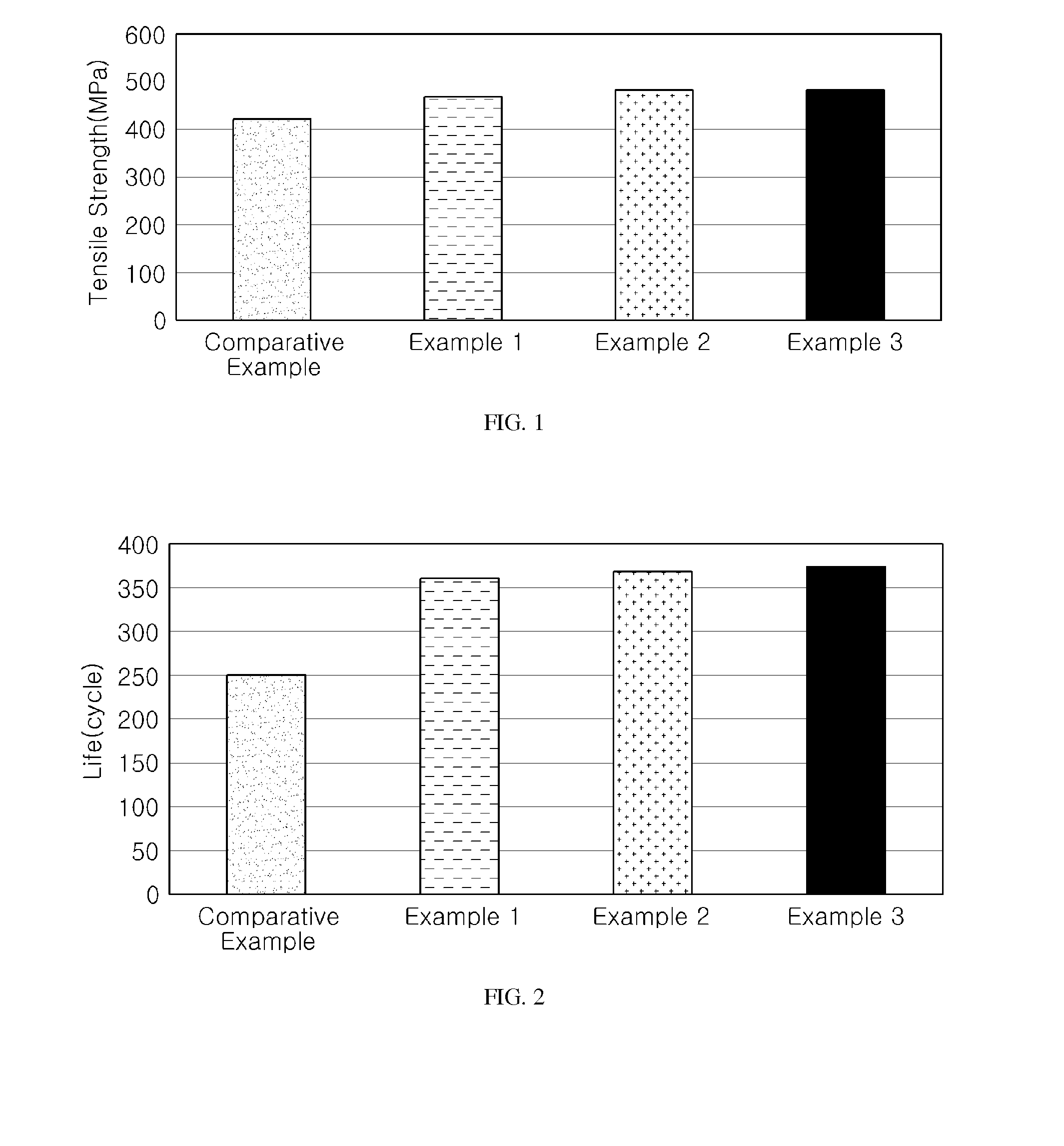

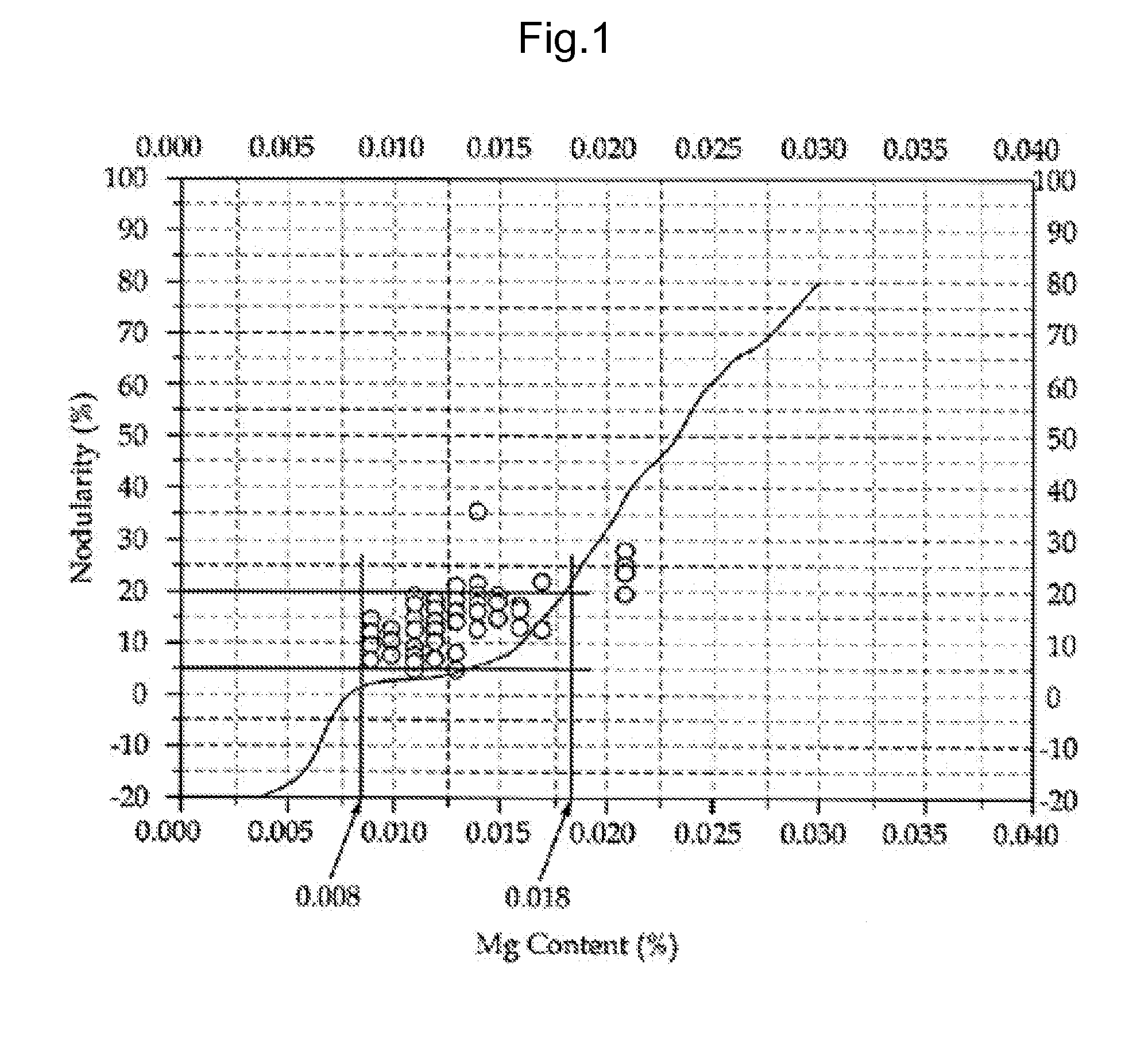

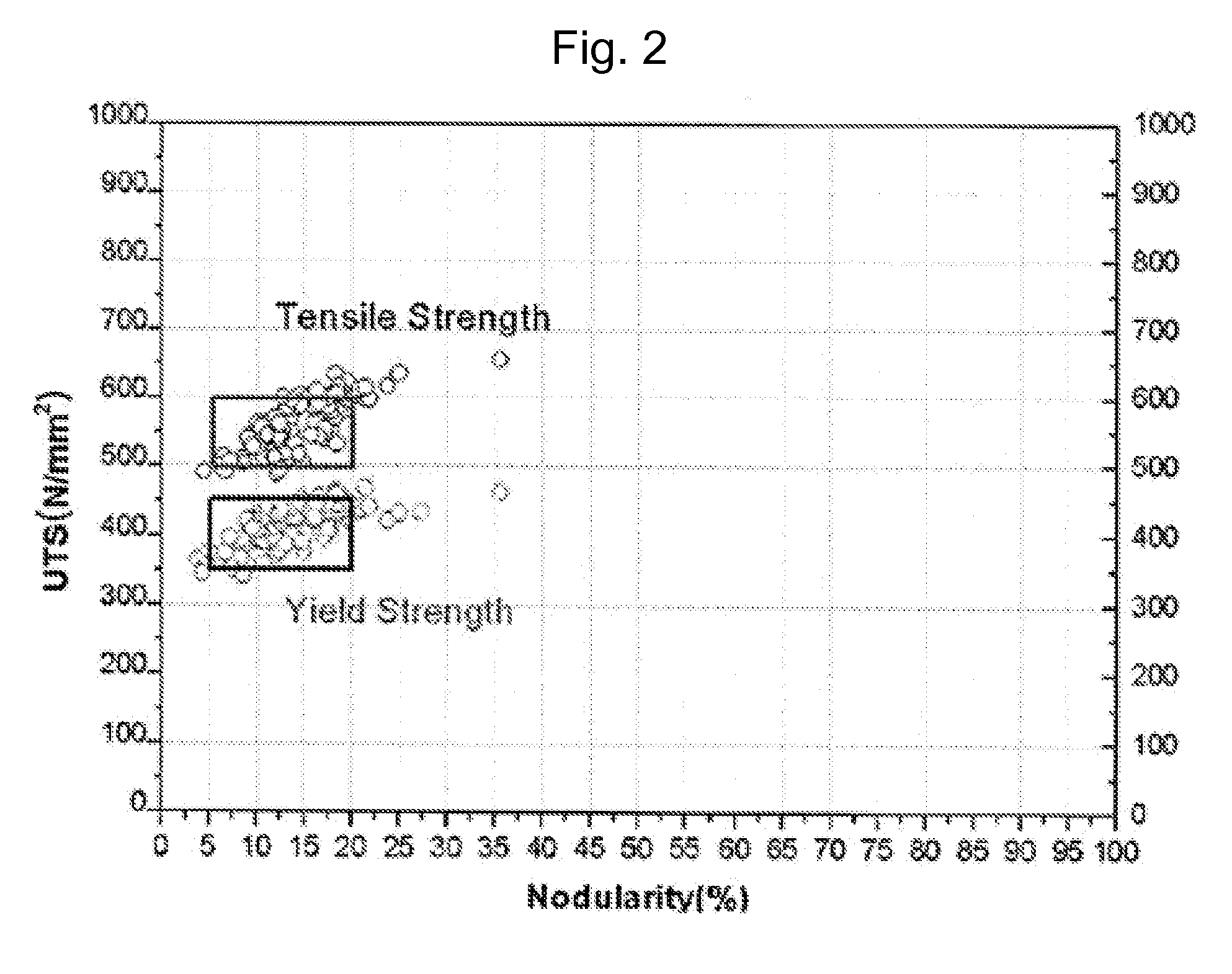

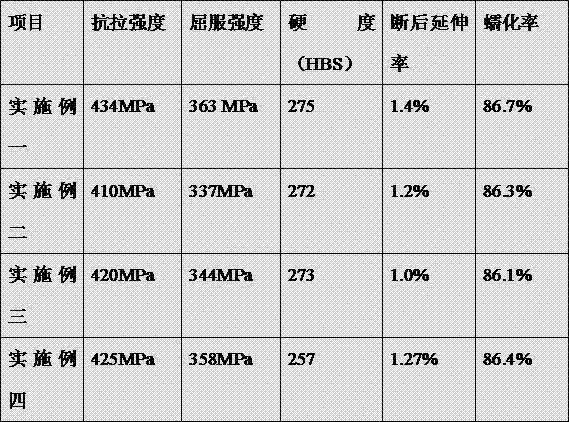

The present invention relates to cast iron, and more specifically relates to CGI (Compacted Graphite Iron) cast iron in which the amounts of carbon (C), silicon (Si), manganese (Mn), copper (Cu), tin (Sn) and magnesium (Mg) are controlled during production, thereby improving the castability and also giving a stable tensile strength and yield strength and giving an appropriate range of hardness, and also to a production method for the same.

