Patents

Literature

31results about How to "Stable yield strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Enamel steel for cold rolling water heater and manufacturing method thereof

InactiveCN101684532AGood explosivenessGood formabilityTemperature control deviceMetal rolling arrangementsEconomic benefitsSurface roughness

The invention discloses enamel steel for a cold rolling water heater and a manufacturing process thereof. The enamel steel for cold rolling water heater comprises components as follows in percentage by weight: C: 0.01%-0.08%. Si: less than or equal to 0.03%, Mn: 0.10%-0.60%, P: less than or equal to 0.02%, S: 0.003%-0.02%, N: 0.001%-0.006%, AIs: less than or equal to 0.04%, Ti: 0.02%-0.12%, and the balance of ferrum and unavoidable impurities, wherein excess Ti content in steel is equal to Ti-(4*C+3.43*N=1.5S) which is less than or equal to 0. The manufacturing process is characterized in that the heating temperature of billet steel is 1160-1300 DEG C; the hot rolling finish rolling temperature is 850-950 DEG C; the coiling temperature of steel plates is 660-760 DEG C; the cold rolling draft is 60%-80%; the annealing temperature is 760-880 DEG C; the temperature preservation time is 60-200s; rapid cooling speed rate is 15-45 DEG C / s, planishing elongation is 0.7%-1.8%; and surface roughness is 0.7-1.9 micrometres. The invention has the advantages of excellent formability, enamel-spreadable property, pressing resistance, weldability and fish-scaling resistance, stable yield strength after enamelfiring, less cost increase, stable effect and significant economic benefits.

Owner:ANGANG STEEL CO LTD

7XXX aluminum alloy

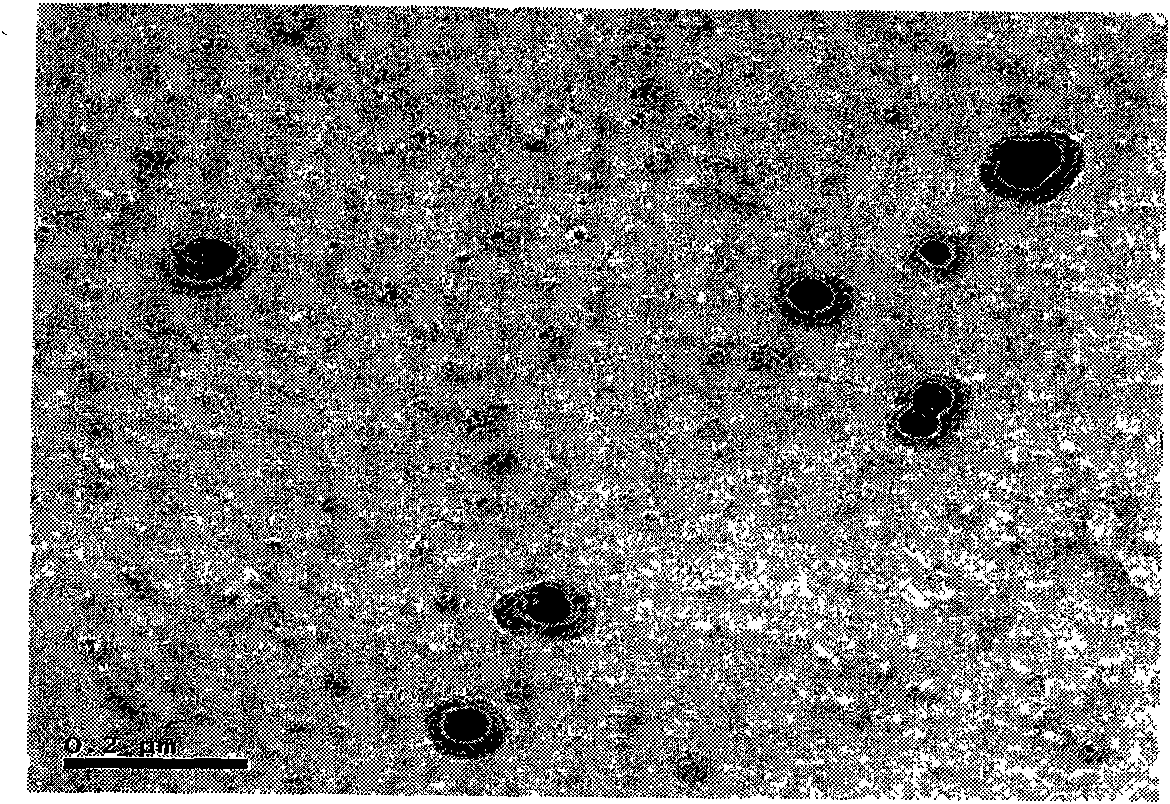

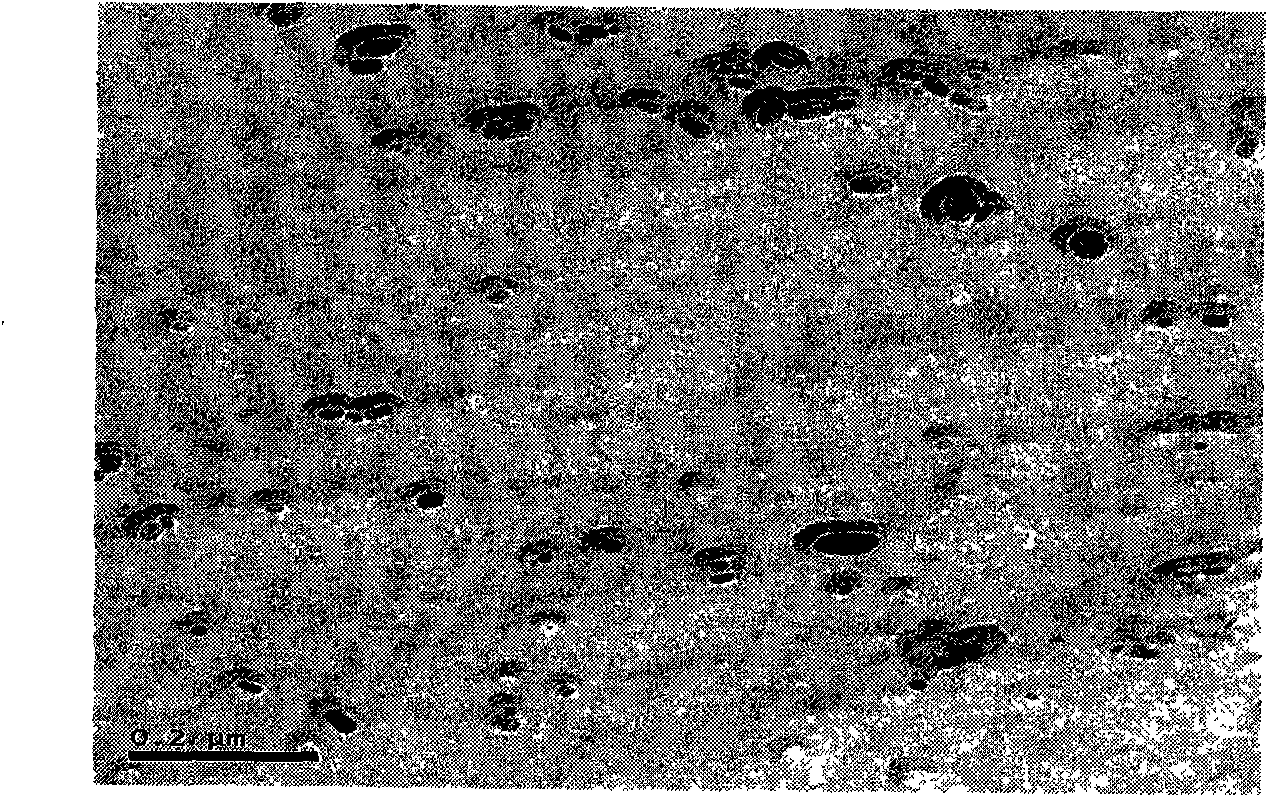

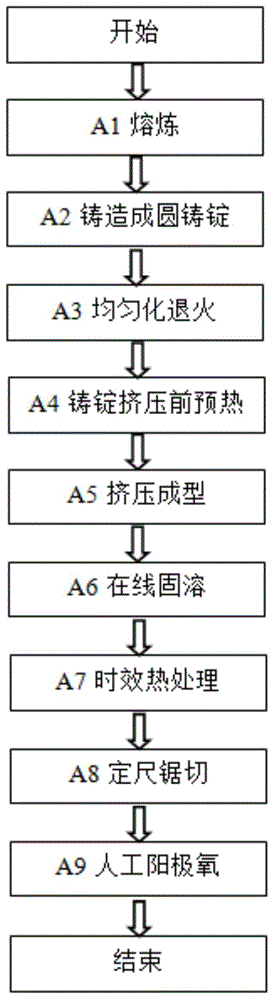

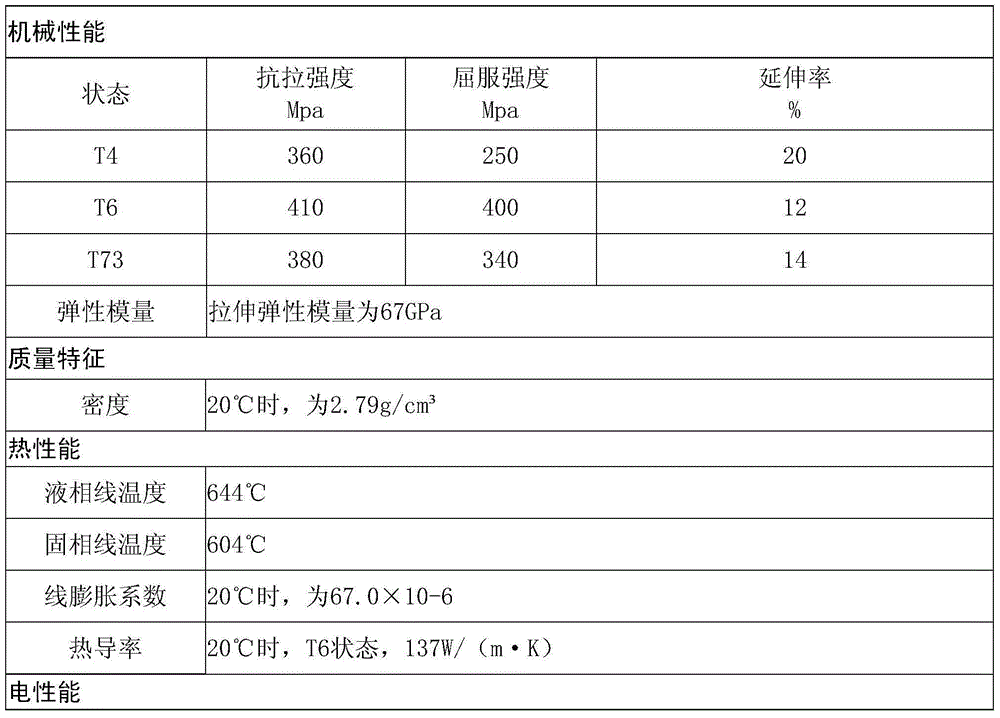

The invention relates to 7XXX aluminum alloy. The 7XXX aluminum alloy comprises the following components by weight percent: 6.6 to 7.6 percent of zinc, 1.25 to 1.80 percent of magnesium, 0.18 to 0.44 percent of copper, less than or equal to 0.06 percent of silicon, less than or equal to 0.16 percent of iron, , less than or equal to 0.03 percent of manganese, less than or equal to 0.03 percent of chromium, less than or equal to 0.02 percent of germanium, less than or equal to 0.02 percent of vanadium, less than or equal to 0.03 percent of titanium, less than or equal to 0.02 percent of zirconium, and less than or equal to 0.03 percent of total weight of manganese and chromium, less than or equal to 0.03 percent of each rest impurity element, less than or equal to 0.10 percent of total weight of rest impurity elements, and the balance of aluminum. On the basis of experiment, the material strength is improved by re-designing the mass fraction and a ratio of Zn to Mg; by re-designing the mass fraction of Cu, the alloy has excellent corrosion resistance, and the oxidation different color problem of silver white can be solved. By strictly controlling the weight percent of the impurity elements such as Mn and Cr, the crystal grains of the alloy material are uniform. Compared with the existing disclosed Al-Zn alloy system, the alloy has better comprehensive performance, and an oxidized membrane formed by oxidizing the material by virtue of anode is more delicate and beautiful.

Owner:TAISHAN CITY KAM KIU ALUMINUM EXTRUSION

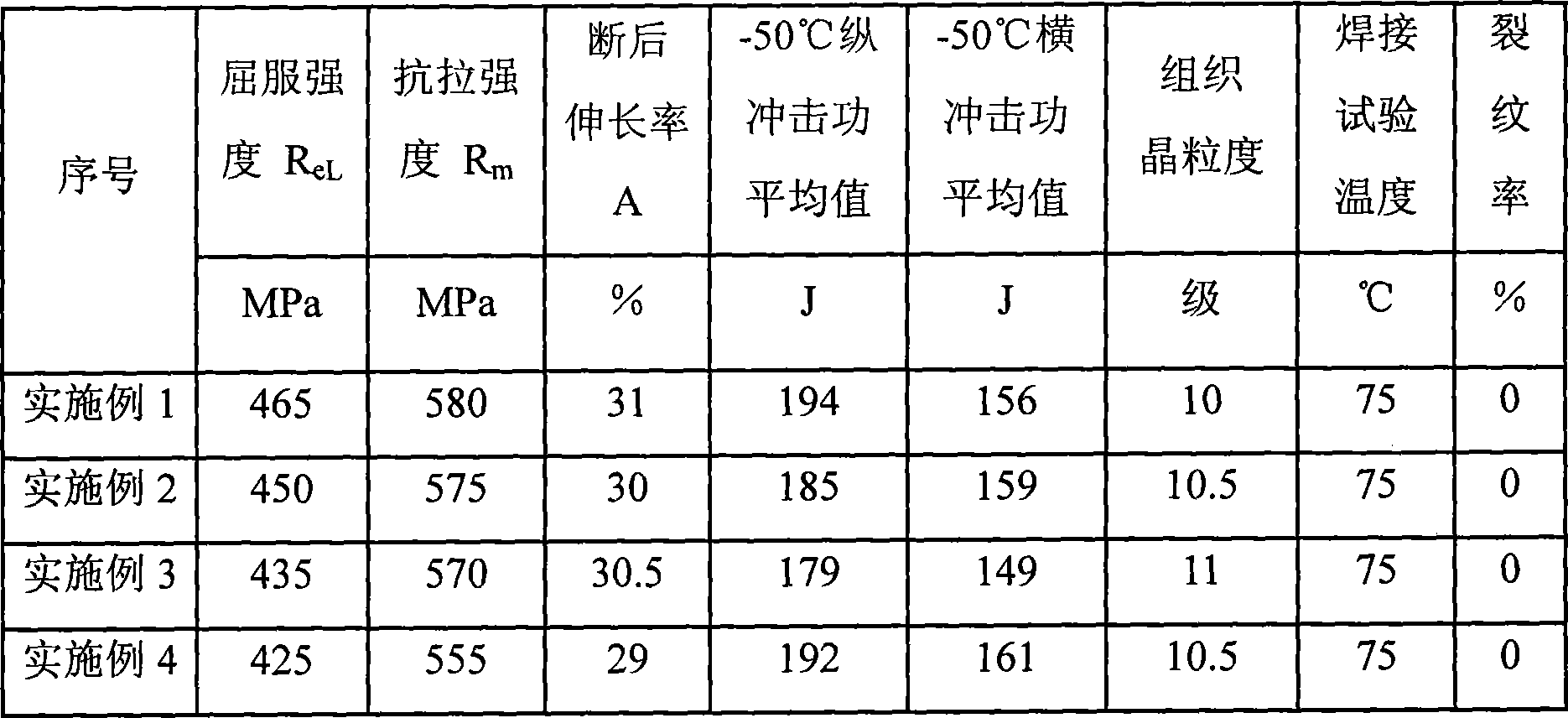

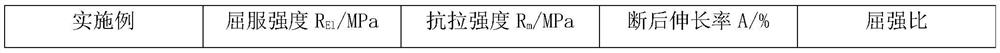

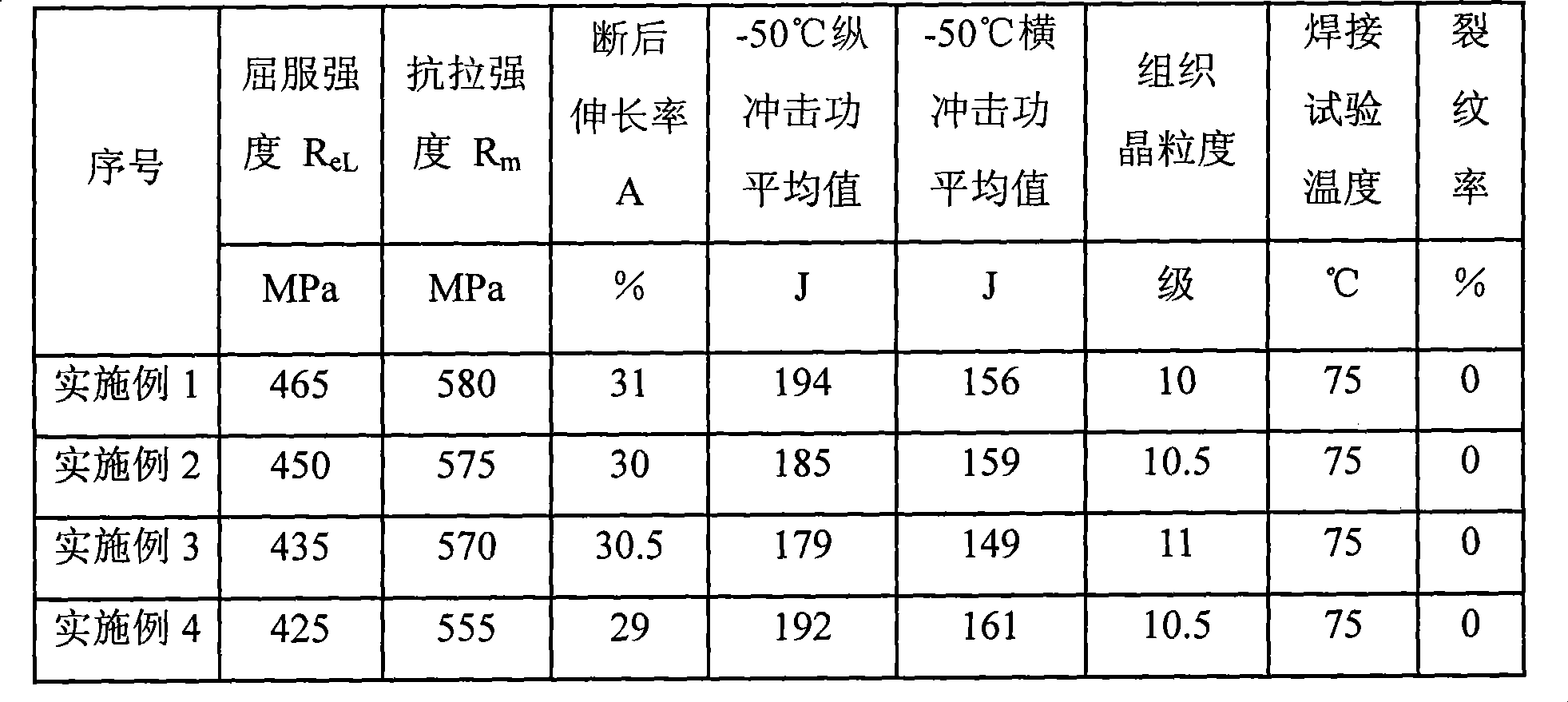

Preparation of normalizing weldable fine grain steel plate with a yield strength of 420MPa

ActiveCN101413049AElimination of internal stress and bainite structureReduces segregation bands and bandingTemperature control deviceMetal rolling arrangementsCooling temperatureImpact energy

The invention provides a method for preparing normalized weldable fine-grain steel plates with the yield strength of 420 MPa, which belongs to the technical field of manufacturing medium thick steel plates. A production process comprises the following steps: a continuous casting billet is heated to be between 1,200 and 1,250 DEG C, and the heat is preserved for 4 to 5 hours; hot rolling is performed after heat preservation; rolling is divided into two stages, namely recrystallization zone rolling and non-recrystallization zone rolling; intermediate temperature waiting thickness is controlled to be between 2.5 and 4.0 times the thickness of a finished product; the initial rolling temperature of a non-recrystallization zone is controlled between 850 and 880 DEG C; the final rolling temperature is controlled between 810 and 830 DEG C; water cooling is performed after hot rolling; the final cooling temperature is controlled between 650 and 740 DEG C, and cooling rate is controlled between 5 and 8 DEG C per second; and the steel plates are normalized at a temperature between 880 and 910 DEG C and then are thermally insulated for 5 to 20 minutes. The method has the advantages that the steel plates are excellent in mechanical properties; the mechanical property of the steel plate can stably reach over 420 MPa; the tensile strength of the steel plates can stably reach over 550 MPa; and the V-type notched impact energy of the steel plates at 50 DEG C below zero can stably reach over 140 J.

