Cgi cast iron and production method for the same

Inactive Publication Date: 2012-11-29

DOOSAN INFRACORE CO LTD

View PDF7 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

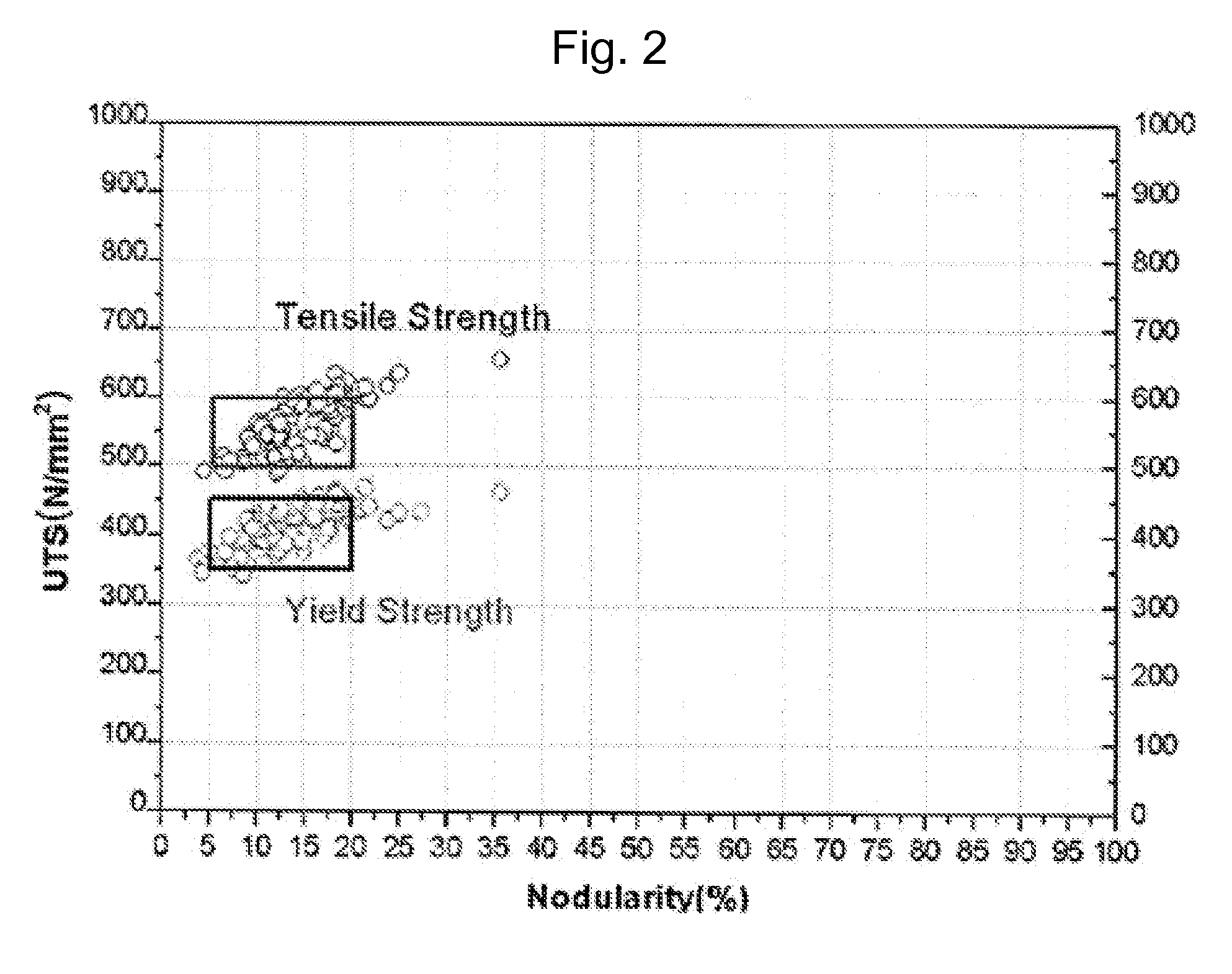

[0025]According to the present invention, it is possible to provide cast iron with tensile strength in the range of 500 to 600 MPa, yield strength in the range of 350 to 450 Mpa, and Brinell Hardness in the range of 255 to 280, by precisely controlling the amount of magnesium (Mg) and controlling the amounts of copper (Cu) and tin (Sn).