Owner:DOOSAN INFRACORE CO LTD

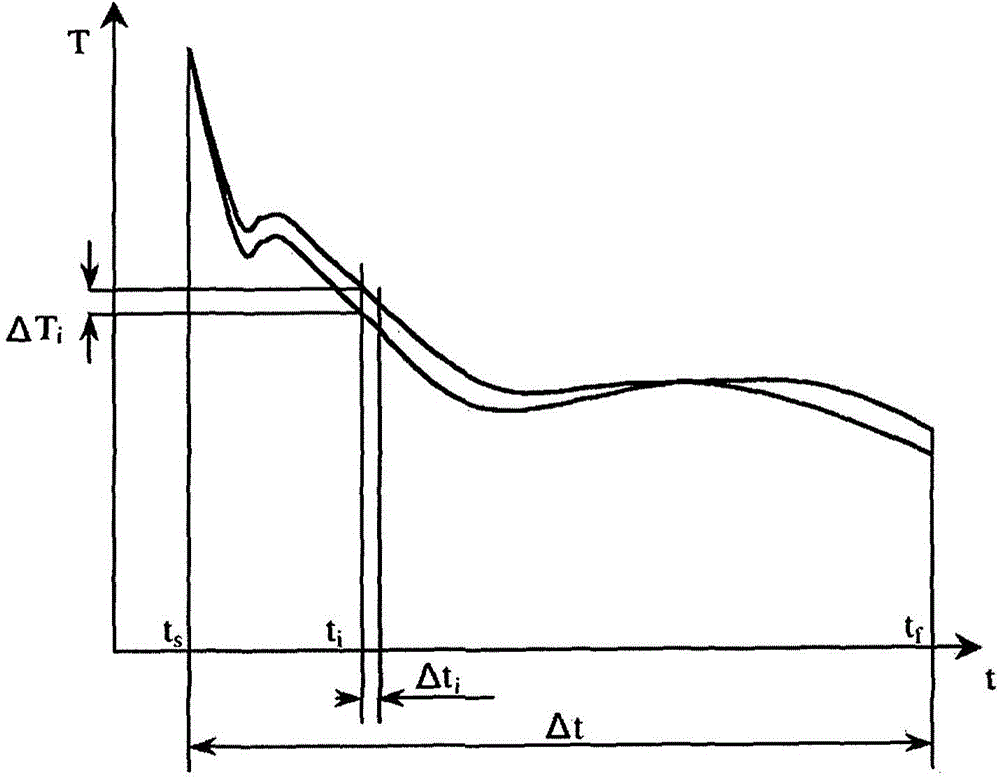

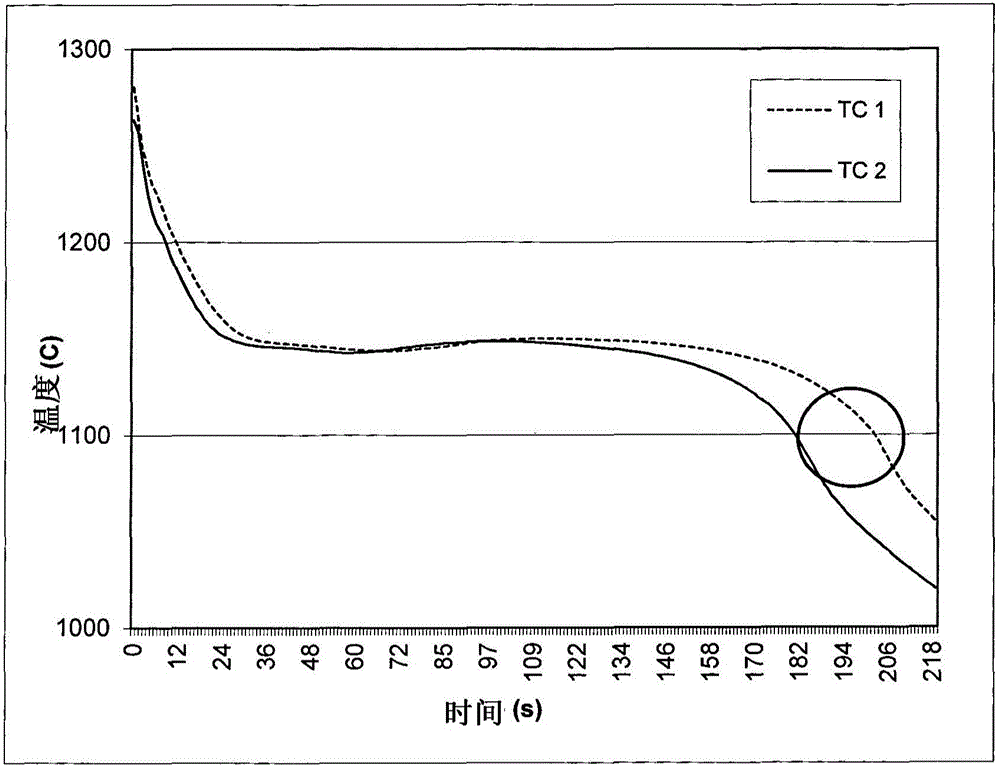

Method of analysing iron melt

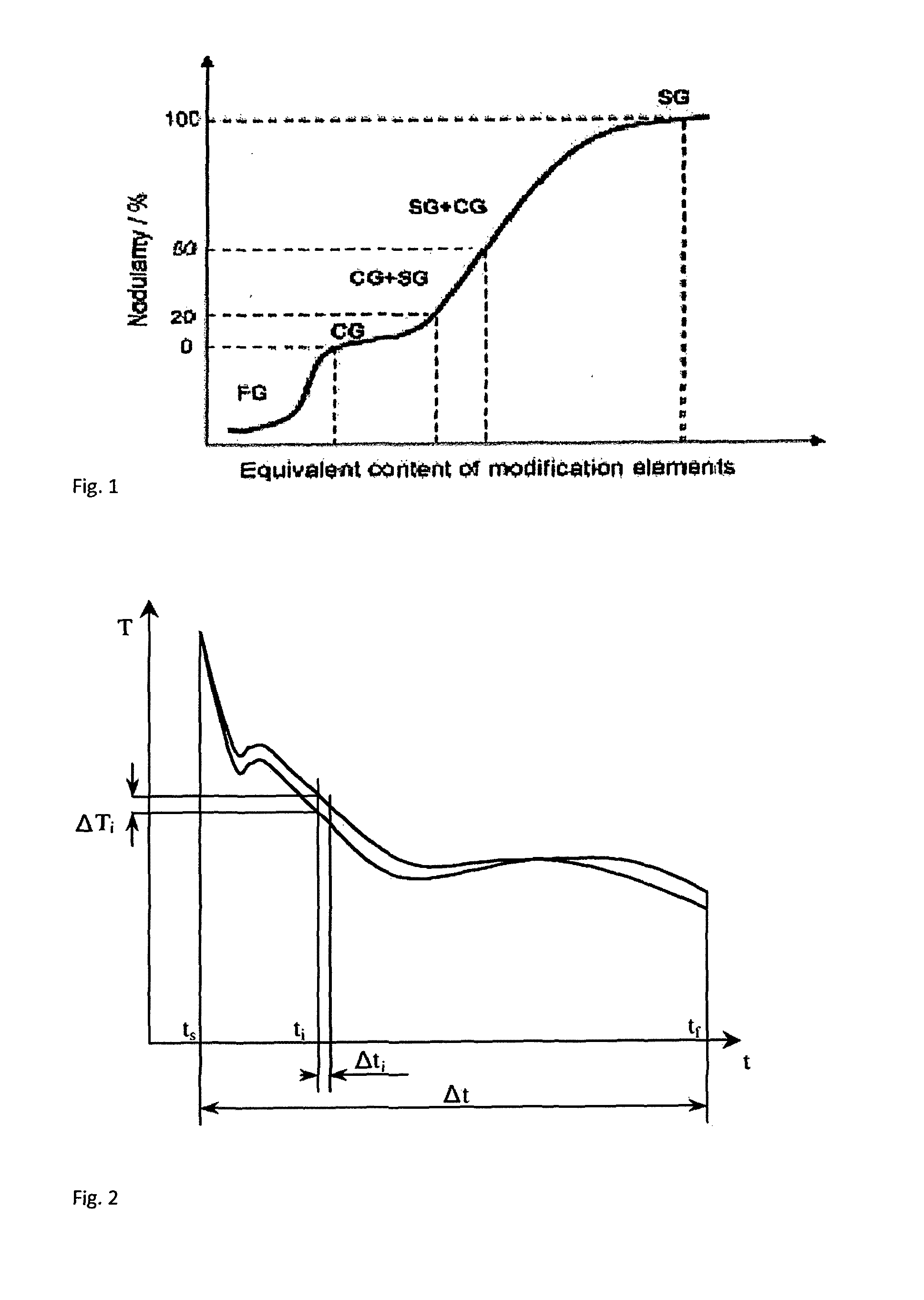

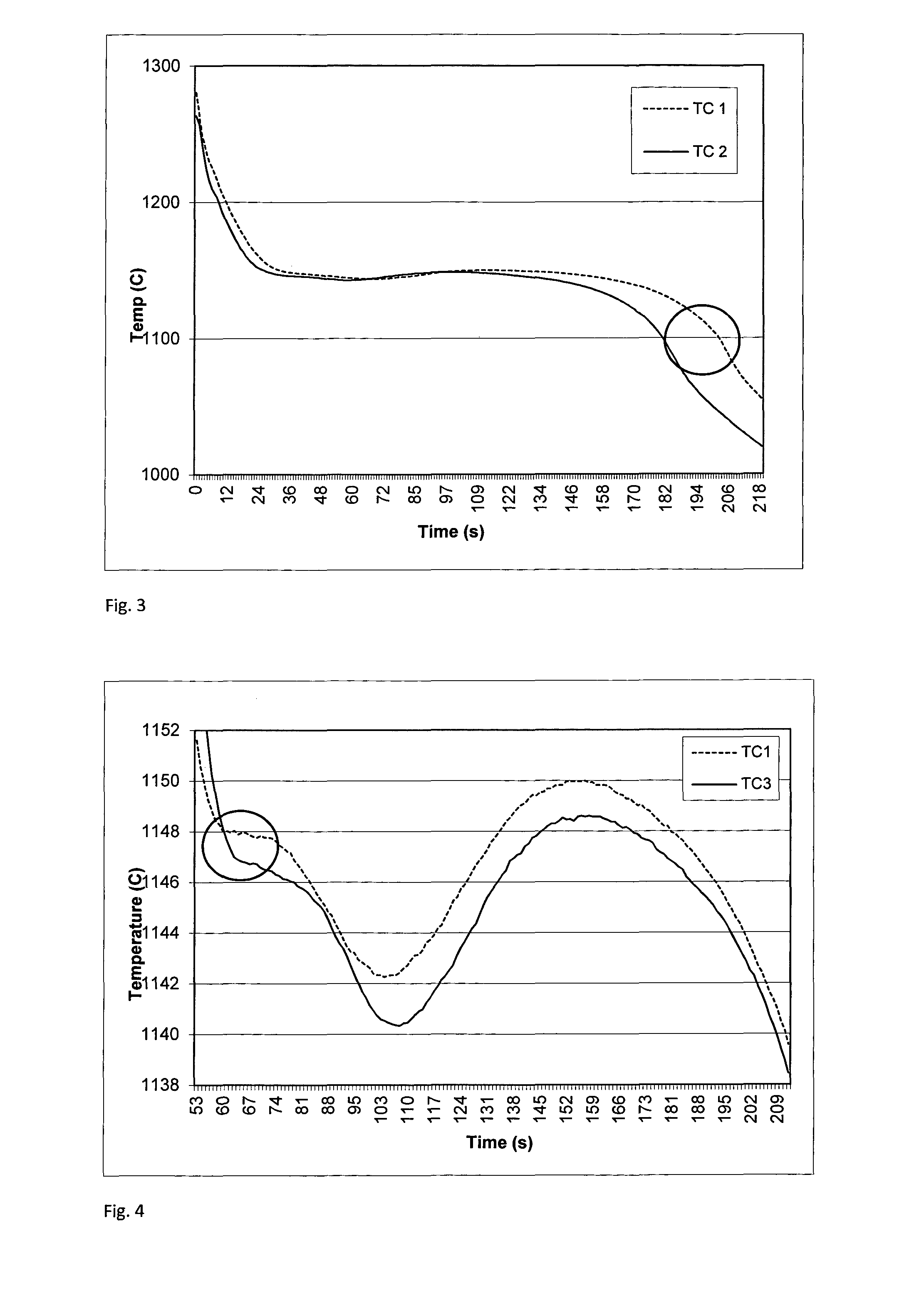

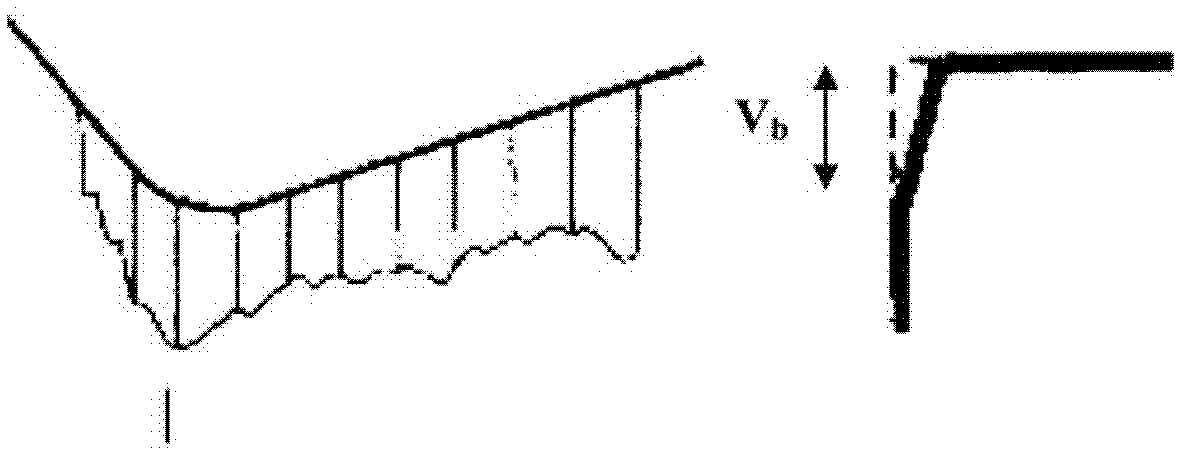

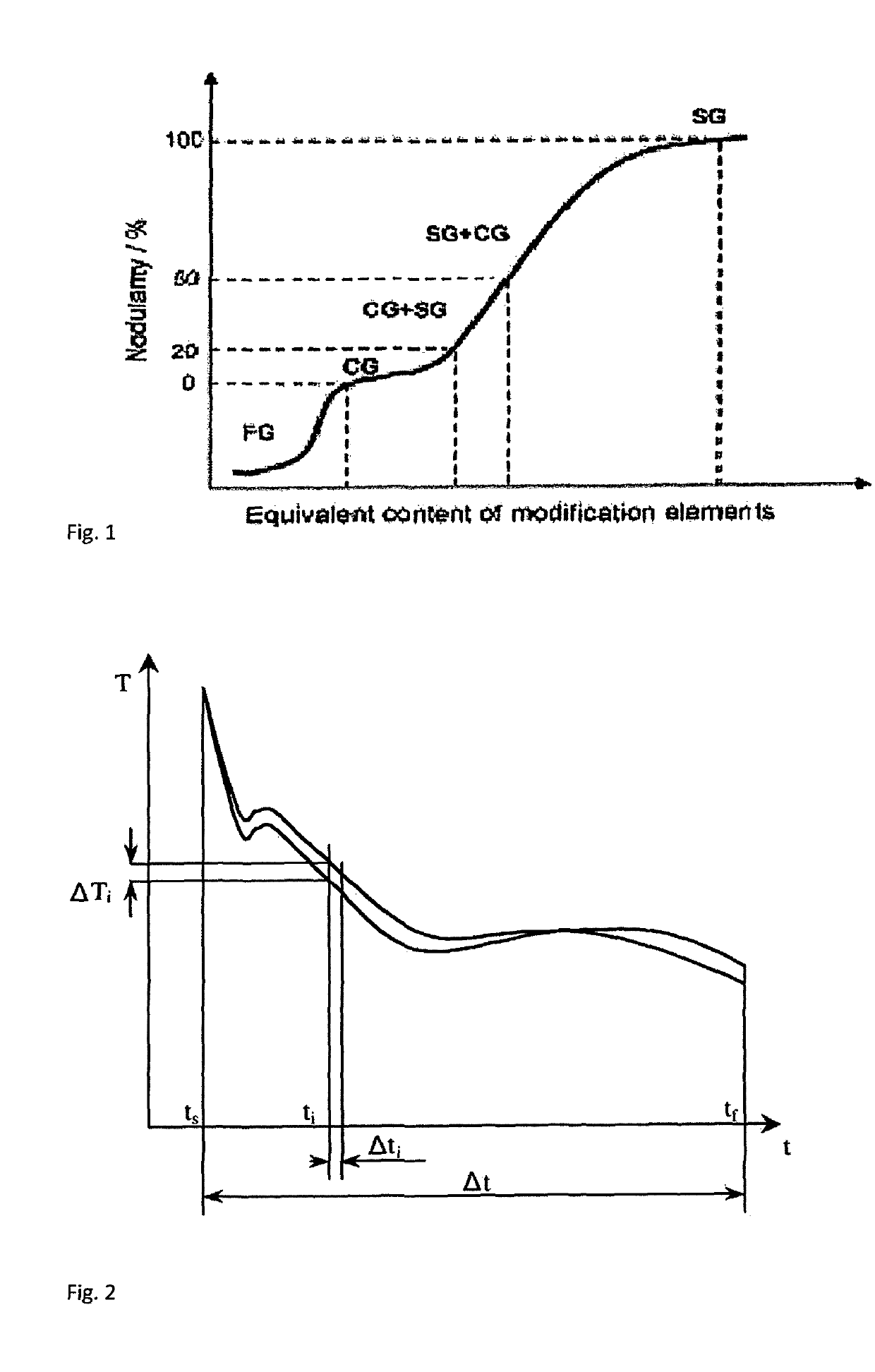

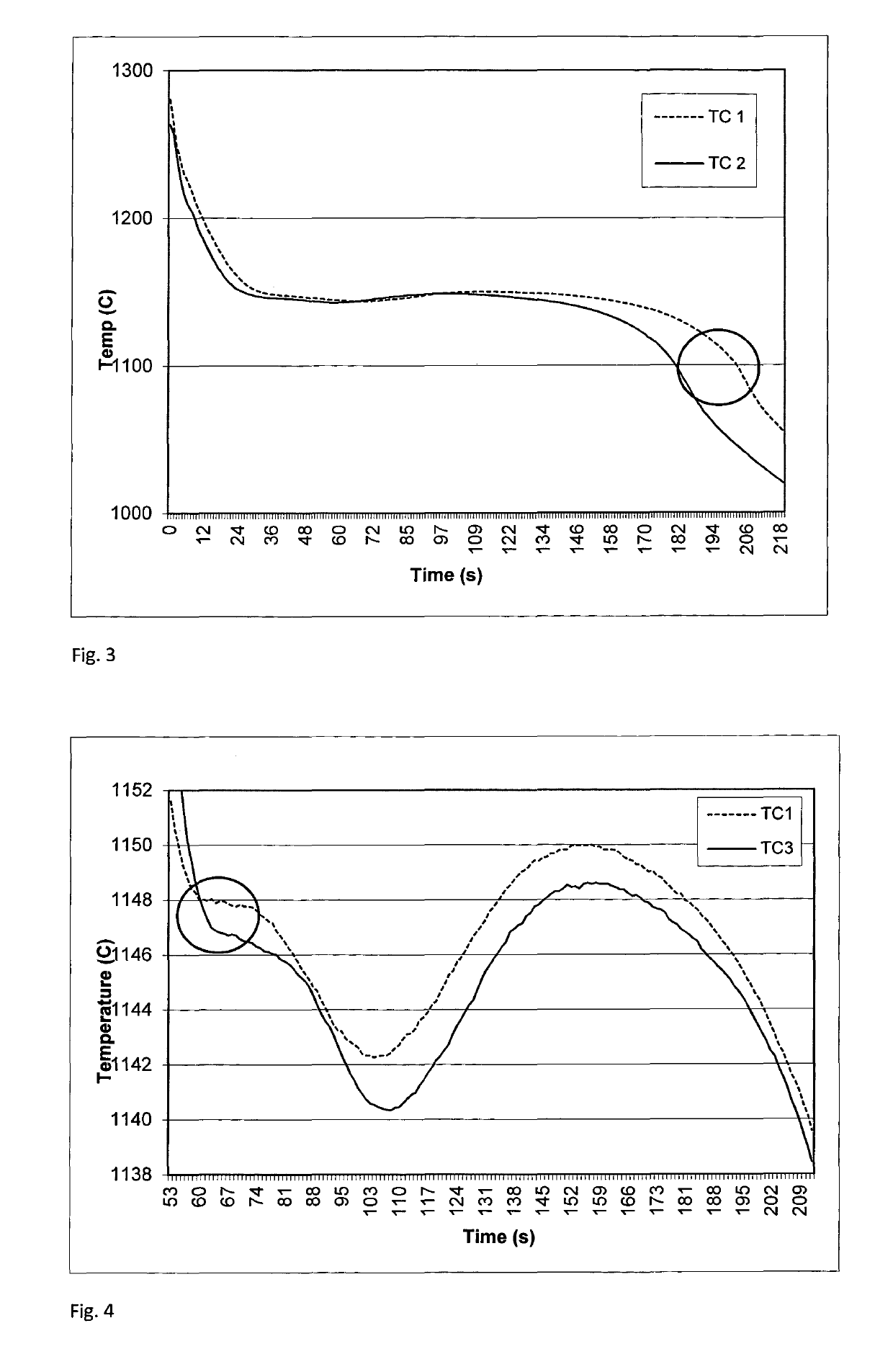

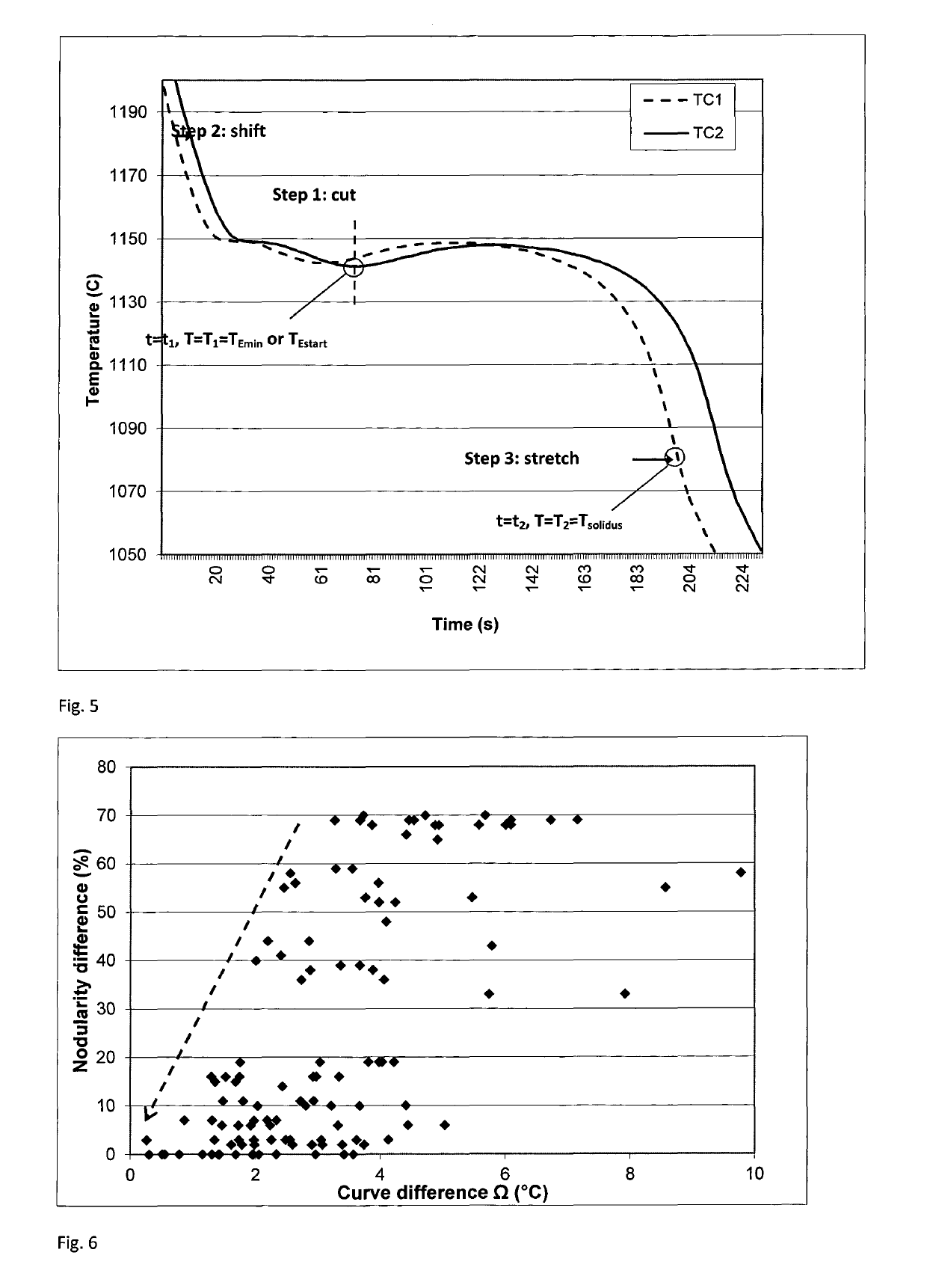

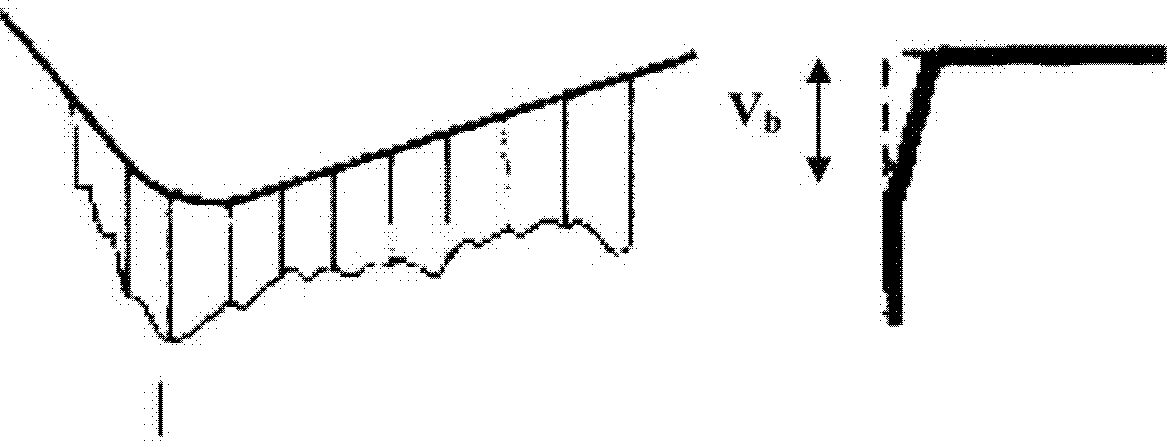

ActiveCN104870996ATesting metalsInvestigating phase/state changeCompacted graphite ironTemperature curve

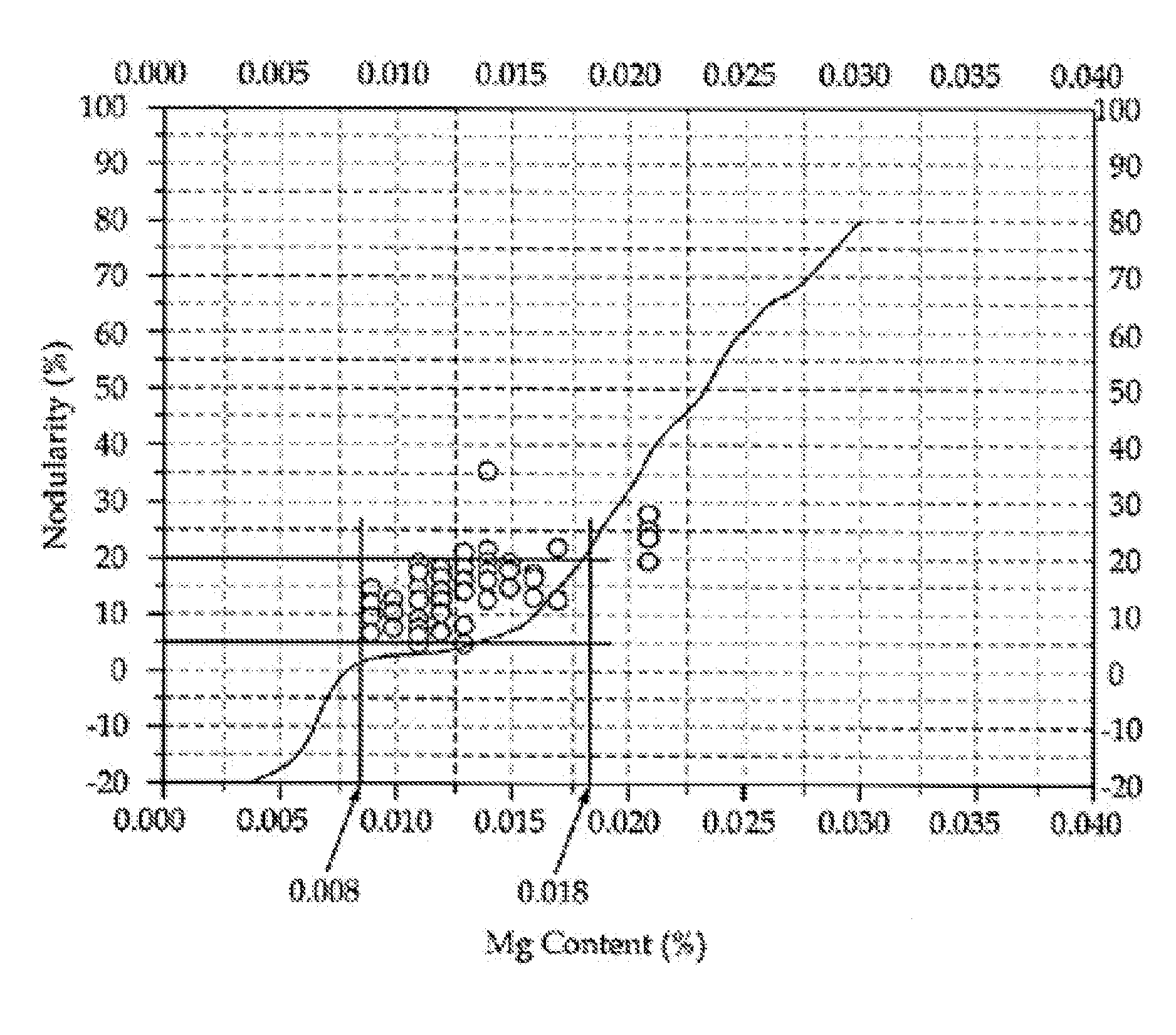

A method of analysing an iron melt for producing compacted graphite iron, comprising the steps of: receiving thermal data from cooling of a cast melt comprising a predetermined amount of carbon, magnesium, balance iron and unavoidable impurities, plotting the temperature of the cast melt against time such that a plotted time-temperature curve is generated, comparing the generated plotted curve to at least one reference curve, said reference curve representing a corresponding thermal analysis of another melt, the resulting nodularity of which is known, for the purpose of predicting the nodularity of the cast melt on basis of the difference between said curves. The comparison on which the nodularity is predicted is performed along each of said curves for a time interval t1-t2 corresponding to a temperature interval T1-T2, where T1 is in the range of TEstart - TEmim where TEstart is the temperature of beginning formation of graphite in the melt and TEmin is a minimum temperature before start of eutectic recalescence in the melt, and T2 is in the range of Tsolidus-(Tsolidus-20oC), and other time intervals in said curves are excluded from said comparison.