Owner:SHOUGANG CORPORATION

355MPa thick steel plate with low-temperature toughness and preparation method thereof

The invention belongs to the technical field of steel material production, and particularly relates to a 355MPa thick steel plate with low-temperature toughness and a preparation method thereof. The 355MPa thick steel plate with the low-temperature toughness is composed of the following components according weight percent: 0.04 to 0.14% of C, 0.2 to 0.5% of Si, 1.0 to 1.6% of Mn, less than 0.018% of P, less than 0.005% of S, 0.015 to 0.045% of Nb, 0.02 to 0.05% of V, 0.008 to 0.020% of Ti, and the balance of Fe and inevitable impurities. The thick steel plate has good low-temperature (-60 DEG C) impact toughness, and additionally, high strength, high toughness and good welding performance of the thick steel plate are achieved in the condition of the low-carbon content by adopting the preparation method.

Owner:SHANDONG IRON & STEEL CO LTD

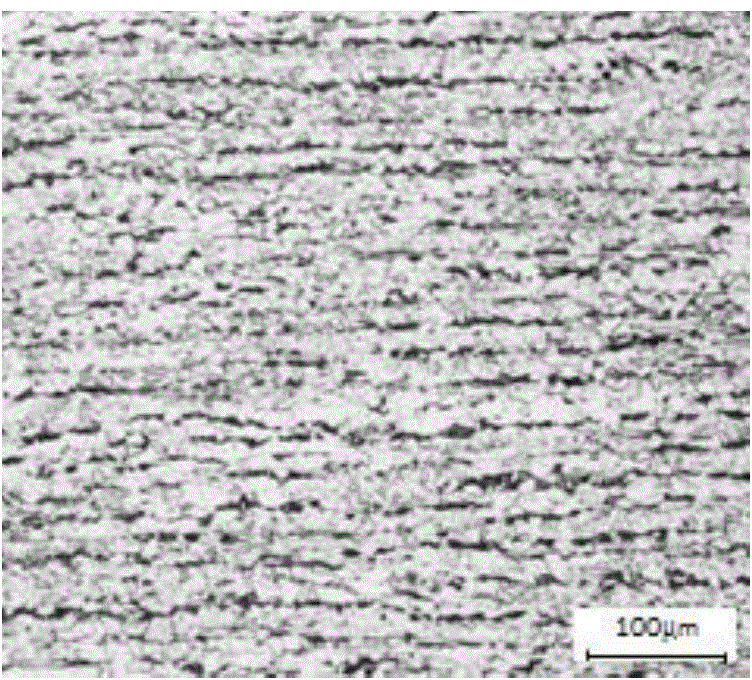

Wide and thick steel plate for normalized and rolled fine-grain pressure-welded steel tube and preparation method thereof

ActiveCN103525998AEliminate offline normalizing heat treatmentReduce production energy consumptionReduction rateChemical composition

The invention discloses a wide and thick steel plate for a normalized and rolled fine-grain pressure-welded steel tube and a preparation method thereof. The wide and thick steel plate comprises the following chemical components in percentage by weight: 0.08-0.16% of C, 0.20-0.60% of Si, 1.20-1.70% of Mn, less than or equal to 0.020% of S, less than or equal to 0.025% of P, less than or equal to 0.050% of Nb, less than or equal to 0.050% of V, less than or equal to 0.050% of Ti, more than or equal to 0.020% of Als, and the balance of Fe and trace impurities. The preparation method comprises the following steps: heating a plate blank to 1150-1250 DEG C, wherein the heating time is more than or equal to 200min and the soaking time is more than or equal to 50min; normalizing and rolling, wherein in a rough rolling stage, the initial rolling temperature is 1150-1200 DEG C, the final rolling temperature is 1100-1160 DEG C and reduction rates in the last three processes in the rough rolling stage are ensured to be more than or equal to 20%, and in a finish rolling stage, the initial rolling temperature is 850-920 DEG C, the thickness of an intermediate blank is 3-6 times of that of a finished product and the final rolling temperature is 800-850 DEG C; and after the final moulding rolling, weakly cooling the steel plate on line to 600-700 DEG C through a multi-functional batch-type accelerated cooling system, and then cooling the steel plate to room temperature in air.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

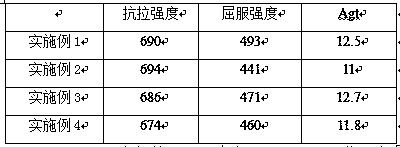

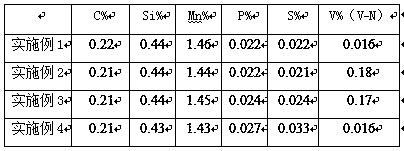

Production method of hot rolled ribbed steel bar

The invention relates to a production method of a hot rolled ribbed steel bar. The size of a spring steel hot rolled wire rod ranges from [phi]8mm to [phi] 10mm; and steel comprises the chemical components in percentage by mass: 0.20 percent to 0.25 percent of C, 0.40 percent to 0.50 percent of Si, 1.40 percent to 1.60 percent of Mn, less than or equal to 0.045 percent of P, less than or equal to0.045 percent of S, 0.015 percent to 0.020 percent of V, and the balance Fe and inevitable impurity elements. A rolling technology is characterized in that the tapping temperature ranges from 1070 to1130 DEG C, the temperature for entering pre-finish rolling ranges from 970 to 1000 DEG C, and the temperature for entering finish rolling ranges from 840 to 880 DEG C; the laying temperature ranges from 845 to 875 DEG C; the finish rolling temperature is the recrystallization temperature or less at an austenitic area; quick cooling is carried out on an air cooling roller through a fan, and the air volume is 100 percent; and heat preservation is carried out through closing a roller way of a heat-preservation cover, the temperature for entering the heat-preservation cover ranges from 640 to 660DEG C, the temperature for exiting from the heat-preservation cover ranges from 600 to 620 DEG C, and the time for staying in the heat-preservation cover ranges from 45 to 55s. According to the production method of the hot rolled ribbed steel bar provided by the invention, through adding a small amount of V alloy and finish rolling unit low-temperature rolling, the stable operation of equipment is ensured, the alloy content is further reduced, and the cost is reduced.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

Cgi cast iron and a production method for the same

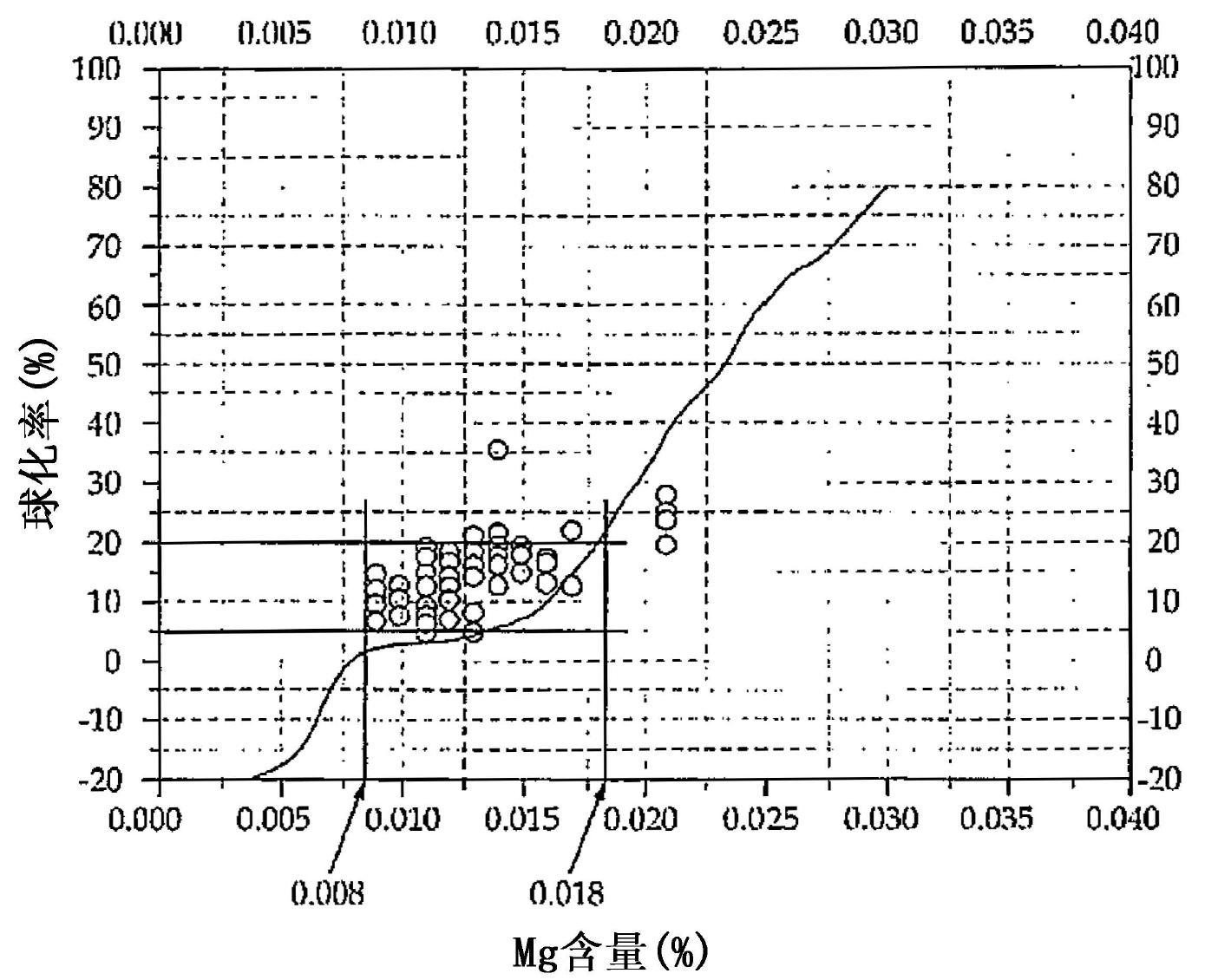

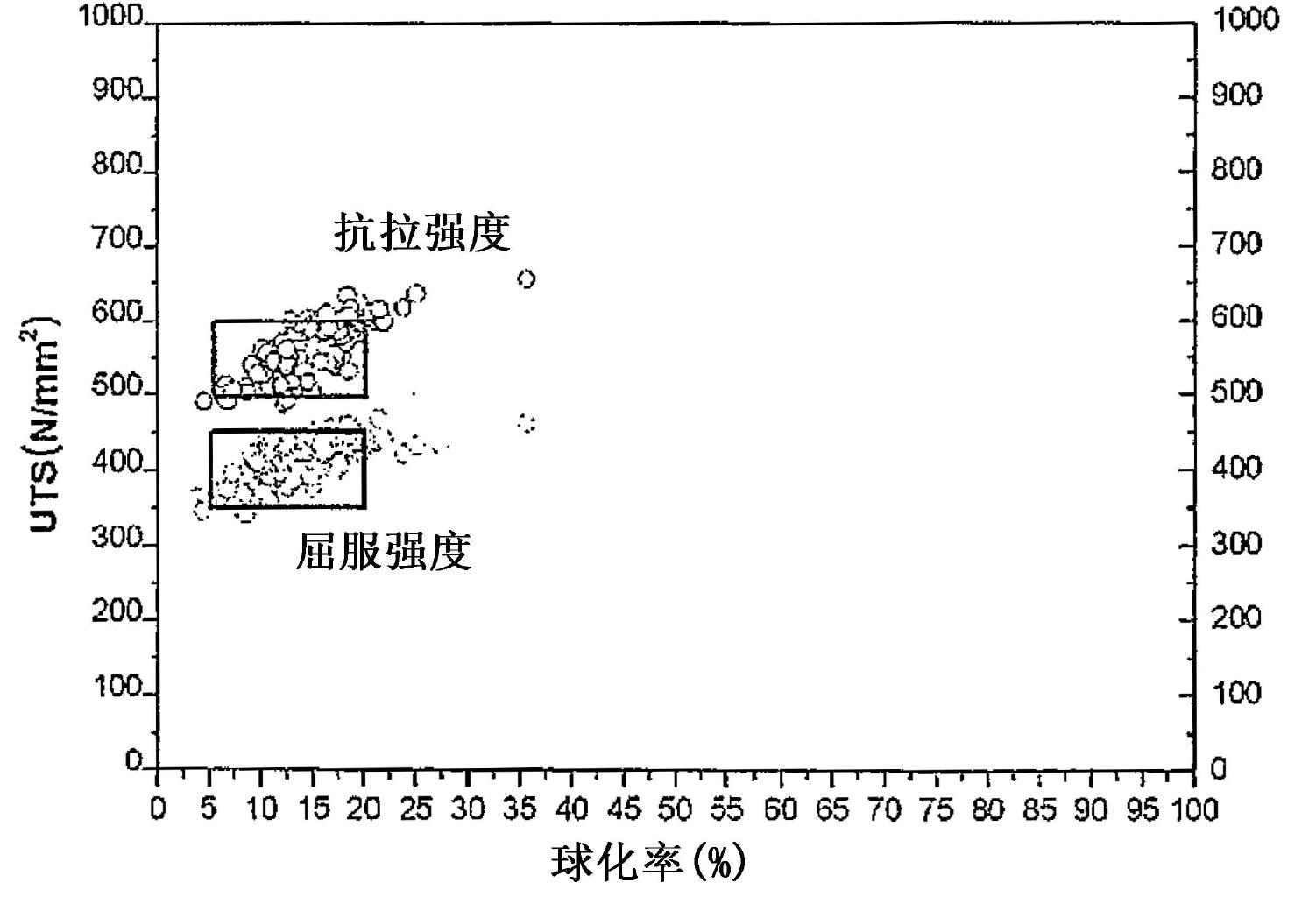

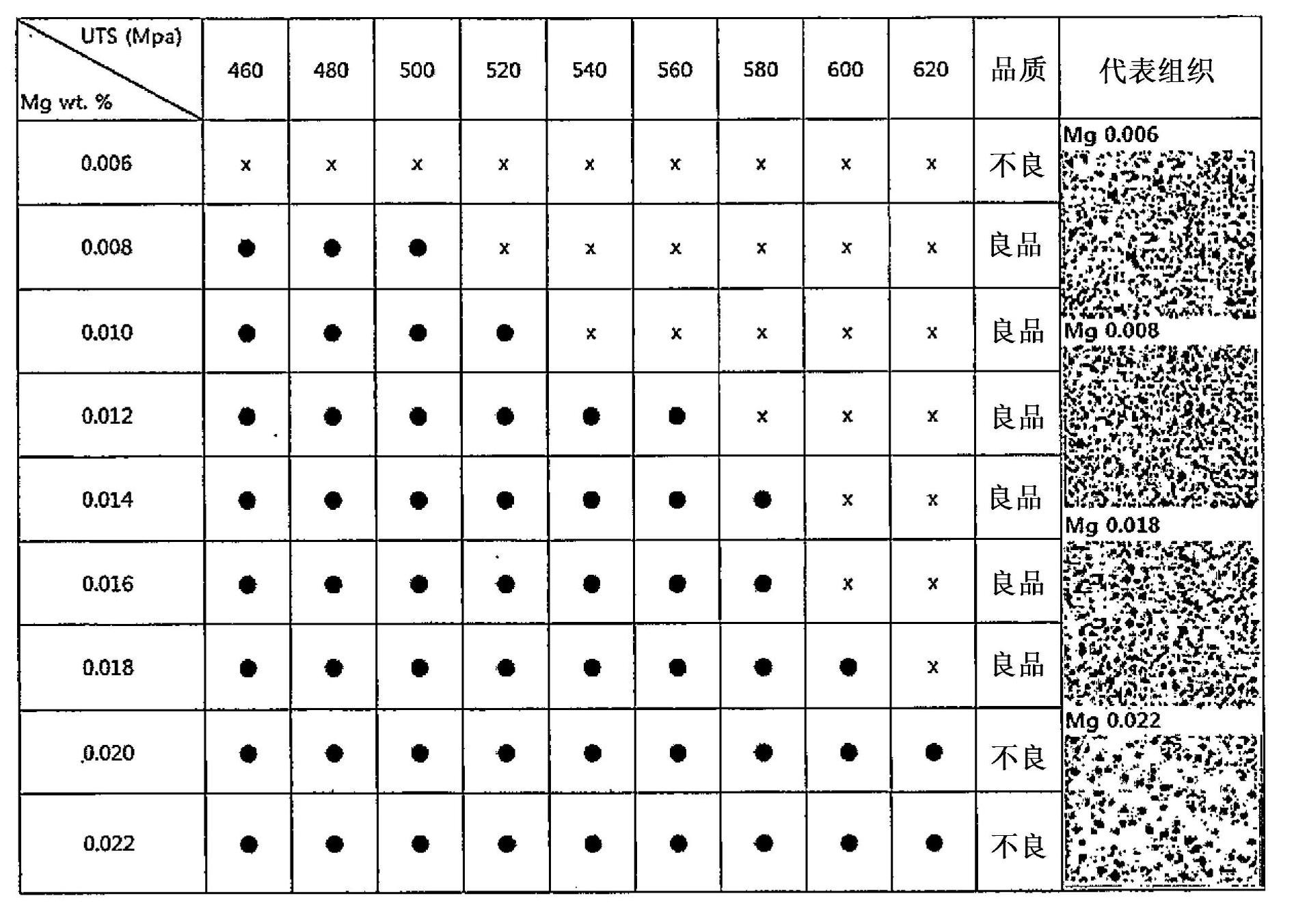

The present invention relates to cast iron, and more specifically relates to CGI (Compacted Graphite Iron) cast iron in which the amounts of carbon (C), silicon (Si), manganese (Mn), copper (Cu), tin (Sn) and magnesium (Mg) are controlled during production, thereby improving the castability and also giving a stable tensile strength and yield strength and giving an appropriate range of hardness, and also to a production method for the same.

Owner:DOOSAN INFRACORE CO LTD

Q370qE-HPS bridge steel with low cost and high performance, and production method

ActiveCN112195406APromote formationFacilitate organizational transformationTemperature control deviceManufacturing convertersMetallurgyYield ratio

The invention discloses Q370qEHPS bridge steel with low cost and high-performance, and relates to the technical field of steel production. The Q370qEHPS bridge steel comprises the following chemical components by mass: 0.05%-0.08% of C, 0.10%-0.40% of Si, 1.61%- 1.70% of Mn, no more than 0.015% of P, no more than 0.0030% of S, 0.030%-0.050% of Nb, 0.010%-0.018% of Ti, no more than 0.05% of residual Ni, 0.20%-0.30% of Cr, no more than 0.05% of residual Mo, no more than 0.05% of residual Cu, no more than 0.05% of residual B, no more than 0.005% of N, 0.020%-0.050% of Al, and the balance Fe and impurities. A TMCP rolling process is adopted, so that the bridge steel plate which is low in yield ratio, excellent in welding performance and capable of meeting standard requirements is obtained, andthe market competitiveness of enterprises is improved.