[0026]Since the cast iron according to the present invention has stable tensile strength and yield strength and appropriate hardness, the cast iron can be used to manufacture

Problems solved by technology

However, the spherical graphite cast iron has high strength required for cylinder blocks, but has an insufficient casting property and low thermal conductivity to be produced in a complicate shape, such that it has a limit in use for cylinder bocks having complicated shap

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Login to View More

Abstract

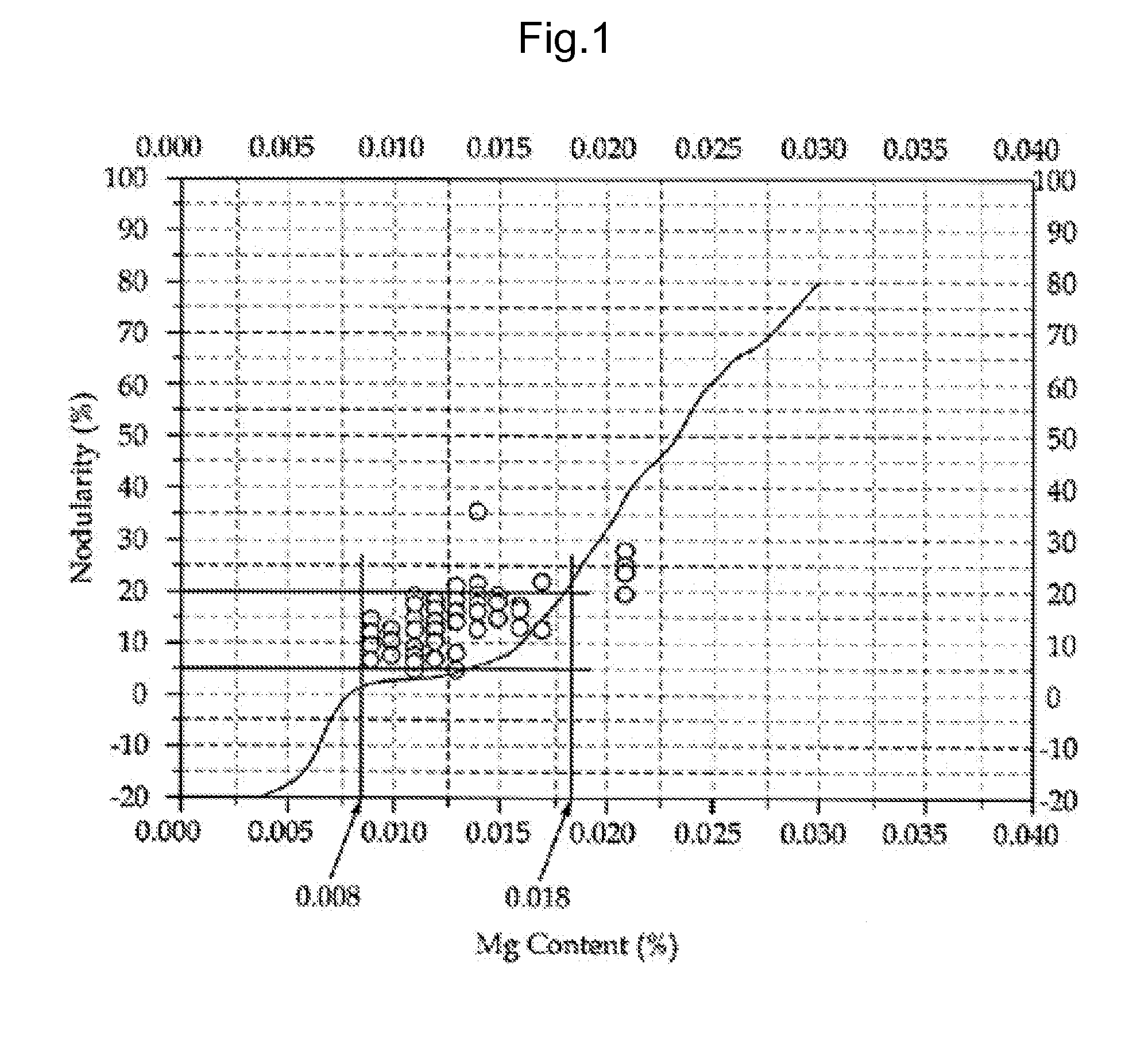

The present invention relates to cast iron, and more particularly, to a compacted graphite iron (CGI) cast iron having an improved casting property, stable tensile strength and yield strength, and hardness in an appropriate range, by being produced with the amounts of carbon (C), silicon (Si), manganese (Mn), copper (Cu), tin (Sn), and magnesium (Mg) controlled, and a production method thereof.

Description

TECHNICAL FIELD[0001]The present invention relates to cast iron and a method of producing the same, and more particularly, to cast iron having an improved casting property and stable tensile strength and yield strength by controlling the contents of components added to iron, and a method of producing the cast iron. Cast iron according to the present invention corresponds to hypereutectic compacted graphite iron (CGI) cast iron that can be applied to the cylinder block of diesel engines with high output.TECHNICAL FIELD[0002]Recently, it is required to reduce the contents of environmental pollutants such as Cox or NOx discharged from engines due to strictly enforced environmental regulation.[0003]For diesel engines, it is necessary to increase the explosive pressure of the engines in order to reduce the exhaust amount of environmental pollutants such as Cox or NOx. It needs to increase the strength of the cylinder block of the engines in order to increase the explosive pressure of the...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C37/10B22D7/00

CPCC22C33/08C21C7/0006C21C1/08C22C37/10

Inventor YANG, SIKSHIM, DONG SEOB

Owner DOOSAN INFRACORE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com