Owner:VOLVO TRUCK CORP

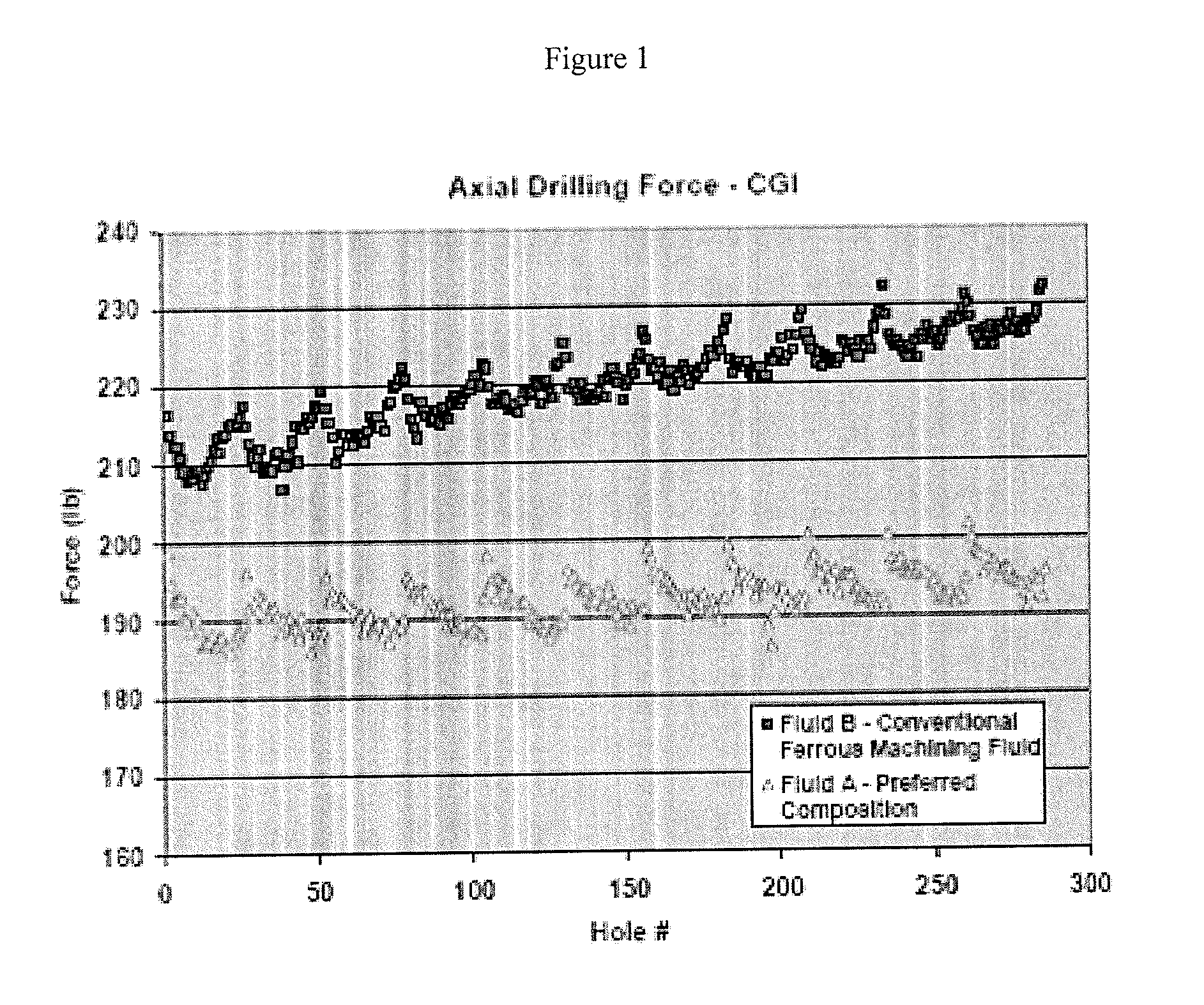

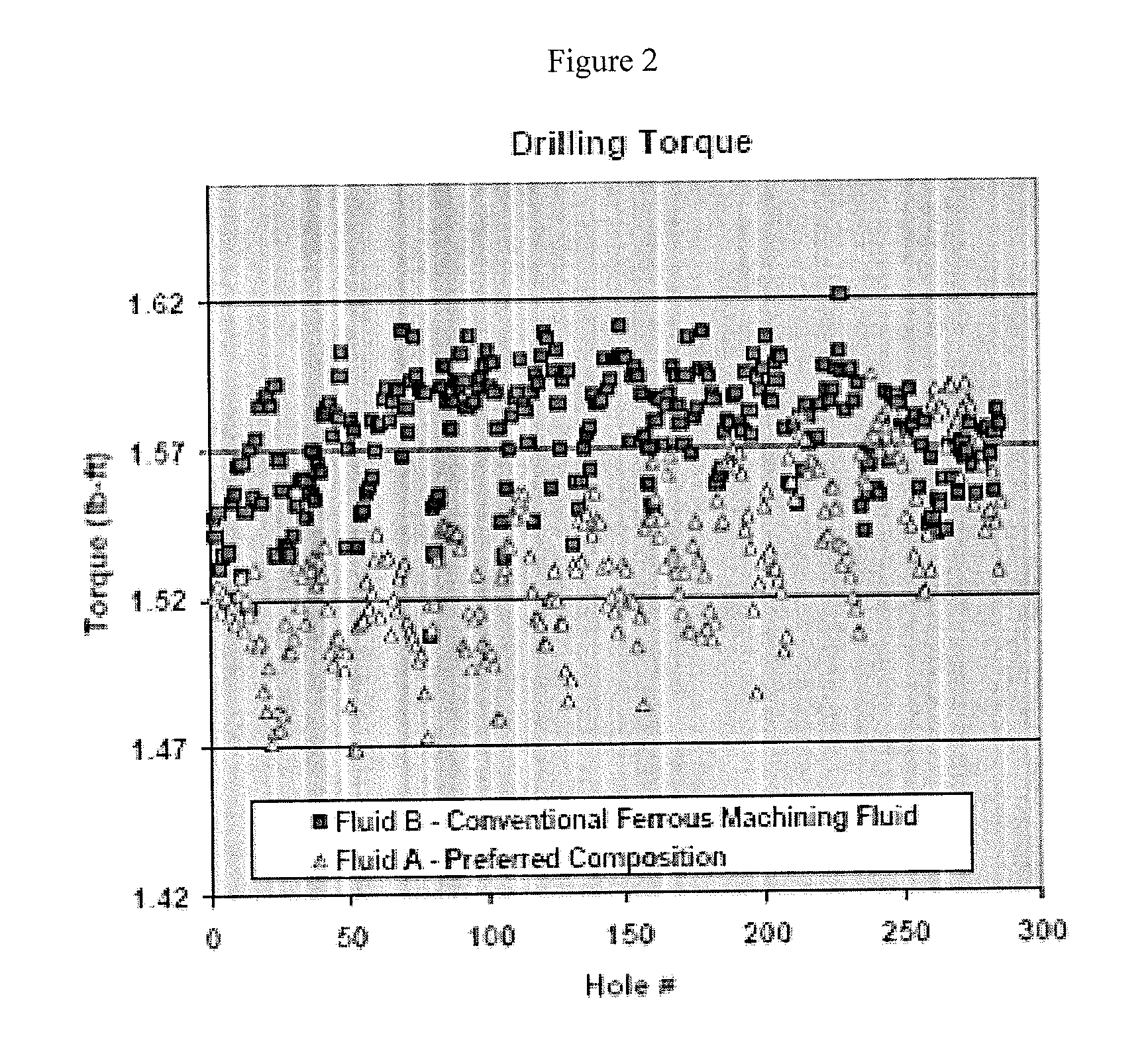

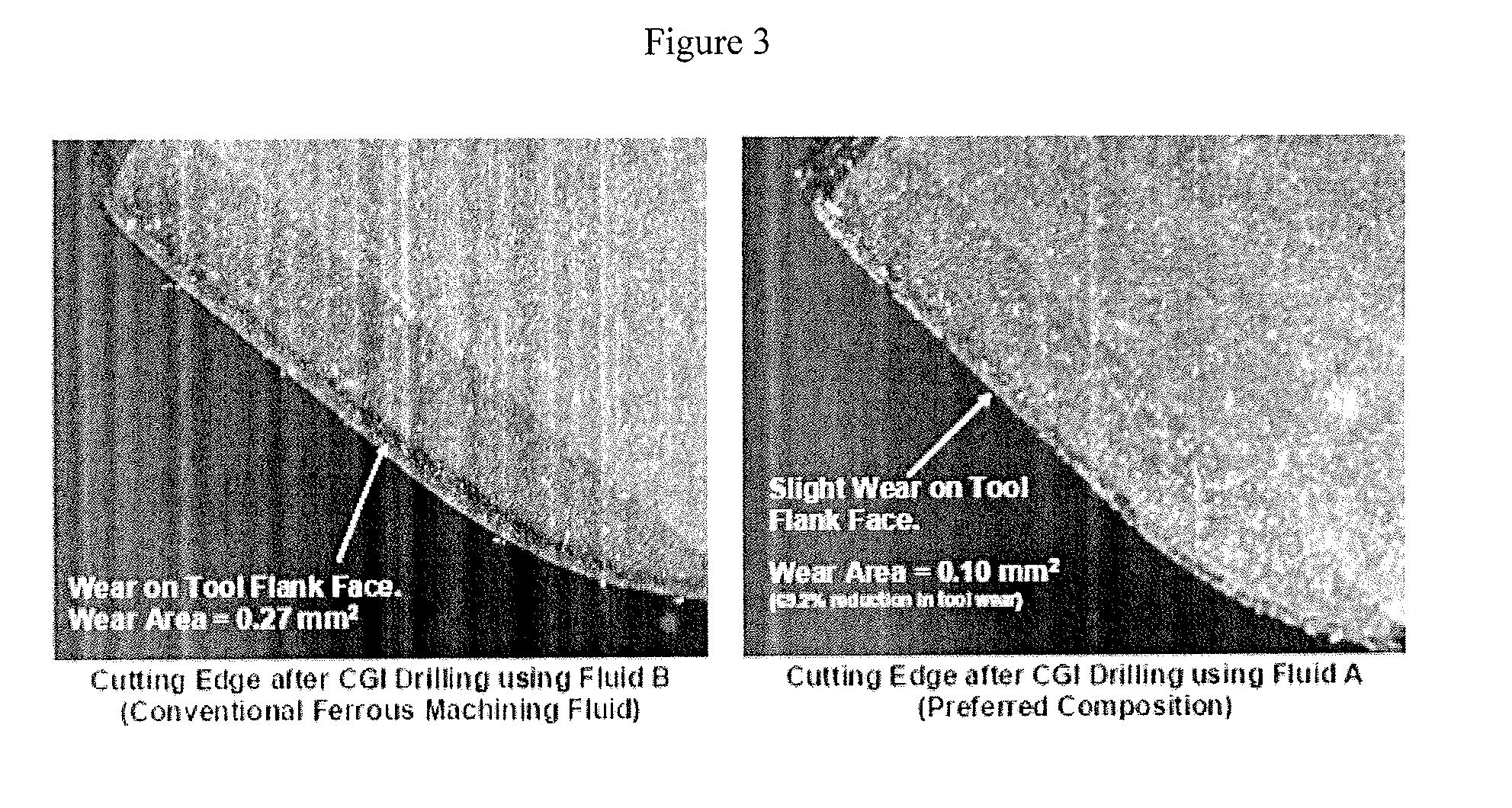

Metalworking fluid composition and method for its use in the machining of compacted graphite iron

Owner:QUAKER CHEMICAL CORPORATION

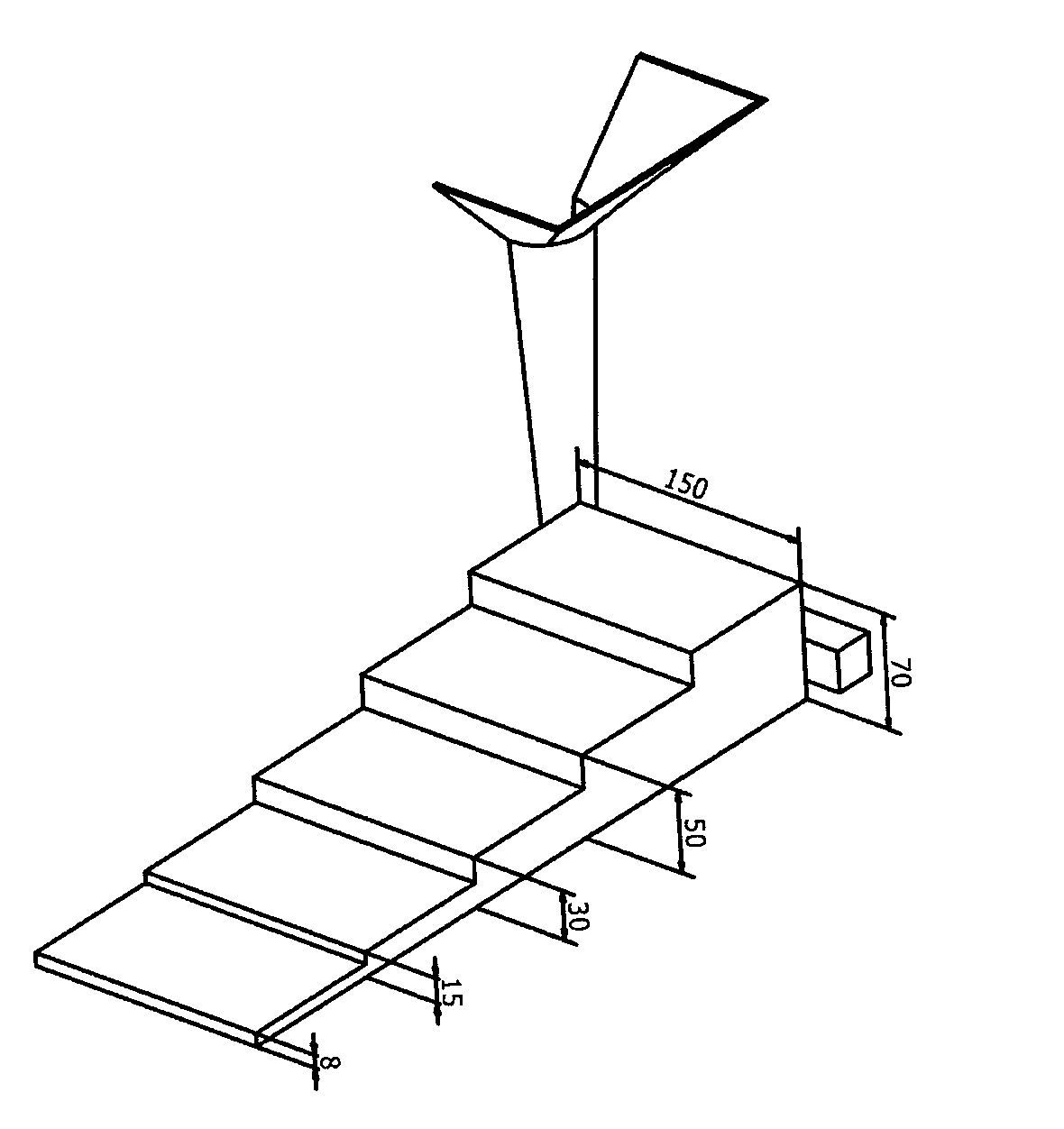

Process for Production of Compacted Graphite Iron

InactiveUS20090183848A1Lower magnesium levelsCasting defects such as dross and micro-shrinkage are minimizedCompacted graphite ironCerium

A process for production of compacted graphite iron using in-mould addition of a magnesium alloy is disclosed. The process is characterised by a step of pre-treating the base iron in a ladle or in a furnace with an alloy containing cerium and performing a structure forming treatment in a reaction chamber in the mould using an alloy containing magnesium and lanthanum.

Owner:NOVACAST

Cgi cast iron and production method for the same

InactiveUS20120301346A1Limited amountStable tensile strengthMolten metal pouring equipmentsMolten metal supplying equipmentsMagnesiumCompacted graphite iron