Owner:NANJING IRON & STEEL CO LTD

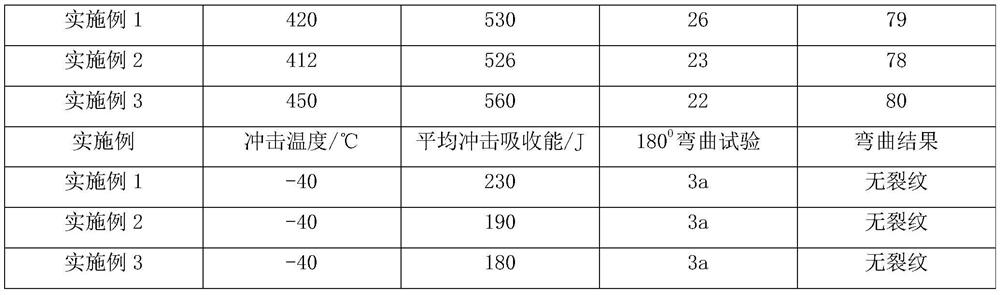

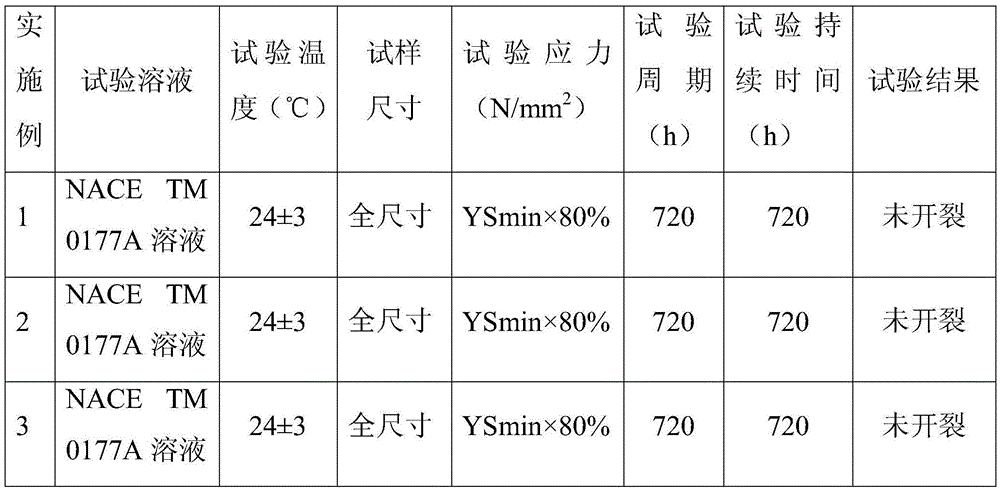

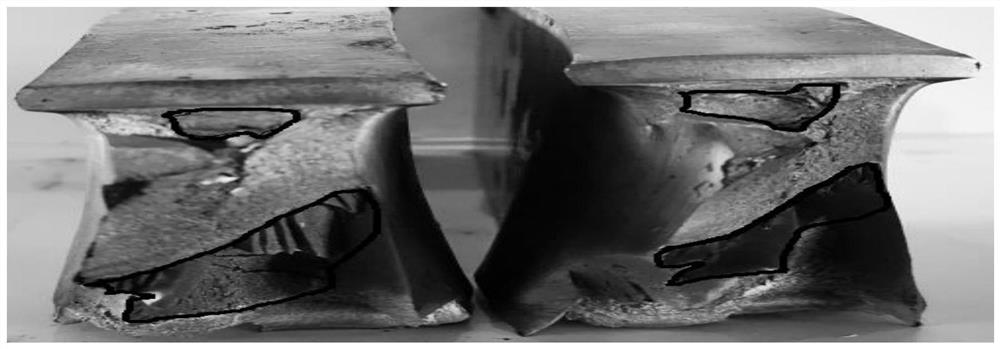

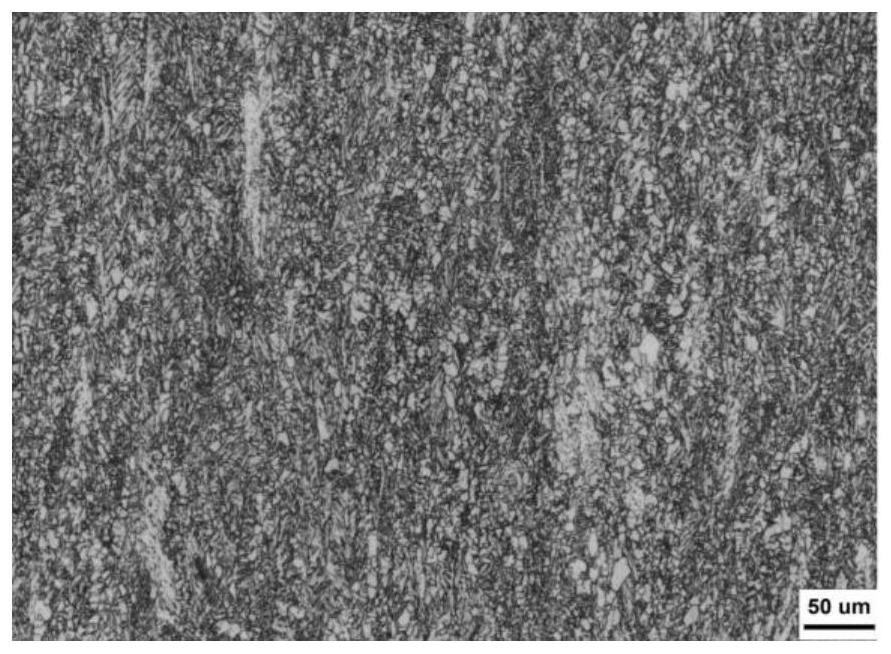

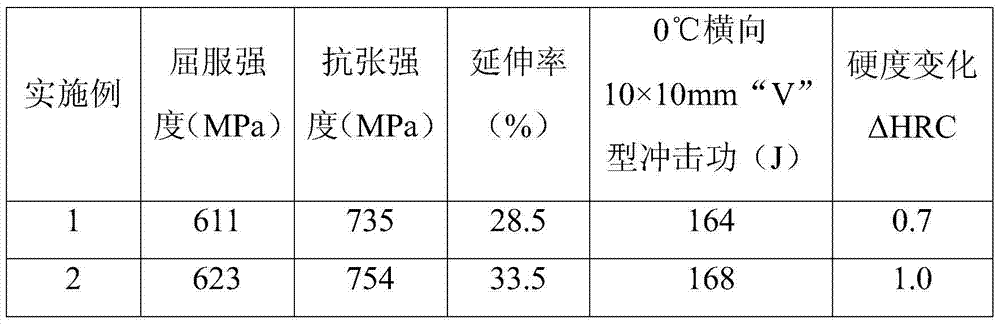

H2S corrosion-resistant 80-ksi casing steel for shale gas and preparation method thereof

ActiveCN105483528AReduce in quantityEasy to shapeElectric furnaceProcess efficiency improvementSteelmakingQuenching

The invention discloses H2S corrosion-resistant 80-ksi casing steel for shale gas. The casing steel is prepared from, by weight, 0.25%-0.29% of C, 0.20%-0.35% of Si, 0.90%-1.10% of Mn, 0.95%-1.15% of Cr and the balance Fe, residual elements and unavoidable impurities. The invention further discloses a preparation method of the H2S corrosion-resistant 80-ksi casing steel for the shale gas. The preparation method comprises the steps of steelmaking, wherein pig iron and waste plain carbon steel are adopted as raw materials in the steelmaking process, a deoxidizing agent is added in the steel tapping process, static blowing treatment is performed in a VD vacuum chamber, and argon blowing and sealing gasket adding for protection are performed during pouring; pipe manufacturing, wherein the temperature of a heating zone ranges from 1210 DEG C to 1270 DEG C, and the temperature of a soaking zone ranges from 1240 DEG C to 1260 DEG C; heat treating, wherein the heat treatment technologies of spraying and inner axial flow water cooling quenching, air cooling tempering and straightening under the temperature are adopted. According to the casing steel, the yield strength is 552-655 MPa, the tensile strength is larger than or equal to 655 MPa, the transverse 10*10-mm V-shaped impact energy at 0 DEG C is larger than or equal to 40 J, the elongation is larger than or equal to 19%, and the allowed hardness change delta HRC is smaller than or equal to 3.0.

Owner:PANGANG GROUP CHENGDU STEEL & VANADIUM

Rolling method of X80 pipeline steel plate

InactiveCN112126865AImprove heating qualityReduce rolling passesChemical compositionUltimate tensile strength

The invention discloses a rolling method of an X80 pipeline steel plate. Steel comprises the following chemical components including, by mass, 0.03%-0.08% of C, 1.40%-1.7% of Mn, less than or equal to0.001% of S, less than or equal to 0.01% of P, 0.015%-0.25% of Si, less than or equal to 0.1% of Nb, less than or equal to 0.04% of V, 0.015%-0.03% of Ti, 0.025%-0.06% of Alt, 0.6%-1.0% of Mo+Ni+Cu+Cr and the balance Fe and inevitable impurity elements. A key process comprises heating and rolling. According to the method, the chemical component design concept of compounding microalloy elements such as low carbon, low sulfur, low silicon, low phosphorus, Mo+Ni+Cu+Cr and the like is adopted, temperature gradient rolling is adopted for rough rolling, low-temperature high-pressure rolling is adopted for finish rolling, and a three-stage cooling manner is adopted for cooling after rolling, so that a pipeline steel plate which mainly comprises QF+BF and has a small amount of MA is produced. According to the pipeline steel plate, dispersed distribution is adopted, the grain size reaches 11 grades to 12 grades, the pipeline steel plate is of a microstructure with uniform structure sizes at different positions in the thickness direction, the yield strength is 500 Mpa-550 Mpa, the DWTT single value is larger than or equal to 70% at the experimental temperature of -20 DEG C, the average value is larger than or equal to 85%, the thickness is 38.5 mm, the width is 4336 mm, the steel grade is X80, and the low-temperature (-20 DEG C) crack arrest performance is excellent.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

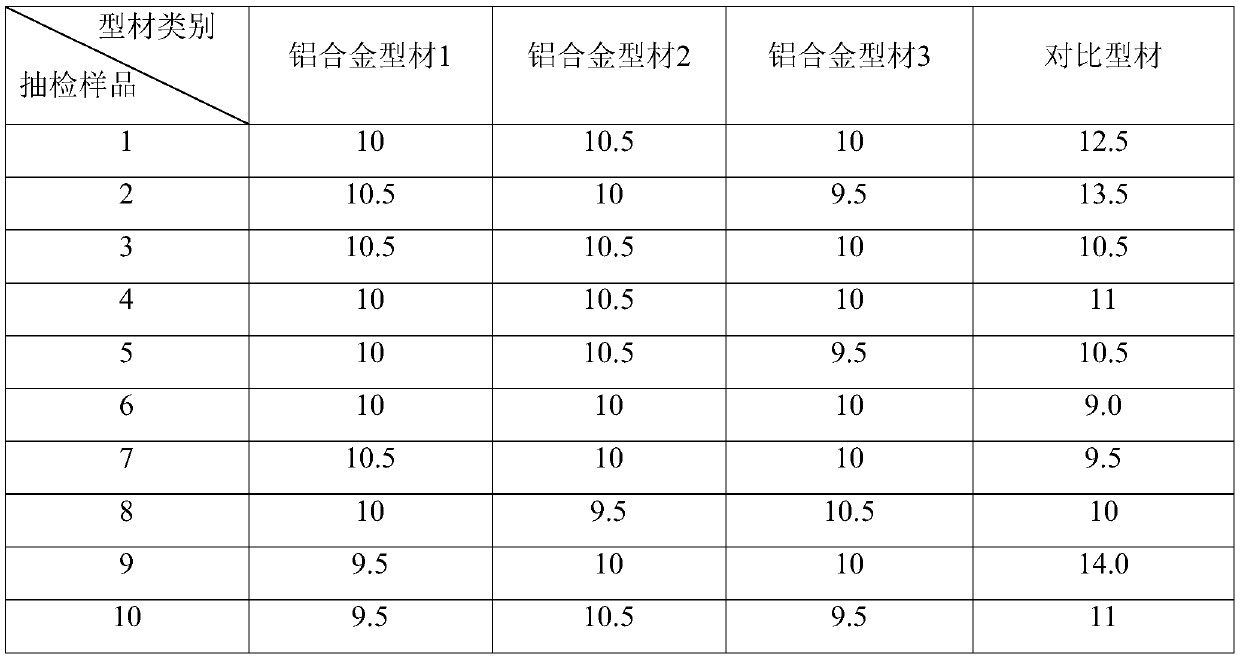

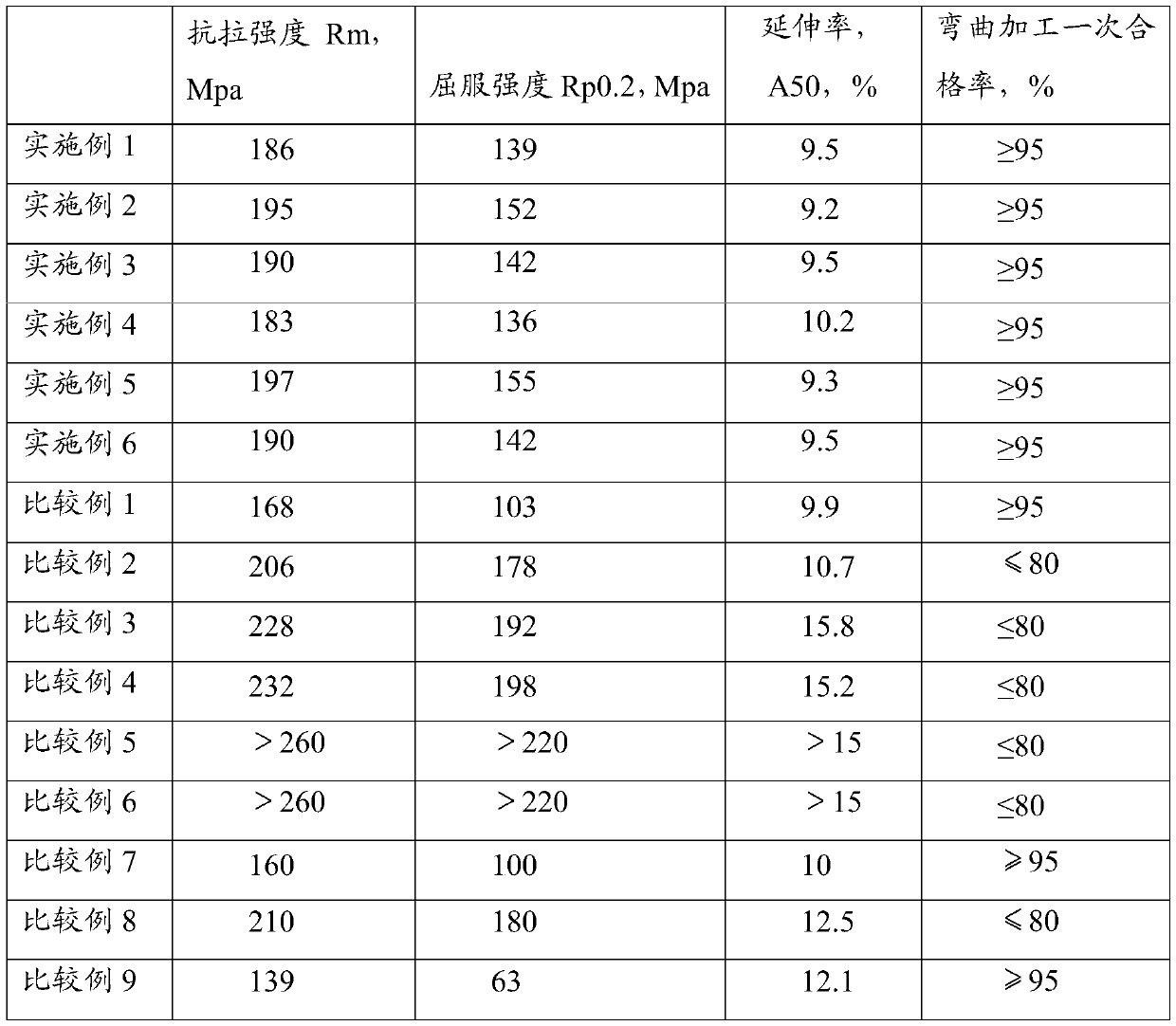

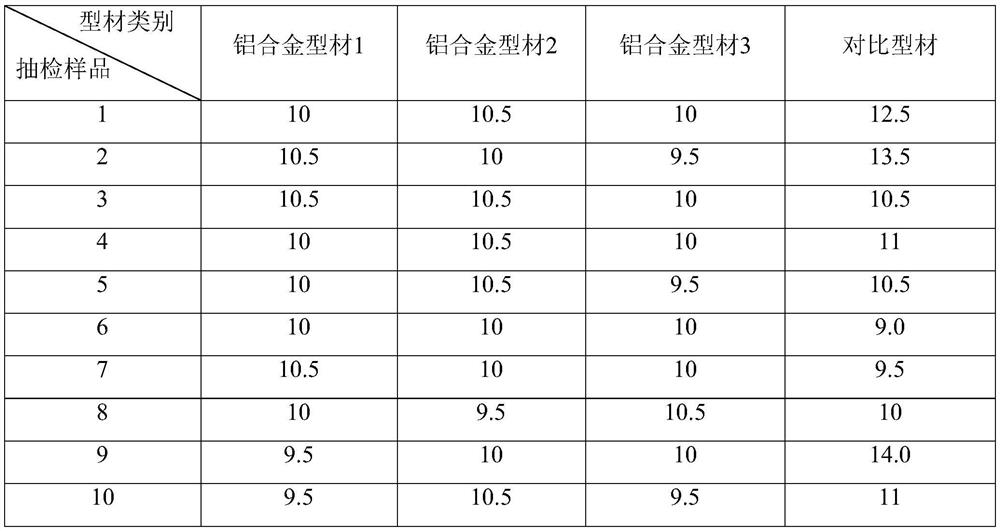

Aluminum alloy for manufacturing vehicle skylight guide rails and production process thereof

The invention discloses an aluminum alloy for manufacturing vehicle skylight guide rails and a production process thereof. The aluminum alloy comprises the following raw materials in parts by weight:0.25-0.31% of Si, Fe not more than 0.15%, Cu not more than 0.05%, 0.03-0.09% of Mn, 0.47-0.53% of Mg, Zn not more than 0.05%, Ti not more than 0.05%, single impurity not more than 0.05%, the sum of impurities not more than 0.15%, and the balance of Al. For vehicle skylight products, the requirements thereof on the mechanical performances of aluminum profiles are strict, for example, the hardness is 9.5-11.5 HW, and the yield strength is 120-160 Mpa. Through a specific formula and specific process, the hardness and yield strength of the skylight windows can be preferably stabilized within the range. During actual production, vehicle skylight guide rail profiles can be obtained through once machining and bending, so that the skylight bending efficiency is improved; and the radian of the products can reach within a tolerance of 0.4 mm, so that a previous aluminum profile screening procedure is totally prevented, the profile cracking phenomenon during machining is eliminated, a punching process has no need to be adjusted according to the hardness of the products, and the efficiency of a production line is improved by above 20%.

Owner:广东齐力澳美高新材料股份有限公司

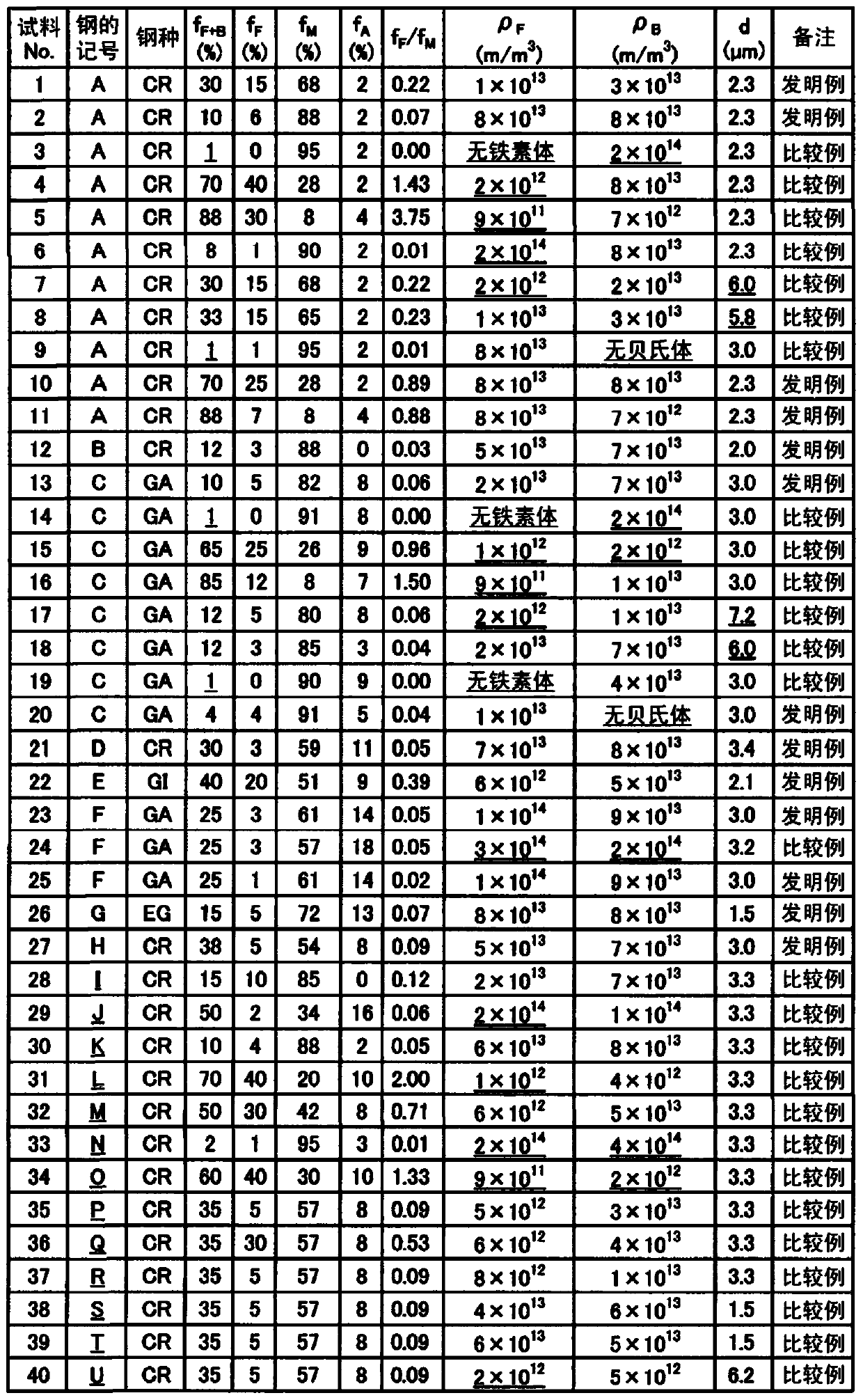

Steel sheet

InactiveUS20180237881A1Stable yield strengthHot-dipping/immersion processesFurnace typesChemical compositionComposite material

