Rapid preparation method of truck vermicular graphite cast iron brake disc

A technology of vermicular graphite cast iron and brake disc, applied in the field of preparation of truck brake disc, can solve the problems of difficult grinding, high production cost, easy entry of impurities, etc., and achieves the effects of good electromagnetic stirring effect, shortening the life of the crucible, and convenient starting operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

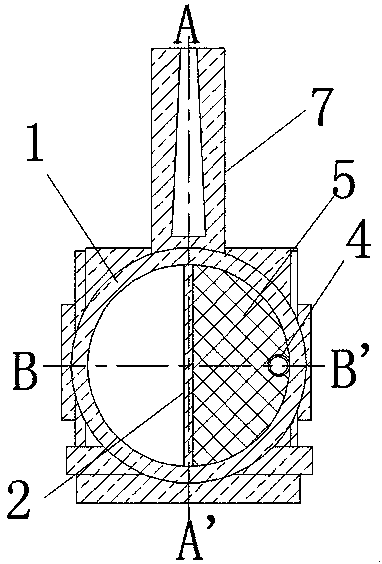

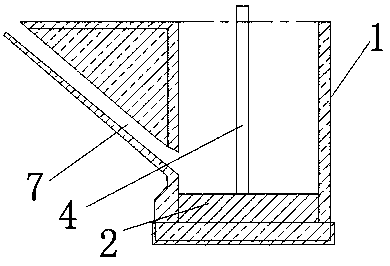

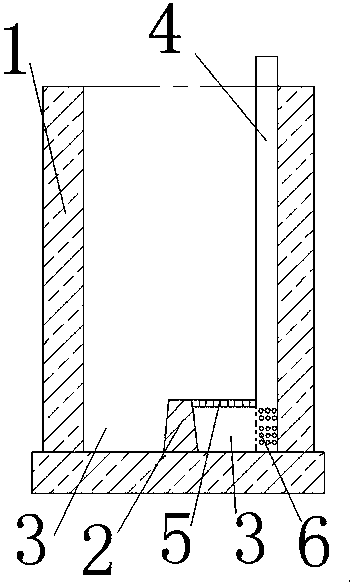

Image

Examples

Embodiment 1

[0051] Example 1. A rapid preparation method of compacted graphite cast iron truck brake disc is characterized in that it comprises the following steps:

[0052] Step 1: Prepare 30kg of steel scrap and 50kg of recycled material for every 100kg of pig iron according to the weight ratio, and put part of the pig iron, all of the scrap steel, and all of the recycled material into a low-frequency induction furnace for melting.

[0053] Step 2: Add carburant, control the amount of carburant added, so that the carbon content of the solution is: 3.75%; wherein the carbon equivalent needs to be kept at 4.35%, and the carbon equivalent=mass percentage of carbon+(mass percentage of silicon / 3); Feed argon gas, add nickel plate, the addition of nickel plate is 0.05% of the total weight of the solution; after the nickel plate is melted, remove slag and set aside.

[0054] Step 3: Lay a layer of ferrosilicon on the bottom of the intermediate frequency induction furnace to form a ferrosilic...

Embodiment 2

[0068] Example 2. A rapid preparation method of compacted graphite cast iron truck brake disc is characterized in that it comprises the following steps:

[0069] Step 1: Prepare 25kg of steel scrap and 40kg of recycled materials for every 100kg of pig iron according to the weight ratio, and put part of the pig iron, all of the scrap steel, and all of the recycled materials into a low-frequency induction furnace for melting.

[0070] Step 2: add carburant, control the amount of carburant added, so that the carbon content of the solution is: 3.7%; wherein the carbon equivalent needs to be kept at 4.2%, and the carbon equivalent=mass percentage of carbon+(mass percentage of silicon / 3); Pass into argon, add nickel plate, the addition of nickel plate is 0.06% of solution gross weight; After nickel plate is melted, remove slag, standby.

[0071] Step 3: Lay a layer of ferrosilicon on the bottom of the intermediate frequency induction furnace to form a ferrosilicon layer, then add ...

Embodiment 3

[0085] Example 3. A rapid preparation method of compacted graphite cast iron truck brake disc is characterized in that it comprises the following steps:

[0086] Step 1: Prepare 25kg of steel scrap and 40kg of recycled materials for every 100kg of pig iron according to the weight ratio, and put part of the pig iron, all of the scrap steel, and all of the recycled materials into a low-frequency induction furnace for melting.

[0087] Step 2: Add carburant, control the amount of carburant added, so that the carbon content of the solution is: 3.6%; wherein the carbon equivalent needs to be kept at 4.07%, and the carbon equivalent=mass percentage of carbon+(mass percentage of silicon / 3); Pass into argon, add nickel plate, the add-on of nickel plate is 0.07% of solution gross weight; After nickel plate is melted, remove slag, standby.

[0088] Step 3: Lay a layer of ferrosilicon on the bottom of the intermediate frequency induction furnace to form a ferrosilicon layer, then add t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com