Owner:DOOSAN INFRACORE CO LTD

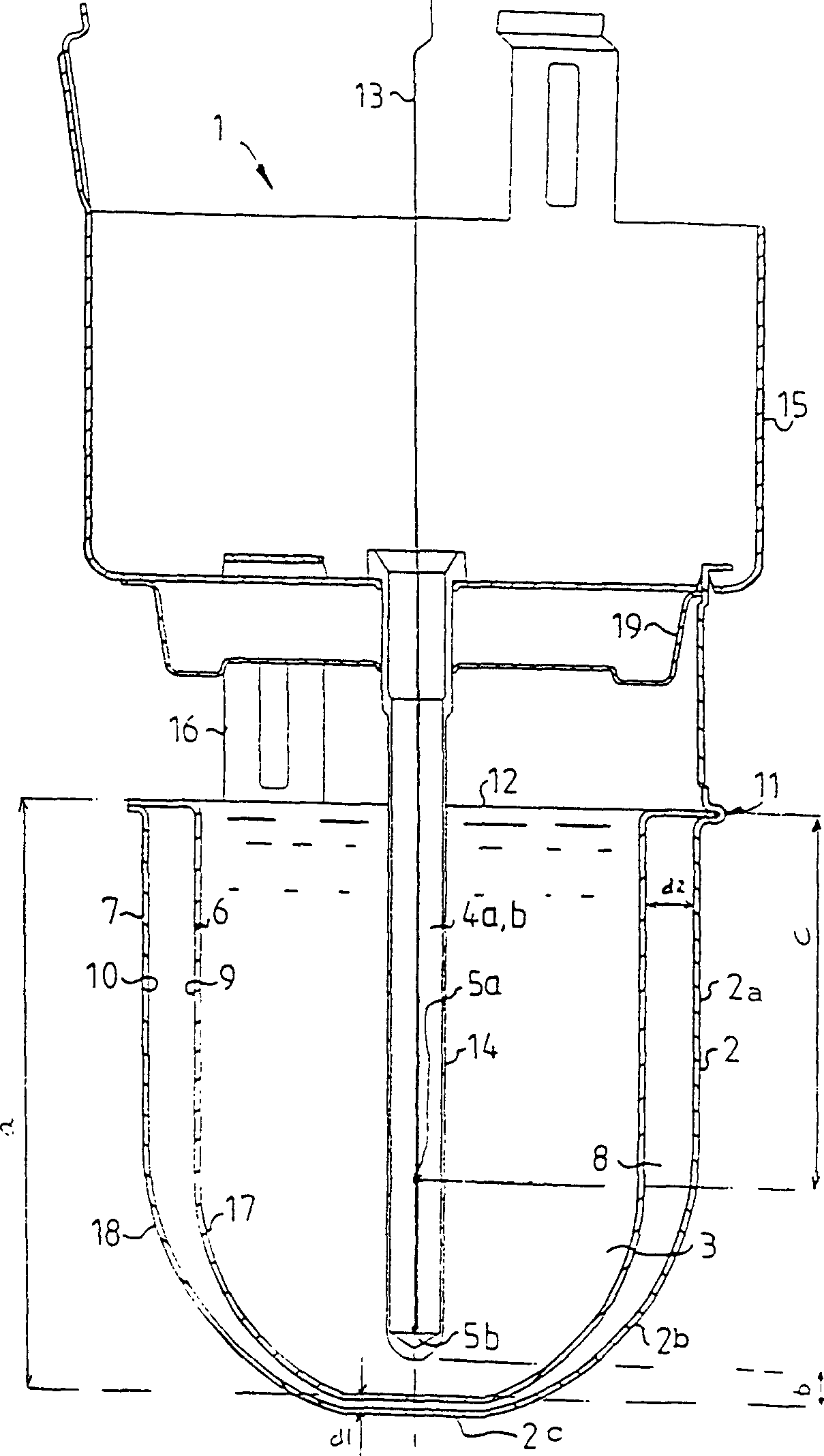

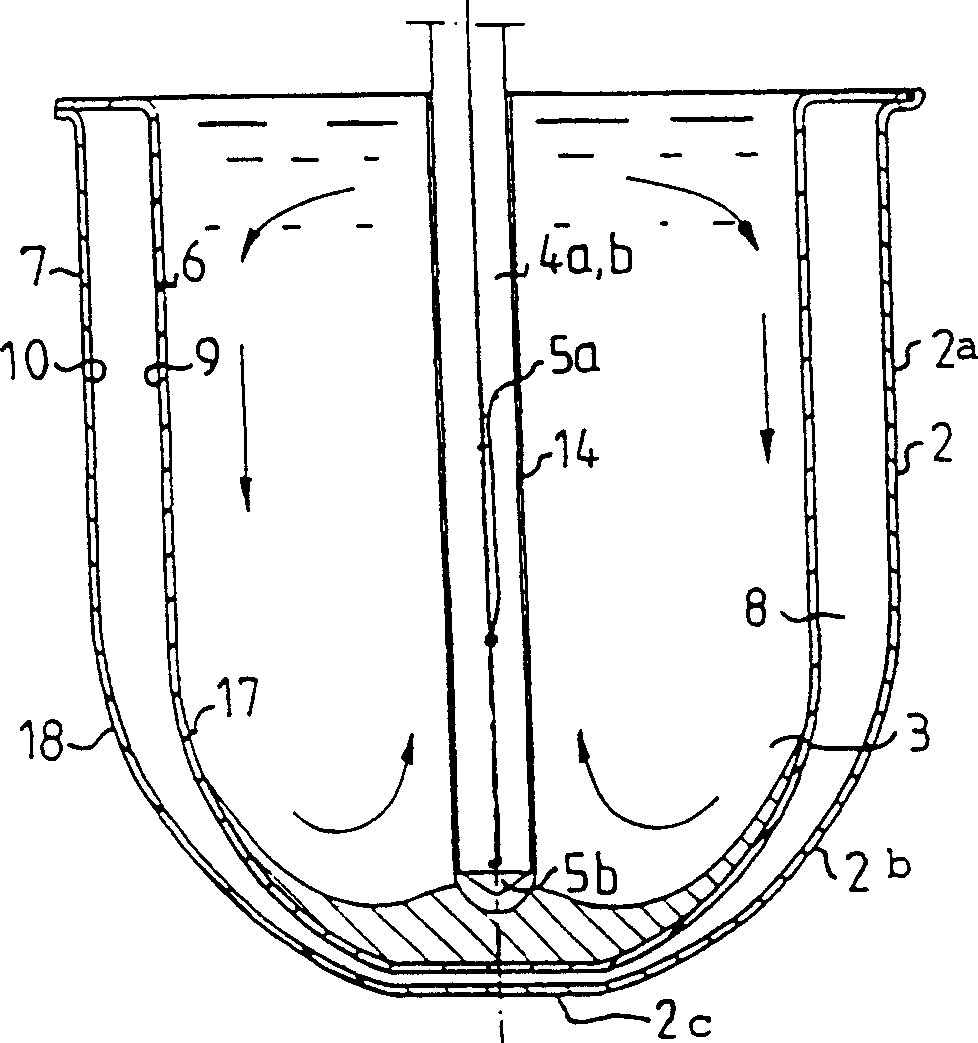

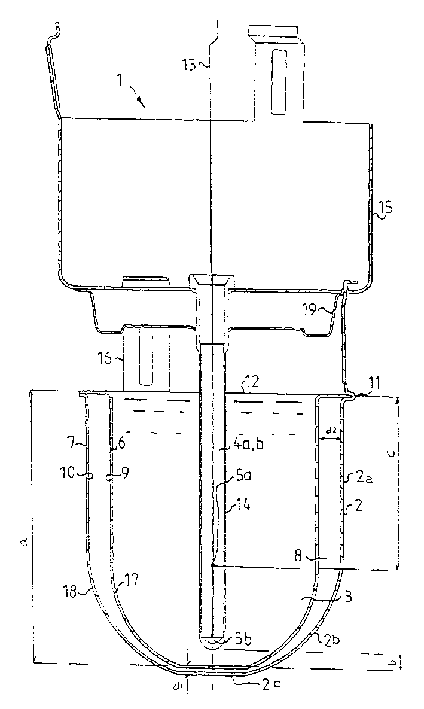

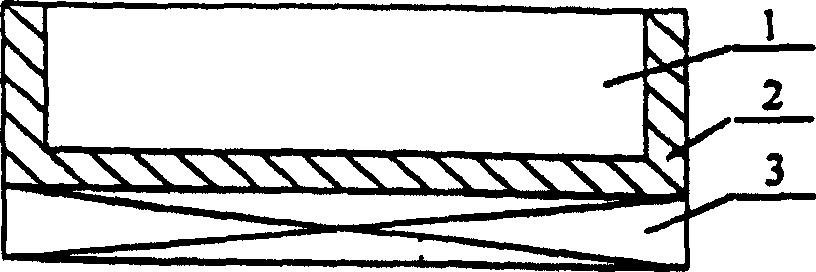

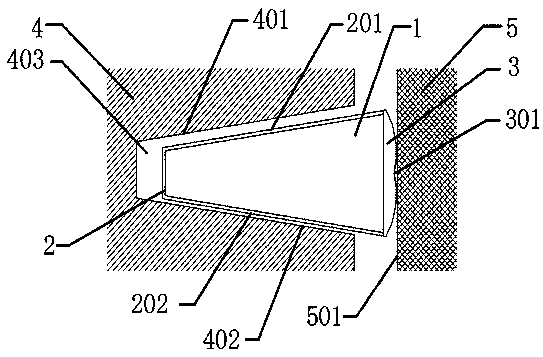

A sampling device for thermal analysis

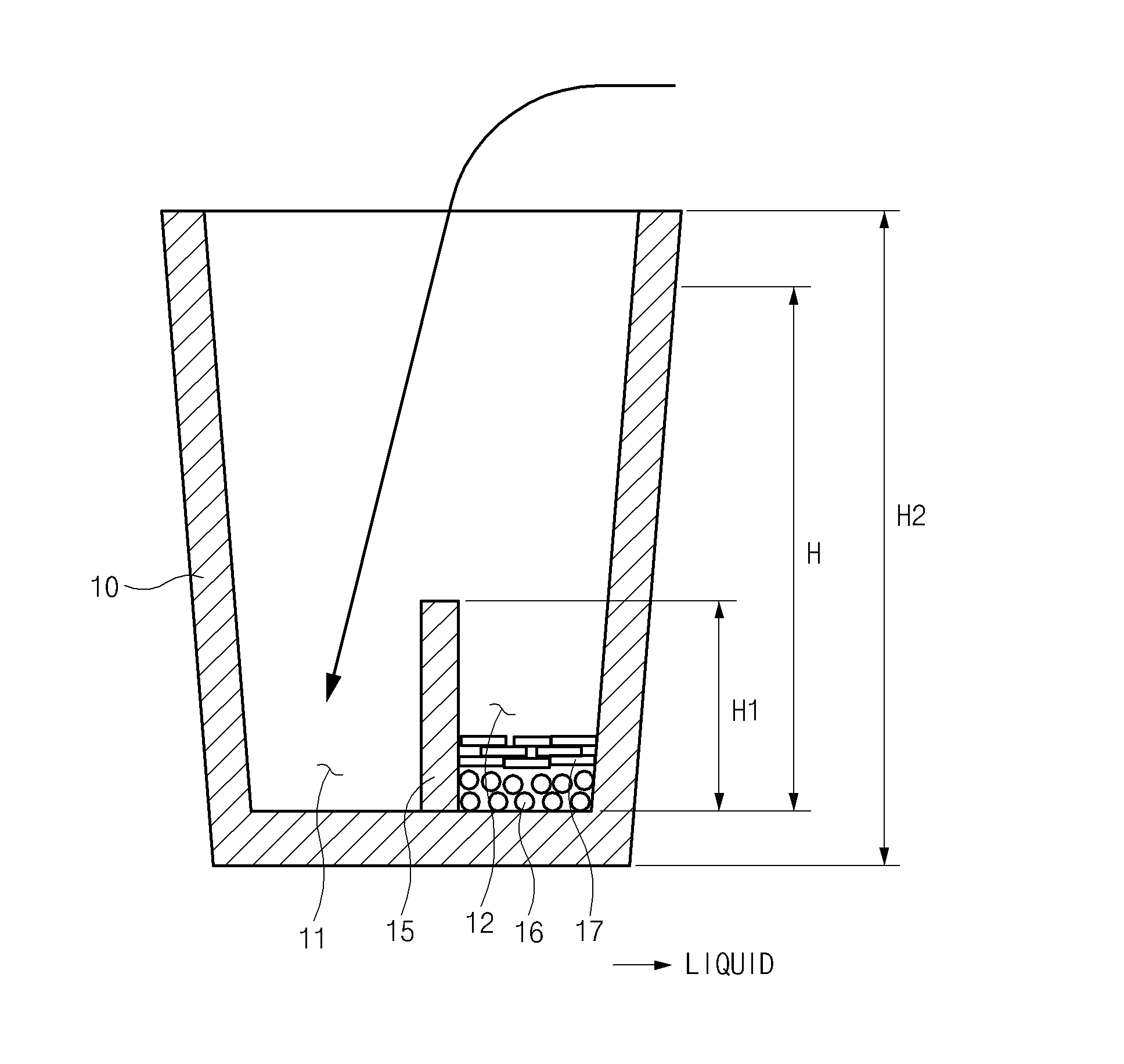

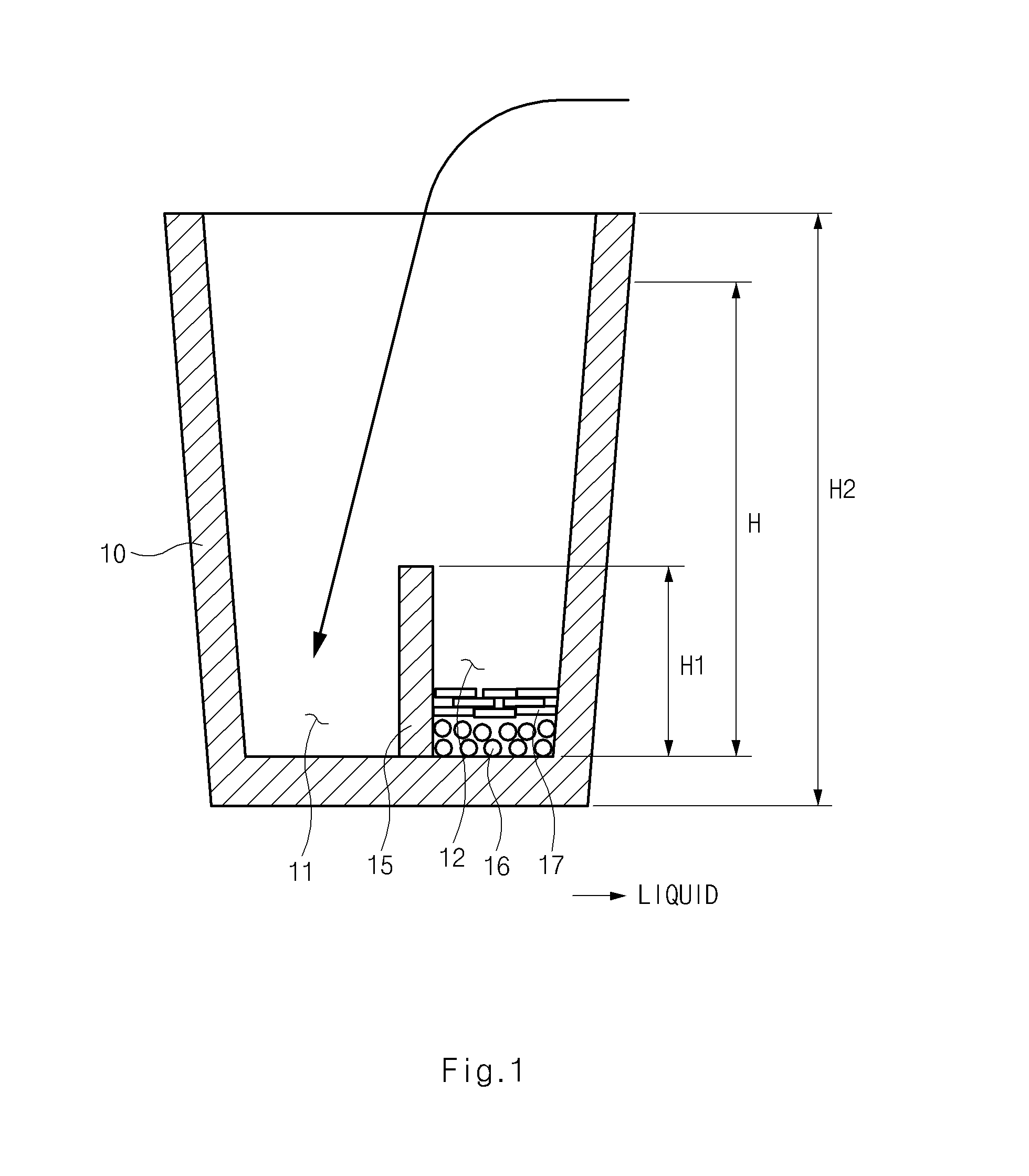

InactiveCN1173160CPrecise positioningAvoid driftingWithdrawing sample devicesTesting metalsCompacted graphite ironLiquid state

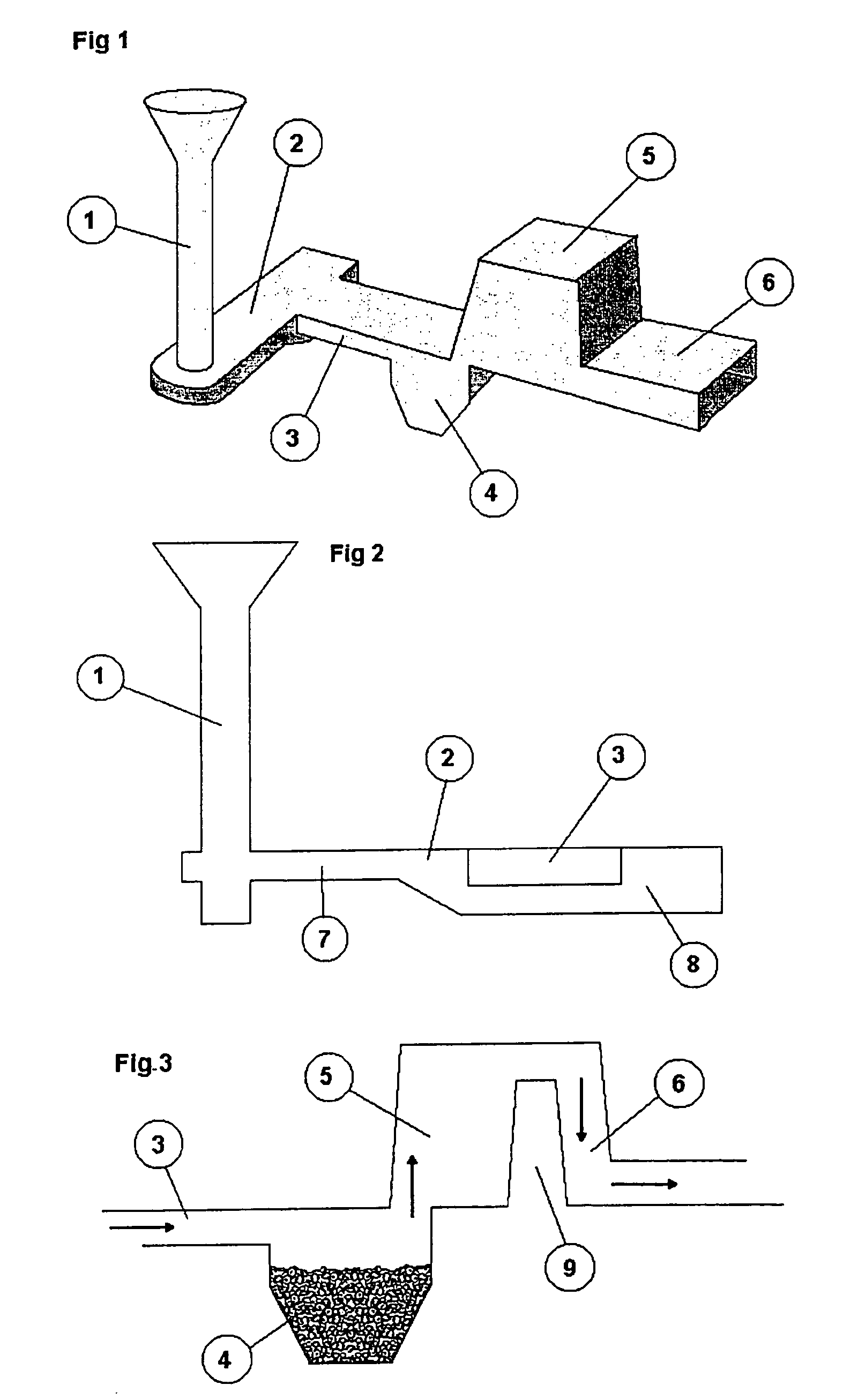

A sampling device for thermal analysis of solidifying metal, particularly compacted graphite iron is disclosed, comprises a container (2) essentially cylindrical, open at the top intended to be immersed down into and filled with a liquid metal to be analyzed, at least one temperature responsive sensor member (4), preferably two, a protective tubing (14) concentrically enclosing said sensor(s), arranged inside said container (2) and supported by a sensor support member (15) arranged above said container and attached to the container (2) by legs (16) and intended to guide and keep the sensors (4) in position, when immersed in the solidifying metal sample quantity (3) during analysis, said container (2) comprises an interior surface (17) intended to contact the sample quantity (3) during analysis, and an exterior surface (18) intended to contact the ambient atmosphere, said surfaces (17 and 18) being joined at the mouth (12) of the container (2), being equally spaced forming a closed insulating space (8), wherein said container (2) has a substantially semi-spherical bottom part (2b), having a concentrically arranged flattened part (2c).

Owner:SINTERCAST

Process for producton of compacted graphite iron

A process for production of compacted graphite iron using in-mould addition of a magnesium alloy is disclosed. The process is characterised by a step of pre-treating the base iron in a ladle or in a furnace with an alloy containing cerium and performing a structure forming treatment in a reaction chamber in the mould using an alloy containing magnesium and lanthanum.