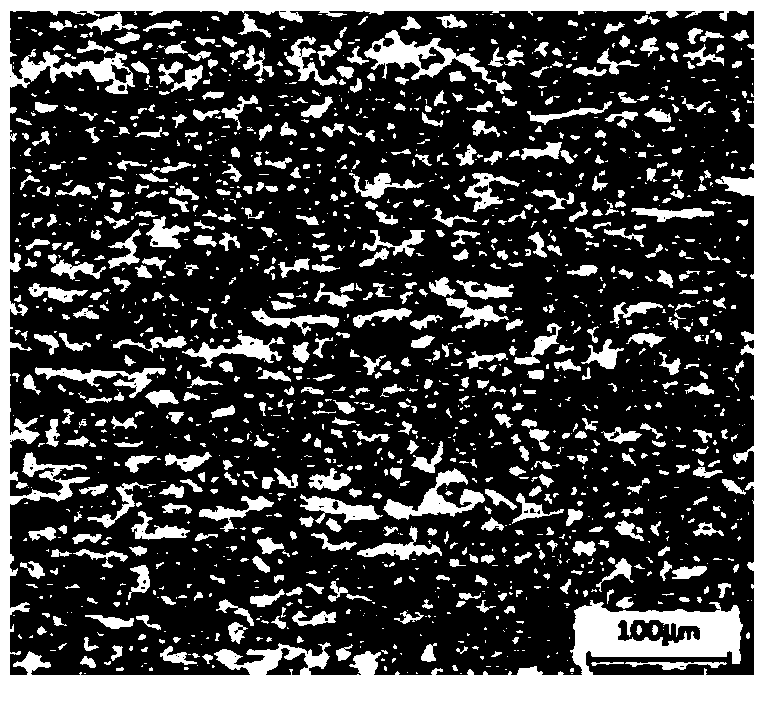

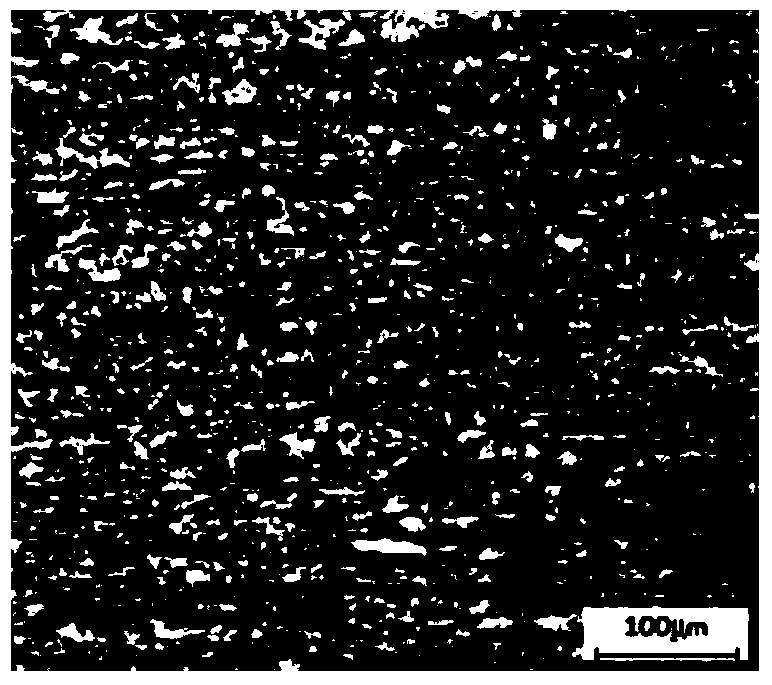

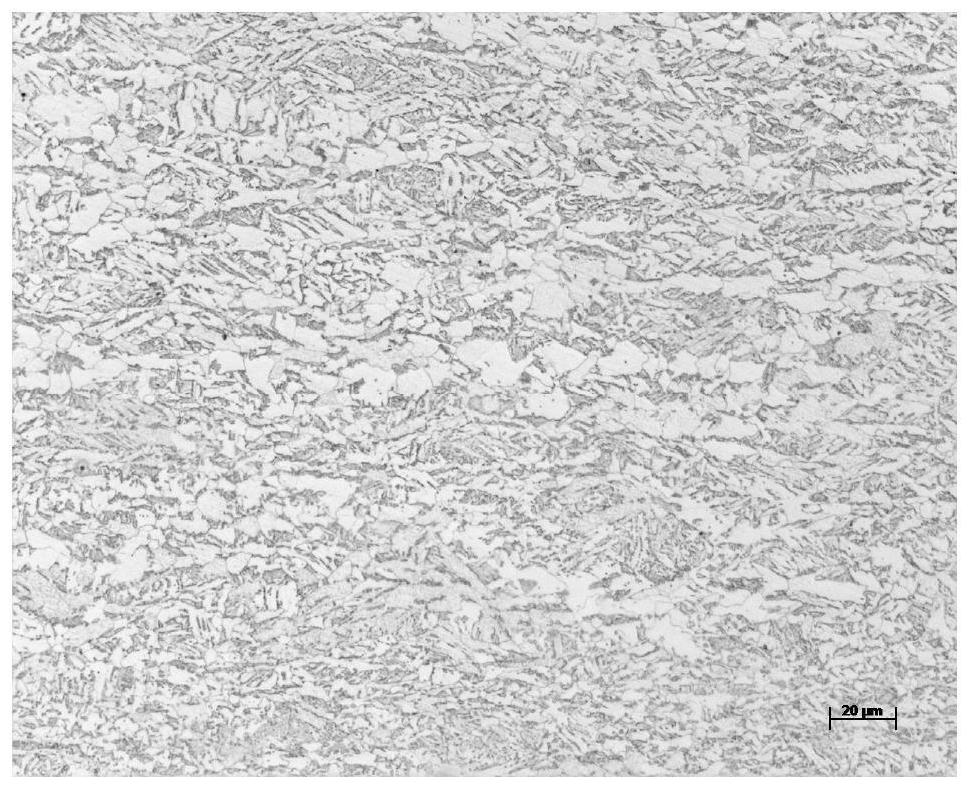

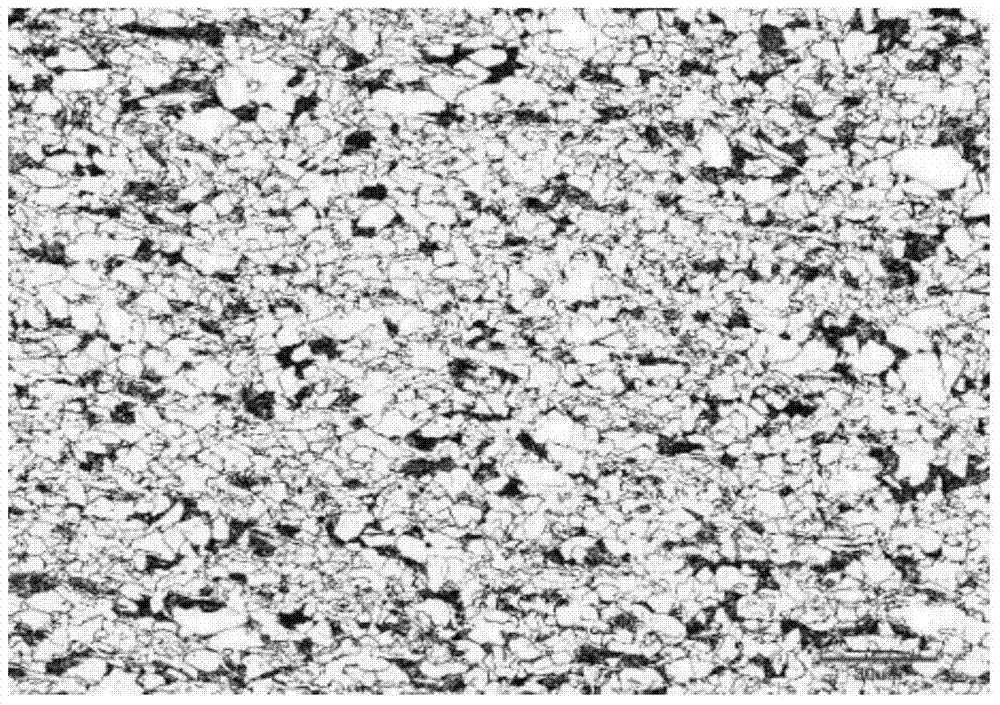

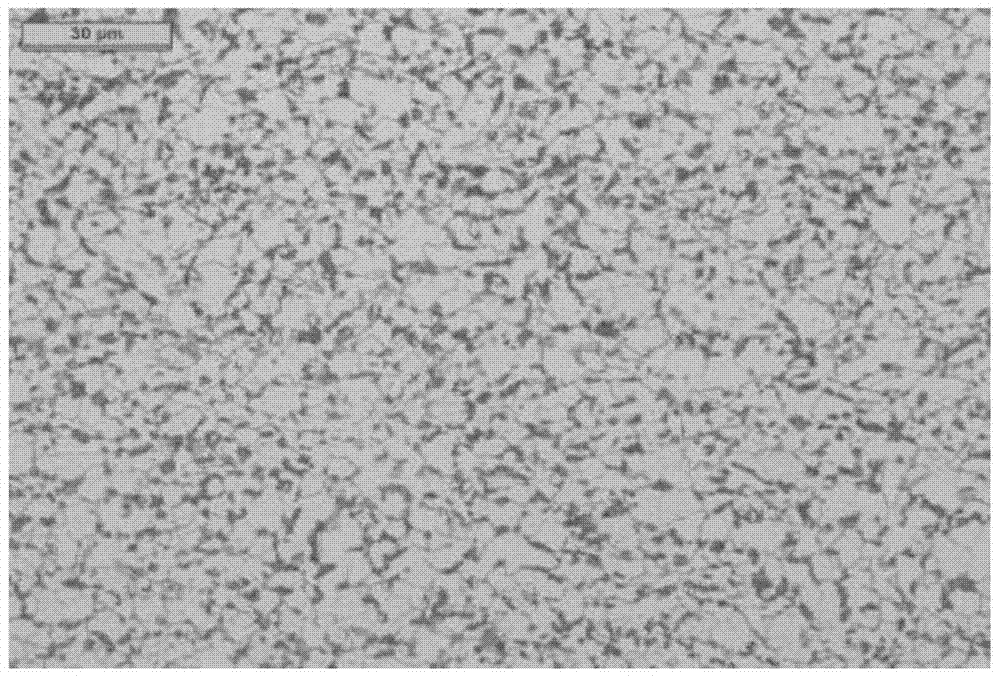

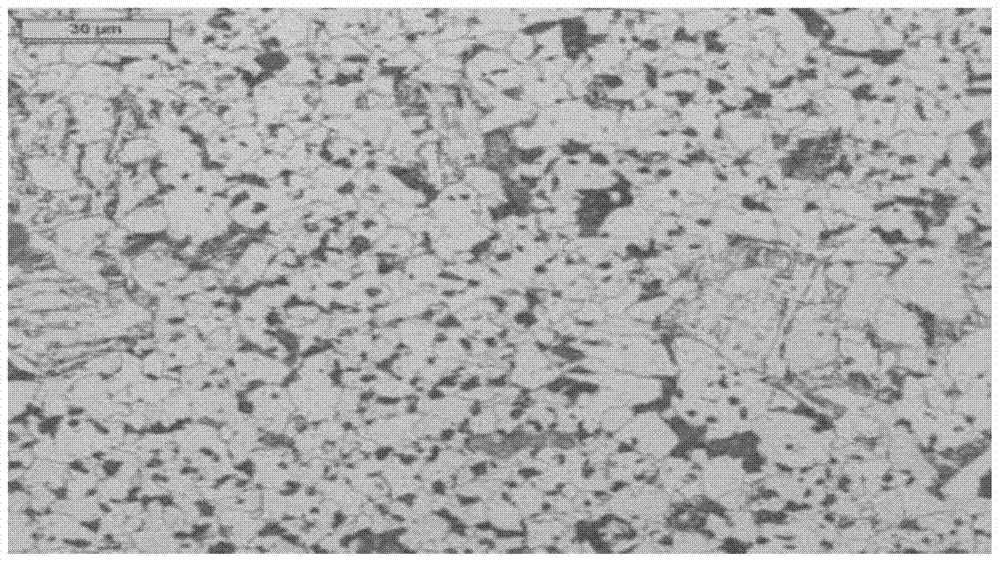

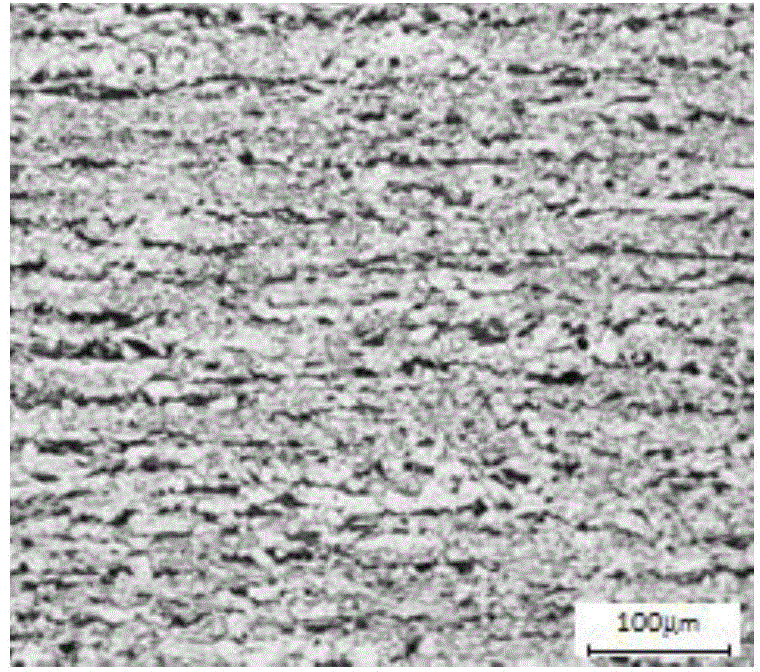

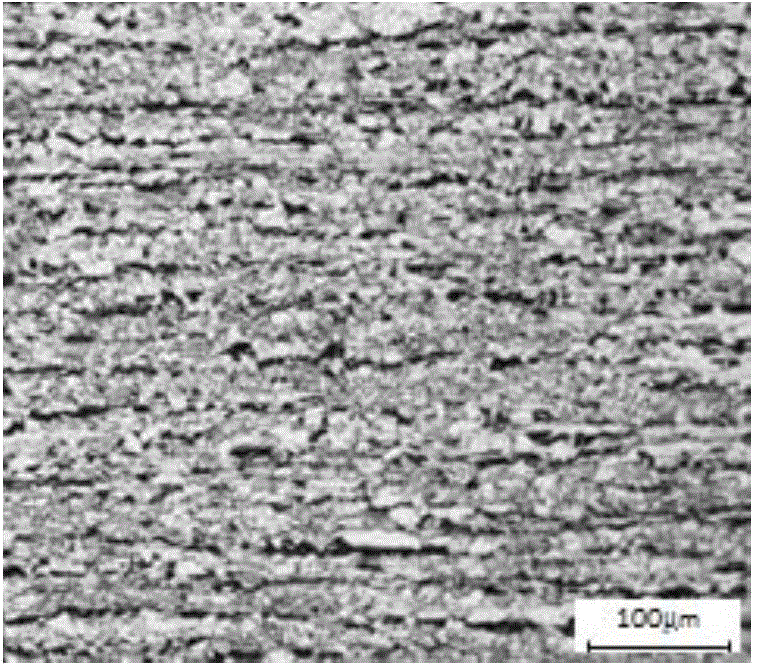

A steel sheet includes: a predetermined chemical composition; and a steel structure containing, in are a fraction, 2% or more of ferrite and bainite, in which an average dislocation density in the ferrite and an average dislocation density in the bainite are both h3×1012 m / m3 to 1×1014 m / m3, and an average grain diameter of the ferrite and the bainite is 5 μm or less.