Owner:NOVACAST

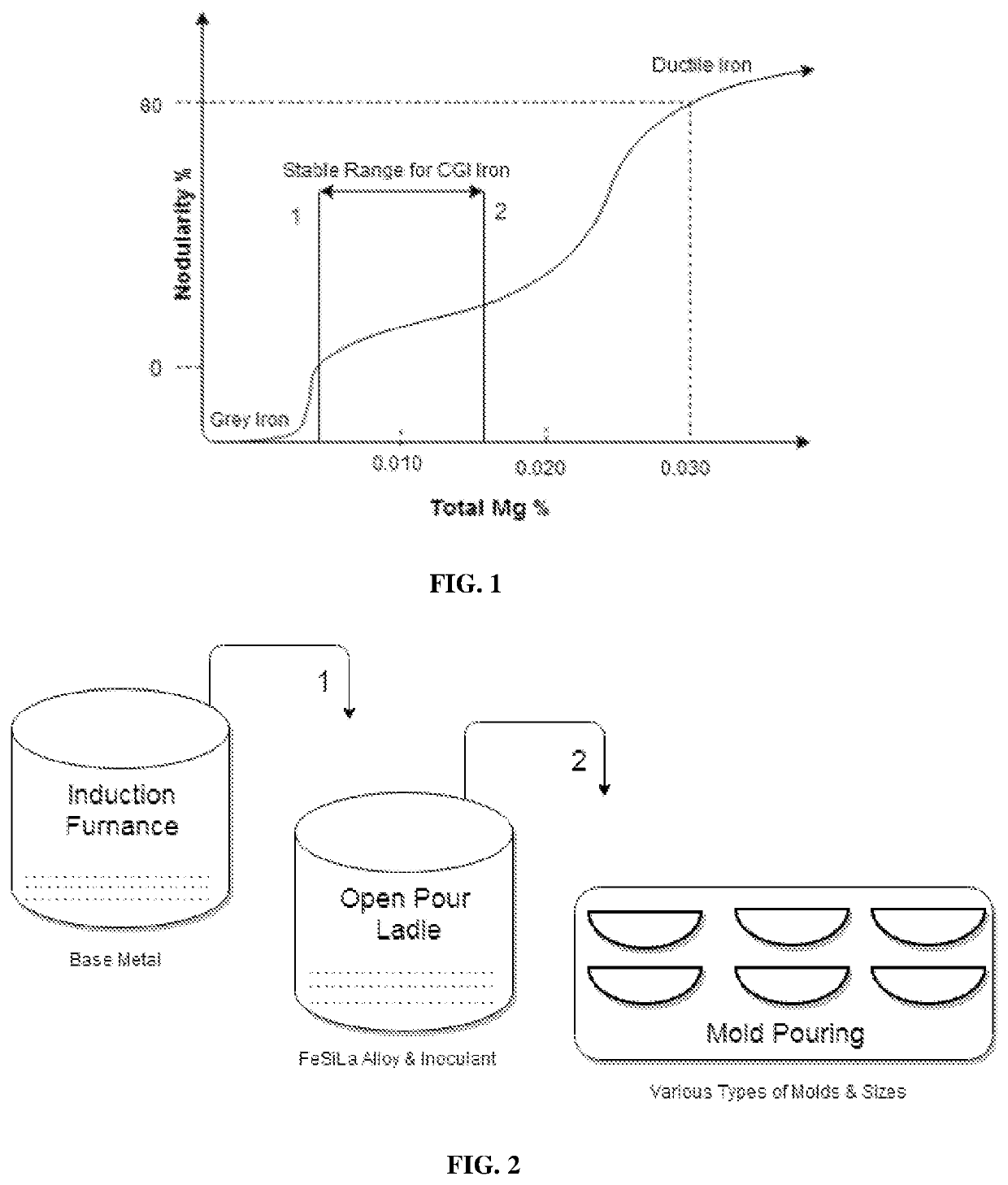

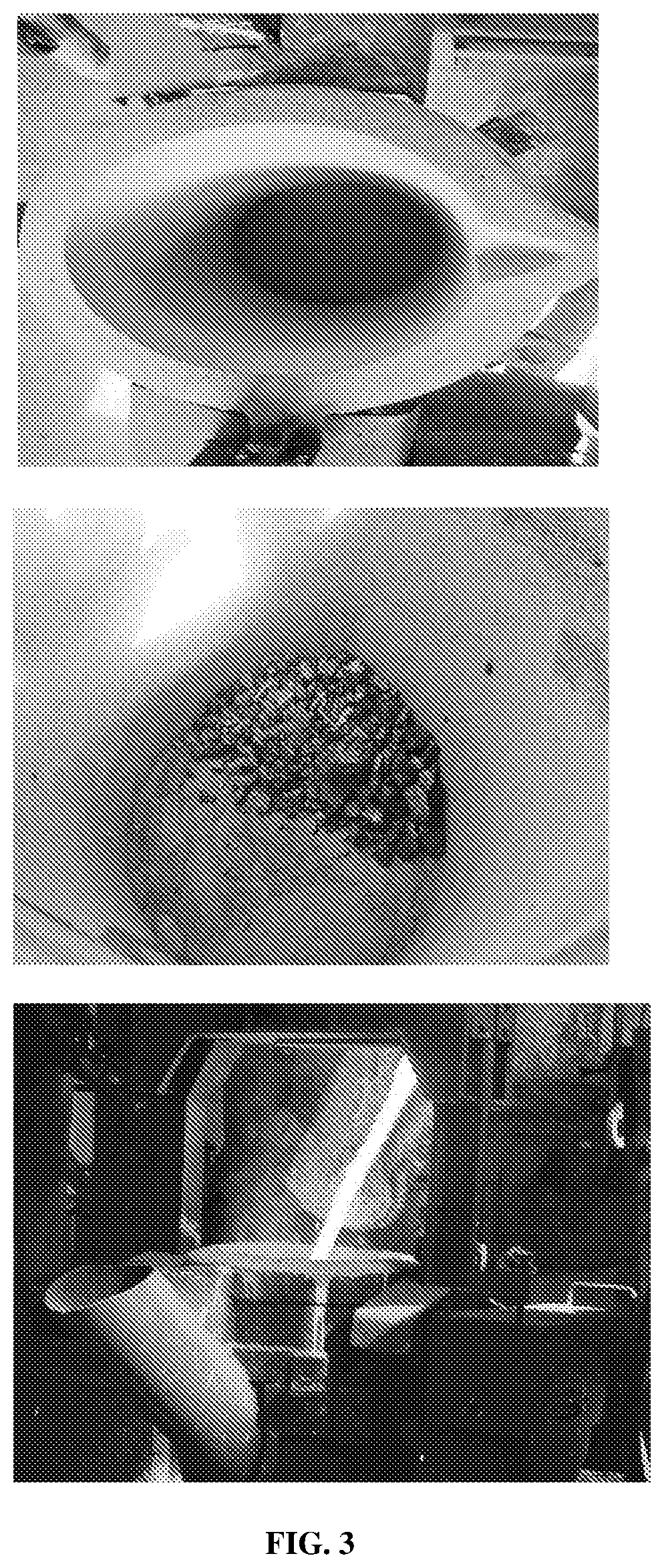

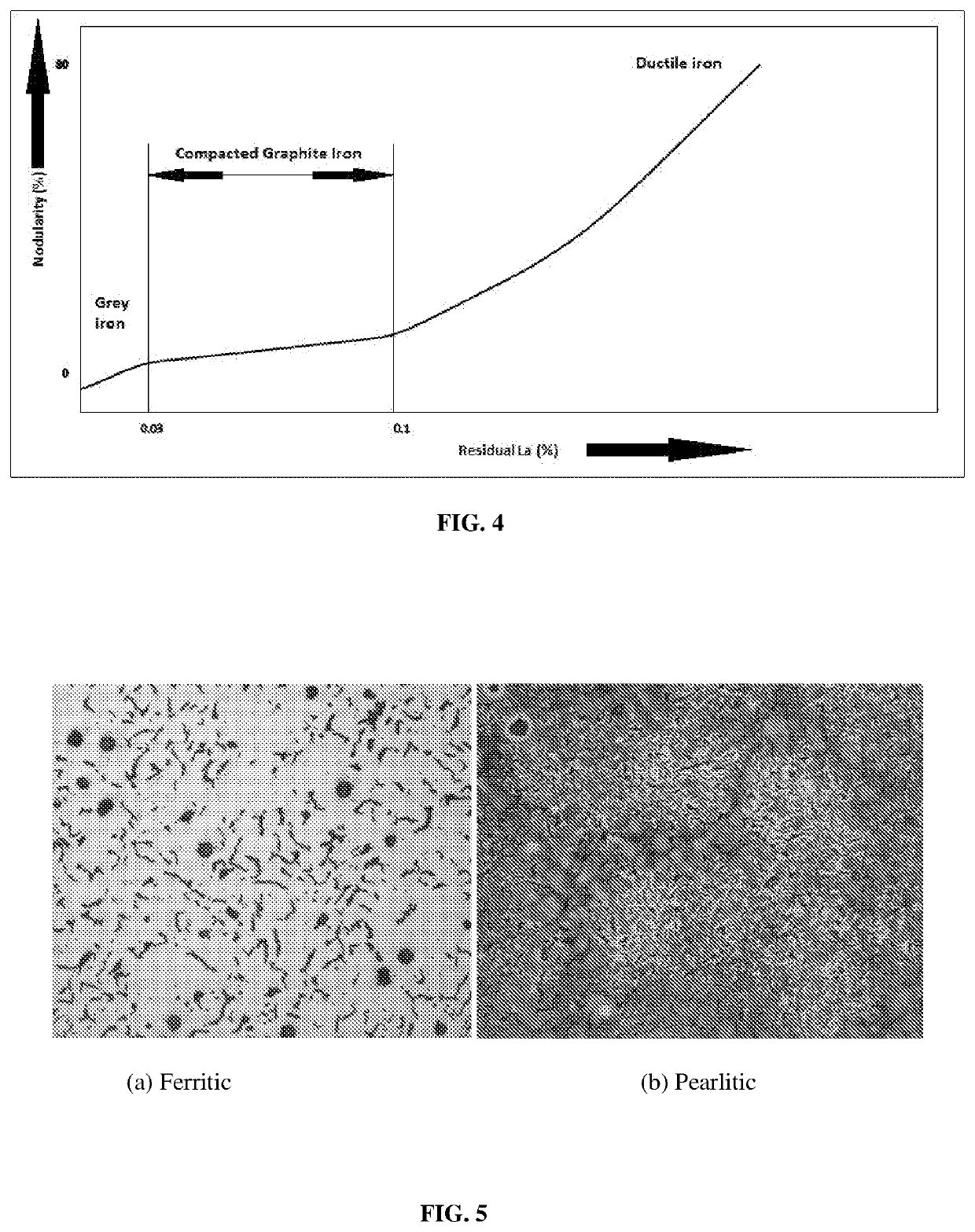

A Non-Magnesium process to produce Compacted Graphite Iron (CGI)

The present invention pertains to a non-magnesium process to produce Compacted Graphite Iron (CGI) by placing a treatment alloy into a treatment ladle, and then placing an inoculant over die treatment alloy in the treatment ladle and pouring a molten base metal there over. The treatment alloy comprises iron, silicon and, lanthanum, wherein lanthanum is 3-30% by weight of the treatment alloy, silicon is 40-50% by weight of the treatment alloy, and the remaining is Iron. Lanthanum in the treatment alloy makes the graphite precipitate as vermiculite (compacted form) instead of flake or spheroids. With extended process window offered by this new process (0.03-0.1% residual lanthanum in the metal) required to make CGI, this new process removes the stringent process control (0.01-0.02% residual magnesium in the metal) dictated by the magnesium process of making CGI.

Owner:SNAM ALLOYS PVT LTD

Coated inserts for rough milling

InactiveUSRE39912E1Pigmenting treatmentOther chemical processesCompacted graphite ironCemented carbide

Coated milling insert has a WC-Co cemented carbide with a low content of cubic carbides and a highly W-alloyed binder phase and a coating including an inner layer of TiCxNy with columnar grains followed by a layer of κ-Al2O3 and a top layer of TiN. The coated milling insert is particularly useful for milling of grey cast iron with or without cast skin under wet conditions at low and moderate cutting speeds and milling of nodular cast iron and compacted graphite iron with or without cast skin under wet conditions at moderate cutting speeds.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Coated inserts for rough milling

InactiveUSRE40082E1Improve cutting performanceMilling cuttersCopying process control systemsCompacted graphite ironCuticle

Coated milling insert has a WC—Co cemented carbide with a low content of cubic carbides and a highly W-alloyed binder phase and a coating including an inner layer of TiCxNy with columnar grains followed by a layer of κ-Al2O3 and a top layer of TiN. The coated milling insert is particularly useful for milling of grey cast iron with or without cast skin under wet conditions at low and moderate cutting speeds and milling of nodular cast iron and compacted graphite iron with or without cast skin under wet conditions at moderate cutting speeds.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

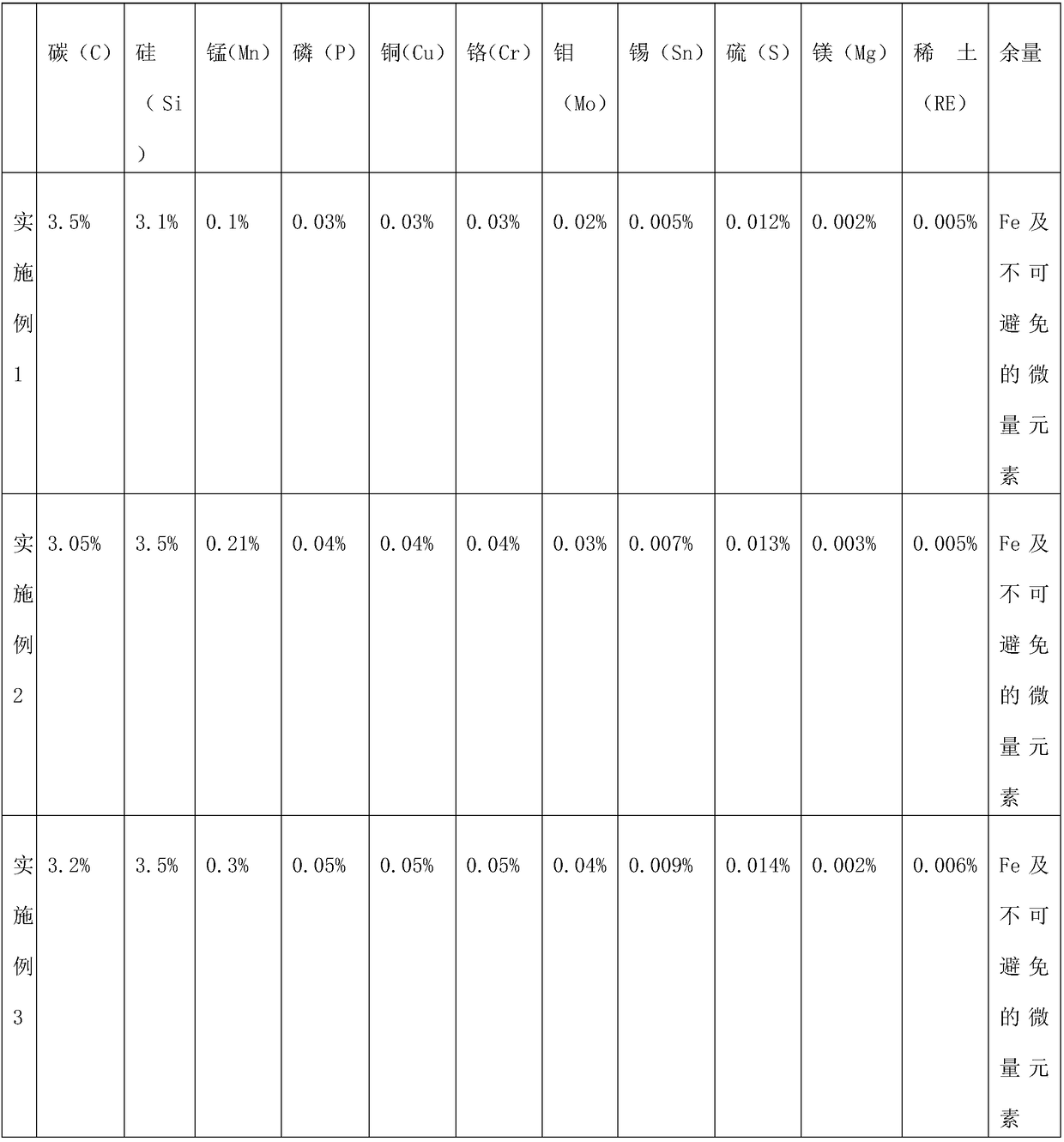

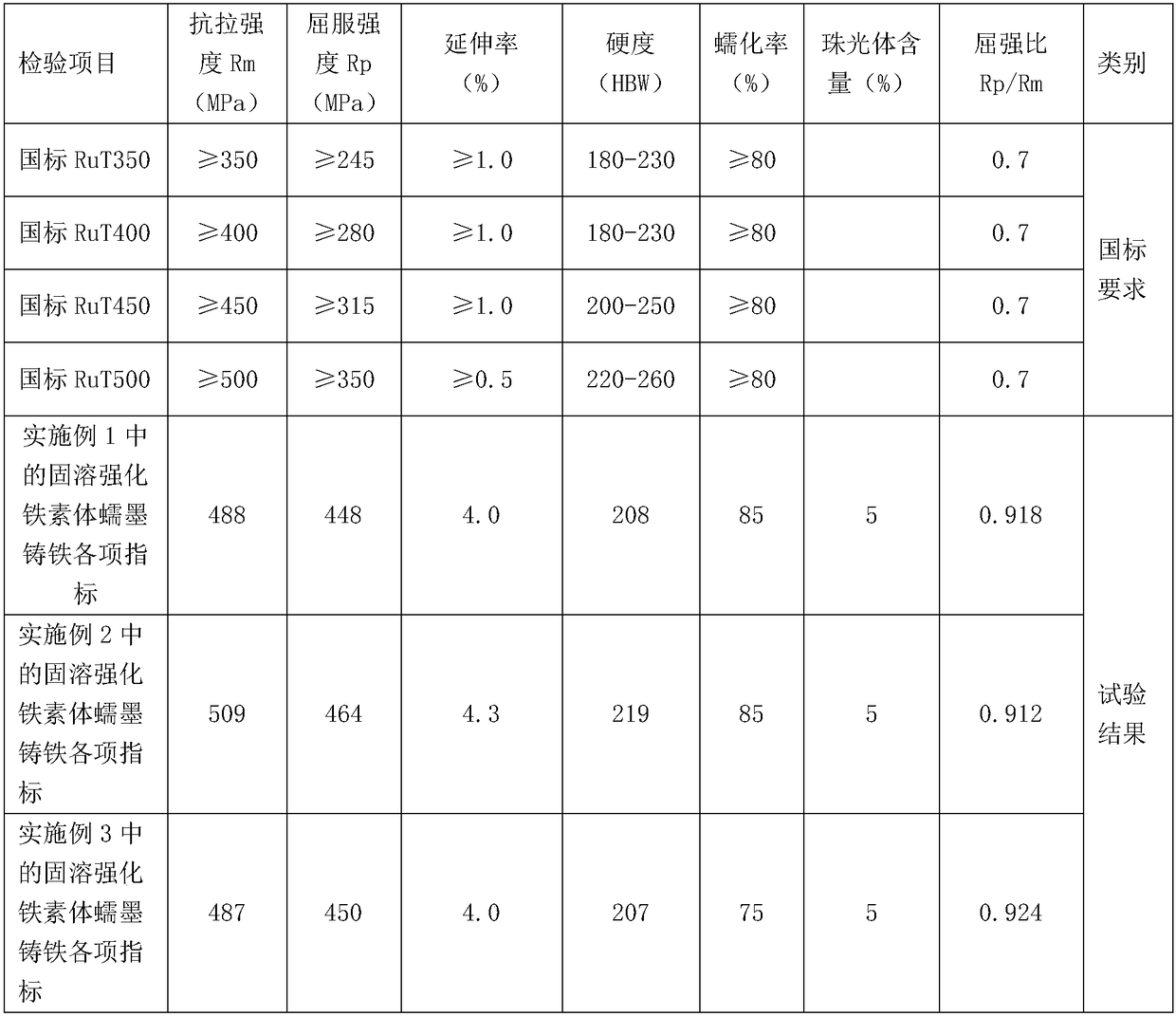

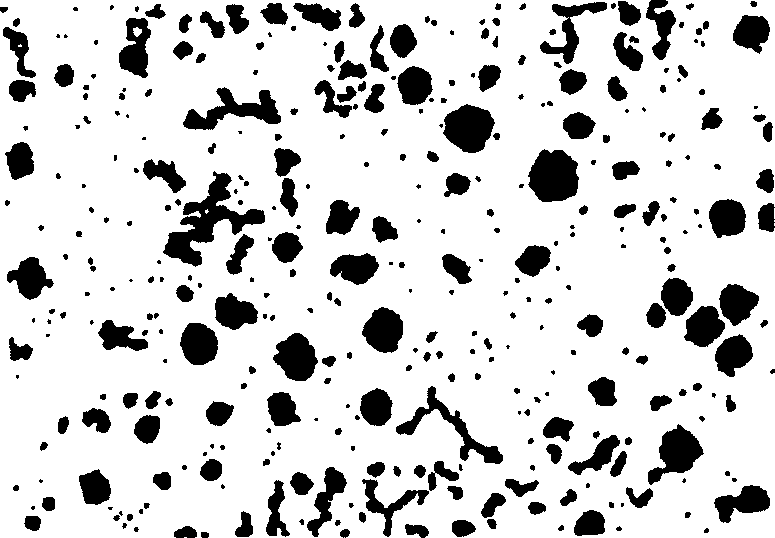

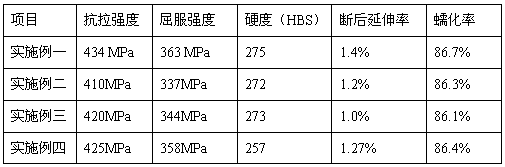

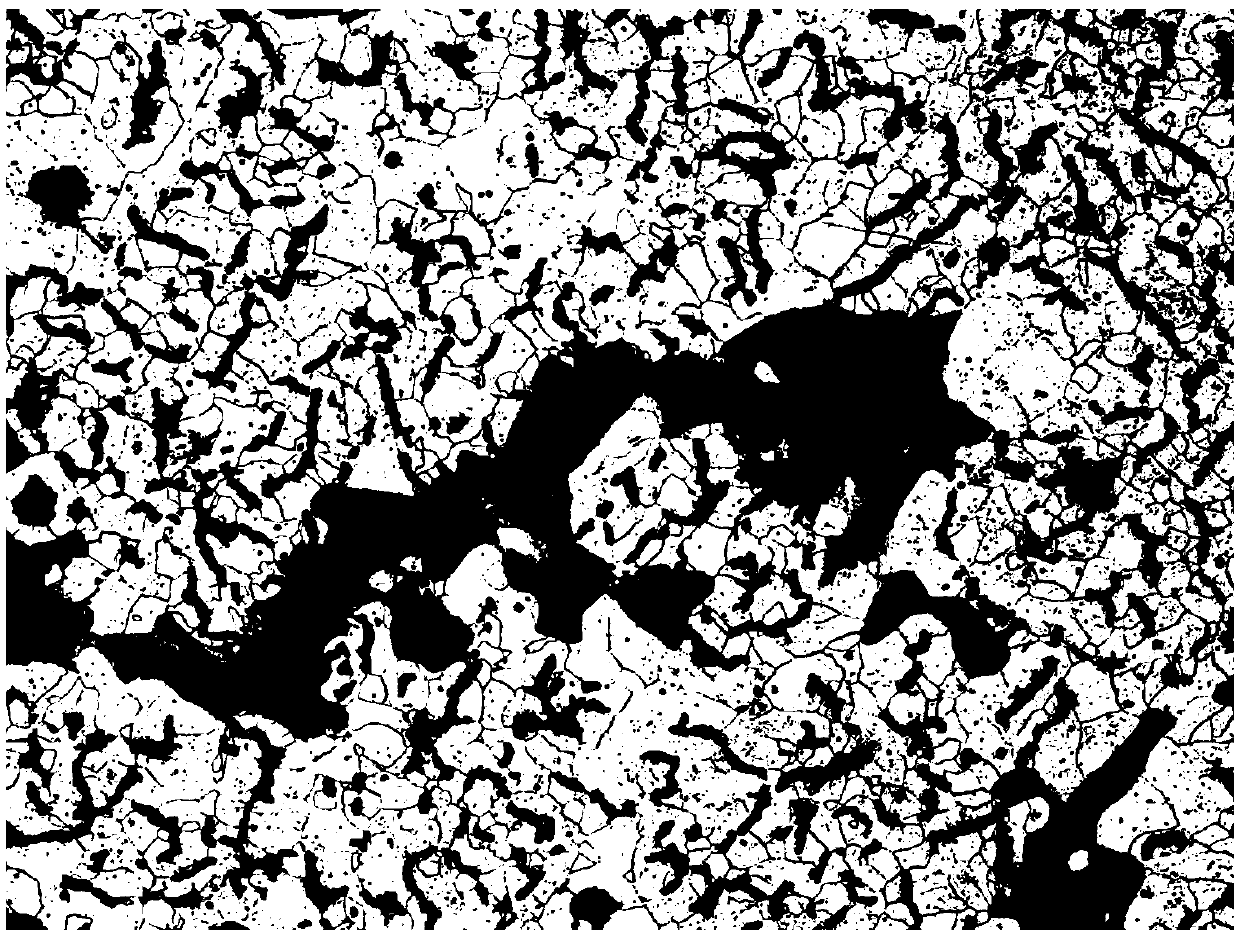

A kind of solid solution strengthened ferritic vermicular graphite cast iron and production method thereof