Owner:NIPPON STEEL CORP

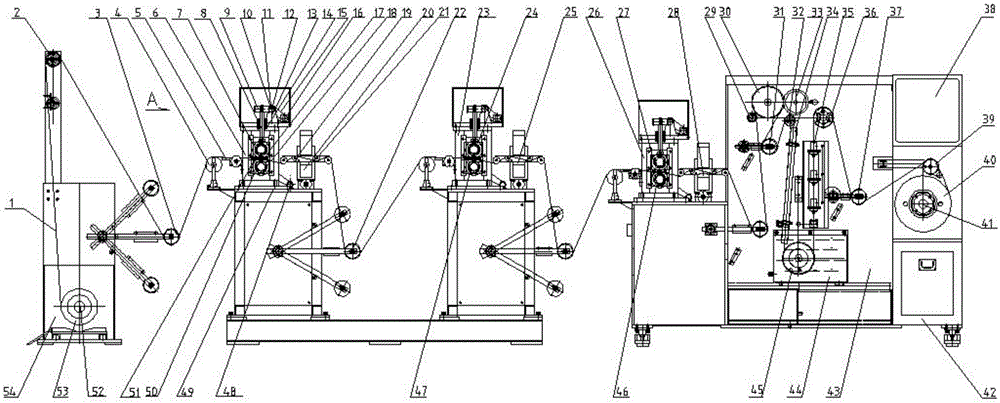

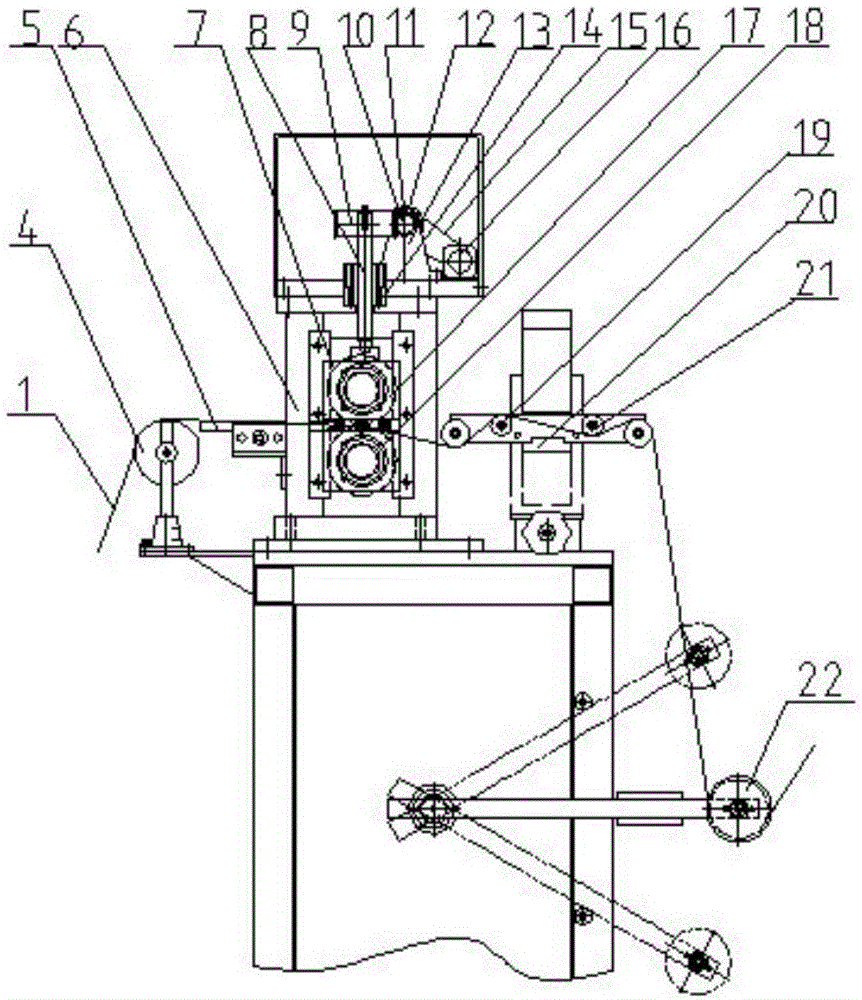

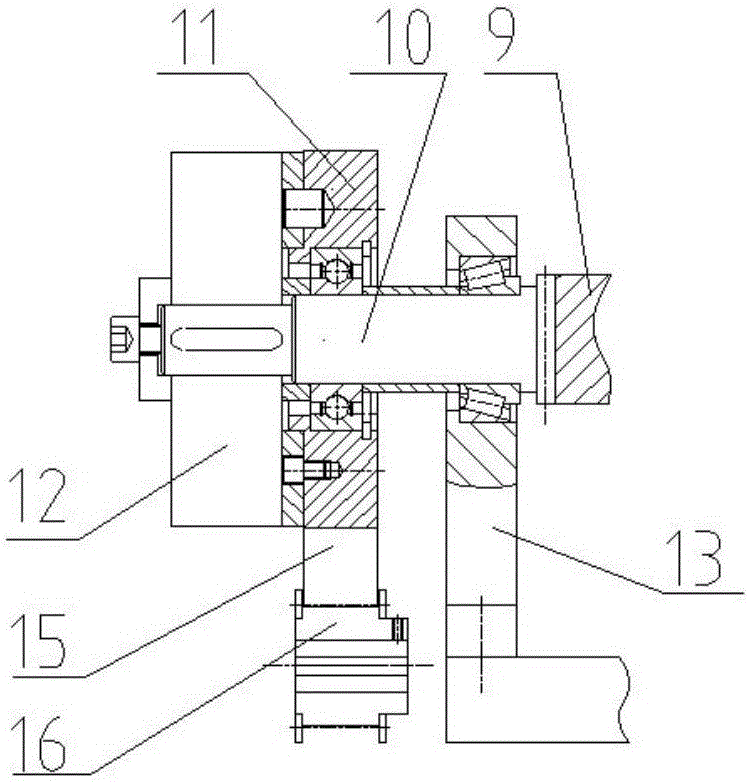

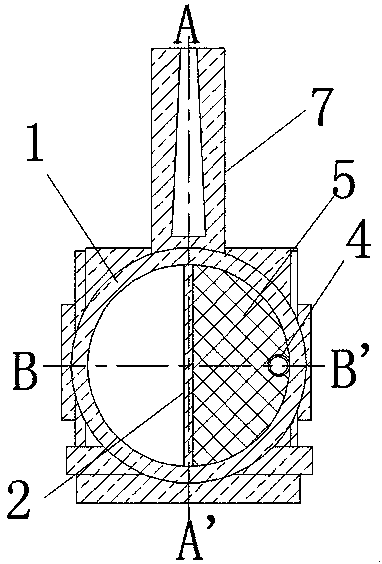

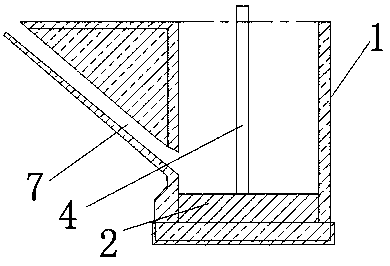

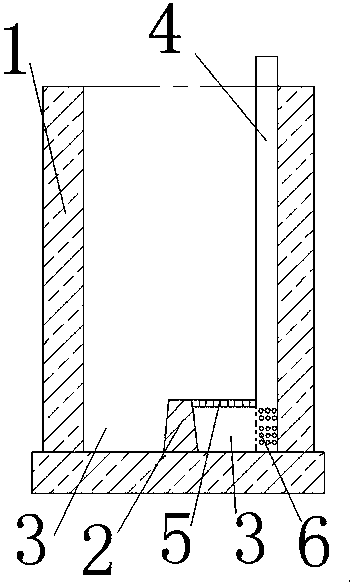

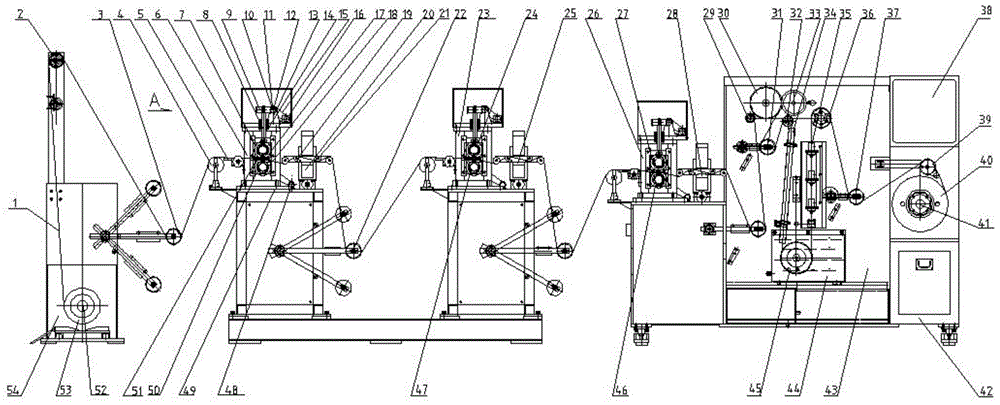

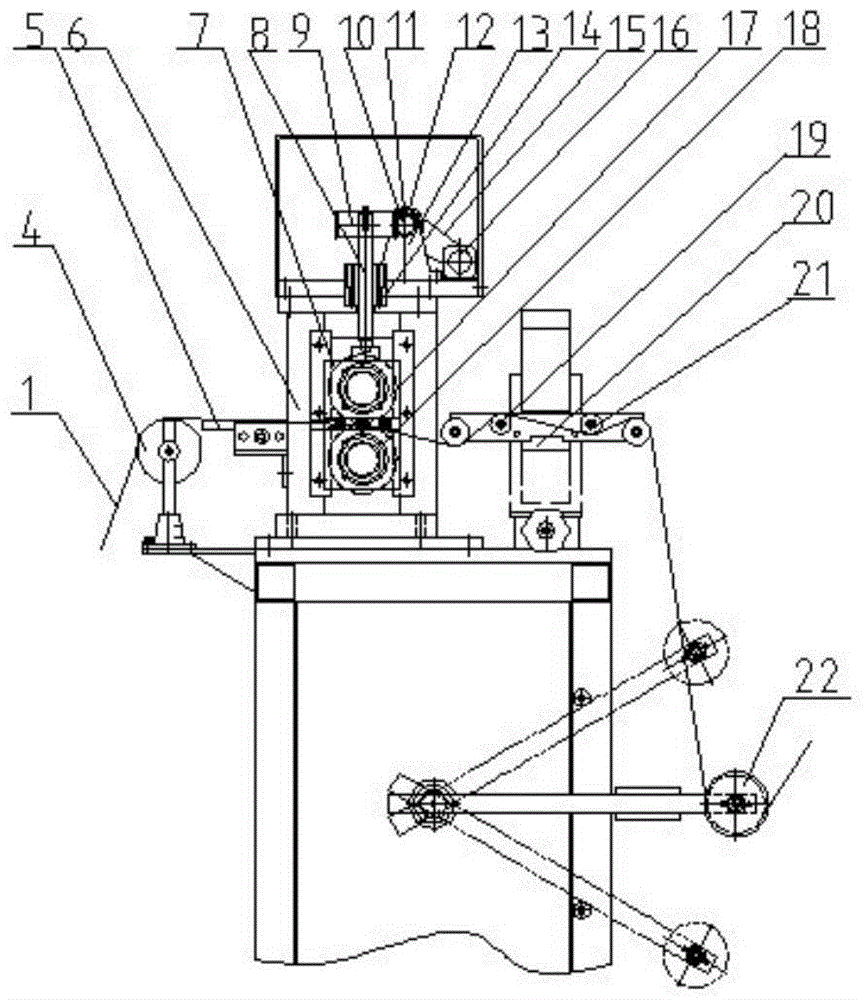

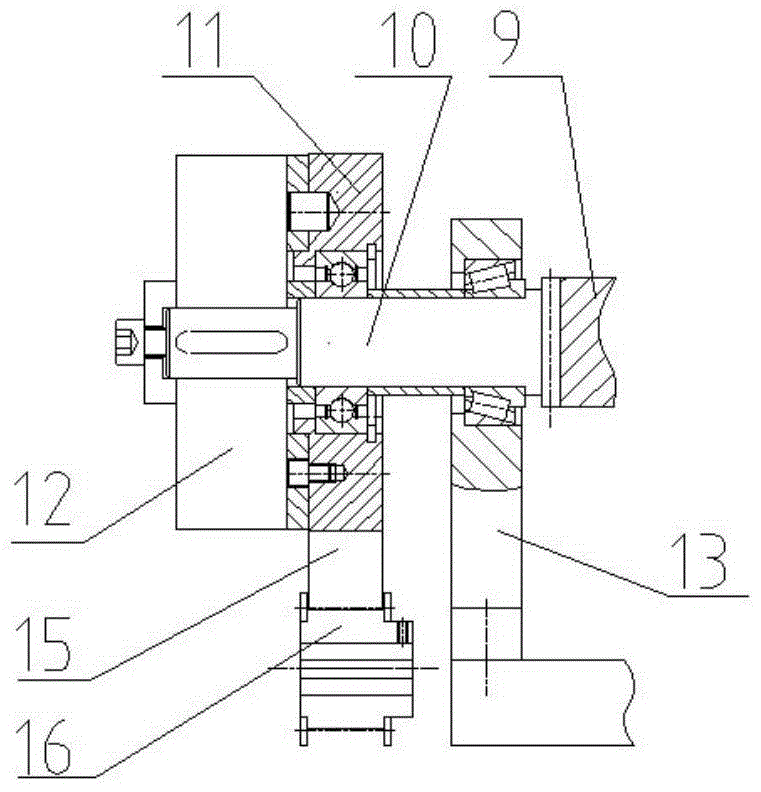

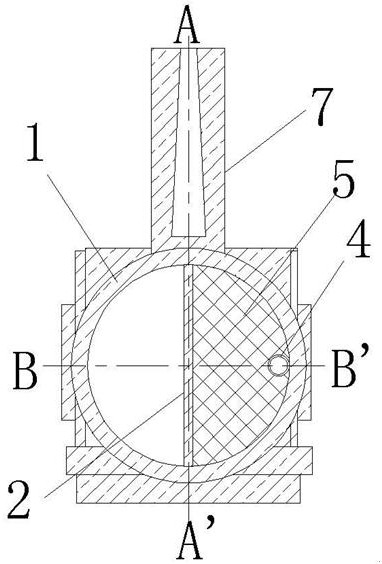

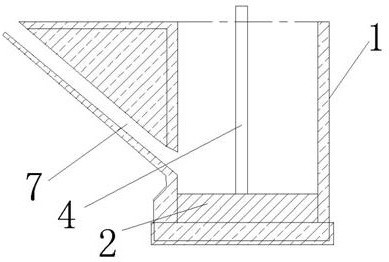

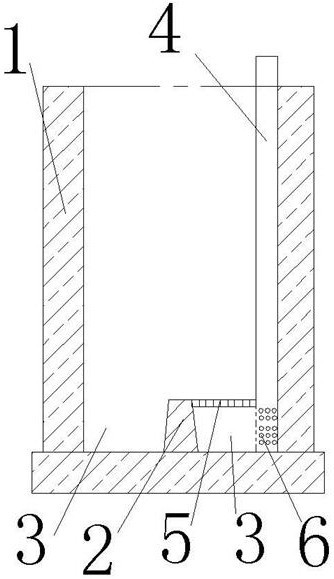

Intelligent embossing solder strip manufacturing unit

ActiveCN105057347AStable yield strengthImprove photoelectric conversion efficiencyTension/compression control deviceMetal rolling arrangementsEngineeringMechanical engineering

The invention discloses an intelligent embossing solder strip manufacturing unit. The intelligent embossing solder strip manufacturing unit comprises a pay-off mechanism, a rolling roller mechanism, an embossing roller mechanism, a finishing roller mechanism, a heat treatment mechanism and an intelligent take-up mechanism. A wire is led out of a pay-off spool in the pay-off mechanism to be paid off to a guide wheel on a rolling roller rack in the rolling roller mechanism; then the wire passes through a first upper roller, a first lower roller and a first laser diameter measuring instrument on the rolling roller rack and then arrives at an embossing roller, a second lower roller and a second laser diameter measuring instrument on an embossing roller rack in the embossing roller mechanism; afterwards, the wire arrives at a finishing roller, a third lower roller and a third laser diameter measuring instrument on a finishing roller rack in the finishing roller mechanism; and the wire passes through an upper electrode wheel and a lower electrode wheel in a heat treatment machine box in the heat treatment mechanism and then arrives at a take-up spool in the intelligent take-up mechanism.

Owner:JIANGSU GAOHE INTELLIGENT EQUIP CO LTD

Outer packing material for high-punching-depth battery device

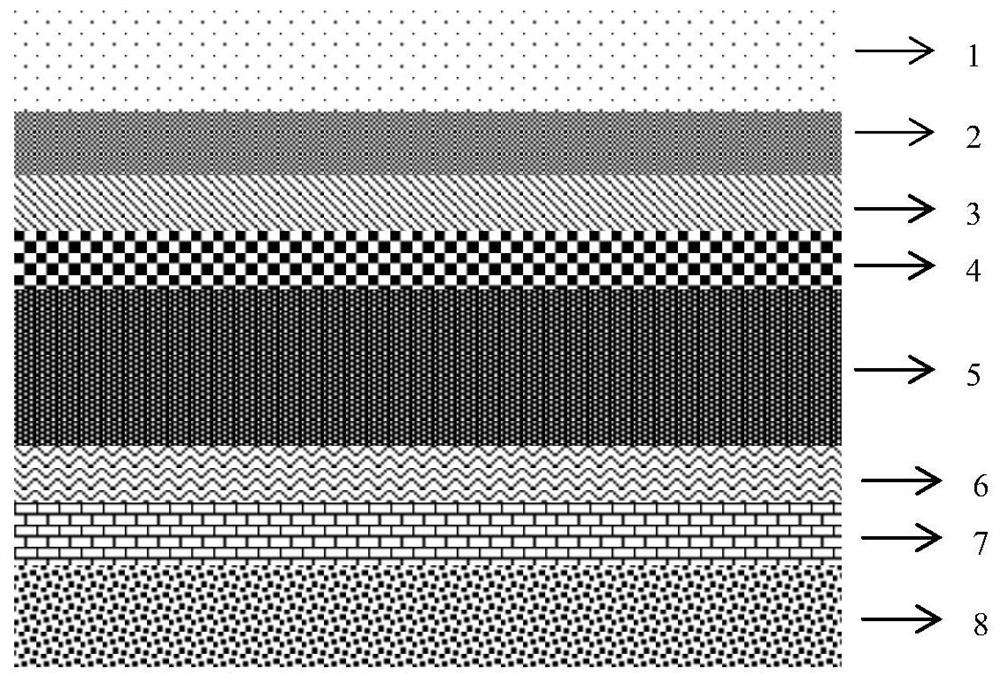

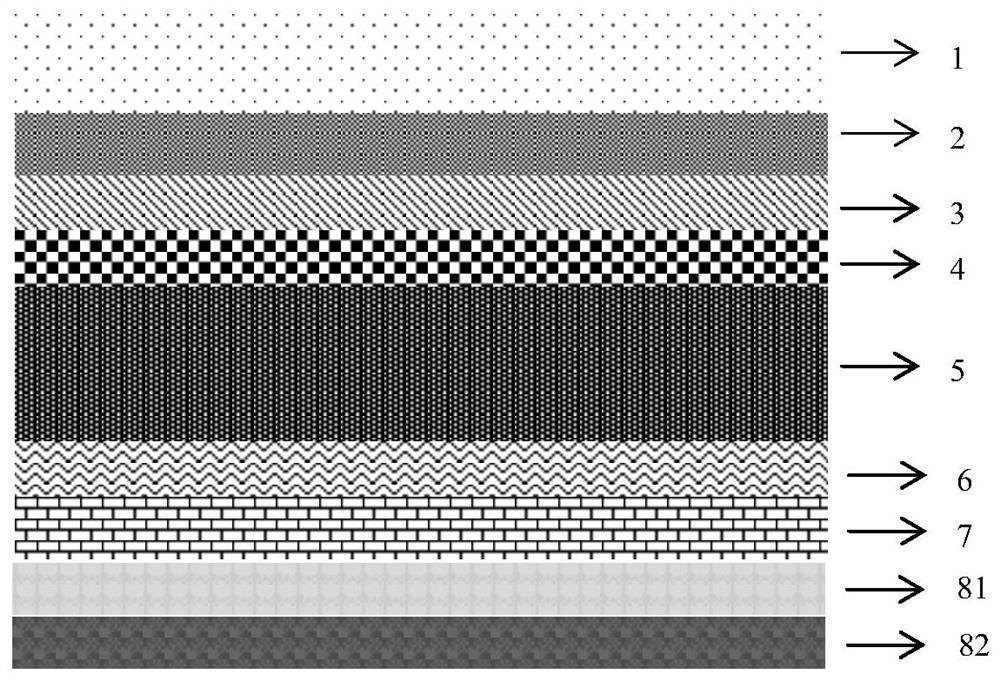

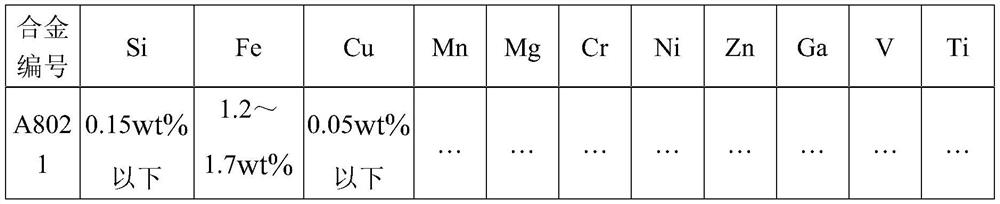

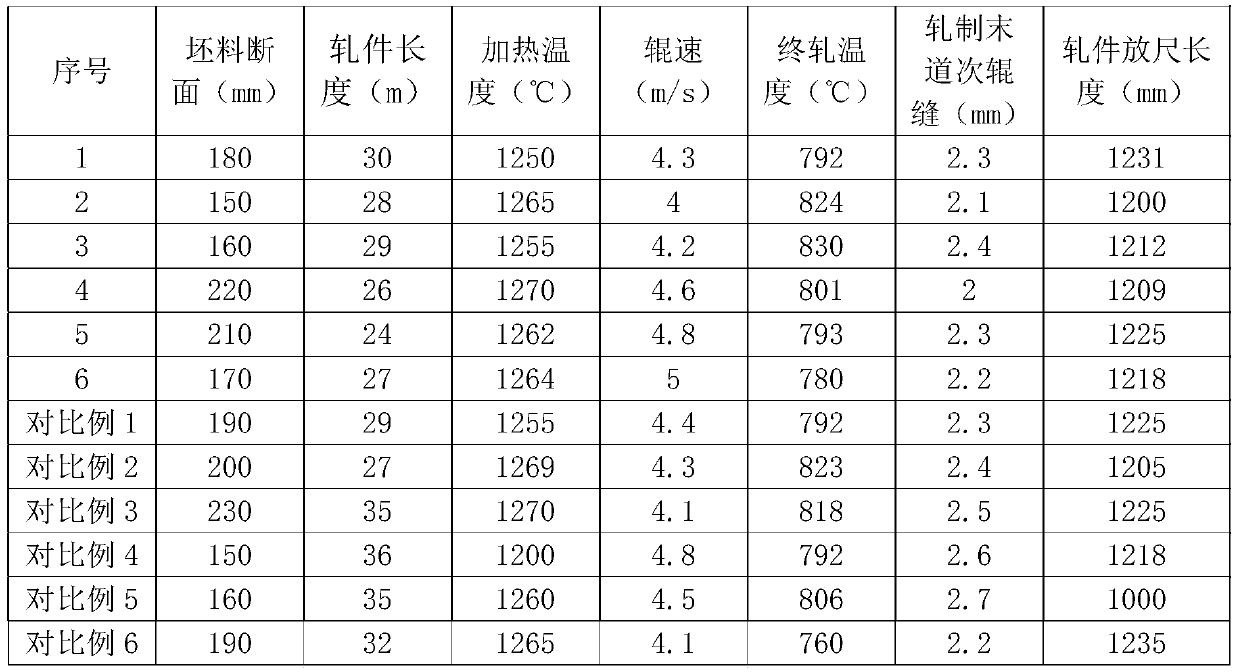

PendingCN113927973AGood formabilityStable breaking strengthTemperature control deviceSynthetic resin layered productsCrystal orientationBattery cell

The invention discloses an outer packaging material for a high-punching-depth battery device. The outer packaging material at least comprises an outer base material resin layer, an intermediate metal layer and an inner hot melting resin layer; the intermediate metal layer comprises an aluminum alloy foil containing aluminum (Al), iron (Fe), silicon (Si), copper (Cu), zinc (Zn), and titanium (Ti), wherein in the aluminum alloy foil, when an aggregate crystal having crystal orientation anisotropy is observed by using EBSD (electron beam back scattering analysis), the orientation distribution of the surface of the aluminum alloy foil is detected, the total ratio of the Cube orientation, the Cu orientation, the s orientation, the Bs orientation, and the R orientation is 70% or more with respect to the total of the detected ratio having anisotropy and the detected ratio having no anisotropy; the total ratio of the Cube orientation and the Cu orientation is 30% or more; the ratio of the Cube orientation is 10% or more; and the average size of the crystal grain size is 10.0 [mu]m or less, the content of the alloy component silicon (Si) is 0.05 wt% or less, the content of the copper (Cu) is 0.004 wt% or more, the content of the zinc (Zn) is 0.01 wt% or less, and the content of the titanium (Ti) is 0.02 wt% or less.

Owner:JIANGXI RUIERGY NEW MATERIAL TECH CO LTD

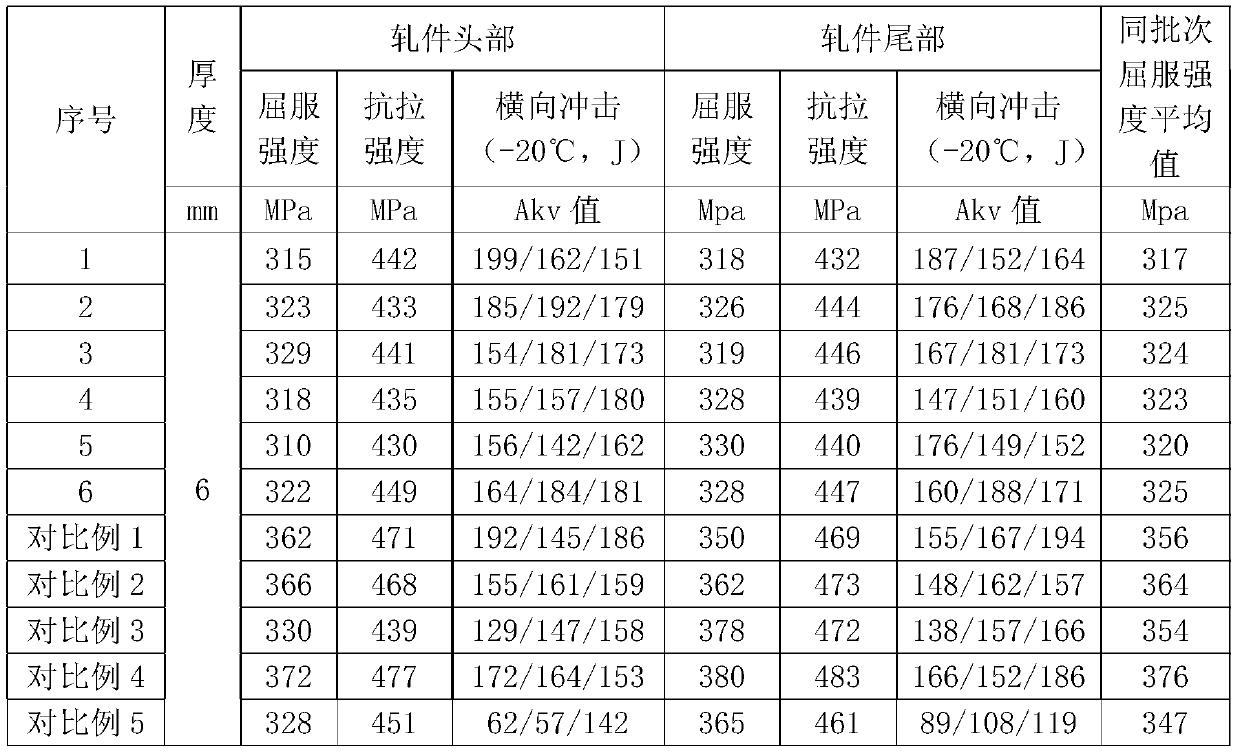

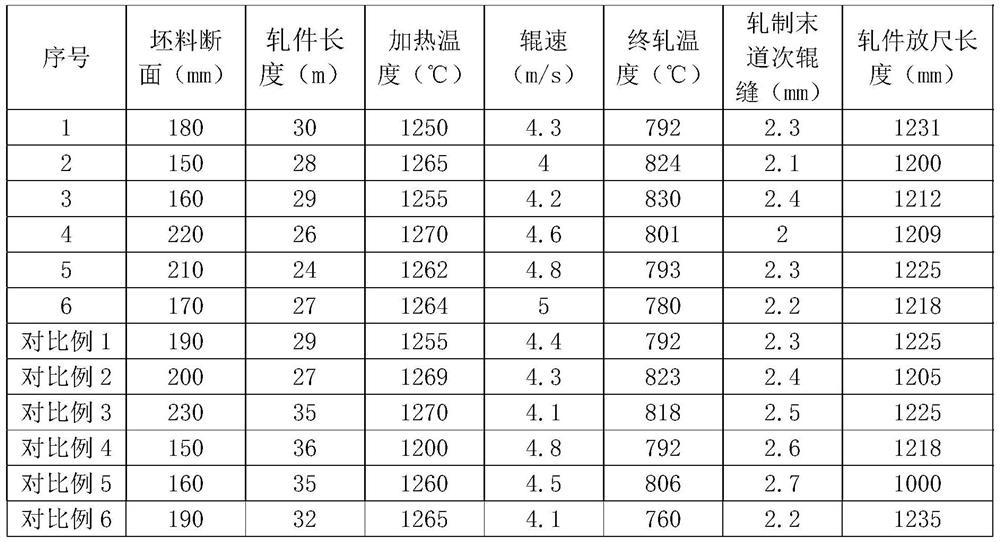

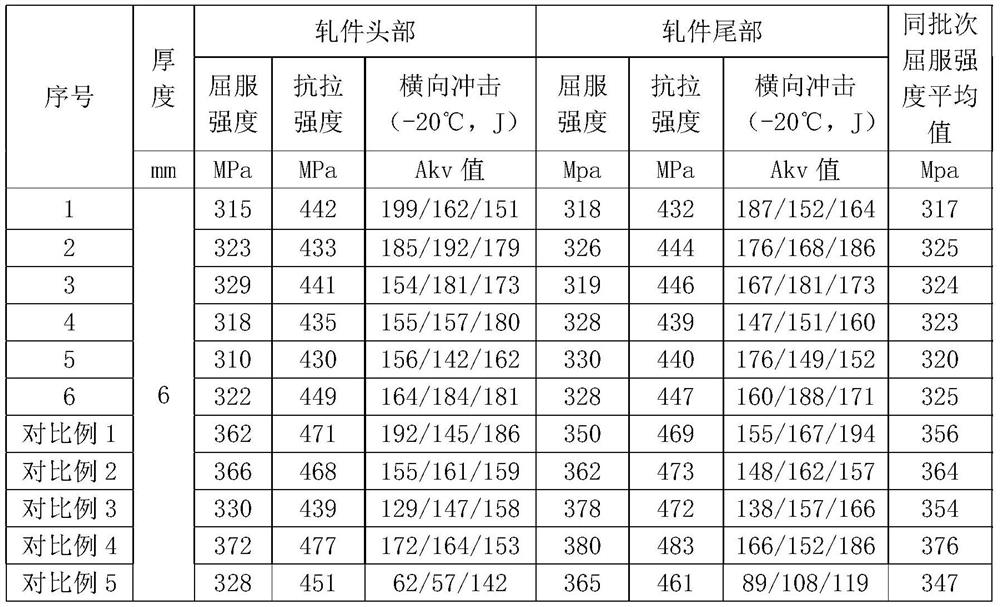

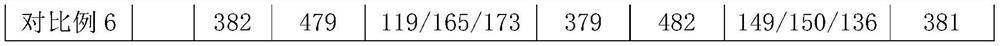

Steel for nuclear-power containment with thickness of 6 mm and manufacturing method of steel

ActiveCN111270153AEnsure yield strength stabilityTaking into account the radiation effectMetal rolling arrangementsNuclear physicsSteel plates

The invention discloses steel for nuclear-power containment with thickness of 6 mm and a manufacturing method of the steel. The low-C and low-Mn composition series design for the steel, extra alloyingcomponents are not added, and an irradiation effect is taken into consideration while yield strength stability is guaranteed. According to the manufacturing method, by means of optimization of blanktype, length of a rolled piece is effectively controlled in a rolling process, and larger temperature fluctuation caused by the too long rolled piece is avoided. With the adoption of superhigh-temperature heating mechanism, higher temperature for blanks is obtained during rolling, and higher final rolling temperature for a steel plate is guaranteed after the rolling is finished. By means of control for the rolling process, temperature drop in the process is reduced, and smaller temperature difference fluctuation of the head and the tail of the rolled piece is guaranteed. The length of the rolled piece is optimized and an area with poorer plate cut is cut off, and performance uniformity of a sampling position is ensured. The 6mm nuclear-power steel produced with the method has the advantages that yield strength is controlled stably, the toughness matching is excellent, and requirements for performance are met completely. The performance qualification rate of production reaches 94%, andthe steel is completely applicable to industrial mass production.

Owner:NANJING IRON & STEEL CO LTD

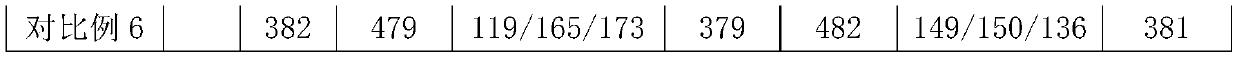

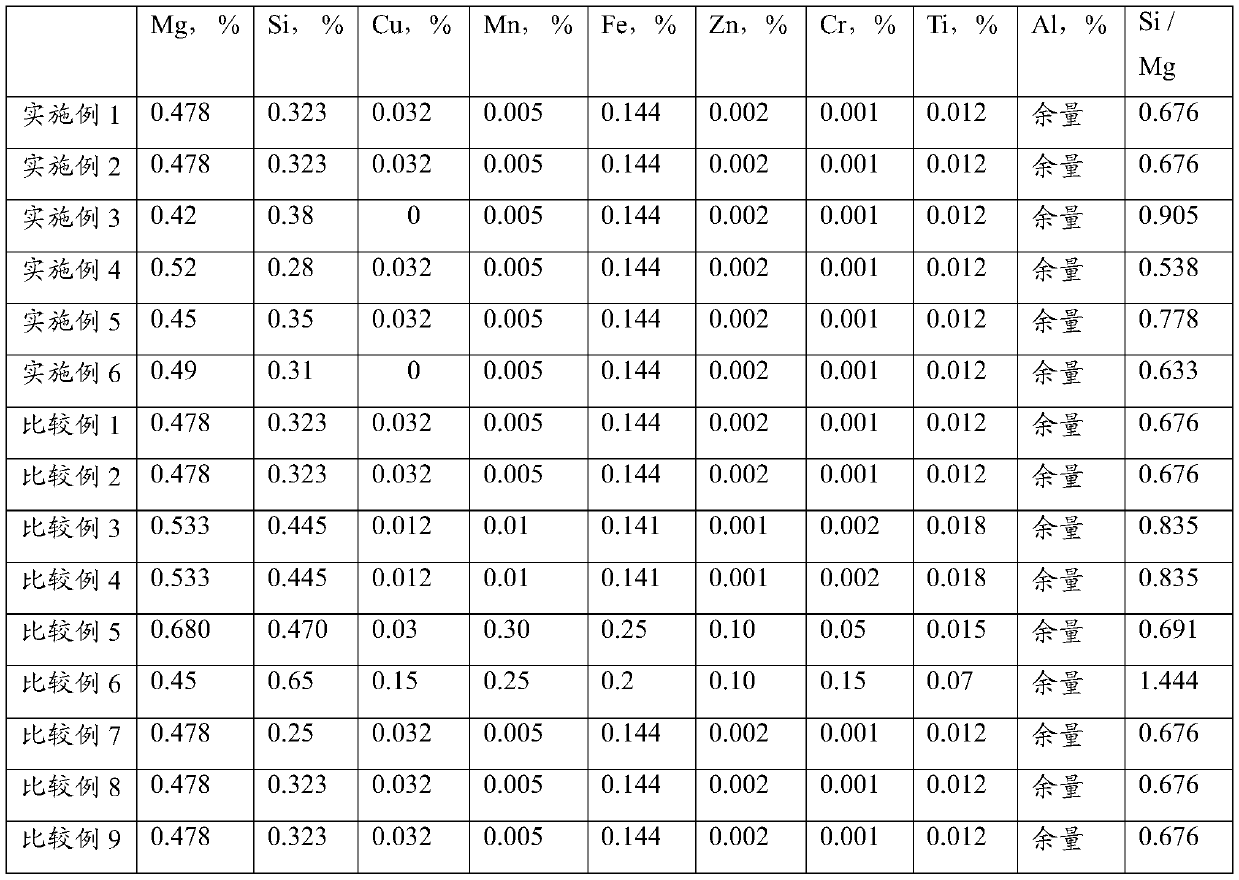

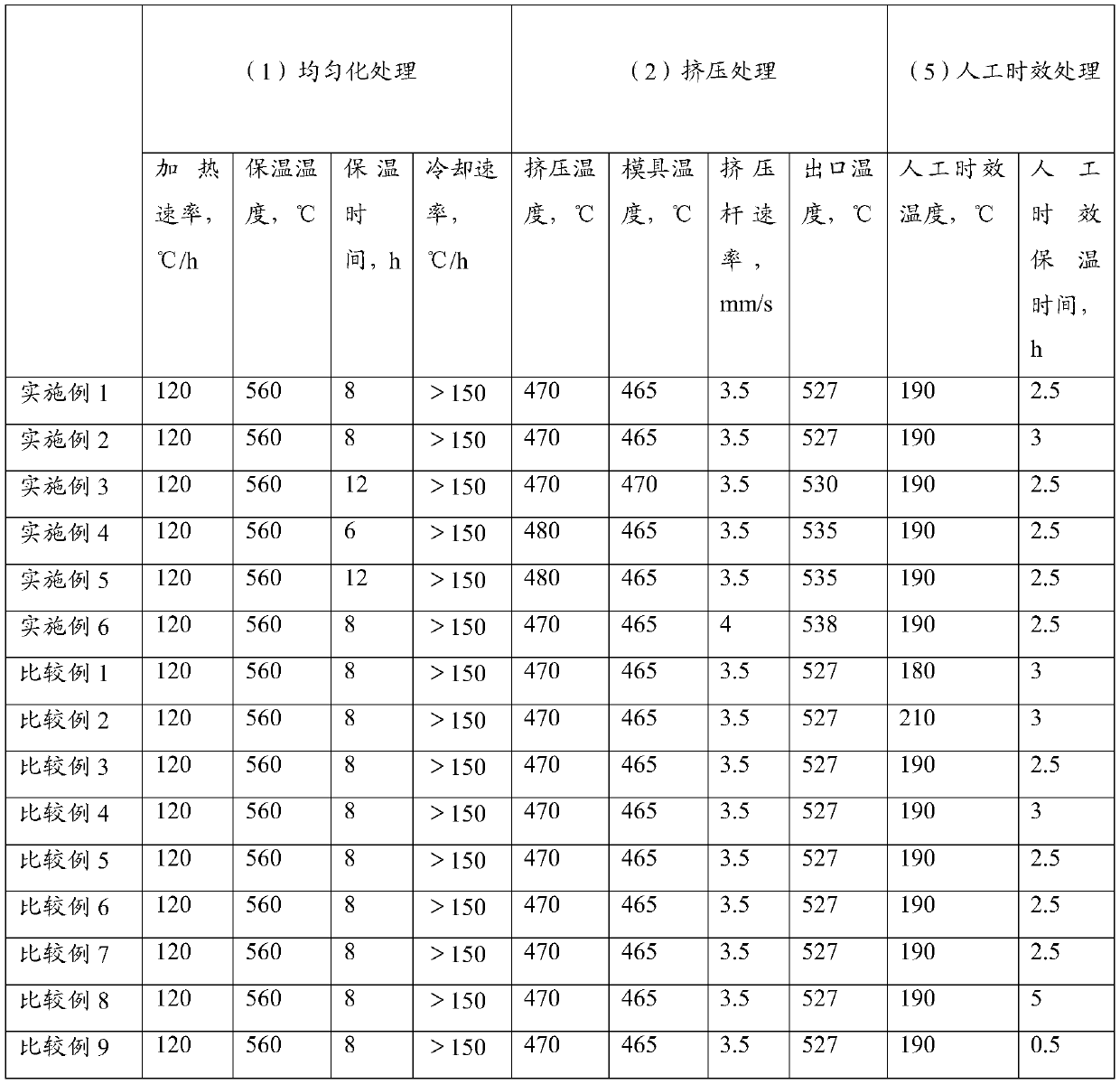

Processing method of aluminum alloy profile and aluminum alloy profile prepared with method

The invention provides a processing method of an aluminum alloy profile and the aluminum alloy profile prepared with the method. The processing method comprises steps as follows: (1), homogenizing treatment: aluminum bars comprising 0.42%-0.52% of Mg, 0.28%-0.38% of Si, smaller than or equal to 0.025% of Mn, smaller than or equal to 0.18% of Fe, smaller than or equal to 0.018% of Zn, smaller thanor equal to 0.012% of Cr, smaller than or equal to 0.03% of Ti and the balance Al are heated to 530-580 DEG C from the room temperature at a heating rate of 50-220 DEG C / h, a mass ratio of Si to Mg is0.538-0.905, the temperature is kept for 5-20 h, and then the aluminum bars are cooled at a cooling rate of smaller than 100 DEG C / h and cooled to be lower than 100 DEG C; (2), extruding treatment: the extruding temperature of the aluminum bars is 450-480 DEG C, die temperature is 450-470 DEG C, the speed of an extruding bar is 3.0-4.0 mm / s, and the temperature of a profile outlet is controlled at 500-540 DEG C; (3), online strong wind cooling treatment; (4), stretch strengthening treatment; and (5), artificial aging treatment: the heat preservation temperature is 185-195 DEG C, and the heatpreservation time is 2-3 h. The aluminum alloy profile prepared with the new processing method has small yield strength and tensile strength fluctuation and good bending processing performance, firstpass yield of bending processing is higher than or equal to 95%, and production cost is reduced.

Owner:中亿丰金益(苏州)科技有限公司

Preparation of normalizing weldable fine grain steel plate with a yield strength of 420MPa

ActiveCN101413049BReduce intensityWarranty Strength RequirementsTemperature control deviceMetal rolling arrangementsMechanical propertyCooling temperature

The invention provides a method for preparing normalized weldable fine-grain steel plates with the yield strength of 420 MPa, which belongs to the technical field of manufacturing medium thick steel plates. A production process comprises the following steps: a continuous casting billet is heated to be between 1,200 and 1,250 DEG C, and the heat is preserved for 4 to 5 hours; hot rolling is performed after heat preservation; rolling is divided into two stages, namely recrystallization zone rolling and non-recrystallization zone rolling; intermediate temperature waiting thickness is controlled to be between 2.5 and 4.0 times the thickness of a finished product; the initial rolling temperature of a non-recrystallization zone is controlled between 850 and 880 DEG C; the final rolling temperature is controlled between 810 and 830 DEG C; water cooling is performed after hot rolling; the final cooling temperature is controlled between 650 and 740 DEG C, and cooling rate is controlled between5 and 8 DEG C per second; and the steel plates are normalized at a temperature between 880 and 910 DEG C and then are thermally insulated for 5 to 20 minutes. The method has the advantages that the steel plates are excellent in mechanical properties; the mechanical property of the steel plate can stably reach over 420 MPa; the tensile strength of the steel plates can stably reach over 550 MPa; and the V-type notched impact energy of the steel plates at 50 DEG C below zero can stably reach over 140 J.

Owner:SHOUGANG CORPORATION

80ksi anti-h for shale gas 2 s-corrosion casing steel and manufacturing method thereof

ActiveCN105483528BReduce in quantityEasy to shapeProcess efficiency improvementElectric furnaceSteelmakingQuenching

The invention discloses H2S corrosion-resistant 80-ksi casing steel for shale gas. The casing steel is prepared from, by weight, 0.25%-0.29% of C, 0.20%-0.35% of Si, 0.90%-1.10% of Mn, 0.95%-1.15% of Cr and the balance Fe, residual elements and unavoidable impurities. The invention further discloses a preparation method of the H2S corrosion-resistant 80-ksi casing steel for the shale gas. The preparation method comprises the steps of steelmaking, wherein pig iron and waste plain carbon steel are adopted as raw materials in the steelmaking process, a deoxidizing agent is added in the steel tapping process, static blowing treatment is performed in a VD vacuum chamber, and argon blowing and sealing gasket adding for protection are performed during pouring; pipe manufacturing, wherein the temperature of a heating zone ranges from 1210 DEG C to 1270 DEG C, and the temperature of a soaking zone ranges from 1240 DEG C to 1260 DEG C; heat treating, wherein the heat treatment technologies of spraying and inner axial flow water cooling quenching, air cooling tempering and straightening under the temperature are adopted. According to the casing steel, the yield strength is 552-655 MPa, the tensile strength is larger than or equal to 655 MPa, the transverse 10*10-mm V-shaped impact energy at 0 DEG C is larger than or equal to 40 J, the elongation is larger than or equal to 19%, and the allowed hardness change delta HRC is smaller than or equal to 3.0.