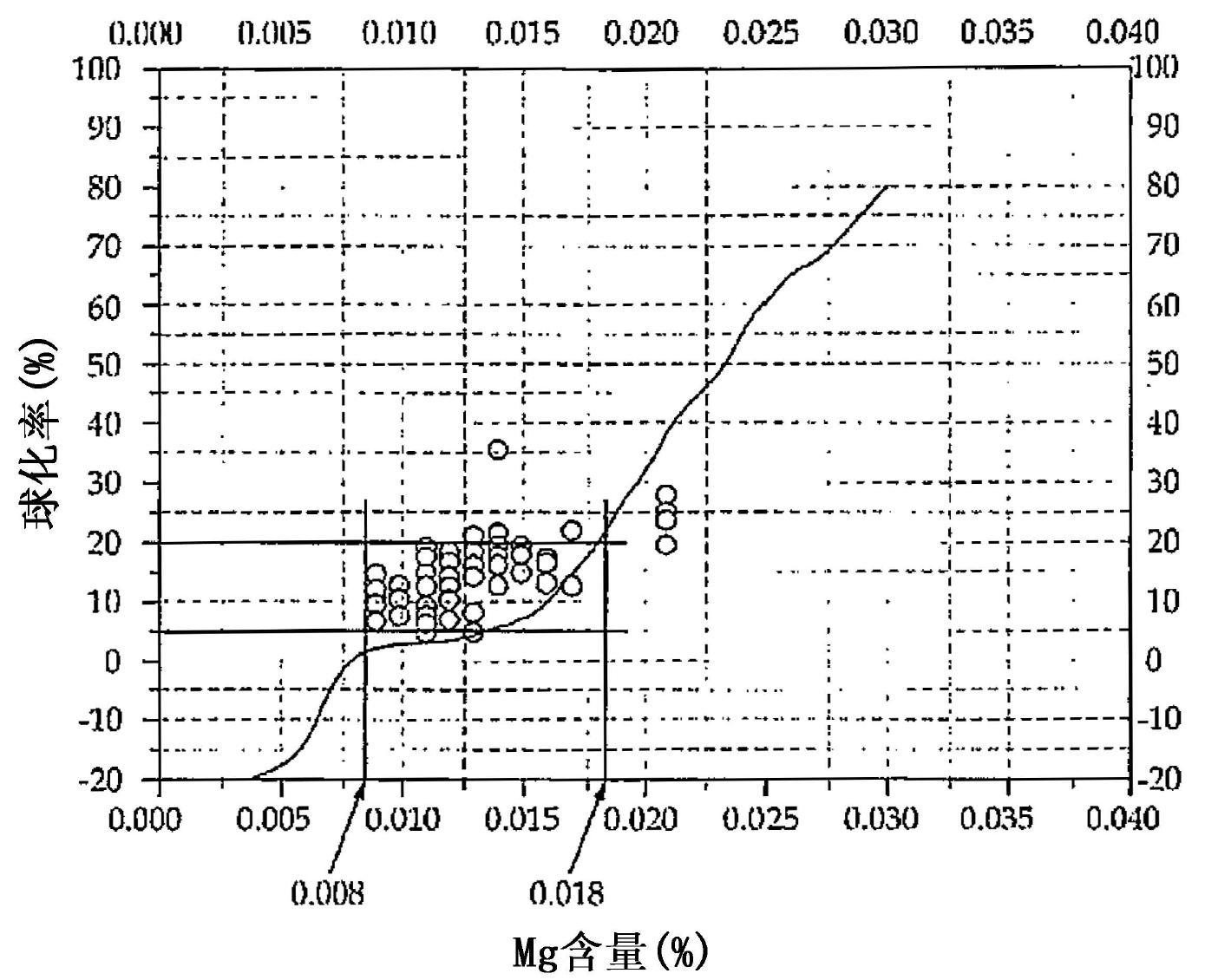

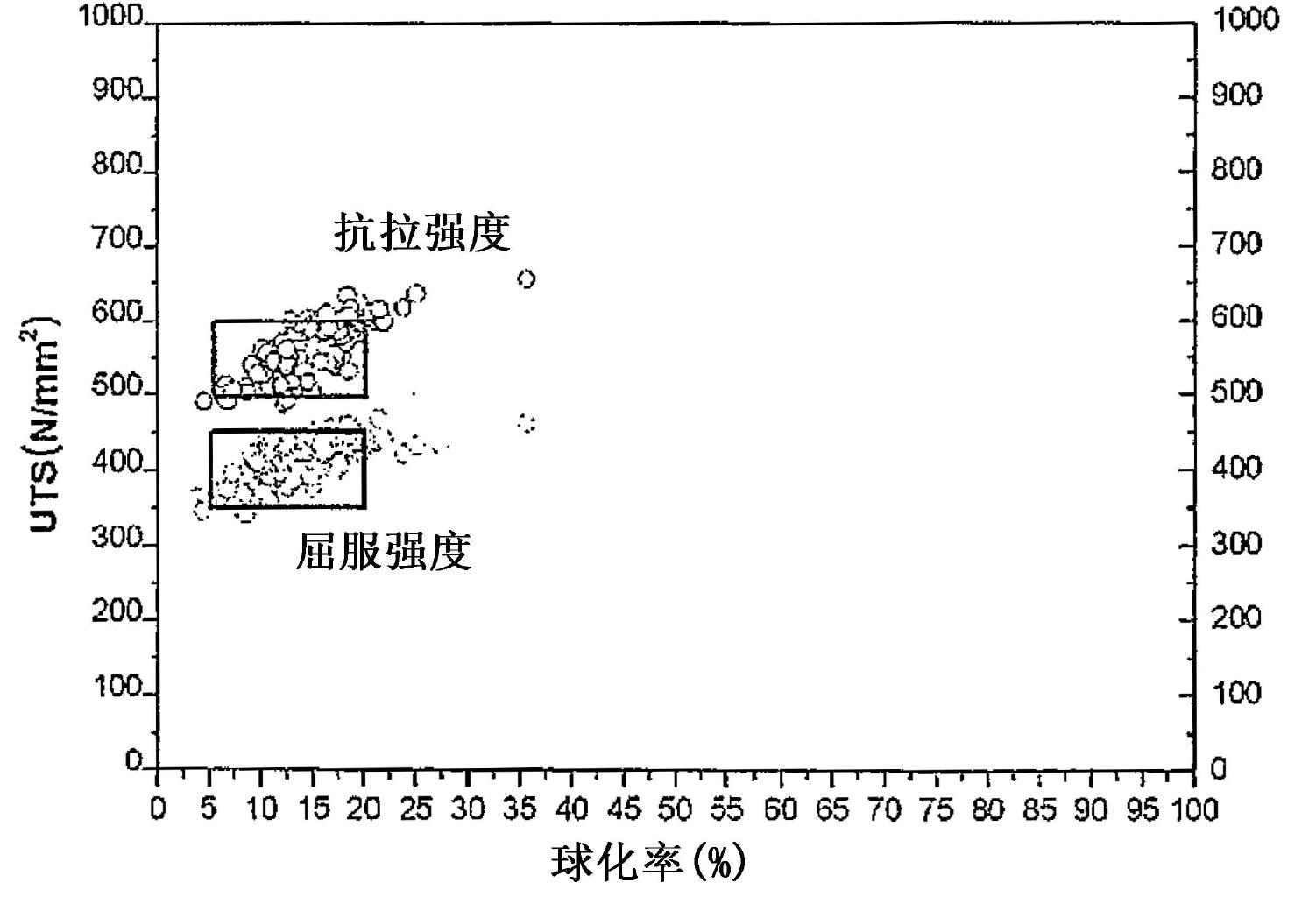

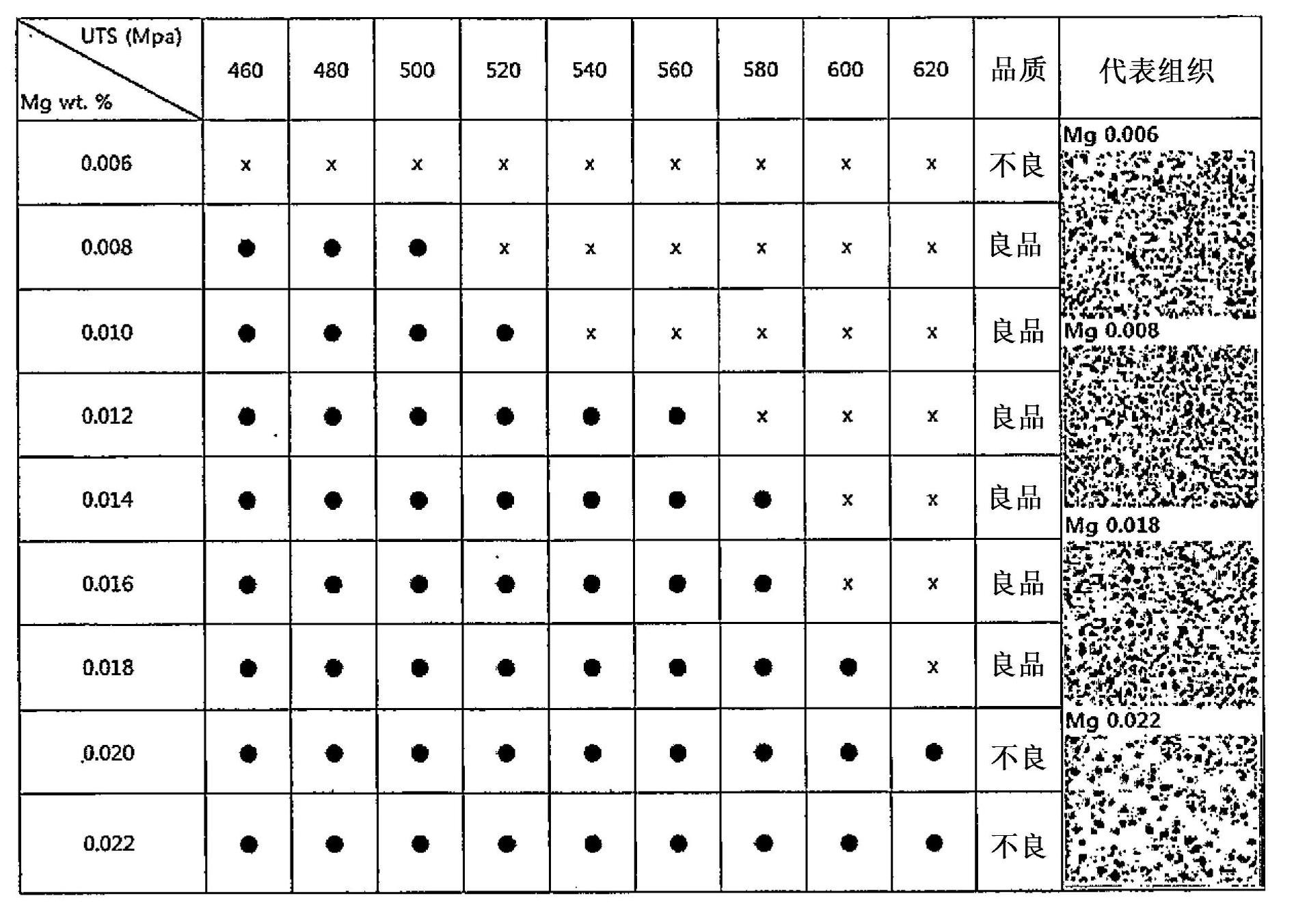

The invention discloses solution strengthening ferrite vermicular graphite cast iron and a production method thereof. The matrix structure of the solution strengthening ferrite vermicular graphite cast iron comprises ferrite with the mass percentage larger than 80%, and the ferrite is subjected to solution strengthening through Si. The components of the solution strengthening ferrite vermicular graphite cast iron include, by mass, 2.9-3.5% of C, 3.0-4.8% of Si, 0.0001-0.3% of Mn, 0.0001-0.07% of P, 0.0001-0.2% of Cu, 0.0001-0.1% of Cr, 0.0001-0.1% of Mo, 0.0001-0.02% of Sn, 0.007-0.020% of S, 0.008-0.030% of Mg, 0.010-0.040% of RE and the balance Fe and inevitable microelements, wherein the carbon equivalent needs to be kept at 4.2-4.6% and is equal to the mass percentage of carbon plus one third the mass percentage of silicon. The production method of the solution strengthening ferrite vermicular graphite cast iron comprises the steps of blending and melting, vermicularizing and inoculation treatment and cooling and unpacking. By adoption of the solution strengthening ferrite vermicular graphite cast iron and the production method thereof, the mechanical performance and machining performance of the vermicular graphite cast iron are effectively improved, and meanwhile, the production cost of the vermicular graphite cast iron is reduced.

Owner:GUANGXI YUCHAI MASCH CO LTD

Method for increasing creep rate of compacted graphite cast iron by electromagnetic field

The invention relates to a production method of vermicular graphite cast iron, in particular to a method for improving the vermicular rate of vermicular graphite cast iron by using a pulsed electromagnetic field. First, add vermative agent and inoculant to the molten iron, perform vermicular treatment at a temperature of 1420-1450°C, and then pour the treated molten iron into the experimental mold, the main point of which is to apply intermittent commutation to the pouring mold Traveling wave magnetic field, the power frequency is 50 Hz, and the magnetic induction is 0.01-0.03T. Finally, vermicular graphite cast iron with a creep rate of more than 75% can be obtained, and the residual content of magnesium and rare earth can reach Mg respectively. 残 =0.01~0.05%, Re 残 = 0.01 to 0.03%. The technical breakthrough of the invention opens up a new way for the production of vermicular graphite cast iron.

Owner:NORTHEASTERN UNIV LIAONING

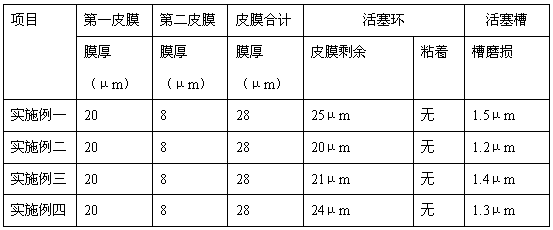

Vermicular graphite cast iron piston rings for internal combustion engines

ActiveCN105351107BAvoid stickingAvoid uneven wearPiston ringsMachines/enginesCompacted graphite ironCombustion

Owner:桃源县永峰机械有限责任公司

High magnesium and low rare earth austenitic vermicular graphite cast iron, its preparation method and application

Owner:BINZHOU BOHAI PISTON CO LTD

Alloy vermicular cast iron for railway vehicle brake disc and its melting method

ActiveCN105483508BIncreased pearlite contentHigh strengthCompacted graphite ironStress concentration

The invention relates to an alloy vermicular cast iron for a railway vehicle brake disc and a melting method thereof. The chemical composition of the vermicular cast iron, in terms of mass percentage, includes: C: 3.3-3.5%, Si: 2.3-2.5%, Mn: 0.4~0.7%, Cu: 0.6~1.0%, Mo: 0.2~0.6%, Ni: 0.6~1.0%, P≤0.07%, S≤0.02%, and the balance of Fe, among them, vermicular graphite cast iron brake disc The creep rate is ≥75%, and the pearlite content is 50%-60%. The invention can increase the stress threshold value of disc cracking and expansion caused by thermal stress concentration, and improve the mechanical properties of the railway vehicle brake disc.