Owner:PANGANG GROUP CHENGDU STEEL & VANADIUM

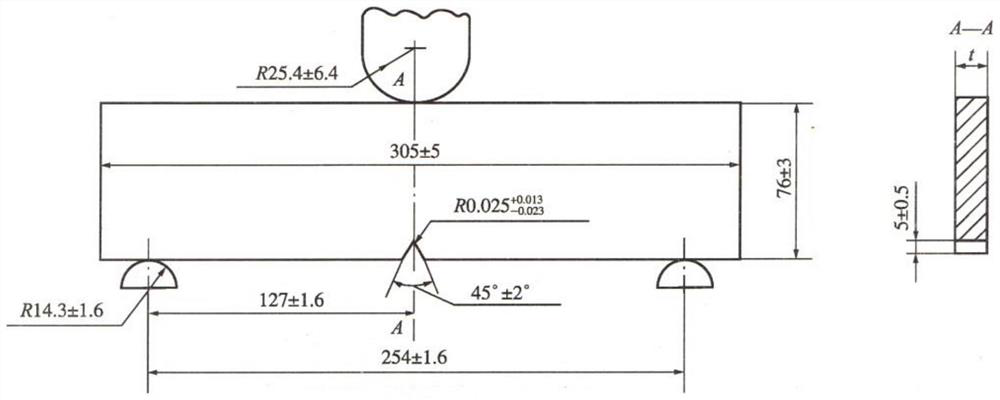

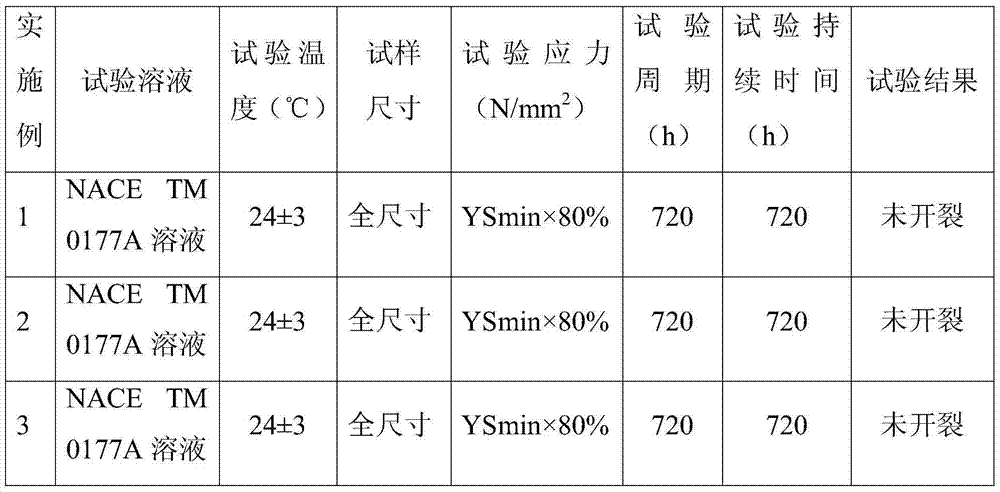

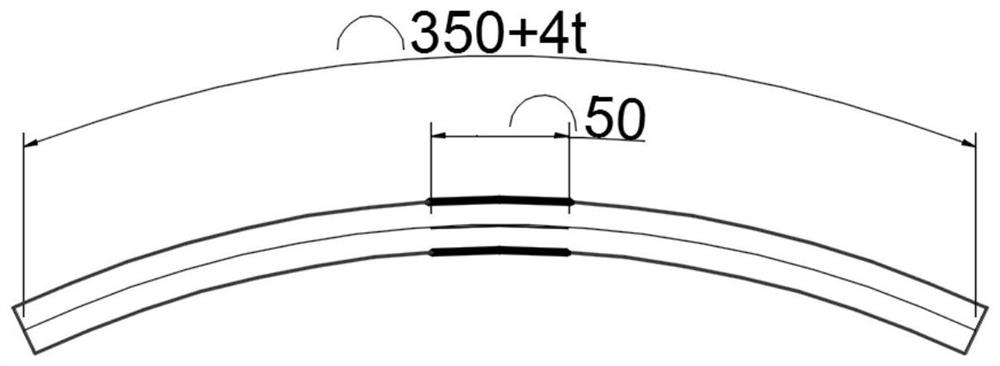

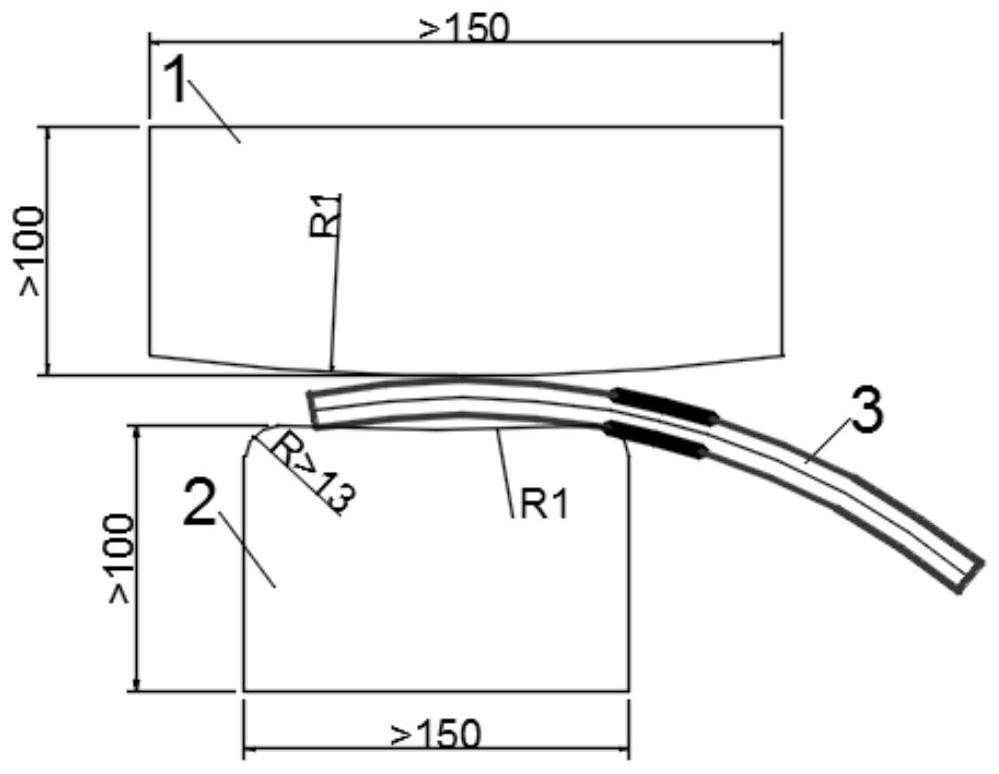

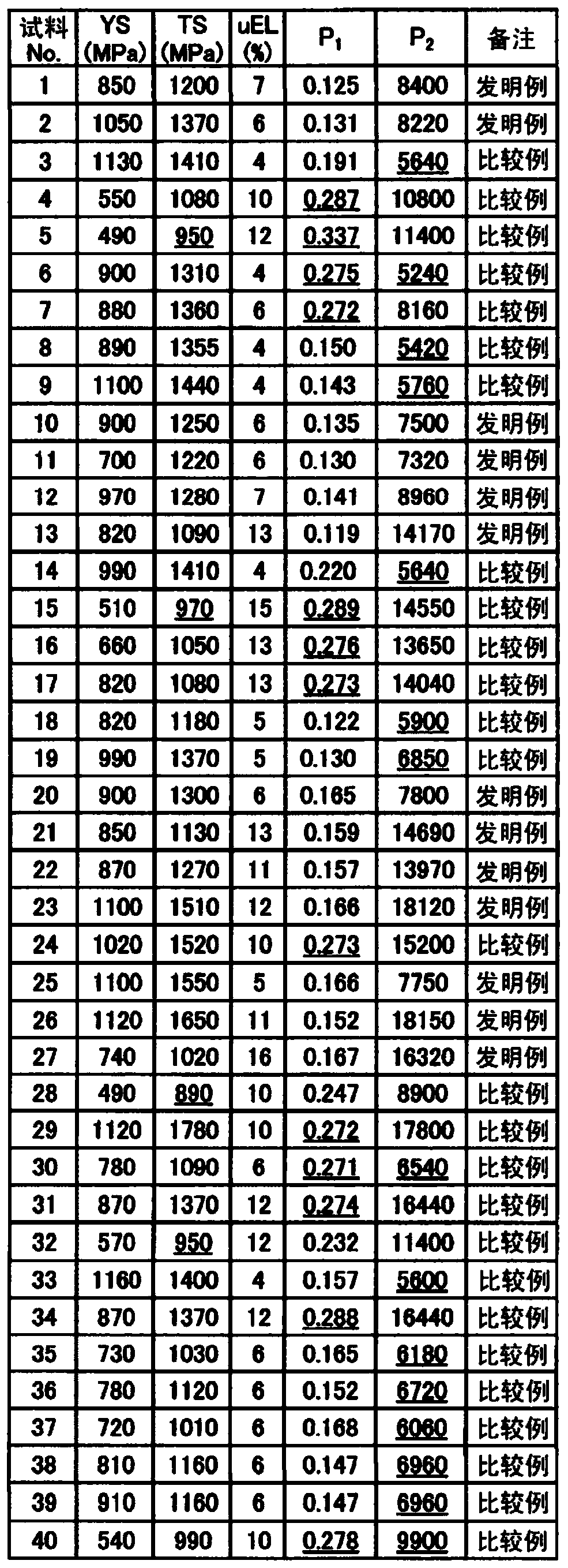

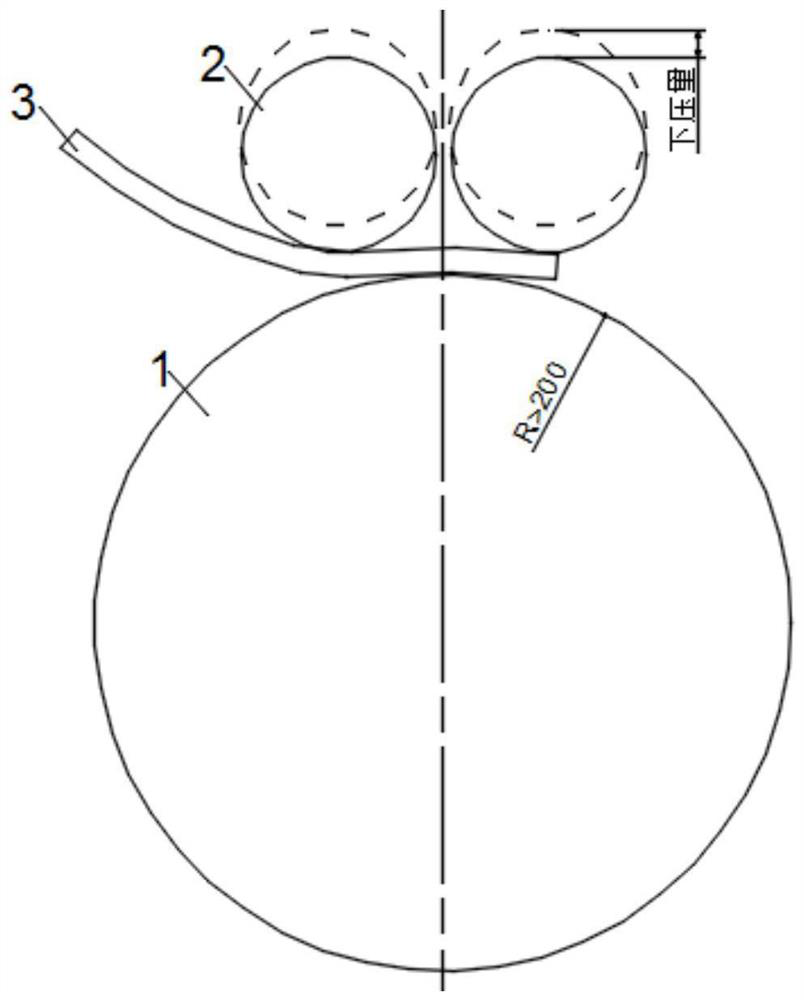

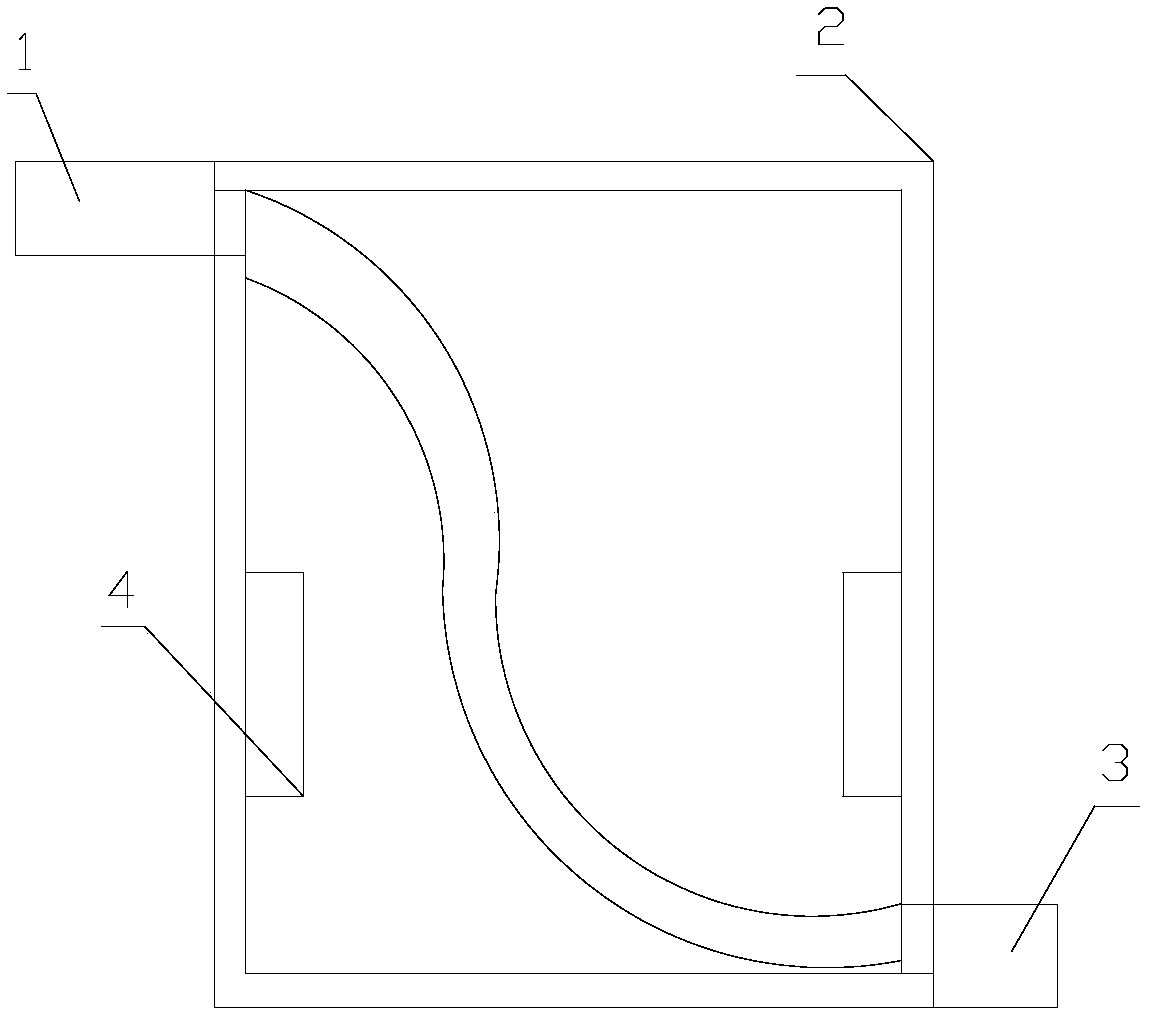

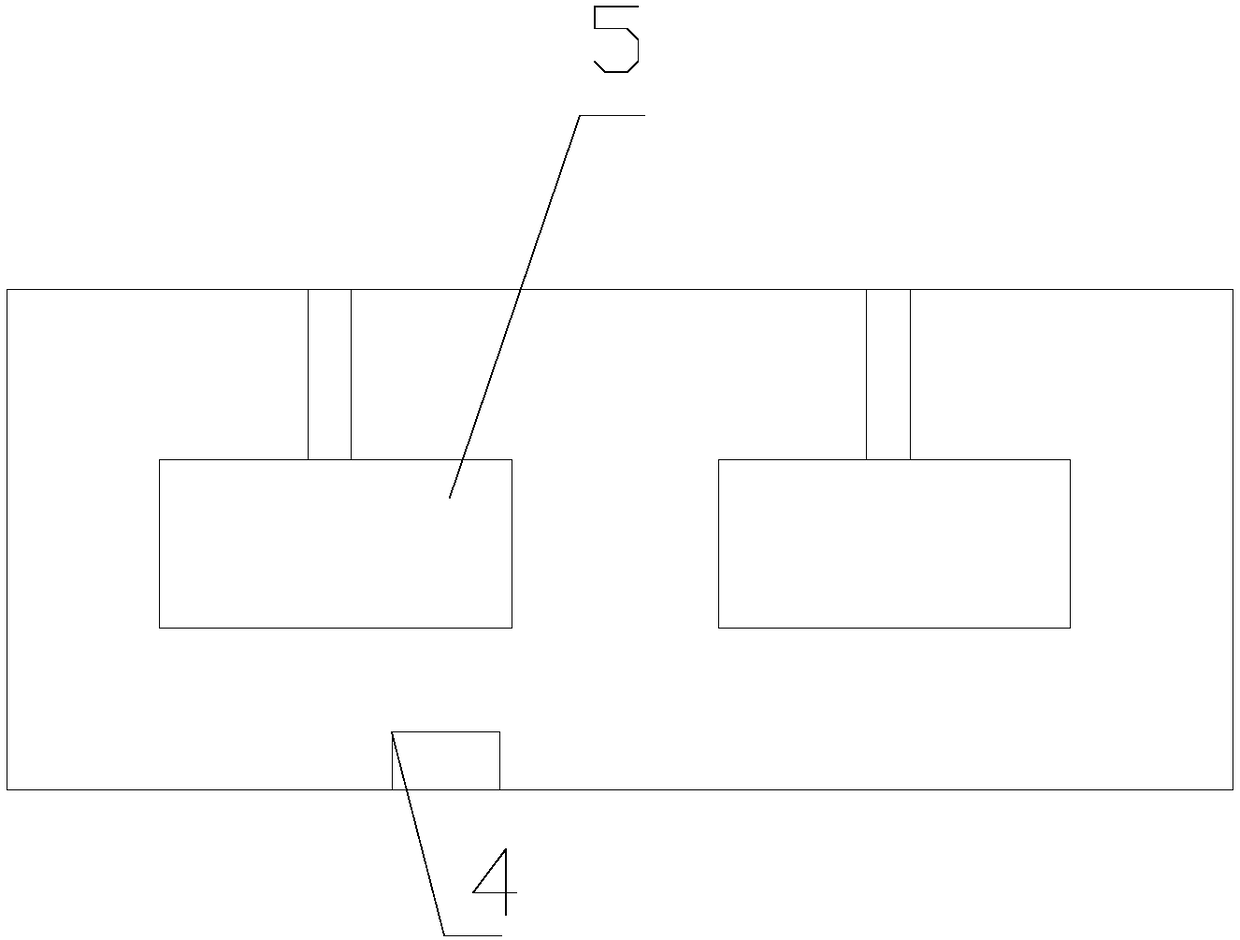

Pressing and flattening method for strip-shaped transverse tensile sample of steel pipe

ActiveCN114646519AGuaranteed straightnessGuaranteed plastic deformationPreparing sample for investigationSteel tubeElastic modulus

The invention provides a flattening and flattening method for a strip-shaped transverse tensile sample of a steel pipe, and solves the problem that the yield strength of the strip-shaped transverse tensile sample of the steel pipe is reduced due to an existing flattening method for the strip-shaped transverse tensile sample of the steel pipe. The method comprises the following steps: cutting a lath-shaped transverse tensile sample with the arc length of about 2a + 4t on a steel pipe, 2a being greater than or equal to 350mm, and t being the thickness of the sample; the upper pressing plate and the first lower supporting plate are both provided with matched arc-shaped parts, the radius R1 of each arc-shaped part is equal to t (E / sigma-1) / 2, sigma is the rated lowest tensile strength of the material, and E is the elastic modulus; two ends of the sample are respectively placed between an upper pressing plate and a first lower supporting plate, and the upper pressing plate is pressed to the lowest position and then released; the second lower supporting plate is provided with an arc-shaped part which is matched with the upper pressing plate and has the radius of R1, and the middle section of the sample is placed between the upper pressing plate and the second lower supporting plate for the length of about 50 + (3-5) t, and the upper pressing plate is released after being pressed to the lowest position; and obtaining a final sample with the length of 350 mm in the middle at two ends of the sample.

Owner:SPECIAL EQUIP SAFETY SUPERVISION INSPECTION INST OF JIANGSU PROVINCE

A kind of aluminum alloy used for manufacturing automobile sunroof guide rail and its production process

The invention discloses an aluminum alloy for manufacturing automobile sunroof guide rails and a production process thereof, wherein the aluminum alloy comprises the following raw materials in proportions by weight: Si 0.25-0.31%, Fe≤0.15%, Cu≤0.05%, Mn 0.03 ~0.09%, Mg 0.47~0.53%, Zn≤0.05%, Ti≤0.05%, single impurity≤0.05%, total impurity≤0.15%, and the balance is Al. As far as automotive sunroof products are concerned, they have strict requirements on the mechanical properties of aluminum profiles, such as hardness requirements of 9.5-11.5HW and yield strength requirements of 120-160Mpa. The invention can well stabilize the hardness and yield strength of skylight products within the above range through specific formula and specific process. In actual production, the automotive sunroof guide rail profile can be obtained through one-time processing and bending, which improves the bending efficiency of the sunroof, and the product arc can reach within a tolerance of 0.4mm, completely avoiding the previous aluminum profile screening process and eliminating the need for profiles in the In case of cracking during processing, there is no need to adjust the stamping process according to the hardness of the product, which improves the efficiency of the production line by more than 20%.

Owner:FOSHAN AOMEI ALUMINUM IND

A kind of 6mm thick nuclear power containment steel and its manufacturing method

ActiveCN111270153BControl lengthIncrease temperatureMetal rolling arrangementsNuclear powerProcess engineering

The invention discloses a 6mm-thick nuclear power containment steel and a manufacturing method thereof. The steel adopts a low C and Mn component series design, does not add additional alloy components, and takes into account the radiation effect while ensuring the stability of the yield strength. The optimization of the material shape of the billet in the manufacturing method realizes the effective control of the length of the rolled piece during the rolling process, and avoids the large temperature fluctuation caused by the excessive length of the rolled piece. The ultra-high temperature heating system is adopted to ensure that the billet obtains a higher temperature during rolling, and to ensure that the steel plate has a higher final rolling temperature after the rolling is completed. The control of the rolling process reduces the temperature drop during the process and ensures that the fluctuation of the temperature difference between the head and the tail of the rolled piece is small. The length of the rolled piece is optimized and the area with poor plate shape is cut off to ensure the uniformity of the performance of the sampling position. The yield strength of the 6mm nuclear power steel produced by the method is stable, and the obtained performance is excellent in strength and toughness matching, which fully meets the performance requirements. The qualified rate of production performance reaches 94%, which is fully suitable for industrial batch production.