Owner:CHANGZHOU LANGRUI CASTING +1

Method of inoculating magnesium on compacted graphite iron, and cylinder block and cylinder head manufactured by using the method

Owner:HYUNDAI MOTOR CO LTD

Coated inserts for milling of compacted graphite iron

The present invention discloses coated inserts particularly useful for milling of compacted graphite iron under wet conditions at moderate cutting speeds comprising a cemented carbide body and a coating. The cemented carbide body comprises WC, from about 7.3 to about 7.9 wt-% Co and from about 1.0 to about 1.8 wt-% cubic carbides of Ta and Nb and a highly W-alloyed binder phase. The radius of the uncoated cutting edge is from about 25 to about 45 μm.The coating comprises:a first, less than about 1 μm, TiCxNyOz layer adjacent to the cemented carbide having a composition of x+y=1, x is greater than or equal to 0;a second, from about 1 to about 2 μm, TiCxNyOz layer having a composition of x greater than about 0.4, y greater than about 0.4 and z is less than about 0.1 and equal to or greater than zero;a third, less than about 1 μm, TiCxNyOz layer having a composition of x+y+z greater than or equal to about 1 and z greater than about 0;an α-Al2O3-layer with a thickness of from about 2.1 to about 3.3 μm; anda further from about 0.1 to about 2.5 μm, thick layer of TiN missing along the edge line.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

A method of analysing an iron melt

ActiveUS20150316525A1Easy to detectLess importanceThermometer detailsTesting metalsCompacted graphite ironTemperature curve

A method of analysing an iron melt for producing compacted graphite iron includes receiving thermal data from cooling of a cast melt including a predetermined amount of carbon, magnesium, balance iron and unavoidable impurities, plotting the temperature of the cast melt against time such that a plotted time-temperature curve is generated, comparing the generated plotted curve to at least one reference curve, the reference curve representing a corresponding thermal analysis of another melt, the resulting nodularity of which is known, for the purpose of predicting the nodularity of the cast melt on basis of the difference between the curves. The comparison on which the nodularity is predicted is performed along each of the curves for a time interval t1-t2 corresponding to a temperature interval T1-T2, where T1 is in the range of TEstart-TEmim where TEstart is the temperature of beginning formation of graphite in the melt and TEmin is a minimum temperature before start of eutectic recalescence in the melt, and T2 is in the range of Tsolidus-(Tsolidus-20° C.), and other time intervals in the curves are excluded from the comparison

Owner:VOLVO LASTVAGNAR AB

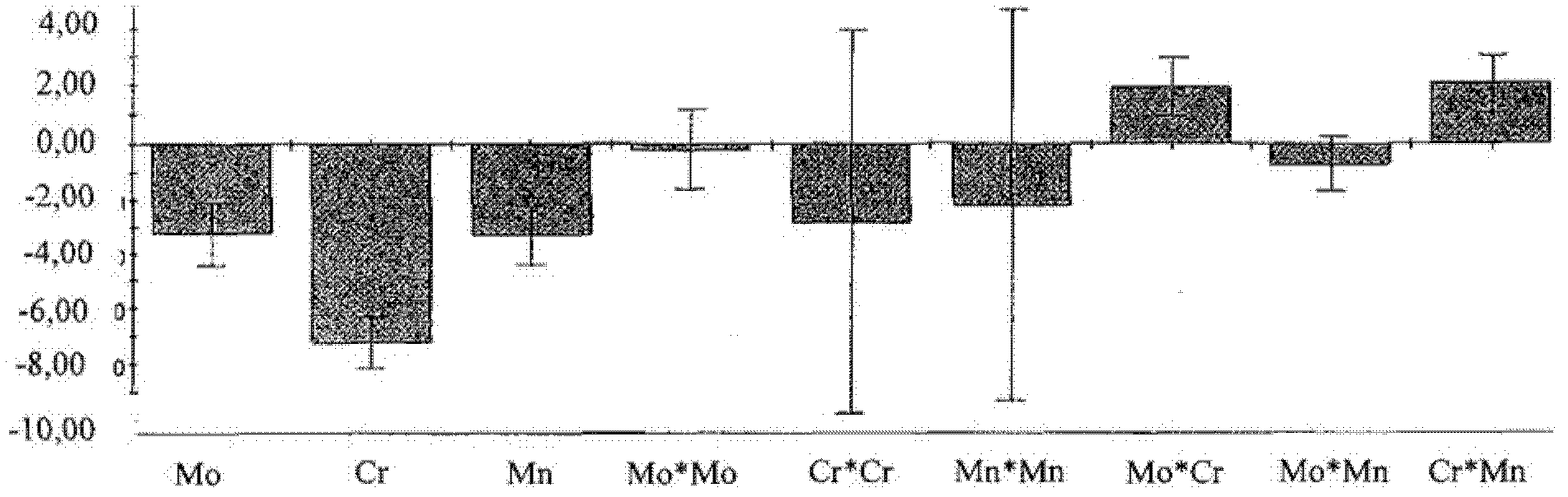

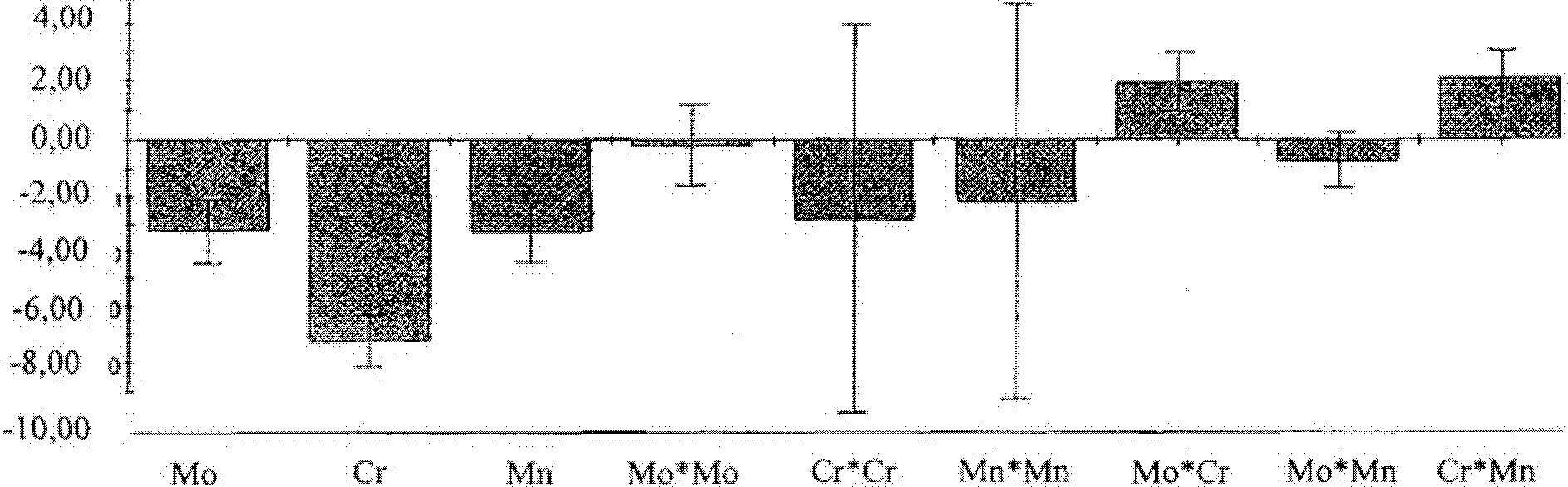

Method for determining the machinability of a compacted graphite iron

InactiveCN102612568ADetermine CuttabilityCost-effectiveInvestigating machinabilityCompacted graphite ironCarbide

Method for determining the cuttability of a compact graphite iron, characterised by the steps of: - arriving at a relationship between cuttability and contents of carbide-stabilising substances in compact graphite iron, which relationship is arrived at empirically from measured cuttability and measured contents of carbide-stabilising substances in a plurality of test pieces of compact graphite iron; - providing a compact graphite iron; - determining the contents of carbide-stabilising substances in the compact graphite iron provided; - determining a value for the cuttability of the compact graphite iron provided on the basis of the relationship and contents of carbide-stabilising substances in the compact graphite iron provided.

Owner:SCANIA CV AB

High vermicularization rate vermicular graphite cast iron single-cylinder diesel engine body and preparation method thereof

ActiveCN104480377BNarrow crystallization rangeImprove liquidityCompacted graphite ironChemical composition

The invention relates to a single cylinder diesel engine body and particularly relates to a vermicular graphite cast iron single cylinder diesel engine body with high vermicular graphite rate. The single cylinder diesel engine body comprises the following chemical components in percentage by mass: 3.5-3.8% of C, 2.1-2.6% of Si, 0.5-0.8% of Mn, less than 0.08% of P, less than 0.03% of S and the balance of iron and inevitable impurities. The single cylinder diesel engine body provided by the invention has the characteristics of less inclination of shrinkage cavity and shrinkage porosity and long service life. The invention further provides a preparation method of the single cylinder diesel engine body, which is reasonable in process.

Owner:SHANDONG YUANTONG MASCH CO LTD

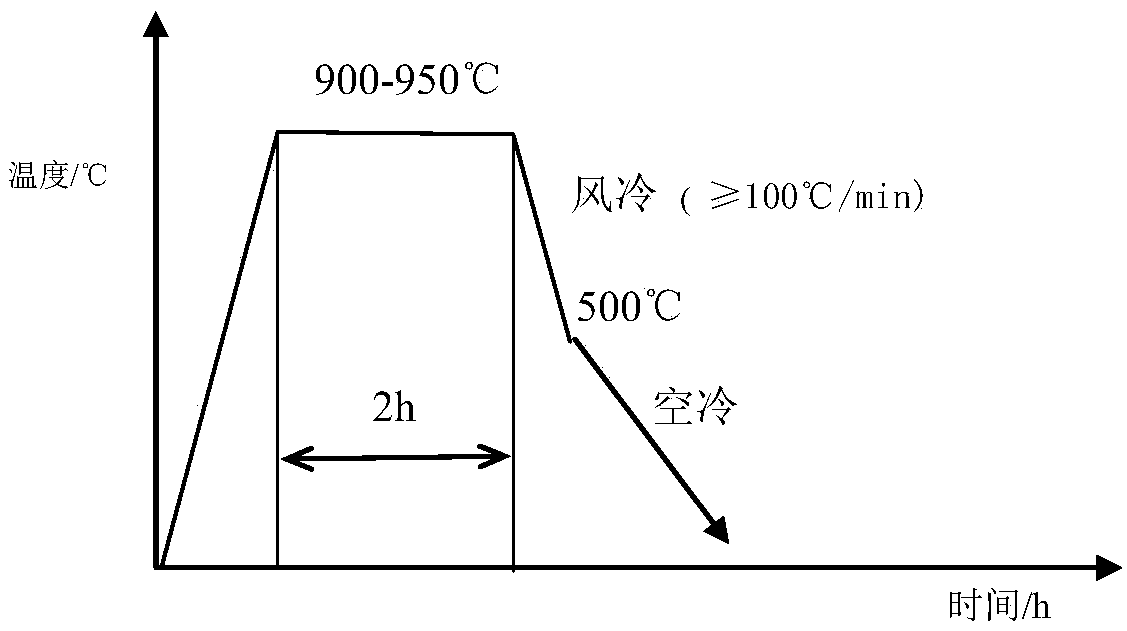

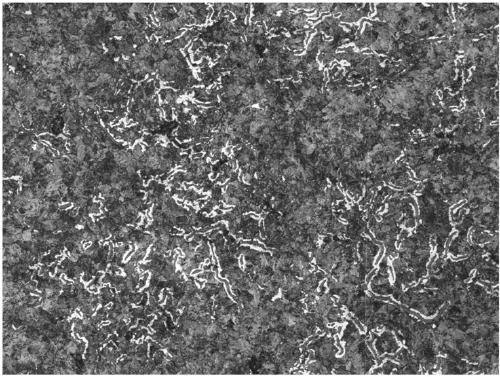

Production process of forced air-cooled full sorbite vermicular graphite cast iron

Provided is a production process of forced air cooling whole-sorbite type vermicular graphite cast iron. Vermicular graphite cast iron workpieces are contained in a stainless steel protecting box, thestainless steel protecting box is filed with particulate charcoal, and then the stainless steel protecting box is placed into a box type electric furnace heated to be 900 DEG C, and is subjected to constant temperature for 2 hours under the set austenitizing temperature; the vermicular graphite cast iron workpiece subjected to diathermanous treatment for regulated time are fast taken out of the protecting box in the box type furnace, and sequentially hung on a hanging frame in front of the furnace; two draught fans are started to be aligned with the direction of the vermicular graphite cast iron workpieces for opposite blowing, and the cooling speed of vermicular graphite cast iron test rods is controlled to be larger than or equal to 100 DEG C / min; and when the temperature of the vermicular graphite cast iron workpieces subjected to air cooling is 490-500 DEG C, air blowing stops, and after air cooling continues to be performed till room temperature is achieved, and the whole-sorbitetype vermicular graphite cast iron workpieces are obtained. The production process of the forced air cooling whole-sorbite type vermicular graphite cast iron has the beneficial effect of being simplein process, after high-temperature heating forced air cooling heat treatment, a novel vermicular graphite cast iron material with higher mechanical performance is obtained, and the strength, hardnessand the abrasion resistance indexes of the novel vermicular graphite cast iron material should approach or reach more than two times those of the common as-cast vermicular iron.

Owner:锦州捷通铁路机械股份有限公司

Coated inserts for milling of compacted graphite iron

The present invention discloses coated milling inserts particularly useful for milling of compacted graphite iron under wet conditions at moderate cutting speeds comprising a cemented carbide body and a coating. The cemented carbide body comprises WC, 7.3-7.9 wt-% Co and 1.0-1.8 wt-% cubic carbides of Ta and Nb and a highly W-alloyed binder phase. The radius of the uncoated cutting edge is 25-45 µm. The coating comprises - a first <1 µm TiC x N y O z layer adjacent to the cemented carbide having a composition of x+y=1, x>= 0, - a second 1-2 µm TiC x N y O z layer having a composition of x>0.4, y>0.4 and 0=<z<0.1 - a third <1 µm TiC x N y O z layer having a composition of x+y+z>=1 and z>0 - an ±-Al 2 O 3 -layer with a thickness of 2.1-3.3 µm and - a further 0.1-2.5 µm, thick layer of TiN missing along the edge line.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Automobile brake disc and manufacturing method thereof

InactiveCN102494057BReduce thermal shock effectsImprove cooling effectBraking discsSolid state diffusion coatingCompacted graphite ironEngineering

The invention relates to an automobile brake disc and a manufacturing method thereof. The appearance of the automobile brake disc is same with that of the brake disc in the prior art. The automobile brake disc is characterized in that the rotating direction of a fin in the brake disc is in spiral torsion from the center to the edge, and the spiral torsion is of an Achimedean spiral structure. Thematerial of the automobile brake disc is compacted graphite iron, and the outer surface of the brake disc is subjected to boronizing treatment.

Owner:宁波精磊汽车零部件有限公司

Method of analyzing an iron melt

ActiveUS10302580B2Suppresses initiationSuppresses propagationTesting metalsInvestigating phase/state changeCompacted graphite ironTemperature curve

A method of analyzing an iron melt for producing compacted graphite iron includes receiving thermal data from cooling of a cast melt including a predetermined amount of carbon, magnesium, balance iron and unavoidable impurities, plotting the temperature of the cast melt against time such that a plotted time-temperature curve is generated, comparing the generated plotted curve to at least one reference curve, the reference curve representing a corresponding thermal analysis of another melt, the resulting nodularity of which is known, for the purpose of predicting the nodularity of the cast melt on basis of the difference between the curves. The comparison on which the nodularity is predicted is performed along each of the curves for a time interval t1−t2 corresponding to a temperature interval T1−T2, where T1 is in the range of TEstart−TEmin where TEstart is the temperature of beginning formation of graphite in the melt and TEmin is a minimum temperature before start of eutectic recalescence in the melt, and T2 is in the range of Tsolidus−(Tsolidus−20° C.), and other time intervals in the curves are excluded from the comparison.

Owner:VOLVO LASTVAGNAR AB

Method for determining the machinability of a compacted graphite iron

InactiveCN102612568BDetermine CuttabilityCost-effectiveInvestigating machinabilityCompacted graphite ironCarbide

Method for determining the cuttability of a compact graphite iron, characterised by the steps of: - arriving at a relationship between cuttability and contents of carbide-stabilising substances in compact graphite iron, which relationship is arrived at empirically from measured cuttability and measured contents of carbide-stabilising substances in a plurality of test pieces of compact graphite iron; - providing a compact graphite iron; - determining the contents of carbide-stabilising substances in the compact graphite iron provided; - determining a value for the cuttability of the compact graphite iron provided on the basis of the relationship and contents of carbide-stabilising substances in the compact graphite iron provided.

Owner:SCANIA CV AB

Low tin silicon molybdenum vermicular graphite cast iron and preparation method thereof

The invention discloses a low-tin-silicon-molybdenum vermicular graphite cast iron. The low-tin-silicon-molybdenum vermicular graphite cast iron consists of the following components by weight percentage: 3.4-3.8% of carbon, 2.1-2.6% of silicon, and 0.1-2.6% of molybdenum 0.3%, manganese 0.2‑0.3%, niobium 0.2‑0.3%, chromium 0.1‑0.2%, tin 0.01‑0.03%, antimony 0.01‑028%, vanadium 0.1‑0.18%, titanium 0.15‑0.25 %, the total content of phosphorus and sulfur does not exceed 0.06%, and the balance is iron and its unavoidable impurities. The low-tin-silicon-molybdenum vermicular graphite cast iron of the present invention has a small whiting tendency and a small length-thickness ratio of the vermicular graphite, so that the low-tin-silicon-molybdenum vermicular graphite cast iron has excellent strength, wear resistance and thermal fatigue resistance. At the same time, the present invention also provides a method for preparing the above-mentioned low-tin-silicon-molybdenum vermicular graphite cast iron, so that the obtained low-tin-silicon-molybdenum vermicular graphite cast iron has high creep rate, good comprehensive performance, simple process operation, and is suitable for large-scale industrial production.

Owner:苏州勤堡精密机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com