Owner:NANJING IRON & STEEL CO LTD

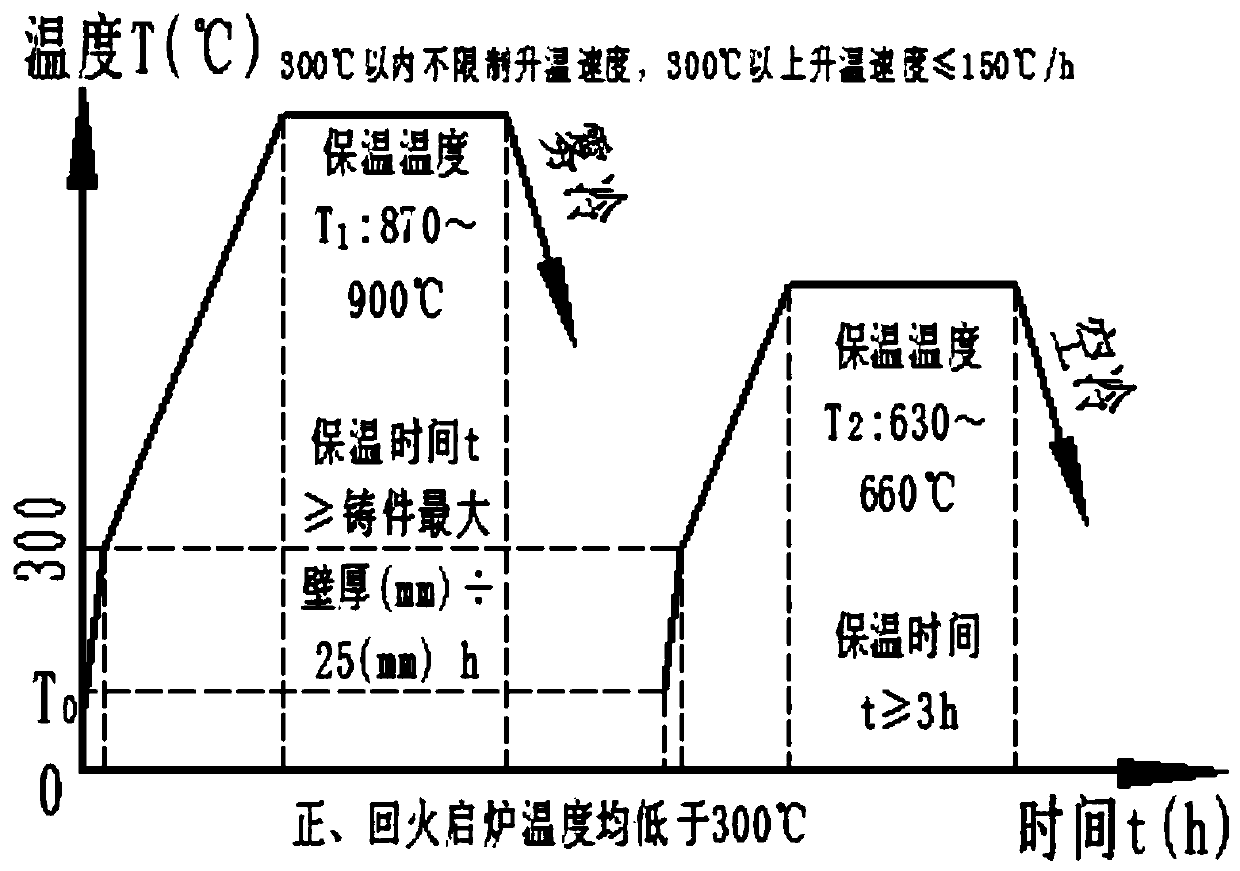

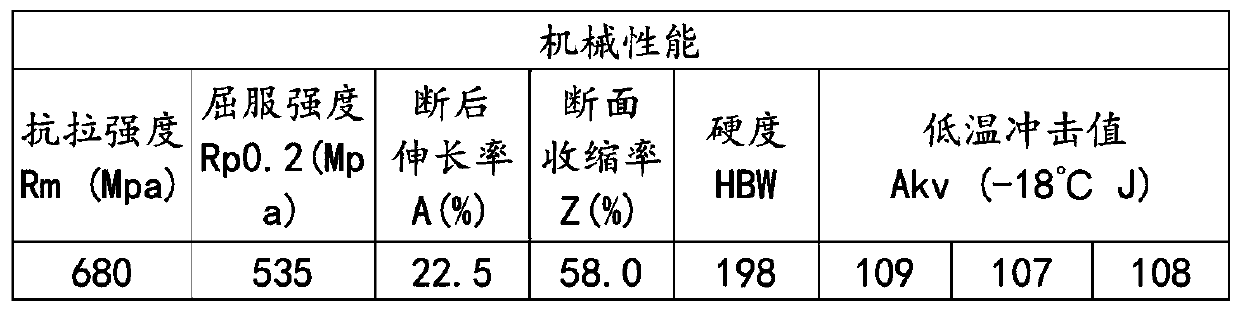

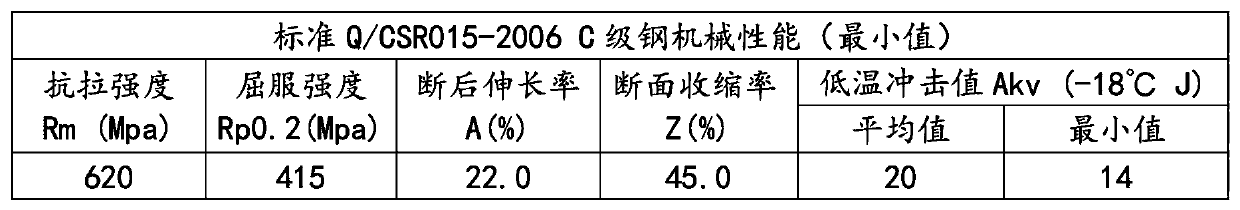

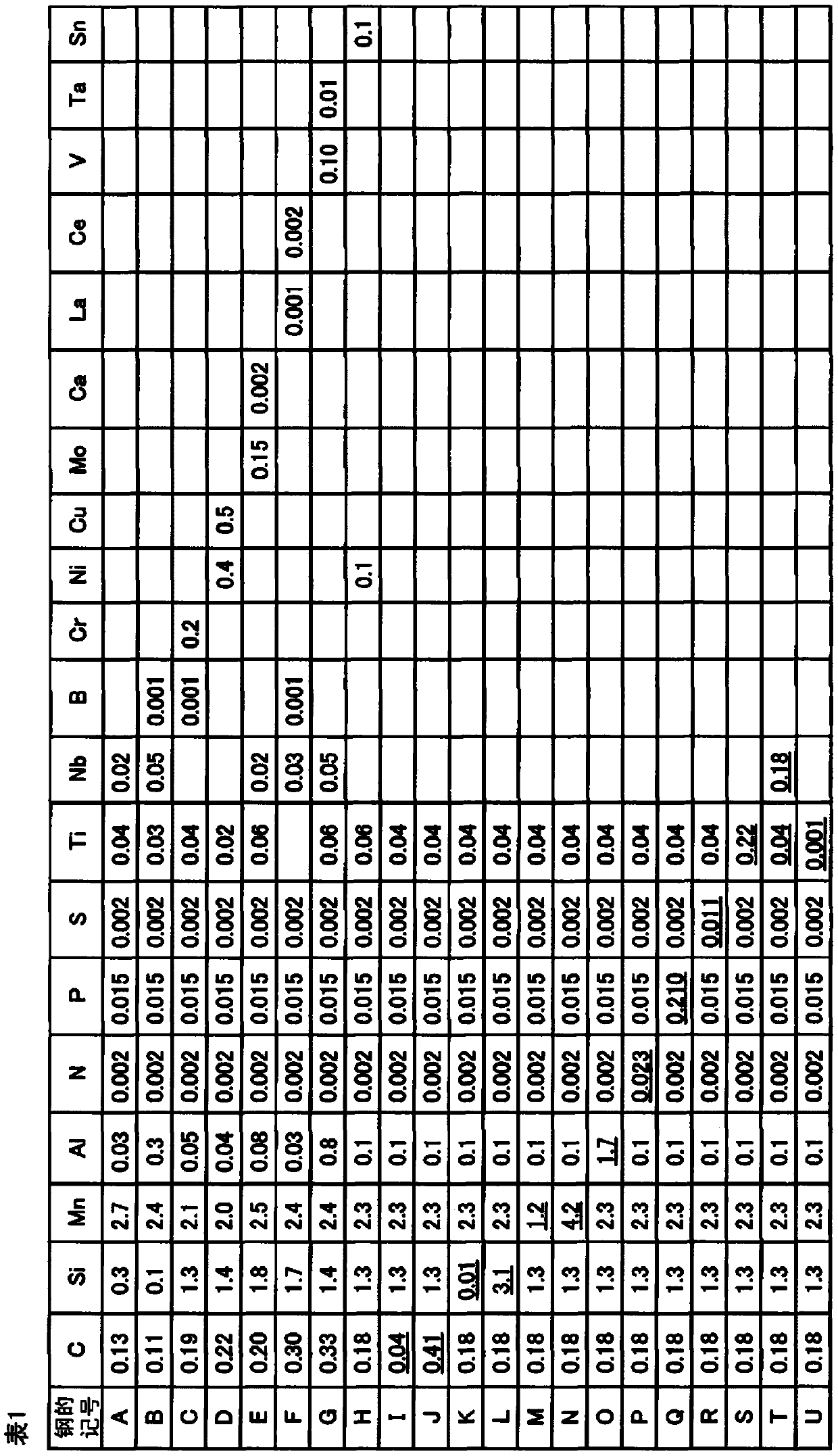

C-grade steel and heat treatment method thereof

InactiveCN111334710AStable mechanical propertiesStable tensile strengthHeat treatment process controlChemical compositionHeat treating

Owner:四川省洪发车辆配件有限公司

steel plate

ActiveCN107923007BStable yield strengthHot-dipping/immersion processesFurnace typesChemical compositionMaterials science

Owner:NIPPON STEEL CORP

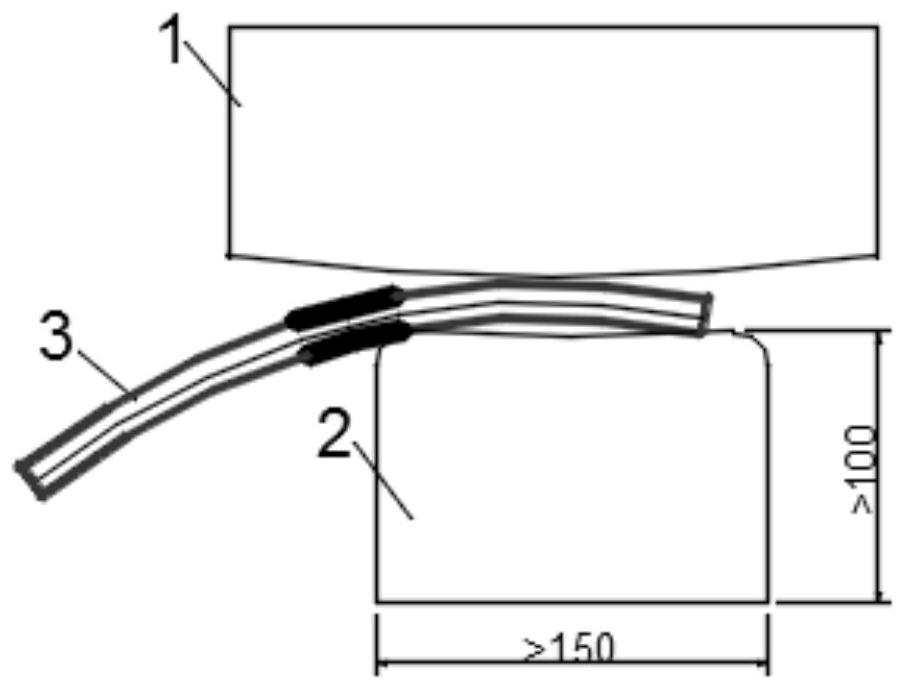

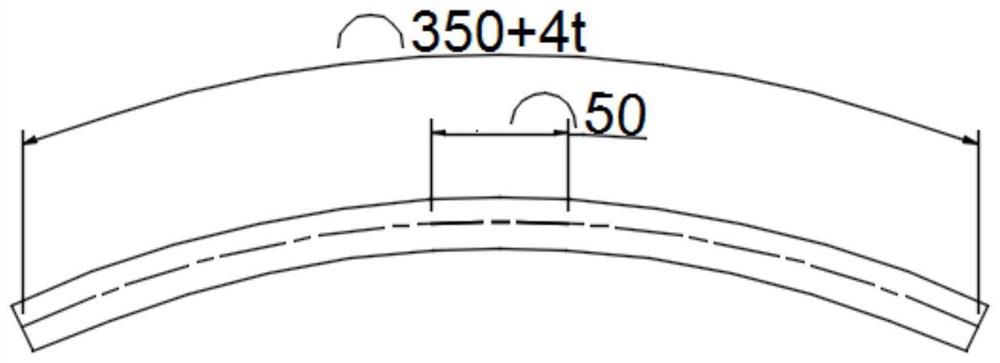

Rolling flattening method for strip-shaped transverse tensile sample of steel pipe

ActiveCN114593971AAvoid inaccurate overvoltage parametersStable yield strengthPreparing sample for investigationSteel tubeElastic modulus

The invention provides a rolling flattening method for a strip-shaped transverse tensile sample of a steel pipe, which solves the problem that the yield strength of the strip-shaped transverse tensile sample is reduced by the existing flattening method, and reasonably controls the Banschinger effect through a unified and standard rolling flattening method, so that the transverse yield strength test result of the steel pipe sample is stable, reliable and comparable. The method comprises the steps that a lath-shaped transverse tensile sample with the arc length of 2a + 4 t is cut on a steel pipe, 2a is larger than or equal to 350 mm, and t is the thickness of the sample; the upper pressing roller is composed of two round rollers with the axis distance of 1, and the lower supporting roller is a driving rotating round roller. Putting the right end of the sample between an upper compression roller and a lower support roller, and moving the upper compression roller and the sample downwards until the lower surface of the sample is in contact with the lower support roller; the pressing amount is (D-t) / 2-((D-t) 2 / 4-l2 / 4) 1 / 2 + l2 / (6t (E / sigma t-1)), and D is the outer diameter of the steel pipe; e is an elastic modulus; sigma t is the rated tensile strength of the material; rotating the lower support roller to enable the sample to move rightwards, and flattening the rest part of the sample; moving the upper compression roller upwards, taking out the sample, and cutting off certain lengths at two ends to obtain a final sample.

Owner:SPECIAL EQUIP SAFETY SUPERVISION INSPECTION INST OF JIANGSU PROVINCE

Normalizing process method for obtaining QT450-12 material

The invention provides a normalizing process method for obtaining a QT450-12 material. The normalizing process method for obtaining the QT450-12 material is characterized in that an as-cast structureis a mixed structure taking ferrite as a matrix, the silicon content of the mixed structure is 2.4%-2.8%, and the content of manganese of the mixed structure is less than or equal to 0.45%; non-complete austenization is carried out on the mixed structure at the temperature of 810 DEG C- 830 DEG C, normalization is carried out, heat preservation is carried out for 1.5 hours, and air cooling is carried out; and a proper pearlite content and the QT450-12 material are obtained. The normalizing process method can solve the problem that a resin sand model casting cannot meet the requirements of theperformance of the QT450-12 material, and is successfully applied to the production of products such as valve plates and valve bonnets which are made of the same material.

Owner:荆州环宇汽车零部件有限公司

Rapid preparation method of truck vermicular graphite cast iron brake disc

ActiveCN111139397APreliminary regulation of carbon contentRealize comprehensive utilizationFoundry mouldsFoundry coresFerrosiliconFerrochrome

The invention discloses a rapid preparation method of a truck vermicular graphite cast iron brake disc. The method comprises the following steps of preparing materials, adding part of pig iron, all scrap steel and all foundry returns into a low-frequency induction furnace for melting, and adding a carburant and a nickel plate; laying a layer of silicon iron on the bottom of a medium-frequency induction furnace to form a silicon iron layer, adding the rest pig iron to form a pig iron layer, heating, and adding electrolytic copper, ferromanganese and ferrochromium before the added silicon iron and pig iron are not completely molten; adding a solution in the low-frequency induction furnace into the medium-frequency induction furnace, wherein the solution in the medium-frequency induction furnace is vermicularized in the vermicularizing casting ladle, and a vermiculizer is a mixture of rare earth silicon-magnesium alloy, a composite material with added calcium element, aluminum wires cut into sections, silicon-barium powder and tin powder; and pouring. The method has the advantages of being high in brake disc production speed, good in brake disc quality and low in cost.

Owner:山东时风(集团)有限责任公司 +1

An intelligent embossed welding strip making unit

ActiveCN105057347BStable yield strengthImprove photoelectric conversion efficiencyTension/compression control deviceMetal rolling arrangementsMeasuring instrumentEngineering

The invention discloses an intelligent embossing solder strip manufacturing unit. The intelligent embossing solder strip manufacturing unit comprises a pay-off mechanism, a rolling roller mechanism, an embossing roller mechanism, a finishing roller mechanism, a heat treatment mechanism and an intelligent take-up mechanism. A wire is led out of a pay-off spool in the pay-off mechanism to be paid off to a guide wheel on a rolling roller rack in the rolling roller mechanism; then the wire passes through a first upper roller, a first lower roller and a first laser diameter measuring instrument on the rolling roller rack and then arrives at an embossing roller, a second lower roller and a second laser diameter measuring instrument on an embossing roller rack in the embossing roller mechanism; afterwards, the wire arrives at a finishing roller, a third lower roller and a third laser diameter measuring instrument on a finishing roller rack in the finishing roller mechanism; and the wire passes through an upper electrode wheel and a lower electrode wheel in a heat treatment machine box in the heat treatment mechanism and then arrives at a take-up spool in the intelligent take-up mechanism.

Owner:JIANGSU GAOHE INTELLIGENT EQUIP CO LTD

A kind of quick preparation method of vermicular graphite cast iron truck brake disc

ActiveCN111139397BPreliminary regulation of carbon contentRealize comprehensive utilizationFoundry mouldsFoundry coresBrakeFerrosilicon

The invention discloses a rapid preparation method for vermicular graphite cast iron truck brake discs. Lay a layer of ferrosilicon on the bottom to form a ferrosilicon layer, then add the rest of the pig iron to form a pig iron layer, raise the temperature, add electrolytic copper, ferromanganese, and ferrochrome before the added ferrosilicon and pig iron are completely melted; add low-frequency ferrosilicon to the medium-frequency induction furnace The solution in the induction furnace, the medium frequency induction furnace solution is vermigrated in the vermicular ladle; the vermicular agent is a mixture of rare earth silicon magnesium alloy, composite material with calcium element, cut aluminum wire, silicon barium powder and tin powder ;pouring. The invention has the characteristics of fast production speed of the brake disc, good quality of the brake disc and low cost.

Owner:山东时风(集团)有限责任公司 +1

A kind of low-alloy high-strength steel hot-rolled plate and its manufacturing method

The invention relates to the technical field of iron and steel smelting and processing, in particular to a low-alloy high-strength steel hot-rolled plate and a manufacturing method thereof. The chemical composition of the hot-rolled plate contains C: 0.15-0.22%, Si: 0.25-0.65 %, Mn: 1.20-1.80%, P≤0.020%, S≤0.010%, Alt: 0.020-0.060%, Ti: 0.020-0.060%, V: 0.10-0.20%, and the rest are Fe and unavoidable impurities. The manufacturing method of the low-alloy high-strength steel hot-rolled plate is as follows: hot metal pretreatment desulfurization-converter smelting-LF furnace refining-slab continuous casting-slab heating-hot continuous rolling-normalizing treatment. The carbon content of the low-alloy high-strength steel hot-rolled plate provided by the present invention is relatively high, only relatively cheap V and Ti elements are added, and precious alloy elements such as Nb, Mo, Ni, and Cu are not added, and the microalloy elements V and Ti are used The fine-grain strengthening and precipitation strengthening effect ensure the mechanical properties of the steel plate after normalizing, and Ti can also improve the welding performance of the steel plate, so the alloy cost of the product is low.

Owner:SHOUGANG CORPORATION

Wide and thick steel plates for normalizing rolled fine grain pressure welded steel pipes

ActiveCN103525998BEliminate offline normalizing heat treatmentReduce production energy consumptionReduction rateHeating time

The invention discloses a wide and thick steel plate for a normalized and rolled fine-grain pressure-welded steel tube and a preparation method thereof. The wide and thick steel plate comprises the following chemical components in percentage by weight: 0.08-0.16% of C, 0.20-0.60% of Si, 1.20-1.70% of Mn, less than or equal to 0.020% of S, less than or equal to 0.025% of P, less than or equal to 0.050% of Nb, less than or equal to 0.050% of V, less than or equal to 0.050% of Ti, more than or equal to 0.020% of Als, and the balance of Fe and trace impurities. The preparation method comprises the following steps: heating a plate blank to 1150-1250 DEG C, wherein the heating time is more than or equal to 200min and the soaking time is more than or equal to 50min; normalizing and rolling, wherein in a rough rolling stage, the initial rolling temperature is 1150-1200 DEG C, the final rolling temperature is 1100-1160 DEG C and reduction rates in the last three processes in the rough rolling stage are ensured to be more than or equal to 20%, and in a finish rolling stage, the initial rolling temperature is 850-920 DEG C, the thickness of an intermediate blank is 3-6 times of that of a finished product and the final rolling temperature is 800-850 DEG C; and after the final moulding rolling, weakly cooling the steel plate on line to 600-700 DEG C through a multi-functional batch-type accelerated cooling system, and then cooling the steel plate to room temperature in air.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com